Brochure Minerals & Mining (PDF, 25.2MB) - Thyssenkrupp

Brochure Minerals & Mining (PDF, 25.2MB) - Thyssenkrupp

Brochure Minerals & Mining (PDF, 25.2MB) - Thyssenkrupp

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

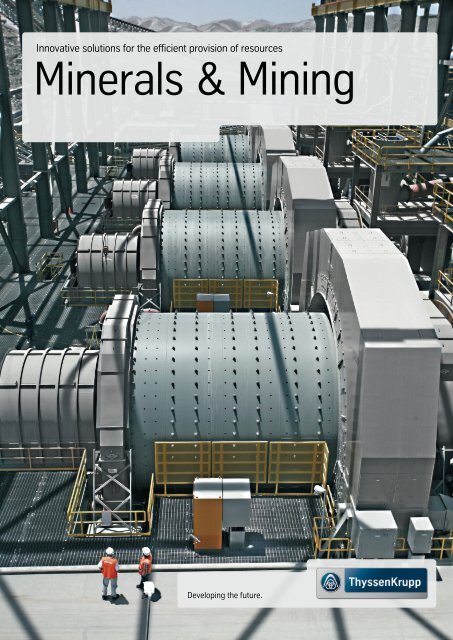

Innovative solutions for the effi cient provision of resources<br />

<strong>Minerals</strong> & <strong>Mining</strong><br />

Developing the future.

Our engineering expertise enables us satisfy demand for<br />

more raw materials in a better way – better for the customer,<br />

better for the environment, better for us all.

innovation + + + 08 Planning and consulting | Finding custom solutions + + + 10 Materials | Mastering challenges + + + 12 Materials services |<br />

18 <strong>Mining</strong> raw materials | Greater efficiency + + + 20 Raw materials processing | The right product for every job + + + 22 Raw materials<br />

After-sales services and logistics | Complete partner to customers + + + 28 Our minerals & mining network is there for you all over the world

Better ideas<br />

for the<br />

minerals & mining<br />

industry<br />

With our engineering expertise, we enable our customers in<br />

the minerals & mining industry to manufacture and process their<br />

products in a cost- and resource-efficient way.<br />

The companies in our Group’s minerals & mining network offer<br />

a wide range of top-quality products and services, working<br />

together closely to exchange ideas and ensure our customers<br />

benefit from maximum synergies. Our solutions set standards<br />

along the entire value chain.<br />

For example, our fully mobile crusher system raises the bar<br />

for the efficient utilization of energy. Material is crushed directly<br />

at the mine face and transported away on belt conveyors, which<br />

eliminates the need for heavy truck transportation, thereby<br />

reducing operating costs and CO 2 emissions.<br />

Our close cooperation with customers around the globe delivers<br />

valuable new ideas on a daily basis. Our engineering expertise<br />

helps us translate those ideas into new and better solutions,<br />

enabling us to master challenges and play our part in shaping<br />

the future of our world. That’s something we’re very proud of.

Better ideas 04 | 05

Knowledge is a basis<br />

for innovation

We are constantly seeking to offer our customers better<br />

solutions. In our research and development facilities, the<br />

focus is on interdisciplinary collaboration throughout the<br />

Group. Our work includes optimizing existing products and<br />

developing new ones, as well as exploring new applications<br />

for proven technologies and services.<br />

ThyssenKrupp companies with<br />

solutions in this area:<br />

Companies throughout our Group<br />

carry out extensive research and<br />

development work.<br />

More information is available<br />

in the contacts flyer.<br />

Research and development 06 | 07<br />

Research Improving facilities slewing and bearings development and rings centers<br />

To meet Our aim the is challenges to constantly of the improve future, the we quality work with of our<br />

renowned slewing universities bearings and and seamless research rolled institutes rings. such In our<br />

as the own Fraunhofer state-of-the-art and Max research Planck and Societies. development We cen-<br />

set ter, the we pace test when bearing it comes designs to developing under the toughest steels for of<br />

extreme conditions, loads. research Materials new with products, revolutionary and develop properties<br />

forward-looking are modeled using solutions computer for practical programs. applications. Our<br />

surface Knowledge engineering and experience center (OberflächenCentrum)<br />

are combined with new<br />

in Dortmund ideas to deliver is one exactly of the world’s the products leading our develop- customers<br />

ment need. centers for flat steel coatings.<br />

Minimizing Enhancing wear the efficiency of machines<br />

We and work equipment continuously to optimize our alloy designs<br />

for Our wear-resistant development steels work (XAR in the materials handling<br />

field is focused on improving the efficiency and<br />

reducing the environmental impact of machinery<br />

and equipment. A new inclined conveyor system<br />

for deep surface mines sets new standards in this<br />

respect: It features two rope-driven skips that<br />

transport materials continuously from the bottom<br />

of the mine up the steep banks to the crusher<br />

station. This system eliminates the need for truck<br />

transportation and thus reduces CO2 emissions.<br />

Capital, operating and labor costs are also lower.<br />

® ), focusing on specific<br />

applications, use of resources and processing characteristics.<br />

Our powerful ProWear simulation software<br />

can accurately predict machine wear and service life.<br />

Optimizing electrical steel<br />

ThyssenKrupp produces high-efficiency electrical<br />

steel for transformers and electric motors. The<br />

production process and product properties are being<br />

constantly improved. We work closely with our<br />

customers to find the best possible designs for<br />

electromagnetic systems and components.<br />

Intensive research is also carried out into electric<br />

motors: We build prototypes that deliver important<br />

information on how the properties of our products<br />

affect the properties of our customers’ motors,<br />

significantly shortening development times.<br />

Non-oriented electrical steel ensures extremely high<br />

energy efficiency in machinery and equipment.

