- Page 1:

Shaft Mount Worm Gear and Bevel Red

- Page 4 and 5:

SMTP Shaft Mount TorqTaper Plus ®

- Page 6 and 7:

The American Standard 4 Team Up wit

- Page 8 and 9:

The New Way... Your Way 6 3 7 6 5 2

- Page 10 and 11:

Note: See “Application Considerat

- Page 12 and 13:

10 Application AGMA Up to 3 Hours P

- Page 14 and 15:

Output RPM 12 Reducer Size Minimum

- Page 16 and 17:

Output RPM Reducer Size Minimum She

- Page 18 and 19:

Output RPM 1/4 HP MOTOR 5 - 50 107S

- Page 20 and 21:

Output RPM Reducer Size Minimum She

- Page 22 and 23:

Output RPM 1/4 HP MOTOR 5 - 50 107S

- Page 24 and 25:

Output RPM Reducer Size Minimum She

- Page 26 and 27:

24 C A G Shaft Mount Reducers SMTP

- Page 28 and 29:

Part Number Explanation 407 SM TP 2

- Page 30 and 31:

Application Inspired... Hydraulical

- Page 32 and 33:

Example No. 1 Units 107 - 315 Hydra

- Page 34 and 35:

32 Application AGMA Up to 3 Hours P

- Page 36 and 37:

Involute Spline Input 34 Output RPM

- Page 38 and 39:

Straight Sided Spline Input 36 Outp

- Page 40 and 41:

Involute Spline Input 38 Output RPM

- Page 42 and 43:

Straight Sided Spline Input 40 Outp

- Page 44 and 45:

Involute Spline Input 42 Output RPM

- Page 46 and 47:

Straight Sided Spline Input 44 Outp

- Page 48 and 49:

46 P1 P C UNIT NO. A G Reversible s

- Page 50 and 51:

Innovative C-Face Motor Connections

- Page 52 and 53:

Example No. 1 Units 107 - 315 C-fac

- Page 54 and 55:

52 Application AGMA Up to 3 Hours P

- Page 56 and 57:

Output RPM 54 CMTP Selection Chart

- Page 58 and 59:

Output RPM 56 CMTP Selection Chart

- Page 60 and 61:

Output RPM 58 CMTP Selection Chart

- Page 62 and 63:

60 Reversible single bushing system

- Page 64 and 65:

62 2 3 1 4 5

- Page 66 and 67:

REDUCER SIZE 107SMTP 115SMTP BUSHIN

- Page 68 and 69:

REDUCER SIZE 307SMTP REDUCER SIZE 3

- Page 70 and 71:

Browning shaft mount reducers may b

- Page 72 and 73:

9.00 * To determine usable input sh

- Page 74 and 75:

9.00 72 S L Motor Frame Size E N V

- Page 77 and 78:

Browning Belt Drives For over 120 y

- Page 79 and 80:

Accessories Shaft Mount Reducers Pr

- Page 81 and 82:

Accessories Shaft Mount Reducers Pr

- Page 83 and 84:

Accessories Shaft Mount Reducers Pr

- Page 85 and 86:

Accessories Shaft Mount Reducers Pr

- Page 87 and 88:

Accessories Shaft Mount Reducers Pr

- Page 89 and 90:

Accessories Shaft Mount Reducers Pr

- Page 91 and 92:

Accessories Shaft Mount Reducers Pr

- Page 93 and 94:

Accessories Shaft Mount Reducers Pr

- Page 95 and 96:

Accessories Shaft Mount Reducers Pr

- Page 97 and 98:

Accessories Shaft Mount Reducers Pr

- Page 99 and 100:

Accessories Shaft Mount Reducers Pr

- Page 101 and 102:

Accessories Shaft Mount Reducers Pr

- Page 103 and 104:

Accessories Shaft Mount Reducers Pr

- Page 105 and 106:

Accessories Shaft Mount Reducers Pr

- Page 107 and 108:

Accessories Shaft Mount Reducers Pr

- Page 109 and 110:

Accessories Shaft Mount Reducers Pr

- Page 111 and 112:

Accessories Shaft Mount Reducers Pr

- Page 113 and 114:

Accessories Shaft Mount Reducers Pr

- Page 115 and 116:

Accessories Shaft Mount Reducers Pr

- Page 117 and 118:

Accessories Shaft Mount Reducers Pr

- Page 119 and 120:

Accessories Shaft Mount Reducers Pr

- Page 121 and 122:

Output rpm Accessories Shaft Mount

- Page 123 and 124:

Output rpm Accessories Shaft Mount

- Page 125 and 126:

Bushing guard kits have the followi

- Page 127 and 128:

STOCK SMTP REDUCER ( 1) Accessories

- Page 129 and 130:

STOCK HMTP REDUCER ( 1) Accessories

- Page 131 and 132:

STOCK CMTP REDUCER ( 1) Accessories

- Page 133 and 134:

REDUCER SIZE Accessories Shaft Moun

- Page 135 and 136:

Accessories Shaft Mount Reducers Op

- Page 137 and 138:

Shaft Mount Engineering Section Inp

- Page 139 and 140:

Output RPM 10 20 30 40 50 60 70 80

- Page 141 and 142:

SMTP, HMTP, CMTP Output Thrust and

- Page 143 and 144:

141 Shaft Mount Engineering SMTP, H

- Page 145 and 146:

Don’t Let An Ounce of Dirt Stop 1

- Page 147 and 148:

SMTP, HMTP, CMTP Face Mounting Dril

- Page 149 and 150:

SMTP, HMTP, CMTP Lubrication Sizes

- Page 151 and 152:

Output RPM AGMA Oil Viscosity Grade

- Page 153 and 154:

12.88 15.55 17.38 4.9375 Bore & 1.2

- Page 155 and 156:

Design Features 1. Rugged Cast Iron

- Page 157 and 158:

10 12 11 3 Accessories Need a reduc

- Page 159 and 160:

QH QHT QHF CH CHT CHF UHMT UHMB QHM

- Page 161 and 162:

Part Description Configuration Cent

- Page 163 and 164:

Example No. 2 - Torque Method Selec

- Page 165 and 166:

Up to 3-10 Over APPLICATION 3 Hrs.

