Short Description : Detail Description : - BTEB

Short Description : Detail Description : - BTEB

Short Description : Detail Description : - BTEB

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

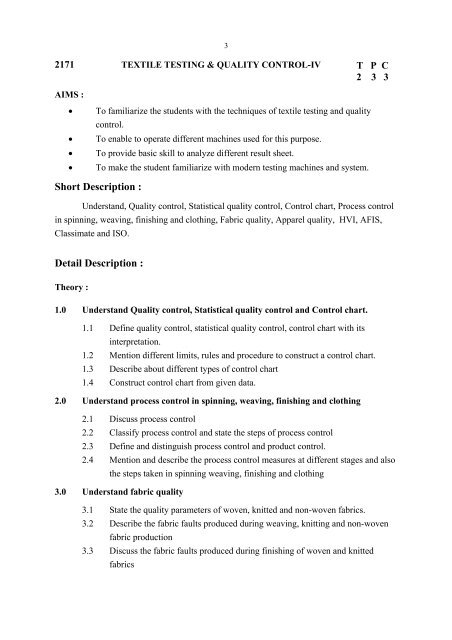

2171 TEXTILE TESTING & QUALITY CONTROL-IV<br />

AIMS :<br />

• To familiarize the students with the techniques of textile testing and quality<br />

control.<br />

• To enable to operate different machines used for this purpose.<br />

• To provide basic skill to analyze different result sheet.<br />

• To make the student familiarize with modern testing machines and system.<br />

<strong>Short</strong> <strong>Description</strong> :<br />

3<br />

T P C<br />

2 3 3<br />

Understand, Quality control, Statistical quality control, Control chart, Process control<br />

in spinning, weaving, finishing and clothing, Fabric quality, Apparel quality, HVI, AFIS,<br />

Classimate and ISO.<br />

<strong>Detail</strong> <strong>Description</strong> :<br />

Theory :<br />

1.0 Understand Quality control, Statistical quality control and Control chart.<br />

1.1 Define quality control, statistical quality control, control chart with its<br />

interpretation.<br />

1.2 Mention different limits, rules and procedure to construct a control chart.<br />

1.3 Describe about different types of control chart<br />

1.4 Construct control chart from given data.<br />

2.0 Understand process control in spinning, weaving, finishing and clothing<br />

2.1 Discuss process control<br />

2.2 Classify process control and state the steps of process control<br />

2.3 Define and distinguish process control and product control.<br />

2.4 Mention and describe the process control measures at different stages and also<br />

the steps taken in spinning weaving, finishing and clothing<br />

3.0 Understand fabric quality<br />

3.1 State the quality parameters of woven, knitted and non-woven fabrics.<br />

3.2 Describe the fabric faults produced during weaving, knitting and non-woven<br />

fabric production<br />

3.3 Discuss the fabric faults produced during finishing of woven and knitted<br />

fabrics

4.0 Understand apparel quality<br />

4.1 List the quality control activities for apparel manufacturing<br />

4.2 Define TAP, AQL.<br />

4<br />

4.3 Mention the quality parameters for assessing sewability and defects caused<br />

during sewing<br />

4.4 State the co-relation between fabric quality and apparel quality<br />

4.5 List the defects of zippers, spreading, patterns, cuttings sewing, seaming and<br />

assembling.<br />

4.6 Mention the operation for controlling fusing, screen printing. embroidering<br />

and pressing/finishing.<br />

5.0 Understand USTER statistics.<br />

5.1 Describe USTER statistics.<br />

5.2 How to prepare USTER statistics.<br />

5.3 Discuss about the application of USTER statistics.<br />

6.0 Understand Classimate.<br />

6.1 State classimate<br />

6.2 Classify the faults by classimates.<br />

6.3 Explain the assessment of faults.<br />

6.4 Mention the control measures to reduce faults<br />

7.0 Understand Evenness tester.<br />

7.1 Discuss the concept of evenness testing.<br />

7.2 Explain the techniques of measurement by evenness testing<br />

7.3 State the types of yarn faults and faults measurement by evenness tester.<br />

7.4 Define U%, CV% & I% and state the testing mode of evenness tester.<br />

7.5 Describe diagram, spectrogram & discuss the methods of interpretation of<br />

USTER curve.<br />

8.0. Understand HVI<br />

8.1. Define HVI<br />

8.2 State the tests that can be done by HVI machine in different module.<br />

8.3. Mention the merits of HVI machine<br />

8.4. Discuss about the operational procedure of HVI and interpretation of HVI<br />

results.

9.0 Understand AFIS<br />

9.1 Describe AFIS<br />

9.2 Mention the tests that can be done by AFIS in different module<br />

5<br />

9.3 Discuss about the operational procedure of AFIS and analysis of AFIS result.<br />

9.4. Define calibration of cotton.<br />

9.5 Classify calibration of cotton.<br />

9.6 Describe the importance of calibration of cotton.<br />

10.0 Understand ISO<br />

Practical:<br />

10.1 Define ISO with its objectives and Principles<br />

10.2 State the importance of ISO certification<br />

10.3 Describe the steps for getting ISO quality certificate.<br />

10.4 Describe the steps of awarding ISO certificate<br />

10.5 Discuss about the functions and quality of quality control personnel<br />

1. Calibrate HVI with calibrating cotton.<br />

2. Perform test with HVI and evaluate the test results.<br />

3. Calibrate AFIS with calibrating cotton.<br />

4. Perform test with AFIS and evaluate the test results.<br />

5. perform test with Uster tester and evaluate the test results.<br />

6. perform test with classimate and evaluate the test results<br />

7. Construct control chart and evaluate the chart for different count of yarn.<br />

8. Construct control chart and evaluate the chart for twist regularity and strength of<br />

Book references:<br />

different count and type of yarn.<br />

1. Quality control in cotton spinning- Md ashraful Islam<br />

2. Process control in spinning- A. R. brade & T.A Subramaniam<br />

3. Testing and quality Management V.K. Kothari.<br />

4. Handbook of textile testing and Quality control Gover & Homby.<br />

5. Sitra focus- SITRA. Conmbatore, India.<br />

6. Testile Testing, Fibre yarn & fabric- Dr. Arindham Basu<br />

7. ÷¨vwUmwUKm A¨vÛ †KvqvwjwU K‡Ûvj- †gvt gwReyi ingvb|

2271 ADVANCED SHORT STAPLE SPINNING-II<br />

AIMS:<br />

1. To develop advance knowledge of special type short staple spinning.<br />

2. To enable to understand the concepts of open end spinning machinery.<br />

3. To develop the knowledge of blended yarn.<br />

SHORT DESCRIPTION<br />

6<br />

T P C<br />

2 3 3<br />

Blended yarn processing, Cotton blended yarn, Special type of spinning i.e warp spinning,<br />

Core spinning & Condensed yarn spinning.<br />

DETAIL DESCRIPTION<br />

Theory<br />

Blended Yarn.<br />

1.0 Understand the polyester cotton blended yarn<br />

1.1 State the importance of blended yarn<br />

1.2 State the properties of fibres considered for P/C blended yarn.<br />

1.3 Mention the blending ratio of polyester & cotton for different count of p/c<br />

blended yarn<br />

1.4 Mention the properties, merits & demerits, uses of p/c blended yarn.<br />

2.0 Understand the techniques of polyester and cotton blended yarn processing.<br />

2.1 Show the flow chart of p/c blended yarn processing.<br />

2.2 Explain the reasons for processing the polyester in blow room and blending in<br />

drawing frame.<br />

2.3 Mention the necessary changes to be done for p/c blended yarn production from<br />

blow room section to ring frame.<br />

2.4 Discuss the necessities and methods of setting for p/c blended yarn.<br />

2.5 Solve the relevant problems of p/c blended yarn production.<br />

3.0 Understand viscose cotton blended yarn.<br />

3.1 Show the flow chart of viscose cotton blended yarn production.<br />

3.2 Mention the necessary changes/works to be done for viscose cotton blended<br />

yarn production from blow room section to ring frame<br />

3.3 Mention the properties, merits and demerits, uses of viscose- cotton blended<br />

yarn.