Knowledge is a basis<br />

for innovation

Improving slewing bearings and rings<br />

Our aim is to constantly improve the quality of our<br />

slewing bearings and seamless rolled rings. In our<br />

own state-of-the-art research and development center,<br />

we test bearing designs under the toughest of<br />

conditions, research new products, and develop<br />

forward-looking solutions for practical applications.<br />

Knowledge and experience are combined with new<br />

ideas to deliver exactly the products our customers<br />

need.<br />

Enhancing the efficiency of machines<br />

and equipment<br />

Our development work in the materials handling<br />

field is focused on improving the efficiency and<br />

reducing the environmental impact of machinery<br />

and equipment. A new inclined conveyor system<br />

for deep surface mines sets new standards in this<br />

respect: It features two rope-driven skips that<br />

transport materials continuously from the bottom<br />

of the mine up the steep banks to the crusher<br />

station. This system eliminates the need for truck<br />

transportation and thus reduces CO 2 emissions.<br />

Capital, operating and labor costs are also lower.<br />

STRAIGHT UP<br />

Our skip conveyor is breaking new ground<br />

in deep surface mines with steep banks.<br />

It can transport ore or overburden from the<br />

bottom of the mine to the crusher station<br />

at the top, which means fewer trucks and<br />

significantly lower costs and CO 2 emissions.<br />

Optimizing plant design<br />

In the construction of plants for processing raw<br />

materials, we combine and focus our know-how to<br />

create new concepts for high availability and ecofriendly<br />

design, reducing energy requirements and<br />

emissions.<br />

In some cases, we test new plants and machinery<br />

on a smaller scale to save costs and time. In the<br />

area of pyroprocessing, for example, ores are examined<br />

under real conditions in a scaled-down rotary<br />

kiln using different preheater systems. This process<br />

delivers important parameters which are later used<br />

to optimize the design of the industrial-scale plant.<br />

Our ideas for the use of secondary raw materials to<br />

generate power set global standards. Using household<br />

waste or wood chippings conserves resources,<br />

reduces costs and maximizes plant efficiency.<br />

With our extensive materials database for ores, we<br />

give our customers a key knowledge edge that<br />

allows ores to be classified quickly and reliably and<br />

plants designed for optimum efficiency.<br />

Skip conveyor station at the bottom of the mine.

Finding<br />

custom solutions

ONE-STOP SHOP<br />

We are one of the few full-range suppliers<br />

to the minerals & mining industry<br />

worldwide – from consulting, planning,<br />

project development, engineering,<br />

manufacture and delivery to erection,<br />

start-up and after-sales service. Our<br />

customers benefit from our decades of<br />

experience and our global presence.<br />

ThyssenKrupp companies with<br />

solutions in this area:<br />

Companies throughout our Group<br />

provide extensive planning and<br />

consulting services.<br />

More information is available<br />

in the contacts flyer.<br />

Our customers benefit from our outstanding engineering expertise. We offer<br />

innovative planning and design solutions for everything from individual machines<br />

to complete plants, and when it comes to modernizing and upgrading existing<br />

