08394059 SPIT-FIRE® Monitor - Elkhart Brass

08394059 SPIT-FIRE® Monitor - Elkhart Brass

08394059 SPIT-FIRE® Monitor - Elkhart Brass

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

VI MAINTENANCE<br />

Monthly Inspection & Maintenance<br />

1. Cycle all monitor functions (LEFT, RIGHT, UP, DOWN) to insure that complete system is fully<br />

functional.<br />

Pressure Drop (PSI)<br />

Six-Month Inspection & Maintenance<br />

1. Grease monitor ball races through grease fittings located at each swivel joint. Recommended grease<br />

for Industrial Spit-Fire® monitors is MOBILITH SHC – 100, High Performance Synthetic Grease.<br />

Temperature range: -40°F (-26°C) to 400°F (250°C) or equal. Greasing procedures are as follows:<br />

a. In the lower grease fitting apply approx. 5-7 pumps of grease.<br />

b. In the upper grease fitting apply approx. 2-3 pumps of grease.<br />

2. Check motor control cables for wear and connectors for damage.<br />

3. Check motor cables for binding through full movement of monitor.<br />

4. Check all painted surfaces for chips or scratches and repaint as required.<br />

5. Visually check all electrical equipment.<br />

WARNING: Do not attempt to disconnect or work on any electrical equipment in this<br />

system unless power is removed or the area is known to be non-hazardous.<br />

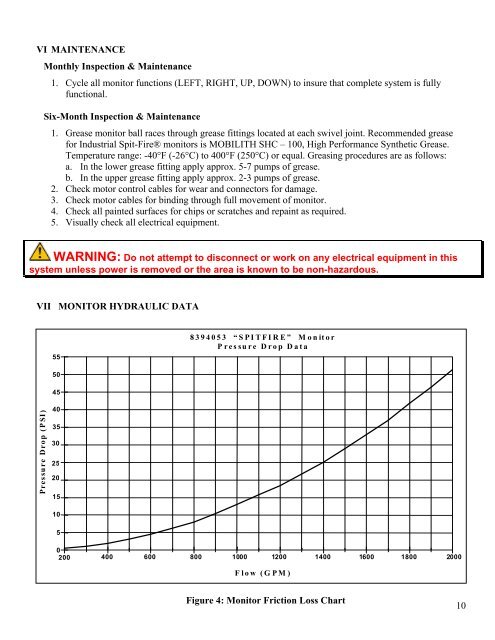

VII MONITOR HYDRAULIC DATA<br />

55<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

8394053 “<strong>SPIT</strong>FIRE” <strong>Monitor</strong><br />

Pressure Drop Data<br />

0<br />

200 400 600 800 1000 1200 1400 1600 1800 2000<br />

Flow (GPM)<br />

Figure 4: <strong>Monitor</strong> Friction Loss Chart<br />

10