a conveyor guard may have saved his life - Workplace Safety North

a conveyor guard may have saved his life - Workplace Safety North

a conveyor guard may have saved his life - Workplace Safety North

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Beyond compliance:<br />

safe <strong>guard</strong>ing at Norampac<br />

6 www.healthandsafetyontario.ca<br />

BY KELLY ANN SMITH, WORKPLACE SAFETY NORTH.<br />

What does it mean to be compliant<br />

with <strong>guard</strong>ing legislation? Simon<br />

Fridlyand, P. Eng. with S.A.F.E. Engineering<br />

in Toronto recommends looking to safety<br />

first. Compliance, he says, means the work<br />

process is “a safe process, which is compliant<br />

to current and applicable standards.”<br />

But how does a company make sure a work<br />

process complies with those standards?<br />

Marshall Greensides, Corporate Health<br />

and <strong>Safety</strong> Coordinator with Norampac,<br />

the largest producer of containerboard<br />

in Canada, says <strong>his</strong> company’s approach<br />

is to “identify the hazards, perform a risk<br />

analysis to prioritize A, B and C risks, define<br />

corrective measures and create an action<br />

plan, and then measure to make sure you’ve<br />

had the appropriate impact.” While legal<br />

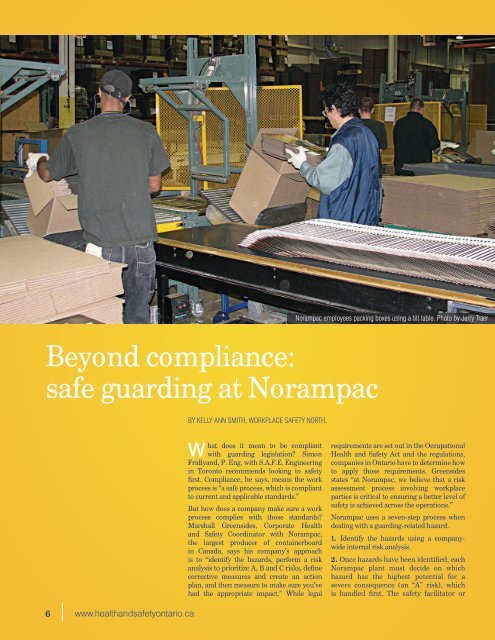

Norampac employees packing boxes using a tilt table. Photo by Jerry Traer<br />

requirements are set out in the Occupational<br />

Health and <strong>Safety</strong> Act and the regulations,<br />

companies in Ontario <strong>have</strong> to determine how<br />

to apply those requirements. Greensides<br />

states “at Norampac, we believe that a risk<br />

assessment process involving workplace<br />

parties is critical to ensuring a better level of<br />

safety is achieved across the operations.”<br />

Norampac uses a seven-step process when<br />

dealing with a <strong>guard</strong>ing-related hazard.<br />

1. Identify the hazards using a companywide<br />

internal risk analysis.<br />

2. Once hazards <strong>have</strong> been identified, each<br />

Norampac plant must decide on which<br />

hazard has the highest potential for a<br />

severe consequence (an “A” risk), which<br />

is handled first. The safety facilitator or