systems, ThyssenKrupp consistently comes up with new approaches. Whatever<br />

the project, we strive to find the technical and economic optimum.<br />

Made-to-measure slewing bearings<br />

ThyssenKrupp develops the ideal slewing bearing<br />

for every application, from excavators to ship<br />

loaders/unloaders. Our engineers consult extensively<br />

with our customers and then design a<br />

custom product. We also draw up all certification<br />

documents on the basis of advanced analyses.<br />

Preliminary studies and geological surveys<br />

To plan and build surface mining equipment efficiently,<br />

it is important to have the most precise picture<br />

possible of the site conditions. Our engineers take<br />

into account the local infrastructure, power supplies,<br />

environmental requirements and possible stockpile<br />

locations. We also support the analysis of mineral<br />

deposits.<br />

Mine planning<br />

ThyssenKrupp has unbeatable expertise in the planning<br />

of mines. We design the ideal process chain for<br />

continuous conveying systems based on material<br />

and process data. We then produce the equipment<br />

and machinery layout in several variants, before<br />

finally checking the profitability of the various alternatives.<br />

Financing strategies<br />

Our offering is rounded out by a wide range of<br />

financing services. For these services, we partner<br />

with a broad selection of national and international<br />

institutes to realize short-, mid- or long-term<br />

financing models for our customers.<br />

To plan equipment efficiently<br />

we use 3-D models of the mine. Detail planning of a plant component.<br />

Planning and consulting 08 | 09

Mastering<br />

challenges

Our unique materials expertise gives our customers a<br />

competitive edge. ThyssenKrupp is one of the world’s<br />

leading suppliers of flat carbon steel. Many of our materials<br />

were specifically developed for extreme conditions –<br />

ideal for the minerals & mining industry. Our innovativeness<br />

is also reflected in PowerCore ® electrical steel, a<br />

high-tech material that sets new standards of efficiency.<br />

LONGER LIFE<br />

Our XAR ® steels open up new possibilities<br />

for the minerals & mining industry, where<br />

wear and abrasion place very high requirements<br />

on materials. These steels significantly<br />

extend the service life of components. Their<br />

extremely high hardness is achieved through<br />

a combination of chemical composition and<br />

a specialized heat treatment process.<br />

Relative service<br />

life of XAR ® steels<br />

compared with<br />

structural steel S355<br />

1<br />

S355 400 HBW 450 HBW 500 HBW 550 HBW<br />

ThyssenKrupp companies with<br />

solutions in this area:<br />

ThyssenKrupp Steel Europe<br />

ThyssenKrupp Electrical Steel<br />

More information is available<br />

in the contacts flyer.<br />

2,3 2,6 3 3,6<br />

PowerCore ® electrical steel for maximum<br />

energy efficiency<br />

ThyssenKrupp is a premium manufacturer of electrical<br />

steel and one of the world market leaders in this<br />

area. Under the PowerCore ® brand we supply this<br />

highly specialized steel grade as grain-oriented and<br />

non-oriented electrical steel. High-tech PowerCore ®<br />

Heavy plate as a robust basis<br />

Heavy plate from ThyssenKrupp is ideal for highly<br />

stressed steel structures. It guarantees maximum<br />

robustness and strength with significantly lower<br />

weight. In the minerals & mining industry it is used<br />

wherever heavy-duty materials are required, for<br />

example, in dump trucks, crawler-mounted vehicles<br />

and electrical excavators. steels offer excellent processing and magnetic<br />

properties and maximum energy efficiency.<br />

Our wear-resistant XAR<br />

Our products are available worldwide for the production<br />

of highly efficient electrical machines. The<br />

unique texture and resultant soft magnetic properties<br />

of grain-oriented electrical steel allow trans formers<br />

to operate at over 99% efficiency. The material<br />

thus makes an important contribution to conserving<br />

resources and protecting the environment.<br />

® steels are the perfect<br />

solution for manufacturers of excavator buckets,<br />

crushers, conveyors and screens. Their high<br />

hardness allows our customers to significantly extend<br />

the service life of wear parts. We developed the<br />

ultrahigh-strength N-A-XTRA ® and XABO ® steels to<br />

reduce the weight of highly stressed structures such<br />

as mobile cranes and shields in underground mining.<br />

Heavy plate in detail<br />

g Use of heavy plate as starting material, for<br />

example, for floor panels<br />

g XAR ® special structural steels offer extremely high<br />

wear resistance, for example, for truck dump<br />

bodies, excavator buckets, crushers, and side<br />

plates for charging hoppers, and are available in<br />

various grades and sizes: Thicknesses from 3 to<br />

100 mm, widths up to 3,600 mm<br />

g N-A-XTRA ® and XABO ® special structural steels<br />

for the manufacture of bucket wheel excavators,<br />

cranes, overburden machines and shield<br />

components to the highest standards of safety,<br />

available in various grades and sizes: Thicknesses<br />

from 3 to 100 mm, widths up to 3,300 mm<br />

XAR ® special structural steel for heavy truck dump bodies.<br />

Materials 10 | 11

Mastering<br />

challenges

PowerCore ® electrical steel for maximum<br />

energy efficiency<br />

ThyssenKrupp is a premium manufacturer of electrical<br />

steel and one of the world market leaders in this<br />

area. Under the PowerCore ® brand we supply this<br />

highly specialized steel grade as grain-oriented and<br />

non-oriented electrical steel. High-tech PowerCore ®<br />

electrical steels offer excellent processing and magnetic<br />

properties and maximum energy efficiency.<br />

Our products are available worldwide for the production<br />

of highly efficient electrical machines. The<br />

unique texture and resultant soft magnetic properties<br />

of grain-oriented electrical steel allow trans formers<br />

to operate at over 99% efficiency. The material<br />

thus makes an important contribution to conserving<br />

resources and protecting the environment.<br />

PowerCore ® electrical steel in detail<br />

g Use of non-oriented electrical steel in the<br />

minerals & mining industry, for example,<br />

as a starting material for generators, motors<br />

and other elec trical components. Available in<br />

the variants fully finished (PowerCore ® A),<br />

high-permeability (PowerCore ® AP) and<br />

semi-finished (PowerCore ® K) in a variety of<br />

grades and thicknesses from 0.2 to 1.0 mm<br />

g Use of laminated or wound grain-oriented<br />

elec trical steel as core material for power<br />

and distribution transformers as well as<br />

small transformers. Available in the variants<br />

PowerCore ® C (conventional grades) and<br />

PowerCore ® H (high-permeability grades)<br />

in thicknesses from 0.18 to 0.35 mm<br />

The texture of the material determines the special<br />

magnetic properties of electrical steel.

Made to measure

HIGH PRECISION<br />

We have a range of materials to satisfy<br />

every need. We also advise our customers<br />

on all areas of processing.<br />

ThyssenKrupp companies with<br />

solutions in this area:<br />

ThyssenKrupp Materials International<br />

(with trading and service companies<br />

in more than 30 countries worldwide)<br />

More information is available in the<br />

contacts flyer.<br />

Our materials services specialists provide expert advice to customers on<br />

all aspects of materials and processing. We offer a full range of services from<br />

a single source, while our sophisticated warehousing and logistics system<br />

guarantees quick availability. Customers receive their materials just in time<br />

and in the exact sizes and shapes requested.<br />

Materials services<br />

ThyssenKrupp is a single-source supplier. Our range<br />

includes carbon steel, stainless steel and nonferrous<br />

metals in the form of flat, tubular and long products,<br />

as well as a wide range of plastics. We also offer a<br />

variety of materials services, including processing<br />

and logistics, warehouse and inventory management,<br />

and supply chain management.<br />

Our processing services include slitting, cutting to<br />

length, and plasma and laser cutting. Blanks can be<br />

saw-cut, drilled, deburred and milled in preparation<br />

for further processing by our customers.<br />

Products for the minerals & mining industry<br />

in detail<br />

g Blanking and processing to customer requirements<br />

g Flat steel products for special requirements and<br />

high-wearing machinery and equipment parts<br />

g Structural shapes and profiles<br />

Materials services 12 | 13<br />

g Carbon and special stainless steel bar for<br />

gearing and drive shafts<br />

g Stainless steel flat, long and tubular products<br />

g Seamless and welded carbon and stainless steel<br />

tubes and pipes<br />

g Flat, long and tubular products of aluminum,<br />

copper, brass and titanium

Perfection<br />

in every dimension

THINKING BIG<br />

Given the dimensions involved in the<br />

minerals & mining industry, our slewing<br />

bearings offer key advantages. We are<br />

one of the few companies worldwide<br />

capable of producing one-piece slewing<br />

bearings in diameters up to 8,000 mm.<br />

ThyssenKrupp companies with<br />

solutions in this area:<br />

ThyssenKrupp Steel Europe<br />

Rothe Erde<br />

More information is available<br />

in the contacts flyer.<br />

ThyssenKrupp manufactures high-quality components for the minerals & mining<br />

industry. Our products are tested under the toughest conditions and constantly<br />

improved by our engineers to ensure their efficiency, safety and reliability.<br />

Slewing bearings and rings<br />

ThyssenKrupp is world market leader for slewing<br />

bearings. Our products can be found in excavators,<br />

bucket wheel loaders, stackers/spreaders and<br />

ship loaders/unloaders. Their compact design with<br />

integrated sealing system permits an excellent<br />

performance-to-weight ratio. At the same time,<br />

our slewing bearings are easy to install and service<br />

and offer cost-efficient solutions for bearings in<br />

com panion structures.<br />

We supply seamless rolled rings for a range of<br />

applications, from simple as-rolled parts to processed,<br />

ready-to-install components.<br />

Two of the bearing designs used in the<br />

materials handling sector: A three-row<br />

roller bearing slewing ring, and a roller<br />

and ball combination bearing.<br />

Slewing bearings and rings in detail<br />

Components 14 | 15<br />

g Custom manufacture of slewing bearings in dia meters<br />

from 300 to 8,000 mm (one-piece design)<br />

and up to 18,000 mm (segmented design)<br />

g Use of coating processes for corrosion protection<br />

on the bearing surface, tailored to the respective<br />

application (up to corrosion classification C5-M<br />

under EN ISO 12944)<br />

g Seamless rolled, heat-treated rings with dia meters<br />

of 300 to 8,000 mm and weighing up to<br />

30,000 kg can be supplied as-rolled or processed<br />

X components ®<br />

We offer processed parts and finished components<br />

for applications that expose the materials to extremely<br />

high stresses. These so-called X components ® are<br />

first choice for cranes, dump bodies, buckets, tubes,<br />

side walls and cutter bars.<br />

On request we can also manufacture custom<br />

X components ® from wear-resistant XAR ® steels and<br />

ultrahigh-strength N-A-XTRA ® and XABO ® grades<br />

from ThyssenKrupp to guarantee the best possible<br />

quality.

