Vaderstad Carrier Drill Brochure - LiveUpdater

Vaderstad Carrier Drill Brochure - LiveUpdater

Vaderstad Carrier Drill Brochure - LiveUpdater

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

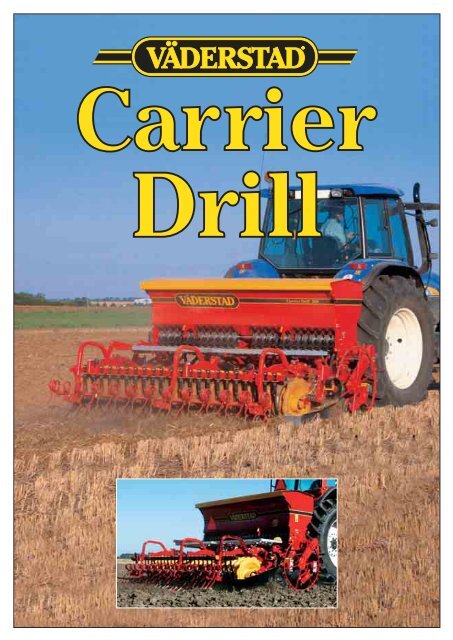

Much to be gained from shallow tillage<br />

For small and medium-sized<br />

farms with good cropping<br />

conditions, <strong>Carrier</strong> <strong>Drill</strong> can be<br />

a very effective solution.<br />

Many farmers view traditional<br />

deep tillage as an expensive but<br />

reliable way to establish a new<br />

crop.<br />

By working at a slightly shallower<br />

depth, great savings can be<br />

made in diesel, labour and wear.<br />

Here <strong>Carrier</strong> <strong>Drill</strong> can do an<br />

excellent job.<br />

However, a shallow tillage<br />

concept places higher demands<br />

on both the farmer and the cultivation<br />

system. Successful shallow<br />

tillage requires level fields,<br />

good soil structure and favourable<br />

growing conditions. Crop<br />

rotation becomes even more<br />

important in controlling recurring<br />

crop diseases.

