Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

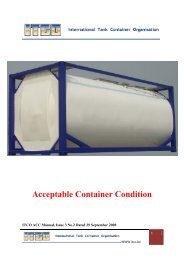

ICHCA International <strong>Safe</strong>ty Panel Briefing Pamphlet No 30<br />

4.2 Pressurised Liquefied Gases<br />

4.2.1 <strong>Tank</strong> containers for pressurised<br />

liquefied gases usually have a mild<br />

steel pressure vessel shell. A few<br />

specialised tank containers for<br />

these gases may have a stainless<br />

steel shell.<br />

4.2.2 Where high ambient temperature or<br />

direct sunlight can affect the cargo<br />

then a heat shield can be fitted<br />

above the top <strong>of</strong> the pressure<br />

vessel (see Picture 13)<br />

Picture 13<br />

4.2.3 Rarely for tank containers, the pressure vessel shell may be totally uninsulated.<br />

4.3 Powders and Granules<br />

4.3.1 <strong>Tank</strong> containers for powders and<br />

granules are generally low<br />

pressure vessels manufactured<br />

from aluminium alloys. An example<br />

is shown in picture 14.<br />

4.3.2 The nature <strong>of</strong> the powder or<br />

granule will dictate the design as<br />

will the loading / unloading process<br />

in which the tank container is to<br />

operate.<br />

4.3.3 The discharge process for powders and granules differs from liquids and<br />

gases insomuch as the cargo may not “flow”. Therefore tank containers for<br />

powders and granules may be manufactured with hopper discharge chutes<br />

built along the underside <strong>of</strong> the shell, or with specialist discharge<br />

mechanisms which facilitate the discharge.<br />

4.3.4 <strong>Tank</strong> containers that carry powder and granules may be mounted on tipping<br />

chassis / trailers<br />

4.4 <strong>Tank</strong> <strong>Containers</strong> for Deeply Refrigerated Liquefied Gases<br />

4.4.1 Some tank containers are designed and constructed to transport liquefied<br />

gases at extremely low temperatures, at around –200 o C or lower. They may<br />

be referred to as “cryogenic tanks” within the freight container industry.<br />

Picture 15 shows an example <strong>of</strong> a 20 ft cryrogenic tank<br />

4.4.2 Due to the nature <strong>of</strong> the<br />

cargoes carried the level <strong>of</strong><br />

insulation varies A typical<br />

cryogenic tank container will<br />

have an outer metal jacket<br />

surrounding the pressure<br />

vessel. A near-perfect<br />

vacuum is created between<br />

the outer metal jacket and<br />

the pressure vessel; this<br />

provides the insulation.<br />

Picture 14<br />

Picture 15<br />

Page 8 ©ICHCA International Limited