When safety counts

STABLE CONDITIONS<br />

Our anchor equipment effectively stabilizes<br />

embankments in surface mines to increase<br />

operating safety. It also allows mine walls to<br />

be built steeper, enabling the raw materials<br />

to be accessed more quickly and shortening<br />

transport routes.<br />

ThyssenKrupp companies with<br />

solutions in this area:<br />

ThyssenKrupp Bautechnik<br />

ThyssenKrupp Tiefbautechnik<br />

More information is available<br />

in the contacts flyer.<br />

We offer our customers reliable foundation solutions. ThyssenKrupp combines<br />

a wide range of services with the sale and hire of steel sheet piling as well<br />

as machinery and anchor equipment. For the minerals & mining industry,<br />

we develop cost-efficient solutions, for drilling work, stabilizing embankments,<br />

excavations, securing roads and railways, landfills and more.<br />

Steel sheet piling<br />

Our steel sheet pile walls offer a range of advantages<br />

in construction projects. They eliminate the<br />

need for excavations, shorten building times, are<br />

fully functional immediately upon installation, and<br />

allow work to proceed independently of the weather.<br />

These advantages cut costs and boost profitability.<br />

Our piling sections display outstanding structural<br />

and sealing properties and have proven their quality<br />

over the decades in a wide range of applications:<br />

Road construction, civil engineering, hydraulic<br />

engineering, port construction and landfill sealing.<br />

Use in landfill construction<br />

Our steel sheet piling has been used successfully<br />

for landfills and the remediation of contaminated<br />

sites for over 30 years. In soils with a very low share<br />

of fines and where a high degree of tightness is<br />

required, we recommend the use of special interlock<br />

seals. In addition to the option of welding the<br />

interlock joints, we also offer special sealing<br />

systems.<br />

Foundation equipment 16 | 17<br />

Piling sections and sealing systems in detail<br />

g Hot-rolled piling sections (hot-rolled sections,<br />

straight-web sections, steel piles, box piles, composite<br />

steel piling, U-steel, wide-flange beams,<br />

wide-flange bearing piles, welded structures,<br />

corner and junction piles, combined steel sheet<br />

piling/intermediate sections, box pile walls)<br />

g Cold-rolled piling sections (trench sheeting<br />

sections, lightweight sections, Krings corner<br />

sections)<br />

g HOESCH interlock sealing system for permanent<br />

structures, resistant to landfill substances and<br />

liquids – available with two lip seals or a polyurethane<br />

seal<br />

g Bitumen-based interlock sealants for temporary<br />

structures effectively limit pollutant transport in<br />

the interlock area, no environmental impact<br />

Machinery and anchor equipment<br />

We offer a full range of machinery for light to heavy<br />

driving of sheet piles, pipes, beams and other<br />

piling sections. Our portfolio also includes drilling<br />

equipment and drill drives as well as compactor<br />

plates and rock hammer drills for aboveground<br />

and underground blast-hole drilling.<br />

Our anchor equipment gives structures greater<br />

stability and enhances their safety. It is used in tunnel<br />

construction, back anchoring for retaining walls,<br />

and foundations for rockfall nets, but it is equally<br />

suitable for stabilizing slopes, roads and embankments,<br />

securing excavations and for refurbishing<br />

unstable slopes.

Greater efficiency

A BREAK<br />

WITH THE PAST<br />

Our fully mobile crusher is revolution izing<br />

the surface mining industry. It reduces<br />

the raw materials directly at the mine face<br />

so that they can then be transported away<br />

on belt conveyors – the use of heavy trucks<br />

is no longer required. This significantly<br />

reduces operating costs and cuts CO 2<br />

emissions by up to 350,000 tons per year.<br />

ThyssenKrupp companies with<br />

solutions in this area:<br />

ThyssenKrupp Fördertechnik<br />

More information is available<br />

in the contacts flyer.<br />

When it comes to the mining, crushing, transporting and spreading of ores,<br />

minerals, coal and overburden, ThyssenKrupp has unique expertise. With our<br />

innovative equipment and detailed planning services, we can design the<br />

entire continuous surface mining process to maximize efficiency. For this we<br />