4.0 Understand wrap spinning.<br />

4.1 State the principle of warp spinning operation.<br />

7<br />

4.2 Discuss the history of development of wrap spinning & working procedure of<br />

wrap spinning machines with technical details.<br />

4.3 Mention the raw material requirements for wrap spinning.<br />

4.4 State the warp yarn characteristics with applications.<br />

5.0 Understand core yarn spinning.<br />

5.1 Define core spun yarn with the method of production.<br />

5.2 Discuss the method of manufacturing core-spun yarn by the following process-<br />

a) Ring frame<br />

b) O.E. Rotor frame<br />

c) Friction spinning<br />

d) Air jet spinning<br />

5.3 Mention the raw material required for core-spun yarn.<br />

5.4 Mention the application of core-spun yarn.<br />

6.0 Understand condensed yarn spinning.<br />

6.1 State the necessities of condensed yarn spinning.<br />

6.2 Discuss the following process –<br />

a) DREF Compact spinning<br />

b) COM for spinning process<br />

c) Elite spinning system.<br />

6.3 State the yarn properties, merits & demerits of condensed yarn spinning.<br />

7.0 Understand different types of yarns and Technical Textile.<br />

7.1 Briefly describe about the introduction manufacturing process of-<br />

7.2 Define technical textiles with its end-uses.<br />

a) Mélange yara<br />

b) Fancy yarn<br />

7.3 Discuss briefly about the following Technical Textile-<br />

a) Protection textile, b) Medical fabrics, c) Agricultural fabrics, d) Filter<br />

8.0 Understand spin plan<br />

fabrics, e) Tarpaulins & covers, f) Textile composites & g) Tyre cords.<br />

8.1 State the importance of spin plan<br />

8.2 Mention the factors to be considered for calculation spin plan.<br />

8.3 State parameters, types of parameters and value of different parameters for<br />

different count and systems (conventional, modern)

Practical :<br />

8<br />

8.4 Prepare spin plan for different count 2 system (conventional, modern).<br />

1. List the necessary change places from blow-room ting frame for P/C blended<br />

yarn production.<br />

2. Demonstrate the process of twist setting.<br />

3. List the necessary change places from blow room to ring frame for viscose<br />

cotton blended yarn production.<br />

4. Demonstrate the working principle of wrap spinning machine.<br />

5. Demonstrate the working principle of producing core spun.yarn by-<br />

Book references:<br />

a) Ring spinning process<br />

b) Rifer spinning process<br />

c) Rotor spinning process<br />

d) Air jet spinning process<br />

1. New spinning system- Nodal centre for up gradation of textile education<br />

(NICTE)<br />

2. New spinning processes- w klein.<br />

3. yarns and technical textiles- K. P. chellamani & Debasis chattapadh yay.<br />

4. Textiles Fibre to fabric- Corbman<br />

5. Textiles- Norma Hollen, jane saddles & Anna L. Langford.

2371 ADVANCED WEAVING-II<br />

AIMS<br />

1. To develop advanced knowledge of special type of woven products.<br />

9<br />

T P C<br />

2 3 3<br />

2. To enable to understand the concepts of special type of weaving machinery.<br />

3. To develop the knowledge of quality control of special woven products<br />

4. To develop the knowledge of weaving defects and weaving wastage.<br />

5. To develop the knowledge of weaving costing and weavers load<br />

SHORT DESCRIPTION<br />

Special type of woven products and machineries i.e. lace, braid, lappet, swivel, net<br />

and terry fabric, weaving defects, loom faults, weaving efficiency, weaving wastage &<br />

costing.<br />

DETAIL DESCRIPTION<br />

Theory:<br />

1.0 Understand the lace fabric.<br />

1.1 Define lace fabric.<br />

1.2 Discuss the basic principle for lace production.<br />

1.3 Mention the characteristics of lace fabric.<br />

1.4 State the characteristics of yarn used in lace production.<br />

1.5 List the names of lace making machinery.<br />

1.6 State the uses of lace.<br />

2.0 Understand the braid fabric.<br />

2.1 Define braid fabric.<br />

2.2 State the classification of braid.<br />

2.3 Mention the characteristics of braid.

10<br />

2.4 Describe the methods of braid production.<br />

2.5 Discuss the technical difficulties of braid production.<br />

2.6 State the uses of braid fabric.<br />

3.0 Understand the net fabrics.<br />

3.1 Define net fabric.<br />

3.2 State knotted and knitted nets.<br />

3.3 Distinguish between knotted and knitted nets.<br />

3.4 Compare between lace and net fabric.<br />

3.5 Mention the uses of net fabrics.<br />

4.0 Understand the lappet weaving<br />

4.1 Define lappet weaving.<br />

4.2 Discuss the basic principle of lappet fabric production.<br />

4.3 State the characteristics of lappet weaving.<br />

4.4 Mention the uses of lappet fabric.<br />

5.0 Understand the swivel weaving.<br />

5.1 Define swivel weaving.<br />

5.2 Discuss the basic principle of swivel weaving.<br />

5.3 Mention the objects swivel weaving.<br />

5.4 Discuss the characteristics of swivel fabric.<br />

5.5 Compare between swivel and lappet fabric<br />

5.6 Mention the uses of swivel fabric.<br />

6.0 Understand the laminated fabric<br />

6.1 Define laminated and bonded fabric.<br />

6.2 Describe the different methods of lamination.<br />

6.3 Compare between laminated and bonded fabric.<br />

6.4 Mention the uses of laminated fabric.

7.0 Understand the Terry weave.<br />

7.1 Define terry weave.<br />

7.2 Classify the terry weave.<br />

7.3 Mention the characteristics of yarn used in terry weaving.<br />

11<br />

7.4 Mention the uses of terry fabric<br />

8.0 Understand the defects of weaving/fabric<br />

8.1 State the types of weaving defects<br />

8.2 List the loom faults.<br />

8.3 Describe the loom faults and their causes and remedies.<br />

8.4 List the fabric faults.<br />

8.5 Briefly describe the fabric faults their causes and remedies.<br />

9.0 Understand the loom efficiency<br />

9.1 Discuss the factors of effective efficiency.<br />

9.2 Calculate the efficiency of winding, warping, sizing, weaving<br />

and knitting efficiency.<br />

9.3 Evaluation of efficiency and production.<br />

9.0 Understand the weaving wastage<br />

9.1 State the term weaving wastage.<br />

9.2 Mention the types of wastage.<br />

9.3 Calculate the waste percentage in weaving and knitting.<br />

9.4 Discuss the measures to be taken to minimize waste percentage.<br />

11.0 Understand the weavers load<br />

11.1 Define weavers load.<br />

11.2 State the factors for the calculation of weavers load.<br />

11.3 Mention the allocation of number of looms/weaver.<br />

11.4 Calculate the weavers load.

12 Understand the costing<br />

Practical:<br />

12.2 Define costing.<br />

12.3 State the factors of costing.<br />

12<br />

12.4 Analysis of total cost of weaving and knitting.<br />

12.5 Define and discuss break-even point of a factory.<br />

1. Identify the lace fabric.<br />

2. Sketch and show the lace machine<br />

3. Identify the braid fabric.<br />

4. Draw the braid machine.<br />

5. Identify net fabric.<br />

6. Show the intersection knot and interlooping of net fabric.<br />

7. Identify the lappet fabric.<br />

8. Draw and identify pattern wheel, shifter bar and needle bar.<br />

9. Identify the swivel fabric.<br />

10. Identify the laminated fabric<br />

11. Identify the terry fabric<br />

12. Draw and identify the different yarn used in terry fabric.<br />

13. Practice the loom operation, calculate the production and loom<br />

efficiency.<br />

14. Calculate the production cost of fabric.

2471 ADVANCED DYEING-II<br />

13<br />

T P C<br />

2 2 3<br />

AIMS<br />

To provide the student with an opportunity to acquire knowledge, skill and attitude in<br />

the area of wet processing with special emphasis on Textile dyeing.<br />

SHORT DESCRIPTION<br />

Application; After-treatment; Stripping process of disperse dyes; Aniline black dyes;<br />

Onium dyes; Mordent dyes, Mineral khaki dyes and Pigments; Blended fabric dyeing.<br />

DETAIL DESCRIPTION<br />

Theory :<br />

1.0 Understand the disperse dyes.<br />

1.1 Define disperse dyes.<br />

1.2 State the properties of disperse dyes.<br />

1.3 State the importance of disperse dyes.<br />

1.4 List the Trade name of disperse dyes.<br />

1.5 Mention the function of dispersing agents.<br />

1.6 List the commercial name of dispersing agents.<br />

2.0 Understand the carrier in disperse dyeing.<br />

2.1 Define carrier<br />

2.2 Explain the functions of carrier.<br />

2.3 Explain the properties of carrier.<br />

2.4 State the advantages of carrier used in disperse dyeing.<br />

2.5 State the disadvantages of carrier used in disperse dyeing.<br />

2.6 Mention the names of carrier and trade name of carrier.<br />

2.7 Mention the amount of carrier in different shades.<br />

3.0 Understand the Disperse dyes and its application.<br />

3.1 State the method of preparation of dye liqueur.<br />

3.2 Explain the typical methods of application of disperse dyes.<br />

3.3 Describe the application of disperse dyes on polyester fibres with carrier<br />

dyeing process.<br />

3.4 Describe the application of disperse dyes on polyester fibrecs with high<br />

temperature dyeing method .