On a small or medium-sized<br />

farm, <strong>Carrier</strong> <strong>Drill</strong> can take care<br />

of all the soil cultivation and<br />

drilling needed to establish a<br />

new crop.<br />

One or two passes with <strong>Carrier</strong><br />

machinery directly after the<br />

combine are enough to start<br />

straw breakdown and to encourage<br />

weeds and volunteer seeds<br />

to germinate. After germination,<br />

these can be controlled by<br />

spraying with e.g. glyphosate or<br />

by a further cultivation. Then<br />

the only remaining task is to fill<br />

up the seed hopper and drill in<br />

Two machines in one!<br />

the next pass. The seed is placed<br />

in a band in the wake of each<br />

disc, covered with soil and<br />

firmed in by the roller packs.<br />

Väderstad <strong>Carrier</strong>’s acknowledged<br />

ability to cultivate to a<br />

shallow, exact working depth<br />

creates the conditions for accurate<br />

seed placement and<br />

uniform emergence.<br />

The metering system has been<br />

tried and tested and is the same<br />

as that on the Rapid seed drill.<br />

However, seed placement is not<br />

quite as accurate as with the<br />

Rapid.<br />

<strong>Carrier</strong> <strong>Drill</strong> is two machines in<br />

one! With a <strong>Carrier</strong> <strong>Drill</strong>, all<br />

soil cultivation and seed<br />

drilling can be carried out with<br />

just one machine. Few other<br />

systems on the market can<br />

measure up to <strong>Carrier</strong> <strong>Drill</strong> in<br />

terms of capital savings and<br />

versatility.<br />

12,5 cm

Powerful soil cultivation<br />

<strong>Carrier</strong> <strong>Drill</strong> has the same soil<br />

cultivation ability as <strong>Carrier</strong>. Two<br />

rows of conical discs ensure very<br />

intensive cultivation and mixing<br />

of the upper 2 - 10 cm. Thanks to<br />

the fact that the disc diameter is<br />

only 430 mm, very high rotation<br />

speeds can be achieved. In practice,<br />

this means very intensive<br />

mixing and a more level soil<br />

surface with a fine structure after<br />

the machine.<br />

Long lifetime<br />

The serrated discs of specially<br />

hardened V-55 steel force their<br />

way aggressively down into the<br />

soil at high speed and take small<br />

‘bites’ of soil, which are thrown<br />

sideways. The permanently<br />

lubricated disc bearings are<br />

carefully sealed with a special<br />

seal unit. This seal cassette has a<br />

multiple sealing action that<br />

effectively withstands dust and<br />

damp.<br />

Each disc arm is suspended in a<br />

rubber mounting, which gives<br />

an even ride and very little wear.<br />

Simple depth adjustment<br />

It is easy to adjust the working<br />

depth on <strong>Carrier</strong> <strong>Drill</strong>. The roller<br />

controls the entire machine and<br />

the depth can be adjusted<br />

hydraulically from the cab.<br />

Maximum cultivation depth is<br />

set using clips placed on the<br />

cylinder. A clear scale displays<br />

the actual working depth.<br />

Flexible

solutions<br />

1<br />

A<br />

2<br />

3<br />

Large hopper<br />

Hopper size is an important<br />

factor for drilling capacity.<br />

<strong>Carrier</strong> <strong>Drill</strong> has a generously<br />

proportioned 1100 litre hopper<br />

that allows for approx. 4 - 6 ha<br />

per fill. The hopper is placed<br />

close to the tractor to minimise<br />

the lifting requirement. A sturdy<br />

platform makes filling and<br />

inspection easy.<br />

(A) An agitator axle is fitted in<br />

the seed hopper above the<br />

rollers to ensure uniform metering<br />

of the seed.<br />

Tried and tested Rapid<br />

technology<br />

The seed metering system is<br />

identical to that in the tried and<br />

tested Rapid 300S/400S drill. A<br />

large metering wheel follows the<br />

soil surface and drives a gearbox.<br />

This gearbox can be steplessly<br />

adjusted for all possible<br />

seed rates between 2 and 300<br />

kg/ha.<br />

Exact metering is essential for<br />

uniform emergence and also<br />

provides the potential for lower<br />

seed rates.<br />

Exact metering<br />

Metering is carried out with the<br />

help of turbine-shaped seed<br />

rollers (1) that continuously<br />

meter the desired amount.<br />

When sowing small-seeded<br />

crops and oilseeds, the system<br />

can be easily adapted so that<br />

metering is carried out by a<br />

microwheel (2), which increases<br />

the precision at low seed rates.<br />

To avoid damage to the metering<br />

system, each base valve is<br />

sprung (3).

Seed placement and soil firming<br />

Seed nozzles place seed<br />

The seeds are broadcast in the<br />

wake of each disc and covered<br />

by the stream of soil from the<br />

neighbouring disc. The seed<br />

nozzles are manufactured from<br />

high-grade rubber material for<br />

good stone resistance and<br />

drilling precision.<br />

Optimal soil consolidation<br />

and surface loosening<br />

For both soil cultivation and<br />

seed drilling, a sufficient degree<br />

of soil consolidation is essential.<br />

<strong>Carrier</strong> <strong>Drill</strong> has a weight of 850<br />

kg per metre working width,<br />

which makes for good penetration<br />

and good contact between<br />

seed and soil. The weight is<br />

particularly important in dry<br />

and hard conditions, where a<br />

light machine only scrapes the<br />

surface.<br />

<strong>Carrier</strong> <strong>Drill</strong> has roller packs of<br />

steel rings that have been well<br />

tested on <strong>Carrier</strong>. Thanks to the<br />

fact that the roller packs are<br />

compressed, each ring acts as a<br />

spring, which means that the<br />

packs do not have to be re-tightened.<br />

The steel rings have completely<br />

smooth sides, which<br />

makes it difficult for wet soil and<br />

straw to stick, even under very<br />

wet conditions. The following<br />

harrow, which is spring-mounted<br />

and easily adjustable, leaves<br />

a loose surface layer.<br />

Optimal soil firming creates<br />

good contact between seed and<br />

soil and ensures that the seeds<br />

are supplied with water.