constantly explore new paths.<br />

Continuous surface mining<br />

In rock quarries, crushers reduce the rock or overburden<br />

directly at the face and the material is then<br />

transported away on belt conveyors. ThyssenKrupp<br />

has advanced the development of these in-pit<br />

crushing systems and is one of the world’s leading<br />

suppliers.<br />

Our mobile and semi-mobile crushers achieve<br />

throughputs of up to 14,000 tons per hour. Fully<br />

mobile crushers are an outstanding example of<br />

innovative engineering; their use lowers transportation<br />

costs in mining operations by up to 50%<br />

and dispenses completely with the need for heavy<br />

trucks. Our crushers are powered exclusively by<br />

electricity, which means that mine operating costs<br />

and CO 2 emissions can be significantly reduced.<br />

Beltwagon and two fully mobile<br />

crushers on an assembly area.<br />

Surface mining equipment and systems in detail<br />

g Bucket wheel excavators, complete bucket wheel<br />

excavator systems<br />

g Beltwagons, tripper cars<br />

g Spreaders<br />

g Stationary, relocatable and shiftable belt<br />

conveyor systems, long-distance and curved belt<br />

conveyor systems<br />

g Transport crawlers<br />

<strong>Mining</strong> raw materials 18 | 19<br />

g Stationary, semi-mobile and fully mobile<br />

crushers, complete in-pit crushing systems

The right product<br />

for every job

We are one of the leading manufacturers of mineral<br />

processing machinery and equipment. We have the right<br />

solution even for specialized jobs. Whether it’s crushing,<br />

feeding, conveying, classifying, separating, grinding,<br />

drying or filtering, our equipment proves its mettle even<br />

under the most extreme conditions.<br />

A WORLDWIDE<br />

SUCCESS<br />

The POLYCOM ® high-pressure grinding<br />

roll delivers superior quality and low<br />

operating costs. Both energy requirements<br />

and the cost of wear parts are relatively<br />

low. The machine offers high throughput<br />

rates as well as metallurgical benefits<br />

for downstream processing operations.<br />

In addition, POLYCOM ® settings can<br />

be changed in an extremely short space<br />

of time.<br />

ThyssenKrupp companies with<br />

solutions in this area:<br />

ThyssenKrupp Fördertechnik<br />

ThyssenKrupp Polysius<br />

More information is available<br />

in the contacts flyer.<br />

Energy requirements of different<br />

grinding systems.<br />

Top: Ball mill<br />

Center: Combination mill<br />

Bottom: POLYCOM ® high-pressure grinding roll<br />

Conveying and classifying equipment<br />

In addition to crushing equipment we can supply<br />

conveying and classifying equipment to build a<br />

complete plant. On request, electrical and automation<br />

systems can be supplied in a package with<br />

mechanical, hydraulic and steel work.<br />

Grinding and processing equipment<br />

Grinding equipment from ThyssenKrupp Polysius is<br />

used in the minerals & mining industry throughout<br />

the world. The reasons for this are low operating<br />

costs, robust design and outstanding availability,<br />

even when grinding extremely abrasive materials.<br />

Our wide range of different mill types offers the<br />

right system for every job.<br />

POLYCOM ® high-pressure grinding rolls have proven<br />

extremely successful in mineral grinding. 60% of<br />

all high-pressure grinding rolls used in the minerals<br />

& mining industry are made by ThyssenKrupp,<br />

making us the global market leader. POLYCOM ® Crusher plants<br />

Crusher plants are used to reduce and process a wide<br />

range of materials. ThyssenKrupp offers more than<br />

20 crusher types in all sizes to suit any applica tion.<br />

Together with feed and discharge conveyors and clas -<br />

si fying equipment, they form highly efficient crusher<br />

plants.<br />

Primary crushing<br />

ThyssenKrupp has developed the world’s most powerful<br />

jaw crushers, gyratory crushers and jaw gyratory<br />

crushers for the primary reduction of hard rock ores.<br />

For soft rock ores, we offer roll crushers and rollsizers.<br />

These ores are efficiently crushed at throughput rates<br />

of over 240,000 t per day, even at 5,000 m altitude<br />

and temperatures from – 50 °C to + 50 °C.<br />

Pre-crushing and raw material processing<br />

Thanks to efficient crushing machinery, today even<br />

overburden can be pre-crushed and transported on<br />

belt systems to the stockpile. As a result there is no is<br />

need suitable for heavy for grinding trucks, which copper significantly ore, gold ore, reduces iron ore,<br />

costs diamond and above ore and all CO platinum 2 emissions. ore. In the processing<br />

of raw materials, for example, limestone or clay,<br />

ThyssenKrupp For other applications has led the we market supply for roller decades mills as with well<br />

hammer as autogenous crushers like and the ball MAMMUT mills for wet and dry<br />

grinding. Our solutions for the pyroprocessing of<br />

diverse materials combine proven processing and<br />

equipment know-how. The range includes rotary<br />

kilns, preheaters, multiple hearth furnaces and<br />

high-temperature shaft kilns, as well as lime shaft<br />

kilns.<br />

® and TITAN ® .<br />

For every job<br />

Whatever the product size and whatever the<br />

material – whether it’s granite, diorite or limestone –<br />

ThyssenKrupp supplies the right machine for primary,<br />

secondary or tertiary crushing. With throughput rates<br />

up to 14,000 t/h, our crushers can handle rocks up<br />

to more than two meters in size.<br />

Impact crusher for crushing limestone<br />

for cement View inside production. an SAG mill for wet grinding.<br />

Raw materials processing 20 | 21

The right product<br />

for every job

Conveying and classifying equipment<br />

In addition to crushing equipment we can supply<br />

conveying and classifying equipment to build a<br />

complete plant. On request, electrical and automation<br />

systems can be supplied in a package with<br />

mechanical, hydraulic and steel work.<br />

Grinding and processing equipment<br />

Grinding equipment from ThyssenKrupp Polysius is<br />

used in the minerals & mining industry throughout<br />

the world. The reasons for this are low operating<br />

costs, robust design and outstanding availability,<br />

even when grinding extremely abrasive materials.<br />

Our wide range of different mill types offers the<br />

right system for every job.<br />

POLYCOM ® high-pressure grinding rolls have proven<br />

extremely successful in mineral grinding. 60% of<br />

all high-pressure grinding rolls used in the minerals<br />

& mining industry are made by ThyssenKrupp,<br />

making us the global market leader. POLYCOM ® is<br />

suitable for grinding copper ore, gold ore, iron ore,<br />

diamond ore and platinum ore.<br />

For other applications we supply roller mills as well<br />

as autogenous and ball mills for wet and dry<br />

grinding. Our solutions for the pyroprocessing of<br />

diverse materials combine proven processing and<br />

equipment know-how. The range includes rotary<br />

kilns, preheaters, multiple hearth furnaces and<br />

high-temperature shaft kilns, as well as lime shaft<br />

kilns.<br />

View inside an SAG mill for wet grinding.<br />

Processing equipment in detail<br />

g Crusher plants: Hammer crushers (MAMMUT ®<br />

and TITAN ® ) up to 3,000 t/h, impact crushers up<br />

to 3,000 t/h, roll crushers up to 14,000 t/h, rollsizers<br />

up to 14,000 t/h, multiple rollsizers for<br />

secondary crushing, jaw crushers up to 1,600 t/h,<br />

gyratory crushers up to 14,000 t/h, jaw gyratory<br />

crushers up to 2,500 t/h and Kubria ® cone<br />

crushers up to 2,000 t/h<br />

g Conveying and classifying equipment: Apron<br />

feeders, chain conveyors, reciprocating plate<br />

feeders, vibrating feeders, screens, roller screens,<br />

magnetic separators<br />

g Grinding and processing equipment: Hammer<br />

mills up to 3,000 t/h, SAG mills with diameters<br />

of over 11 m, ball mills with 24 MW ring motor<br />

drives, POLYCOM ® high-pressure grinding rolls<br />

for throughputs up to and over 3,000 t/h,<br />

DOUBLE ROTATORS ® , roller mills<br />

g Scrubbers<br />

g Filter equipment<br />

g Drum dryers, flash dryers<br />

g Preheaters, rotary kilns, rotary kiln burner systems,<br />

multiple hearth furnaces, high-temperature shaft<br />

kilns, lime shaft kilns<br />

g Various coolers

Moving more<br />

with high-tech systems

ThyssenKrupp is a full-line supplier of machinery and equipment<br />

for bulk material handling. For decades we have been<br />

planning and delivering advanced turnkey systems that help<br />

reduce both costs and environmental impact. We supply<br />

complete solutions for transporting and handling raw materials<br />

in stockyards, bulk material distribution centers, port<br />

terminals and processing plants in the coal and ore industries.<br />

NON-STOP<br />

ADVANTAGES<br />

Our gearless drive systems are the<br />

solution of the future for high-performance<br />

belt conveyors. They are robust, cheaper<br />

to operate and maintain, quieter and offer<br />

variable speeds.<br />

Coupling<br />

Coupling<br />

Brake<br />

Belt Conveyor<br />

Transformer<br />

Converter<br />

Asynch.<br />

Motor<br />

Gear Box<br />

Belt<br />

Drive<br />

Pulley<br />

ThyssenKrupp companies with<br />

solutions in this area:<br />

ThyssenKrupp Fördertechnik<br />

More information is available<br />

in the contacts flyer.<br />

Brake<br />

Belt Conveyor<br />

Transformer<br />

C-Converter<br />

Synch.<br />

Motor<br />

Belt<br />

Drive<br />

Pulley<br />

Comparison between a conventional and a gearless drive system.<br />

Raw materials transportation and handling 22 | 23<br />

Pipe Stockyard conveyors and port handling systems<br />

Pipe for conveyors bulk materials ensure environmentally friendly<br />

transportation We are an experienced of bulk materials and reliable over large partner distances. when<br />