14<br />

3.5 Describe the application of disperse dyes on polyester fibres with<br />

thermo-sole or thermo- fixation process.<br />

3.5 Explain the after-treatment or wash -off process of disperse dyeing.<br />

4.0 Understand the Aniline black dyes.<br />

4.1 Define aniline black dyes.<br />

4.2 State the general properties of aniline black dyes.<br />

4.3 Classify the aniline black dyes.<br />

4.4 Explain how the aniline black formation on the fibres.<br />

4.5 Mention the composition of impregnation bath.<br />

4.6 Mention the general bath composition of dye liqueur (gm/l)<br />

4.7 Describe the application of different classes of aniline black dyes of<br />

cotton.<br />

4.8 State the faults of aniline black dyeing.<br />

4.9 Explain the causes of faults and remedies in aniline black dyeing<br />

process.<br />

4.10 Mention the uses of aniline black dyes.<br />

5.0 Understand the Onium dyes and its application .<br />

5.1 Define onium dyes.<br />

5.2 State the properties of onium dyes.<br />

5.3 Mention the commercial name of onium dyes.<br />

5.4 Classify the dyeing method of onium dyes.<br />

5.5 Describe the application of onium dyes on cotton fibres.<br />

5.6 Describe the stripping process of onium dyes.<br />

6.0 Understand the Mordant dyes and its application .<br />

6.1 Define mordant dyes.<br />

6.2 Mention the general properties of mordant dyes.<br />

6.3 Classify the mordant dyes.<br />

6.4 Mention the trade name of mordant dyes.<br />

6.5 Describe the application of acid mordant dyes on woolen goods.<br />

7.0 Understand the Mineral Khaki dyes and its application.<br />

7.1 Define mineral khaki dyes.<br />

7.2 Mention the properties of mineral khaki dyes.<br />

7.3 Describe the application of mineral khaki dyes on cotton.

8.0 Understated the pigments.<br />

8.1 Define pigments.<br />

8.2 Classify the pigments.<br />

8.3 State the properties of pigments.<br />

8.4 Distinguish between inorganic and organic pigments.<br />

8.5 Mention the uses of pigments in different fields.<br />

8.6 List the trade name of pigments.<br />

15<br />

9.0 Understand the pigments and its application.<br />

9.1 Describe the application of pigments on cotton and other cellulasic<br />

fibres<br />

9.2 Describe the application of pigments on nylon-6/66 or synthetic fibres. .<br />

9.3 Explain the function of binder, fixer migration inhavitor and catalyst<br />

used in pigments.<br />

9.4 State the properties of binder.<br />

9.5 Distinguish between dyes and pigments.<br />

10.0 Understand the blended fabric dyeing.<br />

10.1 Mention the factors depends on blended fabric dyeing.<br />

10.2 Explain the dyeing effect (Solid dyeing reserve dyeing, cross dyeing,<br />

tone-on-effect etc)<br />

10.3 Describe the dyeing process of polyester - cotton blended fabric.<br />

10.4 Describe the dyeing process of polyester- wool blended fabric.<br />

Practical.<br />

1. Application of disperse dyes on polyester fibres with carrier dyeing process.<br />

2. Application of disperse dyes on polyester fibres with high temperature dyeing<br />

process.<br />

3. Application of aniline black dyes on Cotton<br />

4. Application of acid mordant dyes on woolen goods.<br />

5. Application of pigments on cotton/other cellulose.<br />

6. Application of pigments on polyester fibres.<br />

7. Application of pigments on Nylon/ acrylic fibres.<br />

8. Application of mineral khaki dyes on cotton fibres.<br />

9. Application of onium dyes on cotton fibres.<br />

10. Dyeing process of polyester cotton bended fabric.<br />

11. Dyeing process of polyester wool blended fabric.

2571 WOVEN GARMENTS AND FINISHING-II<br />

16<br />

T P C<br />

2 2 3<br />

AIMS<br />

1. To develop the knowledge of woven garments dyeing.<br />

2. To develop the knowledge of woven garments finishing.<br />

3. To develop the basic knowledge of woven garments quality control.<br />

4. To make understand the basic knowledge of garments export.<br />

SHORT DESCRIPTION<br />

Woven garments dyeing; Dryer; water proofing; Fire proofing; Folding; Packing;<br />

Package Marking;.<br />

DETAIL DESCRIPTION<br />

Theory :<br />

1.0 Understand the Garment dyeing.<br />

1.1 Define garment dyeing.<br />

1.2 State the necessities of garment dyeing.<br />

1.3 Classify garment dyes.<br />

1.4 Describe the procedure of dyeing for cotton garments.<br />

1.5 Describe the procedure of dyeing for blended (Cotton –Polyester)<br />

garment.<br />

1.6 Name the faults in garments dyeing and discuss the means for their<br />

remedies.<br />

2.0 Understand the drying machine.<br />

2.1 Classify the drying machines.<br />

2.2 State the purposes of drying machine.<br />

2.3 Illustrate the Processes of drying machine.<br />

2.4 Mention the capacity of drying machines.<br />

2.5 Discuss the controlling of temperature of drying machine.<br />

2.6 Mention the uses of drying machine.

3.0 Understand the steam.<br />

3.1 Define steam.<br />

3.2 Classify the steam.<br />

3.3 Mention the uses of steam<br />

3.4 State the importance of steam.<br />

3.5 List the different steam grades.<br />

3.6 Describe the different steaming process for batch method.<br />

4.0 Understand the water proofing.<br />

4.1 Define water proofing.<br />

4.2 State the purpose of water proofing.<br />

4.3 State the types of water proofing.<br />

4.4 Give a typical recipe for water proofing.<br />

4.5 Describe the process of water proofing.<br />

4.6 Mention the uses of water proofing fabric.<br />

5.0 Understand the Fire proofing.<br />

5.1 Define fire proofing.<br />

5.2 State the Importance of fire proofing.<br />

5.3 Give a typical recipe for fire proofing.<br />

5.4 Describe the process of fire proofing.<br />

5.5 Mention the materials/ chemical used in fire proofing.<br />

5.6 Name the uses of fire proofing fabric.<br />

5.7 Mention the properties of fire proofing agent.<br />

17<br />

6.0 Understand the Folding.<br />

6.1 Define folding<br />

6.2 State the necessities of folding<br />

6.3 Classify folding.<br />

6.4 Describe each type of folding.<br />

6.5 Describe the faults in folding.<br />

6.6 List the precaution during folding.<br />

6.7 State the factors of quality of folding.<br />

7.0 Understand the Faults of Finished Garments.<br />

7.1 State the faults of garments.<br />

7.2 Classify the faults.<br />

7.3 Discuss the garments grading according to the faults.

18<br />

7.4 Discuss the acceptance faults of garments.<br />

7.5 Describe the remedies of garments faults.<br />

8.0 Understand the Packing.<br />

8.1 Define Packing.<br />

8.2 State the necessity of Packing.<br />

8.3 Discuss the style of Packing.<br />

8.4 Discuss the procedure of packing.<br />

8.5 State the packing material and the auxiliaries.<br />

8.6 State the faults of Packing.<br />

8.7 Discuss the precaution of packing.<br />

9.0 Understand the Package Marking.<br />

9.1 Define Package Marking.<br />

9.2 State the importance of package marking.<br />

9.3 Describe the procedure of package marking.<br />

9.4 State the marking faults and their remedies.<br />

9.5 State the materials of package marking.<br />

10.0 Understand the Handling of Finished Garments.<br />

10.1 Define Garments handling.<br />

10.2 State the necessity and importance of garments handling.<br />

10.3 Mention the different material of handling.<br />

10.4 Describe the processes of handling.<br />

Practical.<br />

1. Prepare a recipe of garments dyeing for the specific garments.<br />

2. Prepare a recipe of dyeing and apply to the blended (Cotton- polyester)<br />

Garment.<br />

3. Operate the drying machine for woven garments.<br />

4. Apply water proof finishing for woven garments.<br />

5. Apply fire proof finishing for woven garments.<br />

6. Practice the folding and packing of woven garments.

19<br />

2272 ADVANCED LONG STAPLE SPINNING T P C<br />

2 2 3<br />

AIMS :<br />

1. To familiarize the students with the evolution of long staple spinning.<br />

2. To understand the basic concepts and principles of long staple spinning.<br />

3. To understand the operational techniques of long staple spinning machines.<br />

4. To know the advancement of long staple spinning machines<br />

and diversification of the products.<br />

SHORT DESCRIPTION<br />

To understand the basic concepts of long staple spinning; Technological developments of jute<br />

spinning machines; Utilization of jute mill waste; Jute as floor covering–backing material-<br />

carpets; Research and development of jute; Geo-textiles and geo-jute; Wool–acrylic and<br />