<strong>Carrier</strong> <strong>Drill</strong> is two machines in<br />

one! It can be used to carry out<br />

both powerful soil tillage and<br />

precise drilling and can thus<br />

replace several machines on the<br />

farm. In this way, the farmer can<br />

reduce both the amount of<br />

bound capital and the labour<br />

and diesel requirements on the<br />

farm.<br />

Save capital!<br />

€<br />

100000<br />

80000<br />

60000<br />

40000<br />

20000<br />

0<br />

Capital<br />

With <strong>Carrier</strong> <strong>Drill</strong>, the capital<br />

investment is 16 250 € lower<br />

than with the conventional<br />

system. The annual cost of<br />

financing the machinery (incl.<br />

depreciation and interest) thus<br />

decreases by 2200 €, which<br />

represents a reduction of more<br />

than 15%.<br />

* Depreciation period for tractor set at 10<br />

years, for other equipment 5 years. Interest<br />

set at 5%.<br />

Huge savings<br />

Here is a comparison of the costs<br />

of a common conventional<br />

machine system and a <strong>Carrier</strong><br />

<strong>Drill</strong>.<br />

Assumptions<br />

Crop rotation: Cereal and<br />

oilseed<br />

Area: 200 ha<br />

Save time!<br />

hr/year tim/år<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

Conventional system:<br />

• 135 hp tractor<br />

• 5-furrow plough<br />

• 4 m power harrow/seed drill<br />

combination<br />

<strong>Carrier</strong> <strong>Drill</strong> system:<br />

• 135 hp tractor<br />

• <strong>Carrier</strong> <strong>Drill</strong> 300<br />

Save fuel!<br />

l fuel/year diesel/år<br />

10000<br />

0<br />

0<br />

Conventional <strong>Carrier</strong> <strong>Drill</strong> Conventional <strong>Carrier</strong> <strong>Drill</strong> Conventional <strong>Carrier</strong> <strong>Drill</strong><br />

Time<br />

Conventional system<br />

• Ploughing<br />

• <strong>Drill</strong>ing with power harrow<br />

combination<br />

• Rolling<br />

<strong>Carrier</strong> <strong>Drill</strong> system<br />

• Soil tillage <strong>Carrier</strong> <strong>Drill</strong><br />

• Spraying<br />

• <strong>Drill</strong>ing with <strong>Carrier</strong> <strong>Drill</strong><br />

• Rolling<br />

The <strong>Carrier</strong> <strong>Drill</strong> system brings a<br />

saving of 85 hours/year, i.e. 25% of<br />

the current labour requirement.<br />

8000<br />

6000<br />

4000<br />

2000<br />

Fuel<br />

We assumed that the 135 hp<br />

tractor used 24 litres of diesel<br />

per hour when working at full<br />

capacity. The <strong>Carrier</strong> <strong>Drill</strong><br />

system means a saving of 2000<br />

litres of diesel per year (85 hours<br />

x 24 l/hr=2040 l).<br />

Summary<br />

The <strong>Carrier</strong> <strong>Drill</strong> system saves:<br />

• 85 manhours/year<br />

• Around 2000 litres diesel/year<br />

• Approx. 2200 €/year in capital costs<br />

• The total saving is approx. 5600 €/year (incl. capital<br />

costs, diesel, labour, maintenance and repairs)

Technical data:<br />

Model Working Transport Weight Hopper Roller Hp Hydraulic Notes<br />

width width requirements<br />

m m kg l mm<br />

CRD 300 3,0 3,0 2400 1100 600 120 - 150 1 double<br />

Adapted to individual needs<br />

Depending on individual needs,<br />

<strong>Carrier</strong> <strong>Drill</strong> can be equipped with<br />

a following harrow, bout markers<br />

and a control box for controlling<br />

the hydraulics and monitoring<br />

sensors. All versions of <strong>Carrier</strong><br />

<strong>Drill</strong> have an area meter.<br />

No farm is the same as another.<br />

Therefore <strong>Carrier</strong> <strong>Drill</strong> can be<br />

adapted to your exact needs!<br />

VÄDERSTAD Ltd.<br />

Unit One, Ellesmere Business Park<br />

Grantham, Lincolnshire NG31 7XT<br />

Tel. 01476 581 900 • Fax 01476 581 901<br />

www.vaderstad.com<br />

Distributor:<br />

The company retains the right to make changes to specifications and design. Patents awarded and pending<br />

990008-ENGB Mjölby Tryckeri AB/Desktopteknik AB 2005.10