They it comes can be to adapted designing perfectly and building to the terrain complete with<br />

curves, systems: inclines Handling and declines equipment for optimum for loading routing, and<br />

and unloading there’s no ships need and for additional trains; stockyard structures equipment as with<br />

straight-line for stacking conveyors. and reclaiming The enclosed raw materials; belt protects and<br />

the linked material by from belt conveyors environmental and influences intelligent and control the<br />

environment systems. Our from stockyard dust and technologies spillages. are used<br />

in the homogenization, blending, distribution and<br />

Gearless stockpiling drive of systems raw materials.<br />

for heavy-duty belt conveyors<br />

Gearless Bucket-wheel drive systems stacker/reclaimers<br />

are an efficient alternative<br />

for Combined high-performance bucket-wheel belt conveyors. stacker/reclaimers The system’s allow<br />

simple stacking and robust and reclaiming design guarantees of large amounts high availability of bulk<br />

and material offers reduced in stockyards. running The and machines maintenance are fully costs,<br />

quieter automatable, operation with and corresponding variable speeds. monitoring<br />

equipment, unmanned operation and manage -<br />

Gearless ment of drives raw material permit long levels conveyor in the stockyard belts with are<br />

high possible, throughput saving rates money and large and time. rise heights. The<br />

system features fewer components so drive stations<br />

require With less their space, slewing a major and luffing advantage capabilities, in under- the<br />

ground machines applications. can stack or reclaim individual sections<br />

of the pile. The material is fed to further handling<br />

Custom facilities gear in units a very even flow, making it possible to<br />

We optimize develop and the fill build cross-section custom gear of units downstream specifically belt<br />

designed systems. for use in mining, processing and materials<br />

handling. We also supply gear units for use in lowtemperature<br />

Ship loaders regions with under fully very enclosed high starting conveyors and<br />

shock Eco loads. ship loaders from ThyssenKrupp transfer bulk<br />

materials from terminal to ship’s hold through<br />

completely enclosed conveyor systems. The booms<br />

are designed in the form of a large tube, inside<br />

which are the conveyors and service walkways.<br />

The enclosed design prevents contamination of<br />

port loading zones.<br />

Gearless drive system<br />

for high-throughput belt conveyors.

Moving more<br />

with high-tech systems

Stockyard and port handling systems<br />

for bulk materials<br />

We are an experienced and reliable partner when<br />

it comes to designing and building complete<br />

systems: Handling equipment for loading and<br />

unloading ships and trains; stockyard equipment<br />

for stacking and reclaiming raw materials; and<br />

linked by belt conveyors and intelligent control<br />

systems. Our stockyard technologies are used<br />

in the homogenization, blending, distribution and<br />

stockpiling of raw materials.<br />

Bucket-wheel stacker/reclaimers<br />

Combined bucket-wheel stacker/reclaimers allow<br />

stacking and reclaiming of large amounts of bulk<br />

material in stockyards. The machines are fully<br />

automatable, with corresponding monitoring<br />

equipment, unmanned operation and manage -<br />

ment of raw material levels in the stockyard are<br />

possible, saving money and time.<br />

With their slewing and luffing capabilities, the<br />

machines can stack or reclaim individual sections<br />

of the pile. The material is fed to further handling<br />

facilities in a very even flow, making it possible to<br />

optimize the fill cross-section of downstream belt<br />

systems.<br />

Ship loaders with fully enclosed conveyors<br />

Eco ship loaders from ThyssenKrupp transfer bulk<br />

materials from terminal to ship’s hold through<br />

completely enclosed conveyor systems. The booms<br />

are designed in the form of a large tube, inside<br />

which are the conveyors and service walkways.<br />

The enclosed design prevents contamination of<br />

port loading zones.<br />

Continuous ship unloaders<br />

Rail-mounted continuous ship unloaders are an<br />

outstanding example of our innovative thinking:<br />

They unload bulk freighters by means of a continuously<br />

operating bucket elevator system for faster<br />

removal rates. All conveying equipment on the<br />

ship unloader is enclosed to avoid material spillage<br />

and protect people and the environment.<br />

Bulk materials handling equipment and<br />

systems in detail<br />

g Conveyor belt systems<br />

g Drives, gear units and gearless drive systems<br />

for high-throughput belt conveyors<br />

g Bucket-wheel reclaimers,<br />

combined bucket-wheel stacker/reclaimers,<br />

bridge-type bucket-wheel reclaimers<br />

g Drum reclaimers<br />

g Scrapers (bridge scrapers, portal and side<br />

scrapers, circular stockyards)<br />

g Stackers<br />

g Pipe conveyors<br />

g Ship loaders, continuous ship unloaders,<br />

grab-type ship unloaders (portal crane/luffing<br />

slewing crane)<br />

g Wagon loading stations, wagon tipplers<br />

g Plow feeders (silo discharge units)<br />

g Cable cranes<br />

g Complete stockyard and port handling systems

Excellent<br />

global connections

FIRST-CLASS<br />

CONTACTS<br />

Customers profit from our first-class<br />

contacts on the international raw<br />

materials markets. Our global distribution<br />

network ensures closeness<br />

to customers and smooth logistics<br />

processes right through to just-in-time<br />

delivery, making us the number one<br />

choice for raw materials producers<br />

and users.<br />

Our partners<br />

for raw materials<br />

in the sectors<br />

● Metals<br />

● Ferroalloys<br />

● Energy<br />

● <strong>Minerals</strong><br />

ThyssenKrupp companies with<br />

solutions in this area:<br />

ThyssenKrupp Metallurgical Products<br />

More information is available<br />

in the contacts flyer.<br />

We are one of the world’s leading trading companies for raw materials. As the<br />

link between raw materials producers and manufacturing industry, we consider<br />

the interests of both sides and so ensure smooth production processes. Our<br />

business relationships are geared to the long term, and our global customer<br />