linen/flax Spinning; Silk spinning.<br />

DETAIL DESCRIPTION<br />

Theory :<br />

1.0 Understand the basic concept of long staple spinning.<br />

1.1 State the term ‛‛long staple spinning”.<br />

1.2 Name different long staple spinning process.<br />

2.0 Understand the Technological developments of jute spinning machines.<br />

2.1 List the Technological development of jute spinning machines (from batching<br />

to spinning.)<br />

2.2 Describe the Technological development of jute spinning machines (from<br />

batching to sliver spinning)<br />

3.0 Understand the utilization of jute mills waste.<br />

3.1 List the position and give the percentage of waste in jute mills .<br />

3.2 Mentions the factors influencing the quantities of waste.<br />

3.3 List the name of different types of waste.<br />

3.4 Describe waste processing and recovery systems of jute mills.<br />

3.5 Describe waste processing machine.<br />

3.6 Describe wastes re-used process of jute mills.

4.0 Understand the research and development of jute.<br />

4.1 State the importance of jute research and diversification of jute.<br />

20<br />

4.2 Mention the areas of research and development.<br />

4.3 State the problems of jute industries.<br />

4.4 Discuss about the alternative uses of jute.<br />

4.5 Describe blended jute yarn production.<br />

5.0 Understand geo-textiles<br />

5.1 Define geo-textiles and geo-jute.<br />

5.2 Give the types of geo-textile<br />

5.3 Mention the uses of geo-jute<br />

5.4 Describe the salient features of geo-jute.<br />

6.0 Understand wool, acrylic and linen/flax spinning.<br />

6.1 Show the methods (flow-chart) of wool, acrylic yarn production.<br />

6.2 List the classification of wool.<br />

6.3 Describe wool, acrylic and flax spinning process.<br />

6.4 Give the end-uses of woolen, worsted, flax and acrylic fabrics.<br />

7.0 Understand silk spinning.<br />

Practical<br />

7.1 Describe the history of silk.<br />

7.2 Discuss the methods of silk worm production.<br />

7.3 Describe silk spinning process.<br />

7.4 State the future of silk in Bangladesh.<br />

1. Draw the draftomatic system of jute drawing frame and show its techniques.<br />

2. Draw the can-turning and trumping motion and show it .<br />

3. Draw the techniques of pneumatic spinning and calculate the production.<br />

4. Perform the processes of converting a spinning frame in to a twisting frame.<br />

5. Perform winding process in spool winding machine and explain.<br />

6. Mention the card setting for wool processing.<br />

7. Perform the blending process of wool and acrylic in draw-frame.<br />

8. Prepare wool yarn from wool sliver.<br />

9. Show the waste silk spinning process.<br />

10. Show the reeling process of silk spinning.

Book references:<br />

21<br />

1. Jute and its diversification- ABM Abul Kashem<br />

2. Wool in Indian textiles- NICTAS<br />

3. Wool spinning Vol. I & vol- II – Ya Lipenkov<br />

4. Waste silk spinning-Rayner<br />

5. An Introduction to sericulture- G. ganga & J Sulochana chetly.<br />

6. Sericulture mannual-3 Silk reeling Dr. S. Krishnaswami (FAO)<br />

7. Illustrated text book or sericulture- FAO<br />

8. Flax, Tow and jute spinning – Hurst

2372 ADVANCED KNITTING AND NON-WOVEN T P C<br />

2 3 3<br />

AIMS<br />

1. To develop advance knowledge of knitting fundamentals.<br />

2. To enable to understand the concepts of knitting machinery.<br />

3. To make understand the knowledge of Knit fabric construction .<br />

4. To develop the knowledge of quality control of knit fabrics.<br />

22<br />

5. To develop the knowledge of non-woven fabric .<br />

SHORT DESCRIPTION<br />

Knitting fundamentals developed warp & weft knitting fabric; multi-axial fabrics; Non-<br />

woven fabrics ; Bonding material; Fibrous raw material & production of non-woven fabrics.<br />

1.0 Understand the knitting fundamentals.<br />

1.1 Define the term knitting process.<br />

1.2 Mention the classification of knitting process.<br />

1.3 Describe the different structural fabrics with diagram.<br />

loop, stitch, plain stitch, purl stitch, needle loop, sinker loop, tuck loop ,<br />

float stitch, warp knitted laps, tuck, miss stitch, over lap, under lap,<br />

closed lap, open lap.<br />

1.4 Describe the arrangement of structural elements i.e. Plain knitted fabrics,<br />

double knitted fabrics, double knitted rib fabrics, double knitted interlock<br />

fabrics, double knitted purl fabrics.<br />

2.0 Understand the high quality weft knitting production.<br />

2.1 Describe the high quality cotton knit goods production.<br />

2.2 Describe the production of knit goods from yarn containing man made fibre.<br />

2.3 State the uses of linear and non linear cams in weft knitting.<br />

2.4 Discuss the automation of weft knitting industry.<br />

2.5 Calculate the production of weft knitting.<br />

3.0 Understand the single jersey jacquard.<br />

3.1 State the term of weft knitting jacquard.<br />

3.2 Describe the coloured stitch design in weft knitting.<br />

4.0 Understand the multi-axial knitted fabric construction.<br />

4.1 Define the term of multi-axial knitted fabric.

23<br />

4.2 Describe the multiaxial raschel knitting machine<br />

4.3 Mention the uses of multi-axial fabrics.<br />

5.0 Understand the development of warp knitting machine.<br />

5.1 Define the term ‛‛multiple guide warp knitting machine”.<br />

5.2 Mention the product of multiple guide warp knitting machine<br />

5.3 Describe the multiple guide warp knitting machine.<br />

5.4 Describe the warp knitted fabric faults with their remedies.<br />

6.0 Understand the Non-woven.<br />

6.1 Define the term ‛‛non-woven fabrics”.<br />

6.2 State the history of non –woven fabrics.<br />

6.3 Discuss the characteristic and properties of non woven fabrics.<br />

6.4 Distinguish between woven & non-woven fabrics.<br />

6.5 Describe the binding & bonding techniques of non -woven<br />

fabrics.<br />

6.6 Discuss the arrangement of the fibre in the non- woven<br />

fabrics.<br />

6.7 List the binding elements of non-woven fabrics.<br />

6.8 Mention the classification of non-woven fabrics<br />

6.9 State the characteristics of laminated fabrics .<br />

7.0 Understand the adhesives and bonding.<br />

7.1 Define adhesive and bonding.<br />

7.2 State the functions of bonding process.<br />

7.3 Discuss the testing adhesion stickiness’.<br />

7.1 Mention the problems of adhesives.<br />

7.2 Describe the adhesive substances of non-woven fabrics.<br />

8.0 Understand the fibrous raw materials.<br />

8.1 State the term fibrous raw material.<br />

8.2 State the function of the fibres in non woven fabrics.<br />

8.3 Describe the properties of fibrous for matrices.<br />

8.4 Discuss the requirements of the fibres for non woven fabrics .<br />

9.0 Understand the Production of non woven fabrics.<br />

9.1 Show the flow chart of producing non woven fabric.<br />

9.2 Discuss the flow process of non- woven fabric production.

Practical<br />

9.3 Discuss the principles of production of mechanically bonded<br />

non woven fabric.<br />

24<br />

9.4 Discuss the principles of production stitch bonding without binding thread<br />

with binding thread.<br />

9.5 Mention the uses of non woven fabrics .<br />

1. Show with diagram the inter looping of different knit fabrics.<br />

2. Draw and identify the different loop i.e. Face and reverse meshed loop, closed lap ,<br />

open lap, under lap ,overlap, knitted stitch etc,<br />

3. Draw and identify the cross - section of knitting head of a single jersey machine with<br />

diagram.<br />

4. Show the knitting cycle of a single jersey latch needle machine.<br />

5. Sketch and show the sinker timing on a single jersey machine.<br />

6. Show the tuck stitch produced on latch need machine.<br />

7. show the stitches of single jersey jacquard in a knit fabric.<br />

8. Show the stitches of double jersey structure and the notation of different knit fabrics.<br />

9. Show the diagram of rib loop transfer on a modern V-bed machine.<br />

10. Draw and identify the mechanical jacquard selection on a V-bed flat knitting machine.<br />

11. Show the diagram of knitting element and cross- section of a bearded needle tricot<br />

machine.<br />

12. Show the diagram of cross- section of latch needle rachel machine<br />

13. Show the diagram of mechanical banded non- woven fabrics with production.<br />

14. Show the diagram and production of stitch bonding non -woven fabrics .<br />

15. Show the diagram and production of non woven fabrics without stitch bonding .<br />

Ref : Book:-<br />

Manual of non woven<br />

by –prof . Dipl, Ing. Dr . Radko Krcnea . Manchester Eagland

2472 ADVANCED PRINTING AND FINISHING<br />

AIMS<br />

25<br />

T P C<br />

2 2 3<br />

To provide the student with an opportunity to acquire knowledge, skill and attitude in<br />

the area of wet processing with special emphasis on printing and finishing.<br />

SHORT DESCRIPTION<br />

Basic Concept of preparation of selected thickening agent. Preparation of screen;<br />

screen printing; Engrave roller printing; Transfer printing; Batik printing and Tiedyeing;<br />

