Workshop Manual Datsun 510, 1300-1600, L13 ... - Datsun510.com

Workshop Manual Datsun 510, 1300-1600, L13 ... - Datsun510.com

Workshop Manual Datsun 510, 1300-1600, L13 ... - Datsun510.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

l<br />

5 Fuel System<br />

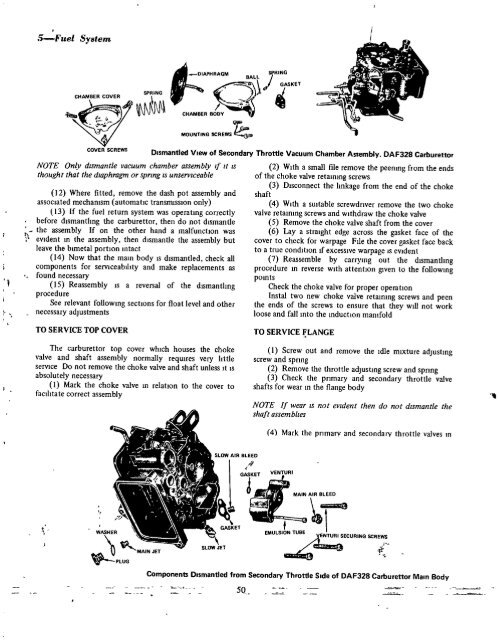

CHAMBER COVER<br />

COVER SCREWS<br />

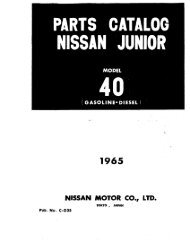

wASHER<br />

MAIN o<br />

V PLUG<br />

SPRING<br />

hJ<br />

r I<br />

CHAMBER BODY<br />

MOUNTING SCREWS<br />

NOTE Only dismantle vacuum chamber assembly If IfIS<br />

thoughtthat the dwphragm or IS<br />

sprmg<br />

unserviceable<br />

12 Where fitted remove the dash pot assembly and<br />

assocIated mechamsm automatic tranSIlllSSlOn only<br />

13 If the fuel return system was operatmg correctly<br />

before dlsmanthng the carburettor then do not dIsmantle<br />

the assembly If on the other hand<br />

j J<br />

Dismantled View of Secondary Throttle Vacuum Chamber Assembly<br />

JET<br />

a malfunctIOn was<br />

eVIdent m the assembly then dIsmantle the assembly but<br />

leave the bunetal portion mtact<br />

14 Now that the mam body IS dIsmantled check all<br />

components for servlceablhty and make replacements as<br />

found necessary<br />

15 Reassembly IS a reversal of the dlSmantlmg<br />

procedure<br />

See relevant followmg sectIOns for float level and other<br />

necessary adjustments<br />

TO SERVICE TOP COVER<br />

The carburettor top cover whIch houses the choke<br />

valve and shaft assembly normally requlfes very httle<br />

serVIce Do notremove the choke yalve and shaft unless It IS<br />

absolutely necessary<br />

I Mark the choke valve m relation to the cover to<br />

faCIlitate correct assembly<br />

SLOW AIR eLEED<br />

I<br />

GjKET<br />

DAF328 Carburettor<br />

2 WIth a small me remove the peenmg from the ends<br />

of the choke yalve retammg screws<br />

shaft<br />

3 DIsconnect the lInkage from the end of the choke<br />

4 With a SUItable screwdnver remove the two choke<br />

valve retammg screws and WIthdraw the choke valve<br />

5 Remove the choke valve shaft from the cover<br />

6 Lay a str31ght edge across the gasket face of the<br />

cover to check for warpage<br />

File the cover gasket face back<br />

to a true condItion IfexcessIve warpage IS eVident<br />

7 Reassemble by carrymg out the dlsmantlmg<br />

procedure m reverse WIth attention gIven to the followmg<br />

pomts<br />

Check the choke valve for proper operation<br />

Instal two new choke valve retammg screws and peen<br />

the ends of the screws to ensure that they WIll not work<br />

loose and fall mto the mductlOn mamfold<br />

TO SERVICE FLANGE<br />

I Screw out and remove the Idle mIXture adJustmg<br />

screw and spnng<br />

2 Remove the throttle adJustmg screw and spnng<br />

3 Check the pnmary and secondary throttle valve<br />

shafts for wear m the flange body<br />

NOTE If wear IS not eVident then do not dismantle the<br />

shaft assemblies<br />

4 Mark the pnmarv and secondary throttle valves m<br />

MAIN AIR BLEED<br />

t 1<br />

EMULSION T<br />

B<br />

ENTURI SECURING SCREWS<br />

Components DIsmantled from Secondary Throttle SIde of DAF328 Carburettor Mam Body<br />

50