portfolio makes us an attractive partner for raw materials producers.<br />

Comprehensive expertise in raw materials<br />

ThyssenKrupp has excellent connections on the<br />

world raw materials markets and offers a wide<br />

variety of metals and alloys. Rigorous quality control<br />

ensures highly efficient processes. Together with<br />

reliable partners, we operate a global logistics and<br />

warehouse network that also benefits raw materials<br />

producers. We supply our customers on a just-intime<br />

basis by ship, truck or rail.<br />

Among the main customers for our wide range of<br />

products are the steel, foundry, refractory, electroplating,<br />

chemical, insulating material and powder<br />

metallurgy industries. We are constantly improving<br />

security of supply for our customers, for example<br />

through equity interests in raw material producers.<br />

Raw materials trading in detail<br />

g Nonferrous metals: Lead, copper, nickel, zinc, tin<br />

g Powder metals: Broad spectrum of almost all<br />

metals and alloys in powder form<br />

g Alloys: Aluminum, broad spectrum of ferroalloys,<br />

graphite electrodes, magnesium and<br />

much more<br />

g <strong>Minerals</strong>: Calcined bauxite, boron carbide,<br />

chromite sand, ferrosilicon nitride, fluorspar metallurgical<br />

and acid-grade, graphite,<br />

sintered and fused magnesia, fireclay, silicon<br />

carbide and much more<br />

g Carburizing agents: Synthetic graphites,<br />

calcined needle coke, calcined petroleum coke,<br />

calcined pitch coke, calcined coal<br />

g Solid fuels: Blast furnace coke, foundry coke,<br />

coke fines, coke breeze/sinter fuels, petroleum<br />

coke, power-generating coal, anthracite<br />

Iron ore stockpile in Duisburg.<br />

Raw materials trading 24 | 25

Complete partner<br />

to customers

Our customers can count on full – and above all fast –<br />

support throughout the world. Our services range from<br />

erection and commissioning to maintenance, automation,<br />

rebuilds and rehabilitation. We also include the<br />

supply of spare parts and regular employee training.<br />

BRIGHT SPOT<br />

FOR EFFICIENCY<br />

Our 3-D laser scanner makes the<br />

impossible possible. For the first time<br />

ever, large and inaccessible parts of<br />

machines can be scanned, making it<br />

possible, for example, to optimize the<br />

design of wear parts. Apart from the<br />

enormous savings of time and effort<br />

allowed by laser scanning, the longterm<br />

efficiency of a plant is also<br />

significantly increased.<br />

The wear rate of the plant component<br />

is continuously displayed during operation.<br />

ThyssenKrupp companies with<br />

solutions in this area:<br />

Comprehensive after-sales<br />

services are performed<br />

by all companies in the Group.<br />

More information is available<br />

in the contacts flyer.<br />

After-sales services and logistics 26 | 27<br />

Know-how for high-strength steel welding<br />

and Inspections wear calculation and preventive maintenance<br />

Welding We give wear-resistant customers precise high-strength knowledge structural of the steels current<br />

requires condition special of their know-how. equipment. Because Any the spare heat-treated parts<br />

material needed is reheated are delivered during and welding, installed particular in the shortest attention<br />

possible must be time, paid allowing to welding customers conditions to and plan cooling shut-<br />

times. downs ThyssenKrupp precisely, avoid offers consequential processors the damage powerful and<br />

software enjoy program maximum ProWeld, availability. which provides recommendations<br />

for preheat and interpass temperatures<br />

and Repairs heat input. to all makes and models<br />

We repair all makes of crusher housings, jaw stocks<br />

Numerous and screens. wear calculations We undertake can overhauls be carried of shafts, out<br />

with bearings the aid of and the drives ProWear of jaw, application. impact and Both gyratory programs<br />

crushers. are included We also on have the special many years’ structural experience steels in<br />

CD-ROM the repair and of can mills. be ordered Depending free on from requirements, the website<br />

www.thyssenkrupp-steel-europe.com/grobblech.<br />

repairs are carried out on site or in our repair and<br />

service center.<br />

All-round service for slewing bearings<br />

With our all-round service, we ensure continuous<br />

smooth operation of our slewing bearings, from<br />

installation, maintenance, condition monitoring and<br />

repair right through to customer training.<br />

Innovative 3-D laser scanner<br />

With an innovative 3-D laser scan system,<br />

ThyssenKrupp opens up new possibilities in wear<br />

optimization, equipment planning and quality<br />

management. Thanks to the new system, mea surements<br />

of wear, for example, can be carried out while<br />

equipment is running. This advancement reduces<br />

technical requirements, and long downtimes can<br />

be avoided. In some cases, machines do not need to<br />

be dismantled for part optimization and preventive<br />

maintenance, saving time and money.<br />

Gold ore wet grinding plant,<br />

consisting of SAG mill and ball mill,<br />

shortly before commissioning.

Complete partner<br />

to customers

Inspections and preventive maintenance<br />

We give customers precise knowledge of the current<br />

condition of their equipment. Any spare parts<br />

needed are delivered and installed in the shortest<br />

possible time, allowing customers to plan shutdowns<br />

precisely, avoid consequential damage and<br />

enjoy maximum availability.<br />

Repairs to all makes and models<br />

We repair all makes of crusher housings, jaw stocks<br />

and screens. We undertake overhauls of shafts,<br />

bearings and drives of jaw, impact and gyratory<br />

crushers. We also have many years’ experience in<br />

the repair of mills. Depending on requirements,<br />

repairs are carried out on site or in our repair and<br />

service center.<br />

Gold ore wet grinding plant,<br />

consisting of SAG mill and ball mill,<br />

shortly before commissioning.<br />

Relocating equipment and moving<br />

large components<br />

When plants have to be relocated, special techniques<br />

and special machinery are needed, as are<br />

skilled and experienced personnel. Our service<br />

organization has unique know-how and a proven,<br />

global track record when it comes to planning and<br />

executing relocation and transportation jobs.<br />

Grinding of tires and rollers<br />

ThyssenKrupp carries out repairs of wear-related<br />

damage to rotary kilns, dryer drums and mill bearings,<br />

as a rule during plant operation.<br />

Service centers<br />

In major mining regions throughout the world we<br />

operate service centers with fully equipped workshops.<br />

Our centers are based close to customers<br />

in Australia, Brazil, China, Peru and South Africa.<br />

Among other services, we recondition the roll units<br />

of POLYCOM ® high-pressure grinding mills. Whereas<br />

in the past new tires were necessary, today tires<br />

can be reconditioned several times in our service<br />

centers – increasing plant availability and saving<br />

costs for our customers.