Drying; Steaming and Ageing; Curing/baking (Thermo fixation); Fabric<br />

printing, Blended fabric Printing, Raising finishing; Starch finishing; Moth proof<br />

finishing, Mildew proof finishing, Fire/ Flame proof finishing.<br />

DETAIL DESCRIPTION<br />

Theory :<br />

1.0 Understand the Preparation of selected thickening agents.<br />

1.1 State the preparation of Sodium alginate thickener.<br />

1.3 State the preparation of British gum-D and British gum on-5<br />

1.4 State the preparation of locust bean gum.<br />

1.5 State the Preparation of gum tragacanth.<br />

1.6 State the preparation of gum Senegal or gum Arabic<br />

1.7 State the preparation of gum Indulca-U<br />

1.8 State the preparation of Nafka crystal gum.<br />

1.9 State the preparation of Solvitose-C5<br />

1.10 Describe the function of ingredients used in printing paste.<br />

2.0 Understand the Preparation of Screen.<br />

2.1 Mention the methods of screen preparation.<br />

2.2 List the common fabrics and metal gauge used in screen preparation.<br />

2.3 State the preparation of Screen frame.<br />

2.4 Mention the stretching and fixing of silk gauze on screen frame.<br />

2.5 State the sensitizing of the screen.<br />

2.6 Describe the preparation of positive design.<br />

2.7 State transfer of positive design.<br />

2.8 Describe the hardening of the exposed design.<br />

2.9 Describe the re-inforcement of the screen.

26<br />

2.10 Describe the preparation of printing table.<br />

3.0 Understand the Screen Printing.<br />

3.1 State the classification of the screen-printing.<br />

3.2 Mention the classification of the scrapper or squeegee.<br />

3.3 Describe the Rotary Screen-Printing machine with working principle.<br />

3.4 Describe the Automatic Flat Bed Screen-printing m/c with working<br />

principle.<br />

3.5 Compare the Flat Bed Screen printing with Rotary Screen-printing .<br />

4.0 Understand the Engrave Roller Printing.<br />

4.1 List the advantages and disadvantages of Roller Printing machine.<br />

4.2 Describe the methods of roller engraving.<br />

4.3 State the causes and remedies of the defects of Roller printing. .<br />

4.4 Compare the Copper Roller printing with Rotary Screen printing.<br />

5.0 Understand the Transfer printing.<br />

5.1 List the common fabrics can be printed with Transfer printing.<br />

5.2 Mention the classifications of Transfer printing machine.<br />

5.3 Describe the Transfer printing machine with printing procedure.<br />

5.4 State the advantages and disadvantages of Transfer-printing machine.<br />

6.0 Understand the Batik printing and Tie-dyeing.<br />

6.1 List the ingredients and instruments used in Batik printing.<br />

6.2 Mention the common dyes used in Batik printing.<br />

6.3 Describe the Batik printing process.<br />

6.4 Define Tie- dyeing.<br />

6.5 Describe the Tie- dyeing process.<br />

7.0 Understand the drying of printed goods.<br />

7.1 State the importance of drying of printed goods.<br />

7.2 Mention the types of drying.<br />

7.3 State the conditions of drying.<br />

7.4 Describe different drying processes.<br />

8.0 Understand Steaming and Ageing.<br />

8.1 State the functions of steam.<br />

8.2 Illustrate the distinctions between steaming and ageing.

27<br />

8.3 Mention the classifications of steam.<br />

8.4 List the name of steamer used for after-treatment of printed goods.<br />

8.5 Describe the Spiral (krostewitz) steamer.<br />

8.6 Describe the Cottage steamer.<br />

9.0 Understand the Curing/Baking (Thermo-fixation)<br />

9.1 State the importance of Curing/Baking in printing.<br />

9.2 Mention the distinctions between Steaming and Curing.<br />

9.3 Describe the Curing/Baking process for after-treatment of printed goods.<br />

10.0 Understand the fabric printing.<br />

10.1 Describe the printing of viscose rayon fabric with reactive dyes.<br />

10.2 Describe the printing of viscose rayon fabric with vat dyes.<br />

10.3 Describe the printing of linen fabric with reactive dyes.<br />

10.4 Describe the printing of linen fabric with vat dyes.<br />

10.5 Describe the printing of acrylic fabric with basic dyes.<br />

11.0 Understand the blended fabric printing.<br />

11.1 Describe the printing of polyester- cellulose blended fabric with vat<br />

dyes .<br />

11.2 Describe the printing of polyester cellulose blended fabric with Reactive<br />

and disperse dyes.<br />

12.0 Understand the fabric printing with pigment colours.<br />

11.1 Describe the printing of cellulose fabric with pigments.<br />

11.2 Describe the printing of synthetic fabrics with pigments.<br />

13.0 Understand the raising finishing.<br />

13.1 Define raising finishing.<br />

13.2 State the object of raising finishing.<br />

13.3 Mention the conditions of raising finishing.<br />

13.4 Mention the classification of the raising machine.<br />

13.5 Describe the raising processes.

14.0 Understand the starch finishing.<br />

14.1 Mention the classifications of starch.<br />

14.2 Mention the properties of starch.<br />

14.3 State purpose of starch finishing.<br />

14.5 Mention the moisture regain of starch materials.<br />

14.6 Describe the preparation of starch solution for application.<br />

14.7 Describe the application of starch on textile materials.<br />

14.8 Describe the effects of different starches on textile materials.<br />

14.9 Mention some standard recipe for fabric finishing.<br />

15.0 Understand the softening finishing.<br />

15.1 Mention the importance of softening finishing.<br />

15.2 List the commercial name of softeners.<br />

15.3 Describe the application of softener of cellulose fibre.<br />

15.4 Describe the application of softener of protein fibre.<br />

15.5 Describe the application of softener to synthetic fibre<br />

28<br />

16.0 Understand the water proof finishing.<br />

16.1 Define water proof and water repellent finishing.<br />

16.2 Mention the distinction between completely water proof and water<br />

repellent fabric.<br />

16.3 List the names of water repellent fabrics.<br />

16.4 List the commercial names of water repellent finishing agents and water<br />

proof finishing agents.<br />

16.5 Describe the application of water repellent finishing agents on<br />

cellulosic, acrylic, wool fabric and their blends.<br />

17.0 Understand the moth proof finishing.<br />

17.1 State the importance of moth proof finishing.<br />

17.2 Mention the classifications of moths.<br />

17.3 List the names of moth proof finishing agents.<br />

17.4 Describe the moth proof finishing process to textile materials.<br />

18.0 Understand the mildew proof finishing.<br />

18.1 State the importance of mildew proof finishing.<br />

18.2 List the name of mildew proof finishing agents.<br />

18.3 Describe the application of mildew proof finishing to textile materials.

Practical.<br />

1. Practice on preparation of screens.<br />

29<br />

2. Practice of Flat bed screen printing machine.<br />

3. Practice on Rotary screen printing machine.<br />

4. Practice on Roller engraving.<br />

5. Practice on engrave Roller printing machine.<br />

6. Practice on Transfer printing machine.<br />

7. Practice on Batik printing.<br />

8. Print viscose rayon fabric with reactive dyes.<br />

9. Print viscose rayon fabric with vat dyes.<br />

10. Print linen fabric with reactive dyes.<br />

11. Print linen fabric with vat dyes.<br />

12. Print acrylic fabric with basic dyes.<br />

13. Print polyester- cellulose bended fabric with vat and disperse dyes.<br />

14. Print polyester cellulose blended fabric with reactive and disperse dyes.<br />

15. Print cellulose fabric with pigments.<br />

16. Print synthetic fabric with pigments.<br />

17. Practice on raising machine.<br />

18. Apply starch on textile materials.<br />

19. Apply softening agents on textile materials.<br />

20. Apply water proofing, moth proofing agents on textile materials.<br />

21. Apply water repellent finishing agent on textile materials.<br />

Fef : Books<br />

1. An introduction to textile printing by W. clark.<br />

2. Textile printing by L. W. C. Miles.<br />

3. An Introduction to Textile finishing by. J. T. MARSH.<br />

4. ‡U·UvBj †Kwgwóª -3q LÛ (wcÖw›U, GÛ wdwbwms)<br />

by Avey wgbv †gvt †ivKbyj Kv‡`i|<br />

5. ‡U·UvBj †Kwgwóª-3 by †gvt gwReyi ingvb<br />

6. Hand book of textile auxitiaries –CIBA.

30<br />

2572 ADVANCED KNIT GARMENTS AND FINISHING T P C<br />

2 3 3<br />

AIMS<br />

1. To understand the fundamentals of knit garments.<br />

2. To develop the knowledge of knit garments production.<br />

3. To become familiar with knit garment washing.<br />

4. To acquire knowledge of knit garments dyeing, printing & finishing.<br />

SHORT DESCRIPTION<br />

Basic concepts of knitted fabrics; Machinery used in knit garments; Knit garments<br />

quality control; Chemical wash; Stone wash; Bleach wash; Dyeing , Printing &<br />

Finishing of knit garments.<br />

DETAIL DESCRIPTION<br />

Theory<br />

1.0 Understand the knit fabrics<br />

1.1 Describe the characteristics of yarn for producing knit fabrics.<br />

1.2 Explain the characteristic properties of knit fabrics.<br />

1.3 Mention the steps of knit fabric production.<br />

1.4 Mention the steps of knit garments production.<br />

1.5 State the different categories of knit garments according to general<br />

production methods.<br />

1.6 Describe the production sequence of fully cut garments, stitch shaped<br />

cut, fully fashioned & integral.<br />

2.0 Understand the machinery for seaming knit garments.<br />

2.1 Discuss the constructional features of sewing process.<br />

2.2 State the four bed type variations in use in the knit garments industries.<br />

2.3 Describe the general view of dial linking machine.<br />

2.4 Discuss the stitch forming action of a conventional needle linking<br />

machine.

