Developments Toward an Intelligent Electric Arc Furnace at - Tenova

Developments Toward an Intelligent Electric Arc Furnace at - Tenova

Developments Toward an Intelligent Electric Arc Furnace at - Tenova

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

OVERVIEW<br />

The CMC Texas EAF is a 22’ diameter EAF, 120 short ton eccentric bottom tapping, AC furnace powered by <strong>an</strong> 80 MVA<br />

tr<strong>an</strong>sformer. Chemical energy is provided by three PTI JetBox modules, three 3.5 MW burners (for carbon, oxygen <strong>an</strong>d meth<strong>an</strong>e) <strong>an</strong>d<br />

one 1 MW EBT conventional burner.<br />

The Goodfellow Expert <strong>Furnace</strong> System Optimiz<strong>at</strong>ion Process (Goodfellow EFSOP ® ) is a dynamic control <strong>an</strong>d optimiz<strong>at</strong>ion system<br />

for electric arc steelmaking furnaces (EAF) based on real-time measurements of off-gas composition. The system uses st<strong>at</strong>e-of-the-art<br />

off-gas <strong>an</strong>alysis combined with process d<strong>at</strong>a acquisition <strong>an</strong>d real-time closed loop control to optimize the oper<strong>at</strong>ion of the EAF.<br />

Typically, the objectives for optimizing the EAF oper<strong>at</strong>ion are to reduce conversion costs (energy <strong>an</strong>d m<strong>at</strong>erial), increase production<br />

<strong>an</strong>d improve safety.<br />

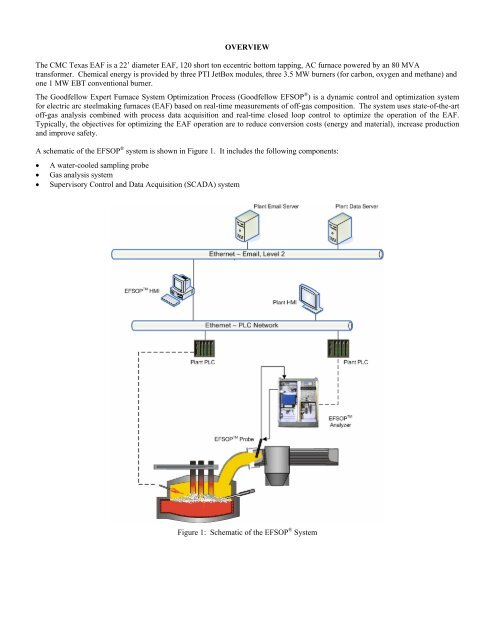

A schem<strong>at</strong>ic of the EFSOP ® system is shown in Figure 1. It includes the following components:<br />

• A w<strong>at</strong>er-cooled sampling probe<br />

• Gas <strong>an</strong>alysis system<br />

• Supervisory Control <strong>an</strong>d D<strong>at</strong>a Acquisition (SCADA) system<br />

Figure 1: Schem<strong>at</strong>ic of the EFSOP ® System