Our minerals & mining network<br />

is there for you all over the world<br />

North America<br />

Canada<br />

Mexico<br />

USA<br />

South America<br />

Argentina<br />

Brazil<br />

Chile<br />

Peru<br />

Europe<br />

Austria<br />

Belgium<br />

Bulgaria<br />

Czech Republic<br />

Denmark<br />

France<br />

Germany<br />

Hungary<br />

Italy<br />

Lithuania<br />

Netherlands<br />

Poland<br />

Portugal<br />

Romania<br />

Russia<br />

Serbia<br />

Slovakia<br />

Spain<br />

Sweden<br />

Switzerland<br />

UK<br />

Ukraine

Africa<br />

South Africa<br />

Asia/Pacifi c<br />

Middle East<br />

Australia<br />

China<br />

India<br />

Indonesia<br />

Japan<br />

Kazakhstan<br />

Korea<br />

Malaysia<br />

New Zealand<br />

Singapore<br />

Thailand<br />

United Arab Emirates<br />

Vietnam<br />

<strong>Minerals</strong> & mining network 28 | 29

General note:<br />

All information given regarding the properties and use of materials and products is for description purposes only. Guarantees in respect of specifi c properties,<br />

availability or uses are subject to separate written agreement.

Kontakte<br />

<strong>Minerals</strong> & <strong>Mining</strong><br />

Wir entwickeln die Zukunft für Sie.

These ThyssenKrupp<br />

companies are moving<br />

the minerals & mining<br />

industry forward<br />

ThyssenKrupp Steel Europe AG<br />

Heavy Plate<br />

Mannesmannstr., Tor 9<br />

47259 Duisburg<br />

Germany<br />

Tel.: +49 203 52-75604<br />

Fax: +49 203 52-75653<br />

E-mail: Roland.Riesbeck@thyssenkrupp.com<br />

Internet: www.thyssenkrupp-steel-europe.com<br />

Locations: Chile, Germany<br />

Solutions for materials: Heavy plate<br />

Solutions for components: X components ®<br />

ThyssenKrupp Electrical Steel GmbH<br />

Kurt-Schumacher-Str. 95<br />

45881 Gelsenkirchen<br />

Germany<br />

Tel.: +49 209 407-0<br />

Fax: +49 209 407-50832<br />

E-mail: info.electricalsteel@thyssenkrupp.com<br />

Internet: www.thyssenkrupp-electrical-steel.com<br />

Locations: France, Germany, India, Italy<br />

Solutions for materials: Electrical steel<br />

ThyssenKrupp Materials International GmbH<br />

Am Thyssenhaus 1<br />

45128 Essen<br />

Germany<br />

Tel.: +49 201 844-0<br />

Fax: +49 201 844-536000<br />

E-mail: materials-services@thyssenkrupp.com<br />

Internet: www.thyssenkrupp-materialsinternational.com<br />

Regional companies: Austria, Belgium, Bulgaria,<br />

Canada, China, Czech Republic, Denmark, France,<br />

Germany, Hungary, Korea, Netherlands, Poland,<br />

Portugal, Romania, Russia, Serbia, Slovakia, Spain,<br />

Sweden, Switzerland, Thailand, UK, USA, Vietnam<br />

Solutions for materials services

Rothe Erde GmbH<br />

Tremoniastr. 5–11<br />

44137 Dortmund<br />

Germany<br />

PO Box 10 50 25<br />

44047 Germany<br />

Tel.: +49 231 186-0<br />

Fax: +49 231 186-2500<br />

E-mail: rotheerde@thyssenkrupp.com<br />

Internet: www.rotheerde.com<br />

Locations: Brazil, China, France, Germany,<br />

India, Italy, Japan, Spain, UK, USA<br />

Solutions for components: Slewing bearings, rings<br />

ThyssenKrupp Bautechnik GmbH<br />

Hollestr. 7a<br />

45127 Essen<br />

Germany<br />

PO Box 10 22 53<br />

45022 Germany<br />

Tel.: +49 201 844-562313<br />

Fax: +49 201 844-562333<br />

E-mail: bautechnik@thyssenkrupp.com<br />

Internet: www.thyssenkrupp-bautechnik.com<br />

Locations: Australia, Brazil, China, Germany, Lithuania,<br />

New Zealand, Russia, Ukraine, United Arab Emirates<br />

Solutions for foundations: Construction equipment<br />

ThyssenKrupp Tiefbautechnik GmbH<br />

Alte Liederbacher Str. 6<br />

36304 Alsfeld<br />

Germany<br />

PO Box 13 65<br />

36293 Germany<br />

Tel.: +49 6631 781-0<br />

Fax: +49 6631 781-150<br />

E-mail: tiefbautechnik@thyssenkrupp.com<br />

Internet: www.thyssenkrupp-tiefbautechnik.com<br />

Location: Germany<br />

Solutions for foundations: Specialized civil engineering<br />

ThyssenKrupp Fördertechnik GmbH<br />

ThyssenKrupp Allee 1<br />

45143 Essen<br />

Germany<br />

Tel.: +49 201 828-04<br />

Fax: +49 201 828-2566<br />

E-mail: marketing-tkf@thyssenkrupp.com<br />

Internet: www.thyssenkrupp-foerdertechnik.de<br />

Locations: Australia, Brazil, Canada, Chile, China,<br />

France, Germany, India, Indonesia, Kazakhstan, Russia,<br />

South Africa, United Arab Emirates, USA, Vietnam<br />

Solutions for open pit mining<br />

Solutions for mineral processing<br />

Solutions for bulk materials handling<br />

ThyssenKrupp Polysius AG<br />

Graf-Galen-Str. 17<br />

59269 Beckum<br />

Germany<br />

Tel.: +49 2525 99-0<br />

Fax: +49 2525 99-2100<br />

E-mail: polysius@thyssenkrupp.com<br />

Internet: www.polysius.com<br />

Locations: Argentina, Australia, Brazil, Canada,<br />

China, France, Germany, India, Indonesia, Malaysia,<br />

Mexico, Peru, Russia, Singapore, South Africa, Spain,<br />

Switzerland, UK, Ukraine, USA, Vietnam<br />

Solutions for processing<br />

ThyssenKrupp Metallurgical Products GmbH<br />

Hollestr. 7a<br />

45127 Essen<br />

Germany<br />

Tel.: +49 201 844-563901<br />

Fax: +49 201 844-563902<br />

E-mail: metpro@thyssenkrupp.com<br />

Internet: www.thyssenkrupp-metallurgical-products.com<br />

Locations: China, Germany, USA<br />

Solutions for raw materials trading

ThyssenKrupp Group of Companies<br />

ThyssenKrupp Allee 1<br />

45143 Essen · Germany<br />

www.thyssenkrupp.com<br />

For inquiries concerning business activities in the US please contact ThyssenKrupp North<br />

America Inc., ThyssenKrupp North America, 111 West Jackson Blvd., Suite 2400, Chicago,<br />

IL 60604, United States, www.thyssenkrupp-usa.com<br />

TK 760 e.1.1,5.11.12 MA