The safe isolation of plant and equipment (HSG253) - Health and ...

The safe isolation of plant and equipment (HSG253) - Health and ...

The safe isolation of plant and equipment (HSG253) - Health and ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

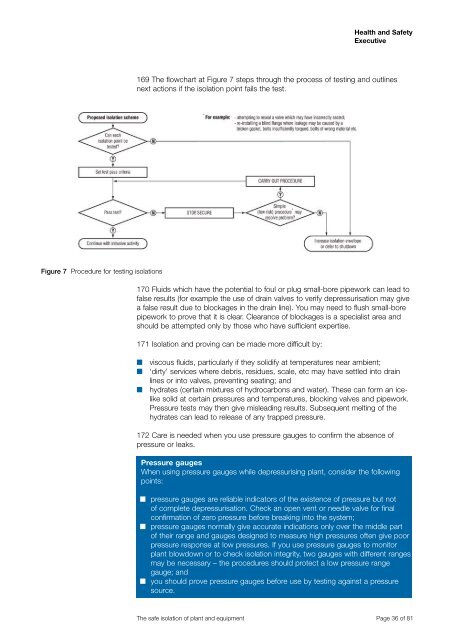

Figure 7 Procedure for testing <strong>isolation</strong>s<br />

<strong>Health</strong> <strong>and</strong> Safety<br />

Executive<br />

169 <strong>The</strong> flowchart at Figure 7 steps through the process <strong>of</strong> testing <strong>and</strong> outlines<br />

next actions if the <strong>isolation</strong> point fails the test.<br />

170 Fluids which have the potential to foul or plug small-bore pipework can lead to<br />

false results (for example the use <strong>of</strong> drain valves to verify depressurisation may give<br />

a false result due to blockages in the drain line). You may need to flush small-bore<br />

pipework to prove that it is clear. Clearance <strong>of</strong> blockages is a specialist area <strong>and</strong><br />

should be attempted only by those who have sufficient expertise.<br />

171 Isolation <strong>and</strong> proving can be made more difficult by:<br />

■<br />

■<br />

■<br />

viscous fluids, particularly if they solidify at temperatures near ambient;<br />

‘dirty’ services where debris, residues, scale, etc may have settled into drain<br />

lines or into valves, preventing seating; <strong>and</strong><br />

hydrates (certain mixtures <strong>of</strong> hydrocarbons <strong>and</strong> water). <strong>The</strong>se can form an icelike<br />

solid at certain pressures <strong>and</strong> temperatures, blocking valves <strong>and</strong> pipework.<br />

Pressure tests may then give misleading results. Subsequent melting <strong>of</strong> the<br />

hydrates can lead to release <strong>of</strong> any trapped pressure.<br />

172 Care is needed when you use pressure gauges to confirm the absence <strong>of</strong><br />

pressure or leaks.<br />

Pressure gauges<br />

When using pressure gauges while depressurising <strong>plant</strong>, consider the following<br />

points:<br />

■ pressure gauges are reliable indicators <strong>of</strong> the existence <strong>of</strong> pressure but not<br />

<strong>of</strong> complete depressurisation. Check an open vent or needle valve for final<br />

confirmation <strong>of</strong> zero pressure before breaking into the system;<br />

■ pressure gauges normally give accurate indications only over the middle part<br />

<strong>of</strong> their range <strong>and</strong> gauges designed to measure high pressures <strong>of</strong>ten give poor<br />

pressure response at low pressures. If you use pressure gauges to monitor<br />

<strong>plant</strong> blowdown or to check <strong>isolation</strong> integrity, two gauges with different ranges<br />

may be necessary – the procedures should protect a low pressure range<br />

gauge; <strong>and</strong><br />

■ you should prove pressure gauges before use by testing against a pressure<br />

source.<br />

<strong>The</strong> <strong>safe</strong> <strong>isolation</strong> <strong>of</strong> <strong>plant</strong> <strong>and</strong> <strong>equipment</strong> Page 36 <strong>of</strong> 81