Shell Bitumen - Shell Cariphalte Brochure

Shell Bitumen - Shell Cariphalte Brochure

Shell Bitumen - Shell Cariphalte Brochure

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Shell</strong> <strong>Cariphalte</strong> dense mixture<br />

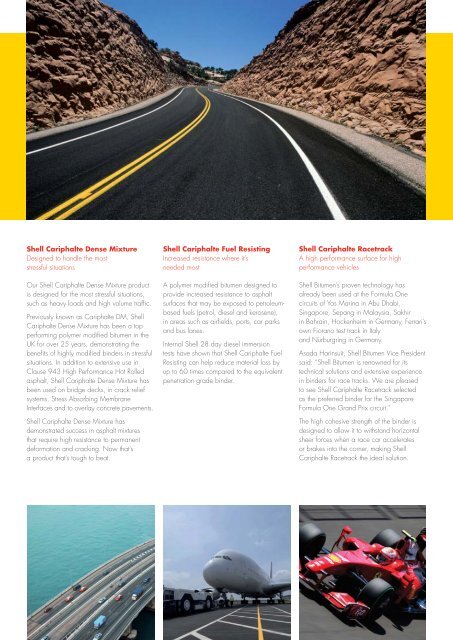

Designed to handle the most<br />

stressful situations<br />

Our <strong>Shell</strong> <strong>Cariphalte</strong> Dense Mixture product<br />

is designed for the most stressful situations,<br />

such as heavy loads and high volume traffic.<br />

Previously known as <strong>Cariphalte</strong> DM, <strong>Shell</strong><br />

<strong>Cariphalte</strong> Dense Mixture has been a top<br />

performing polymer modified bitumen in the<br />

UK for over 25 years, demonstrating the<br />

benefits of highly modified binders in stressful<br />

situations. In addition to extensive use in<br />

Clause 943 High Performance Hot Rolled<br />

asphalt, <strong>Shell</strong> <strong>Cariphalte</strong> Dense Mixture has<br />

been used on bridge decks, in crack relief<br />

systems, Stress Absorbing Membrane<br />

Interfaces and to overlay concrete pavements.<br />

<strong>Shell</strong> <strong>Cariphalte</strong> Dense Mixture has<br />

demonstrated success in asphalt mixtures<br />

that require high resistance to permanent<br />

deformation and cracking. Now that’s<br />

a product that’s tough to beat.<br />

<strong>Shell</strong> <strong>Cariphalte</strong> fuel resisting<br />

Increased resistance where it’s<br />

needed most<br />

A polymer modified bitumen designed to<br />

provide increased resistance to asphalt<br />

surfaces that may be exposed to petroleumbased<br />

fuels (petrol, diesel and kerosene),<br />

in areas such as airfields, ports, car parks<br />

and bus lanes.<br />

Internal <strong>Shell</strong> 28 day diesel immersion<br />

tests have shown that <strong>Shell</strong> <strong>Cariphalte</strong> Fuel<br />

Resisting can help reduce material loss by<br />

up to 60 times compared to the equivalent<br />

penetration grade binder.<br />

<strong>Shell</strong> <strong>Cariphalte</strong> racetrack<br />

A high performance surface for high<br />

performance vehicles<br />

<strong>Shell</strong> <strong>Bitumen</strong>’s proven technology has<br />

already been used at the Formula One<br />

circuits of Yas Marina in Abu Dhabi,<br />

Singapore, Sepang in Malaysia, Sakhir<br />

in Bahrain, Hockenheim in Germany, Ferrari’s<br />

own Fiorano test track in Italy<br />

and Nürburgring in Germany.<br />

Asada Harinsuit, <strong>Shell</strong> <strong>Bitumen</strong> Vice President<br />

said: “<strong>Shell</strong> <strong>Bitumen</strong> is renowned for its<br />

technical solutions and extensive experience<br />

in binders for race tracks. We are pleased<br />

to see <strong>Shell</strong> <strong>Cariphalte</strong> Racetrack selected<br />

as the preferred binder for the Singapore<br />

Formula One Grand Prix circuit.”<br />

The high cohesive strength of the binder is<br />

designed to allow it to withstand horizontal<br />

sheer forces when a race car accelerates<br />

or brakes into the corner, making <strong>Shell</strong><br />

<strong>Cariphalte</strong> Racetrack the ideal solution.