3.0 Understand the normal wash of knit garments.<br />

31<br />

3.1 State the term o “ knit garment”.<br />

3.2 Discuss the importance of garment washing.<br />

3.3 Describe the normal washing process of knit garments.<br />

3.4 Describe the necessity of chemical wash.<br />

3.5 List the different chemicals of knit garment wash.<br />

4.0 Understand the stone wash of knit garments<br />

4.1 State the term “ stone wash”.<br />

4.2 Discuss the shape and size of stone for the washing of knit garments.<br />

4.3 Mention the recipe of stone wash and their typical m: l ratio.<br />

4.4 Describe the stone washing process for knit garments.<br />

4.5 Explain the appearance of knit garments after stone wash.<br />

5.0 Understand the bleach wash of knit garments.<br />

5.1 Define bleach wash.<br />

5.2 Mention the recipe of bleach wash.<br />

5.3 Describe the process of bleach wash.<br />

5.4 Mention the recipe of bleach wash and their m: l ratio.<br />

6.0 Understand the knit garments dyeing<br />

6.1 State the term ‛‛garments dyeing”.<br />

6.2 Describe the purpose of knit garments dyeing.<br />

6.3 List the important dyes used in knit garments dyeing.<br />

6.4 Describe the application of dyeing for different knit garments<br />

6.5 Describe the application of double bath dyeing for blended ( wool-<br />

acrylic) garments<br />

7.0 Understand the knit garments printing.<br />

7.1 State the term ‛‛garments printing”.<br />

7.2 Describe the necessity of garments printing.

32<br />

7.3 Mention the recipe of knit garments printing and their typical m: l ratio.<br />

7.4 Describe the process of knit garments printing.<br />

8.0 Understand the knit garments finishing.<br />

8.1 State the term knit ‛‛garments finishing”.<br />

8.2 State the purpose of knit garments finishing.<br />

8.3 Describe the pressing , folding and packing of knit garments finishing.<br />

9.0 Understand the quality control of knit garments<br />

Practical :<br />

9.1 State the term knit fabric quality.<br />

9.2 Calculate the weight per unit area and tightness factor of knit fabric.<br />

9.3 Describe the different faults of knit garments and with their causes and<br />

remedies.<br />

9.4 Describe the steps of quality control during manufacturing of knit<br />

garments<br />

- Yarn assessment<br />

- Fabric assessment<br />

- Spreading<br />

- Cutting<br />

- Sewing<br />

- Finishing<br />

- Final inspection<br />

1. Draw and identify the sewing equipments of knit garments industry.<br />

2. Draw and identify the sewing thread of knit garments industry<br />

3. Draw and identify the pressing equipment of knit garment industry.<br />

4. Draw and identify the different pattern for different knit garments.<br />

5. Show the different cut to produce knit garments<br />

6. Draw and show the comparism between knitted pattern cut and woven<br />

cuts.<br />

7. Construct and identify the sewing machine.

Ref: Books.<br />

33<br />

8. Prepare a stitch forming action of the principle elements of 3-thread over<br />

lock machine.<br />

9. Prepare a knitted fabric before cutting.<br />

10. Draw the pattern for different categories.<br />

11. Prepare a recipe of stone wash for knit garments<br />

12. Prepare a recipe of normal chemical wash for knit garments.<br />

13. Prepare a recipe of bleach wash for knit garments.<br />

14. Show the application of knit garments dyeing.<br />

15. Show the application of knit garments printing.<br />

16. Show the application of knit garments finishing.<br />

1. Knitted clothing technology ---- . by Terry Brackenbury.<br />

2. Dress making simplified ----- by Bvlerie I. Cock.

34<br />

2273 MAN-MADE FIBRE PRODUCTION T P C<br />

AIMS<br />

1. To develop basic knowledge of man made fibre structures.<br />

2. To develop basic knowledge of man made fibre properties.<br />

3. To provide the student with the basic knowledge of<br />

regenerated fibre.<br />

3. To familiarized the students about formation of synthetic fibre.<br />

4. To acquaint with the knowledge of texturising and multi-<br />

component fibre.<br />

SHORT DESCRIPTION<br />

2 3 3<br />

Basic concept of man made fibre production ; Monomer and polymer properties ; Production<br />

of acetate, Viscose rayon ;Polyamide; Polyester, Polypropylene; Acrylic and P.V.A fibre.<br />

DETAIL DESCRIPTION.<br />

Theory :<br />

1.0 Understand man made fibre<br />

1.1 Define man made fibre.<br />

1.2 Briefly discuss the history of introducing man-made fibre.<br />

1.3 Mention the classification of man- made fibre .<br />

2. Understand the principles of different spinning method.<br />

2.1 Explain the principles of different spinning method.<br />

2.2 Discuss different types of spinning system (viz. wet spinning, dry spinning,<br />

melt spinning, bi-component spinning and bi-constituent spinning ect.)<br />

3.0 Understand the Polymerization of man made fibre.<br />

3.1 Define the term ‛‛Polymerization”.<br />

3.2 State the types of polymerization.<br />

3.3 Explain the degree of polymerization.<br />

3.4 Define the term ‛‛Repeated Unit”.<br />

4.0 Understand the monomer & polymer of fibre.<br />

4.1 Define monomer & polymer.

4.2 State the crystallization, drawing and stretching of man-made fibre.<br />

4.3 Mention the properties of crystalline and amorphous polymers<br />

35<br />

4.4 Explain the requirement of fibre forming polymers.<br />

5.0 Understand the texturising<br />

5.1 Define texturising.<br />

5.2 Discuss the steps of texturising process.<br />

5.3 Explain P.O.Y (Pre-Oriented yarn) & D.T.Y.( Drawn textured yarn)<br />

5.4 Mention the properties and uses of textured yarn.<br />

6.0 Understand the viscose rayon.<br />

6.1 State the term ‛‛rayon”.<br />

6.2 Describe the history of rayon.<br />

6.3 State the flow sheet of producing viscose rayon.<br />

6.4 Describe the manufacturing process of viscose rayon.<br />

6.5 Discuss the properties of viscose rayon.<br />

6.6 Mention the uses of viscose rayon.<br />

7.0 Understand the acetate fibre.<br />

7.1 State the term ‛‛acetate fibre”.<br />

7.2 Mention the classification of acetate fibres.<br />

7.3 State the polymers of primary & secondary acetate fibre.<br />

7.4 Describe the history of cellulose acetate.<br />

7.5 State the flow chart of the manufacturing process of acetate fibre.<br />

7.6 Describe the manufacturing process of acetate & tri acetate.<br />

7.7 Explain the properties of acetate & triacetate fibre.<br />

7.8 Mention the uses of acetate & triacetate fibres.<br />

8.0 Understand the polyamide fibre.<br />

8.1 List the type of polyamide fibres.<br />

8.2 State the chemical structures of Nylon 6 & Nylon 6.6<br />

8.3 Discuss the polymerization & manufacturing process of Nylon 6<br />

& Nylon-6.6.<br />

8.4 Illustrate the properties of Nylon-6 & Nylon-6.6.<br />

8.5 Mention the uses of Nylon.

9.0 Understand the Polyester fibre.<br />

9.1 State the term ester & Polyester.<br />

36<br />

9.2 Discuss the polymerization of polyester.<br />

9.3 Describe the manufacturing process of polyester.<br />

9.4 Discuss the properties of polyester.<br />

9.5 Mention the uses of polyester.<br />

10.0 Understand the acrylic and modacrylic fibre.<br />

Practical<br />

10.1 State the term polyacrylonitrile.<br />

10.2 Discuss the production of polyacrylonitrile.<br />

10.3 Describe the manufacturing process of acrylic fibre.<br />

10.4 Mention the properties & uses of acrylic fibre.<br />

10.5 State the term mod acrylic.<br />

10.6 Describe the manufacturing process of mod acrylic fibre.<br />

10.7 Mention the properties & uses of mod acrylic fibre.<br />

1. Identify the man-made fibre from the cross sectional & longitudinal view with help<br />

of microscope.<br />

2. Draw the cross -sectional and longitudinal view of different man made fibres.<br />

3. Identify the man made fibres by burning test.<br />

4. Identify the man made fibres by chemical test.<br />

5. Test the properties (moisture regain and strength)of different fibres.<br />

a) Viscose.<br />

b) Acetate.<br />

c) Nylon.<br />

d) Polyester.<br />

e) Acrylic.<br />

6. Find out the percentage composition of different blends<br />

7. Identify the different fibres by staining.<br />

Ref : Books :-<br />

1. Man made fibre. by R.w Moncrief.<br />

2. Man made fibre.F knit garments<br />

H.F. Mark / S.M Hlas & E. Cernia .<br />

3 Textile Fibre by Mohibul Islam.

2373/2473 TEXTILE DESIGN AND COLOUR<br />

AIMS :<br />

1. To familiarize the students with the drawing instrument and their uses.<br />

2. To develop the skill of the student in making designs .<br />

3. To give the students a clear concept about light and colour.<br />

37<br />

4. To familiarize with colour and weave effects.<br />

SHORT DESCRIPTION<br />

T P C<br />

2 3 3<br />

Basic concept of drawing instruments and their uses; Designing; Motif and repeat of a design;<br />

Construction of design from incomplete repeats; Light and colour phenomena; Theory of<br />

colour; Colour harmony and contrast of colour; Colour and weave effect; Check-stripe and<br />

shaded design.<br />

DETAIL DESCRIPTION<br />

Theory :<br />

1.0 Understand drawing instruments and their uses.<br />

1.1 List the instruments used for drawing.<br />

1.2 Describe different instruments used for drawing.<br />

1.3 Discuss about tracing paper with its use.<br />

1.4 State the causes of dirty drawing papers<br />

1.5 Explain the general rules to be obeyed during drawing.<br />

1.6 Describe the effect of light and shade in a drawing.<br />

2.0 Understand the basic concept of design:<br />

2.1 State the importance of design.<br />

2.2 Mention the classification of designs with their definition and differences.<br />

2.3 Discuss the principles of selecting a design for particular end product.<br />

2.4 Discuss about different colour viz water colour, oil colour and pastal colour.<br />

3.0 Understand motif and repeat of a design.<br />

3.1 Define motif and repeat of a design with their differences.<br />

3.2 Describe the uses of motif and design.<br />

3.3 Discuss the techniques of enlarging or reducing a design.<br />

3.4 Describe the process of drafting a design from plain paper to graph paper<br />

according to fabric construction.

