The safe isolation of plant and equipment (HSG253) - Health and ...

The safe isolation of plant and equipment (HSG253) - Health and ...

The safe isolation of plant and equipment (HSG253) - Health and ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

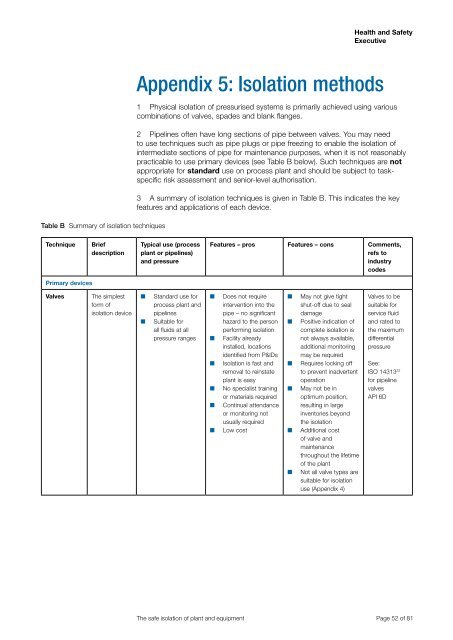

Table B Summary <strong>of</strong> <strong>isolation</strong> techniques<br />

Technique Brief<br />

description<br />

Primary devices<br />

Valves <strong>The</strong> simplest<br />

form <strong>of</strong><br />

<strong>isolation</strong> device<br />

<strong>Health</strong> <strong>and</strong> Safety<br />

Executive<br />

Appendix 5: Isolation methods<br />

1 Physical <strong>isolation</strong> <strong>of</strong> pressurised systems is primarily achieved using various<br />

combinations <strong>of</strong> valves, spades <strong>and</strong> blank flanges.<br />

2 Pipelines <strong>of</strong>ten have long sections <strong>of</strong> pipe between valves. You may need<br />

to use techniques such as pipe plugs or pipe freezing to enable the <strong>isolation</strong> <strong>of</strong><br />

intermediate sections <strong>of</strong> pipe for maintenance purposes, when it is not reasonably<br />

practicable to use primary devices (see Table B below). Such techniques are not<br />

appropriate for st<strong>and</strong>ard use on process <strong>plant</strong> <strong>and</strong> should be subject to taskspecific<br />

risk assessment <strong>and</strong> senior-level authorisation.<br />

3 A summary <strong>of</strong> <strong>isolation</strong> techniques is given in Table B. This indicates the key<br />

features <strong>and</strong> applications <strong>of</strong> each device.<br />

Typical use (process<br />

<strong>plant</strong> or pipelines)<br />

<strong>and</strong> pressure<br />

■<br />

■<br />

St<strong>and</strong>ard use for<br />

process <strong>plant</strong> <strong>and</strong><br />

pipelines<br />

Suitable for<br />

all fluids at all<br />

pressure ranges<br />

Features – pros Features – cons Comments,<br />

refs to<br />

industry<br />

codes<br />

■<br />

■<br />

■<br />

■<br />

■<br />

■<br />

Does not require<br />

intervention into the<br />

pipe – no significant<br />

hazard to the person<br />

performing <strong>isolation</strong><br />

Facility already<br />

installed, locations<br />

identified from P&IDs<br />

Isolation is fast <strong>and</strong><br />

removal to reinstate<br />

<strong>plant</strong> is easy<br />

No specialist training<br />

or materials required<br />

Continual attendance<br />

or monitoring not<br />

usually required<br />

Low cost<br />

May not give tight<br />

shut-<strong>of</strong>f due to seal<br />

damage<br />

Positive indication <strong>of</strong><br />

complete <strong>isolation</strong> is<br />

not always available,<br />

additional monitoring<br />

may be required<br />

Requires locking <strong>of</strong>f<br />

to prevent inadvertent<br />

operation<br />

May not be in<br />

optimum position,<br />

resulting in large<br />

inventories beyond<br />

the <strong>isolation</strong><br />

Additional cost<br />

<strong>of</strong> valve <strong>and</strong><br />

maintenance<br />

throughout the lifetime<br />

<strong>of</strong> the <strong>plant</strong><br />

Not all valve types are<br />

suitable for <strong>isolation</strong><br />

use (Appendix 4)<br />

<strong>The</strong> <strong>safe</strong> <strong>isolation</strong> <strong>of</strong> <strong>plant</strong> <strong>and</strong> <strong>equipment</strong> Page 52 <strong>of</strong> 81<br />

■<br />

■<br />

■<br />

■<br />

■<br />

■<br />

Valves to be<br />

suitable for<br />

service fluid<br />

<strong>and</strong> rated to<br />

the maximum<br />

differential<br />

pressure<br />

See:<br />

ISO 14313 22<br />

for pipeline<br />

valves<br />

API 6D