Pyrocrete® 241 Pyrocrete® 241 - Carboline

Pyrocrete® 241 Pyrocrete® 241 - Carboline

Pyrocrete® 241 Pyrocrete® 241 - Carboline

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

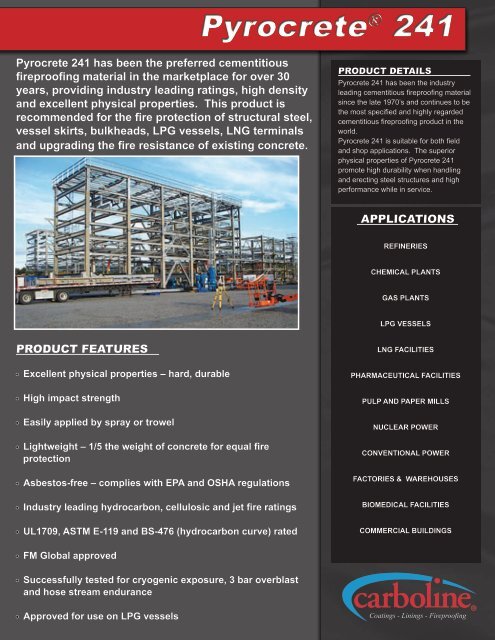

Pyrocrete <strong>241</strong> has been the preferred cementitious<br />

fireproofing material in the marketplace for over 30<br />

years, providing industry leading ratings, high density<br />

and excellent physical properties. This product is<br />

recommended for the fire protection of structural steel,<br />

vessel skirts, bulkheads, LPG vessels, LNG terminals<br />

and upgrading the fire resistance of existing concrete.<br />

Product Features<br />

• Excellent physical properties – hard, durable<br />

• High impact strength<br />

• Easily applied by spray or trowel<br />

• Lightweight – 1/5 the weight of concrete for equal fire<br />

protection<br />

• Asbestos-free – complies with EPA and OSHA regulations<br />

• Industry leading hydrocarbon, cellulosic and jet fire ratings<br />

• UL1709, ASTM E-119 and BS-476 (hydrocarbon curve) rated<br />

• FM Global approved<br />

• Successfully tested for cryogenic exposure, 3 bar overblast<br />

and hose stream endurance<br />

• Approved for use on LPG vessels<br />

Pyrocrete ® <strong>241</strong><br />

Product details<br />

Pyrocrete <strong>241</strong> has been the industry<br />

leading cementitious fireproofing material<br />

since the late 1970’s and continues to be<br />

the most specified and highly regarded<br />

cementitious fireproofing product in the<br />

world.<br />

Pyrocrete <strong>241</strong> is suitable for both field<br />

and shop applications. The superior<br />

physical properties of Pyrocrete <strong>241</strong><br />

promote high durability when handling<br />

and erecting steel structures and high<br />

performance while in service.<br />

aPPlications<br />

rEFINErIES<br />

CHEMICAL PLANTS<br />

GAS PLANTS<br />

LPG VESSELS<br />

LNG FACILITIES<br />

PHArMACEUTICAL FACILITIES<br />

PULP ANd PAPEr MILLS<br />

NUCLEAr POwEr<br />

CONVENTIONAL POwEr<br />

FACTOrIES & wArEHOUSES<br />

BIOMEdICAL FACILITIES<br />

COMMErCIAL BUILdINGS<br />

Coatings - Linings - Fireproofing<br />

THE PROTECTIVE COATINGS PROFESSIONALS

Quality Product Backed By Quality service<br />

Pyrocrete ® <strong>241</strong><br />

• <strong>Carboline</strong> Company has over 64 years of solving tough corrosion and fireproofing problems<br />

• Over 100 industrial service centers and sales offices located around the world<br />

• 23 worldwide manufacturing locations with a global network of sales and technical support<br />

• Industry leading field service and technical engineering support team<br />

• Certified to ISO 9001<br />

Reasons To use PyRocReTe <strong>241</strong><br />

PeRfoRmance feaTuRe advanTage BenefiT<br />

High density Harder, more durable material<br />

Resists handling and transportation damage,<br />

fewer onsite repairs<br />

Good coverage<br />

14.3 board ft. per bag<br />

(1.3 m² per bag @ 25.4 mm)<br />

Good yield per bag, economical application<br />

High compressive strength Resists cracking and impact damage Can resist impact damage during construction<br />

High bond strength Prevents disbondment and cracking<br />

Prevents failures, lower repair and maintenance<br />

costs<br />

Low thicknesses Less material required for projects Savings on material and labor to install<br />

Long Material Shelf Life<br />

Hourly Rating<br />

coveRage RaTes<br />

(Based on 4 Sided UL 1709 Contour Designs) 1<br />

Pyrocrete <strong>241</strong><br />

Thickness<br />

(UL XR-701)<br />

Longer storage window, greater flexibility for<br />

ordering and stocking material<br />

Pyrocrete <strong>241</strong><br />

Coverage Rates<br />

(ft² per bag) 2<br />

3/4 1/2”(13 mm) 28.6 (2.6 m²)<br />

1 11/16”(17 mm) 20.8 (1.9 m²)<br />

1-1/2 15/16”(24 mm) 15.3 (1.4 m²)<br />

2 1-1/8”(29 mm) 12.7 (1.2 m²)<br />

2-1/2 1-5/16”(33 mm) 10.9 (1.0 m²)<br />

3 1-3/8”(35 mm) 10.4 (0.9 m²)<br />

4 1-9/16”(40 mm) 9.2 (0.8 m²)<br />

Coatings - Linings - Fireproofing<br />

Reduces chance for overage (expired material)<br />

during project delays<br />

coveRage RaTes<br />

(3) (4)<br />

(Based on 4 Sided BS-476 Hydrocarbon Designs)<br />

Rating in<br />

Minutes<br />

Pyrocrete <strong>241</strong><br />

Thickness<br />

(HP/A of 159)<br />

2150 Schuetz Road THE • St. PROTECTIVE Louis, MO 63146 COATINGS • PH: PROFESSIONALS<br />

800-848-4645 • www.carboline.com<br />

Pyrocrete <strong>241</strong><br />

Coverage Rates<br />

(m² per bag) 2<br />

30 10 mm (0.4”) 3.3 (36.3 ft²)<br />

60 15 mm (0.6”) 2.2 (24.2 ft²)<br />

90 20 mm (0.8”) 1.7 (18.2 ft²)<br />

120 25 mm (0.9”) 1.3 (14.5 ft²)<br />

150 30 mm (1.2”) 1.1 (12.1 ft²)<br />

180 35 mm (1.4”) 0.9 (10.4 ft²)<br />

240 45 mm (1.7”) 0.7 (8.1 ft²)<br />

1<br />

Notes: UL 1709 thicknesses based on W10 x 49 (W/D = 0.84, or HP/A = 159)<br />

2<br />

Coverage based on 50 lbs. (22.7 kg) bags (one board ft = one ft² of material at one inch or 0.09 m² of material at 25.4 mm)<br />

3 BS-476 (hydrocarbon curve) thicknesses based on W10 x 49 (W/D = 0.84, or HP/A = 159) to 550°C limiting temperature<br />

4 BS-476 (hydrocarbon curve) ratings range from HP/A: 30 to 305<br />

01-46-1111-476