4.0 Understand the construction of design from incomplete repeats.<br />

38<br />

4.1 Give the quality of a designer to complete a design from an incomplete design.<br />

4.2 List the causes of incomplete design.<br />

4.3 Describe a design can be completed from an incomplete design.<br />

4.4 Describe the methods of reproducing a design from a woven or printed fabric.<br />

5.0 Understand the light and colour phenomena.<br />

5.1 Describe the dependence of lusture and colour of fabric on light.<br />

5.2 State the physical basis of colour and colour of matters.<br />

5.3 Describe about colour vision.<br />

5.4 Discuss about absorption and emission of light.<br />

6.0 Understand theory of colour.<br />

6.1 State the theory of colour.<br />

6.2 Mention the classification of the theory of colour with their description<br />

and differences.<br />

6.3 Describe the Brewster circle and explain pigment theory of colour<br />

from Brewster theory.<br />

7.0 Understand colour.<br />

7.1 Mention the classification of colour with their definition and uses.<br />

7.2 Describe complementary colour and explain it with young-Helmholtz theory.<br />

7.3 Define chromatic circle and state the technique of drawing chromatic circle.<br />

7.4 List the uses of chromatic circle.<br />

7.5 Describe the attributes of primary and secondary colour.<br />

7.6 Define pure colour, broken colour, shade, tint, tone, hue, cold colour, hot<br />

colour, opaque colour, transparent colour.<br />

8.0 Understand harmony and contrast of colour.<br />

8.1 Define, classify and describe the harmony and contrast of colour.<br />

8.2 Discuss about modifications of colour.<br />

8.3 Define and discuss coloured grey.<br />

8.4 Describe the practical applications of modified colour.<br />

8.5 State the factors, modifying the colouring of textile fabrics.<br />

9.0 Understand colour and weave effect .<br />

9.1 Define colour and weave effects.<br />

9.2 Mention the classifications of colour and weave effects.<br />

9.3 Explain the methods of producing colour and weave effect with the<br />

techniques of representing the design and colour on graph paper.

39<br />

10.0 Understand Check, Stripe and Shaded design.<br />

10.1 Define stripe and check design with their differences.<br />

10.2 Describe the defects of colour and weave effects.<br />

10.3 Discuss the factors to be considered for the selection of weave for stripe and<br />

check designs.<br />

10.4 Describe check and stripe design.<br />

10.5 Describe shaded design with example.<br />

11.0 Understand dark -room activities for screen preparation.<br />

Practical:<br />

11.1 Mention the importance of a dark room for screen preparation.<br />

11.2 Explain the role of a camera for screen preparation.<br />

11.3 Describe the process of making a screen.<br />

1. Draw at least 5 designs with water colour, oil colour and pastal colour.<br />

2. Draw at least 5 designs showing shaded effect.<br />

3. Draw at least 5 designs for shirt.<br />

4. Draw at least 5 designs for selvedge of a Sari.<br />

5. Draw at least 5 designs for body of a Sari.<br />

6. Draw at least 10 geometrical designs mention the purpose.<br />

7. Enlarge a given design to the required size.<br />

8. Construct a plain paper design from a given printed sample.<br />

9. Construct a graph paper design from a given fabric sample.<br />

10. Draw Brewster circle and explain the pigment theory of colour.<br />

11. Draw chromatic circle and prove young-Helmholtz theory.<br />

12. Draw some designs from given motif.<br />

13. Prepare screen from given design for screen printing.<br />

Book references.<br />

1. Watsons Textile design & colour- Nisbet<br />

2. Designers guide to colour- D.Patterson Allen.<br />

3. WªBs wWRvBb A¨vÛ Kvjvi- cÖ‡KŠkjx Av.K.g dwi`yj AvRv`<br />

4. Pvi“ I Kvi“Kjv - lô †kªYx RvZxq wkvµg I cvV¨cy¯—K †evW©|<br />

5. cÖv_wgK BwÄwbqvwis WªBs - ‡ngš— Kzgvi fUªvPvh©¨|<br />

6. Textile weaving and design-W. S. Murphy.

2573 FASHION AND DESIGN<br />

AIMS<br />

40<br />

1. To develop basic knowledge regarding fashion.<br />

2. To develop knowledge of design.<br />

3. To familiarize with fashion accessories.<br />

4. To acquire knowledge in fashion drawing.<br />

5. To develop skill, knowledge and market promotion of apparels.<br />

SHORT DESCRIPTION :<br />

T P C<br />

2 3 3<br />

Basic concept of fashion style and accessories; Product and design development; Fashion<br />

mercendising and market promotion; Fashion drawing from life; Fabric representation ;<br />

Fashion illustration.<br />

Theory :<br />

1.0 Understand the style and fashion.<br />

1.1 Define the term style and fashion.<br />

1.2 State the importance of style and fashion in human life.<br />

1.3 Mention the classification of fashion.<br />

1.4 State the importance of hair style to fashion.<br />

1.5 State the importance of make-up to fashion.<br />

1.6 State the importance of costume to fashion.<br />

1.7 State the importance of body fitness to fashion.<br />

1.8 State the importance of contact lance to fashion.<br />

1.9 State the importance of jewelry to fashion.<br />

1.10 State the importance of footwear to fashion.<br />

2.0 Understand the Trimmings, Leather and Fur .<br />

2.1 Explain how threads, elastic, interfacings, narrow fabrics, zippers, buttons and<br />

belts are produced and used.<br />

2.2 Mention the sources of fur and leather and the steps in processing them.<br />

3.0 Understand the international fashion centers.<br />

3.1 Name the well known international fashion creators.<br />

3.2 Explain the reasons for French fashion leadership.<br />

3.3 Discuss the growth and importance of the pret-a-porter.<br />

3.4 List the reasons for the importance of New York as a fashion centers.<br />

3.5 Discuss the role of international and domestic fashion centers.

4.0 Understand the product and design development.<br />

41<br />

4.1 Describe line development by item or by group.<br />

4.2 Explain the important elements and principles of design and their application<br />

to development.<br />

4.3 Describe the process of creation a sample garment.<br />

5.0 Understand the fashion accessory and fur manufacturing.<br />

5.1 Discuss the unique design considerations of various accessories.<br />

5.2 List the fashion accessories.<br />

5.3 Describe production methods for the major accessories.<br />

5.4 Explain accessory design and production centers.<br />

5.5 Discuss the marketing aspects for accessories.<br />

5.6 Explain fur garment production.<br />

6.0 Understand the wholesale markets, sales promotion and distribution.<br />

6.1 List the major international markets of apparel.<br />

6.2 Discuss collection openings, line releases and market weeks.<br />

6.3 Describe distribution polices.<br />

6.4 Discuss various aids to selling.<br />

6.5 Mention the forms of sales promotion.<br />

6.6 Explain the use of EDI in distribution.<br />

7.0 Understand the retail stores.<br />

7.1 Explain Today`s retail situation and trends.<br />

7.2 Discuss the various types of retail store.<br />

7.3 Explain the organizational differences between single-unit and multiple-unit<br />

stores.<br />

7.4 Mention the major international stores and famous shopping areas.<br />

7.5 Distinguish between the organizational structure of small store with that of a<br />

large store.<br />

7.6 Explain the growing importance of non-store retailing.<br />

7.7 Explain store’s fashion image is conveyed to consumer groups and<br />

manifested in store policies.<br />

8.0 Understand the retail fashion mercendising.<br />

8.1 Discuss the buying and selling aspects of mercendising.<br />

8.2 Explain buying procedures at the market.<br />

8.3 Describe all aspects of inventory control and evaluation.<br />

8.4 Discuss the importance of customer service and sales associates.

42<br />

9.0 Understand the retail fashion promotion.<br />

9.1 Explain the purpose of sales promotion.<br />

9.2 Explain the purpose goals and procedures of advertising, publicity, special<br />

events, fashion show and visual mercendising.<br />

9.3 Describe various types of media and their relation to store needs and target<br />

customers.<br />

9.4 Describe the buyer`s role is promotion.<br />

10.0 Understand the drawing from life.<br />

10.1 Mension proportion-natural, elongated figures (men`s and women`s).<br />

10.2 Mension women’s, men’s and children’s poses.<br />

10.3 Mension children’s, women’s and men’s heads.<br />

10.4 Mension proportion-heads, hands and feet.<br />

10.5 Mension women’s and men’s hands.<br />

10.6 Mension children’s hands and feet<br />

10.7 Mension women’s and men’s feet.<br />

10.8 Mension womes`s men’s, children’s and babies boots and shoes.<br />

11.0 Understand the fabric representation.<br />

11.1 Describe depth and shine.<br />

11.2 Describe faux fur and wool and lace.<br />

11.3 Describe wool and faux fur.<br />

11.4 Describe folds and fringing.<br />

11.5 Describe highlights and pleats.<br />

11.6 Describe lace and embroidery.<br />

12.0 Understand the sketch book.<br />

11.7 Describe Ideas and concept of sketch look.<br />

11.8 State Shop or reports.<br />

11.9 Describe design development.<br />

13.0 Understand the fashion illustration.<br />

13.1 State composition of fashion illustration.<br />

13.2 Describe stylization.<br />

13.3 Describe drawing for promotion.<br />

13.3 Describe drawing children.<br />

13.5 Describe children as cartoons.<br />

13.6 Describe children’s wear.<br />

13.7 Describe illustration garments and detail.

43<br />

14.0 Understand the drawing for manufacture.<br />

14.1 List the basic equipment of drawing.<br />

14.2 Describe the drawing from the dress stand.<br />

14.3 Describe developing the template.<br />

14.4 Describe developing the stencil.<br />

14.5 Describe design with a template of stencil.<br />

14.6 Describe rendering a working drawing.<br />

14.7 Explain the garment construction.<br />

15. Understand the specialist areas.<br />

Practical :<br />

15.1 Describe active sportswear.<br />

15.2 Describe swimwear / lingerie<br />

15.3 Describe drawing accessories.<br />

Fashion drawing<br />

1.0 Demonstrate from life.<br />

1.1 Draw proportion-natural, elongated figures (men’s and women’s).<br />

1.2 Draw women’s poses.<br />

1.3 Draw men’s poses.<br />

1.4 Draw children’s poses.<br />

1.5 Draw children’s heads.<br />

1.6 Draw women’s heads.<br />

1.7 Draw men’s heads.<br />

1.8 Draw proportion-heads, hands and feet.<br />

1.9 Draw women’s hands.<br />

1.10 Draw men’s hands.<br />

1.11 Draw children’s hands and feet<br />

1.12 Draw babies` hands and feet.<br />

1.13 Draw women’s feet.<br />

1.14 Draw men’s feet.<br />

1.15 Draw womes`s boots and shoes.<br />

1.16 Draw men’s boots and shoes.<br />

1.17 Draw children` boots and shoes.<br />

1.18 Draw babies` boots and shoes.<br />

2.0 Show skill of fabric representation.<br />

2.1 Identify depth and shine.

2.2 Identify faux fur.<br />

2.3 Identify wool and lace.<br />

2.4 Identify wool and faux fur.<br />

2.5 Identify folds and fringing.<br />

2.6 Identify highlights and pleats.<br />

2.7 Make lace.<br />

2.8 Make embroidery.<br />

3.0 Show skill in sketch book.<br />

3.1 Ideas and concept.<br />

3.2 Shop or show reports.<br />

3.3 Design development.<br />

4.0 Show skill in fashion illustration.<br />

4.1 Show composition.<br />

4.2 Show stylization.<br />

4.3 Draw for promotion.<br />

4.4 Draw children.<br />

4.5 Show children as cartoons.<br />

4.6 Prepare children’s wear.<br />

4.7 Illustration garments and detail.<br />

5.0 Drawing for manufacture.<br />

5.1 Identify basic equipment.<br />

5.2 Draw the dress stand.<br />

5.3 Develop the template.<br />

5.4 Develop a stencil.<br />

44<br />

5.5 Design with a template of stencil.<br />

5.6 Render a working drawing.<br />

5.7 Prepare garment construction<br />

6.0 Specialist areas.<br />

6.1 Active sportswear/Prepare.<br />

6.2 Swimwear / lingerie/Prepare<br />

6.3 Identify drawing accessories.

Ref : Books.<br />

1. Fashion<br />

45<br />

From concept of consumer.------By Gini Stephens Frings.<br />

2. Fashion Accessories<br />

The complete 20 th century sourcebook<br />

with 2000 full- colour illustrations ------ By. John peacok<br />

3. Fashion illustration now ------- By. Laird Borrelli<br />

4. Illustrating fashion By----- Kathryn Mc kelvey and janine Munslow.

2274 MAINTENANCE OF YARN<br />

AIMS:<br />

46<br />

MANUFACTURING MACHINERY – II<br />

1. To enable the students to operate the individual machines of spinning.<br />

2. To enable the students to make the maintenance schedule of spinning<br />

machinery.<br />

3. To enable the students to set and adjust the spinning machinery as per<br />

requirement.<br />

T P C<br />

0 6 2<br />

4. To enable the students to dismantle and resetting the spinning machinery.<br />

5. To enable the students to change and set all the parts of spinning machinery as<br />

per requirement.<br />

6. To enable the students to replace the broken or worn-out parts.<br />

7. To make the students familiar with oiling, greasing, cleaning of spinning<br />

machinery.<br />

SHORT DESCRIPTION :<br />

Basic concept of cleaning; Setting; Adjustment; Lubricating; Making maintenance schedule.<br />

Draft and Twist setting; Taper & coils setting; Roller setting; Tap joining; Cot buffing and<br />

pushing and cot treatment of different machinery.<br />

Practical :<br />

1.0 Demonstrate the application of cleaning of spinning machinery.<br />

1.1 Perform the lap former cleaning.<br />

1.2 Perform the comber cleaning.<br />

1.3 Perform the simplex cleaning.<br />

1.4 Perform the ring frame cleaning.<br />

1.5 Perform the winding machine cleaning.<br />

2.0 Demonstrate the skill of setting of spinning machinery.<br />

2.1 Identify setting point of lap former and set it.<br />

2.2 Identify setting point of comber and set it.<br />

2.3 Identify setting point of simplex and set it.<br />

2.4 Identify setting point of ring frame and set it.<br />

2.5 Identify setting point of cone winding machine and set it.

3.0 Demonstrate the skill in adjustment of spinning machines.<br />

3.1 Identify adjustment area of lap former and adjust it.<br />

47<br />

3.2 Identify adjustment area of comber and adjust it.<br />

3.3 Identify adjustment area of simplex and adjust it.<br />

3.4 Identify adjustment area of ring frame and adjust it.<br />

3.5 Identify adjustment area of cone winding machine and adjust it.<br />

4.0 Demonstrate skill in lubricating of spinning machinery.<br />

4.1 Identify the lubricating point and lubricate the spinning machinery.<br />

4.2 Practice operate the individual spinning machinery.<br />

4.3 Practice to make maintenance schedule of spinning machinery.<br />

4.4 Practice dismantle of spinning machinery.<br />

4.5 Practice change and reset broken parts of spinning machinery.<br />

5.0 Perform the cotton spinning machinery maintenance.<br />

5.1 Show the skill to set the gauge for different parts of comber.<br />

5.2 Practice to cheek the combing cycle thorough index wheel and adjust<br />

correctly.<br />

5.3 Practice to set noil percentage as per requirement.<br />

5.4 Practice to set draft and twist for simplex machine.<br />

5.5 Practice to adjust building motion correctly.<br />

5.6 Practice to set the required taper and coils/inch.<br />

5.7 Practice to cot buffing and cot pushing.<br />

5.8 Perform cot treatment.<br />

5.9 Perform spindle tape joining.<br />

5.10 Practice to set the tapering of the bobbin as per roving hank.<br />

6.0 Perform the jut spinning machinery maintenance.<br />

6.1 Practice cleaning of draw frame, spinning frame, spool winding and cop<br />

winding machine.<br />

6.2 Show skill in lubricating of draw frame, Spinning frame, Spool winding and<br />

cone winding.<br />

6.3 Show skill in setting of draw frame, Spinning frame, spool winding and cop<br />

winding.<br />

6.4 Practice to make maintenance schedule of jute spinning machinery.<br />

7.0 Demonstrate the skill in jute spinning machinery maintenance.<br />

7.1 Practice to set the faller pin to the faller bar.

48<br />

7.2 Calculate the faller speed in the draw frame.<br />

7.3 Practice to set draft to the machine.<br />

7.4 Identify to can turning and trumping motion.<br />

7.5 Practice to adjust the stop motion.<br />

7.6 Practice to set draft and twist of spinning frame.<br />

7.7 Practice to set the spindle drive of spinning frame.<br />

7.8 Practice to adjust auto stop motion of the spinning frame.<br />

7.9 Practice of change the alignment of the package holder for conical and parallel<br />

package.<br />

7.10 Practice to slub catcher settings.

2374 MAINTENANCE OF FABRIC T P C<br />

0 6 2<br />

MANUFACTURING MACHINERY – II<br />

AIMS<br />

49<br />

1. To enable the students to make the maintenance schedule of knitting<br />

machinery<br />

2. To enable the students to set and adjust the knitting machinery as per<br />

requirement<br />

3. To enable the students to dismantle and re-assemble the knitting machinery<br />

4. To enable the students the change and set all the parts of knitting machinery as<br />

per requirement<br />

5. To enable the students to repair and replace the broken or worn out parts.<br />