- Page 167 and 168:

Unit Size Engineering Data Input Ho

- Page 169 and 170:

Engineering Data Input Horsepower,

- Page 171 and 172:

Complete Gearing Solutions... Emers

- Page 173 and 174:

Dimensions (Inches) for Style “U

- Page 175 and 176:

Worm Gear Reducers Dimensions (Inch

- Page 177 and 178:

Worm Gear Reducers Dimensions (Inch

- Page 179 and 180:

DIMENSIONS (INCHES) FOR STYLE “QT

- Page 181 and 182:

Dimensions (Inches) for Style “UV

- Page 183 and 184:

181 Raider Plus Dimensions (Inches)

- Page 185 and 186:

Fan Kit Ref. No. Fan Kit AA Tap Dee

- Page 187 and 188:

Worm Gear Reducers Dimensions (Inch

- Page 189 and 190:

Dimensions (Inches) for Style “CF

- Page 191 and 192:

Fan Kit Ref. No. Fan Kit A A Tap De

- Page 193 and 194:

CD UNIT SIZE N.E.M.A. FRAME A B C D

- Page 195 and 196:

Worm Gear Reducers Dimensions (Inch

- Page 197 and 198:

Worm Gear Reducers Dimensions (Inch

- Page 199 and 200:

C.D. COMPONENTS u PART NO. H FLANGE

- Page 201 and 202:

DIMENSIONS (INCHES) FOR STYLE “QH

- Page 203 and 204:

Fan Kit R ef. No. Fan Kit AA Tap De

- Page 205 and 206:

C. D. Dimensions (Inches) for Style

- Page 207 and 208:

Worm Gear Reducers Dimensions (Inch

- Page 209 and 210:

Dimensions (Inches) for Style “QH

- Page 211 and 212:

Worm Gear Reducers Dimensions (Inch

- Page 213 and 214:

Worm Gear Reducers Dimensions (Inch

- Page 215 and 216:

213 Raider Plus Dimensions (Inches)

- Page 217 and 218:

Worm Gear Reducers Dimensions (Inch

- Page 219 and 220:

Worm Gear Reducers Dimensions (Inch

- Page 221 and 222:

A C N.E.M.A. Frame Adapter Kit Kit

- Page 223 and 224:

D L C O E F M Dia. B A K N Dia. Dim

- Page 225 and 226:

Tack-On Reducers Off the shelf Tack

- Page 227 and 228:

R L R L L1 R1 Floor Mount Tack-On R

- Page 229 and 230:

Reducers Primary Secondary Output

- Page 231 and 232:

SECONDARY UNIT * Secondary Unit PRI

- Page 233 and 234:

Complete Gearing Solutions... Emers

- Page 235 and 236:

Washdown White epoxy paint • Prov

- Page 237 and 238:

1. Determine Service Factor From se

- Page 239 and 240:

Dimensions (Inches) for Style “QW

- Page 241 and 242:

Stainless Raider Plus Designed for

- Page 243 and 244:

How to Order Part Description Confi

- Page 245 and 246:

Up to 3-10 Over APPLICATION 3 Hrs.

- Page 247 and 248:

Stainless Raider Plus Input Horsepo

- Page 249 and 250:

KB AA C.D. HB N. E. M. A. Frame L J

- Page 251 and 252:

AA C.D. K H L J E C A W Key U T 8 H

- Page 253 and 254:

Stainless Accessories A C B G F DIA

- Page 255 and 256:

Design Features 1. Compact light-we

- Page 257 and 258:

Example No. 2 - Torque Method Selec

- Page 259 and 260:

Up to 3-10 Over APPLICATION 3 Hrs.

- Page 261 and 262:

UNIT SIZE ■ 690 RPM MECHANICAL In

- Page 263 and 264:

Making it move is our business. Whe

- Page 265 and 266:

Type QH CD Basic Unit NEMA Frame Wo

- Page 267 and 268:

Type UH CD CD Basic Unit Basic Unit

- Page 269 and 270:

3 1. Flange Kit • Industry standa

- Page 271 and 272:

Accessories Torqube Adapter Dimensi

- Page 273 and 274:

POWERGEAR ® W Series The RW and W

- Page 275 and 276:

Example No. 2 - Torque Method Selec

- Page 277 and 278:

Up to 3-10 Over APPLICATION 3 Hrs.

- Page 279 and 280:

Angle brackets shown are for illust

- Page 281 and 282:

Lubricating Instructions - Reducers

- Page 283 and 284:

Angle brackets are not included wit

- Page 285 and 286:

Worm Gear Reducers R-W and WD Serie

- Page 287 and 288:

Worm Gear Reducers W-DB and W-DV Sh

- Page 289 and 290:

Angle brackets are not included wit

- Page 291 and 292:

Angle brackets are not included wit

- Page 293 and 294:

291 POWERGEAR® PoweRgear s Inch-po

- Page 295 and 296:

Angle brackets are not included wit

- Page 297 and 298:

Angle brackets are not included wit

- Page 299 and 300:

297 POWERGEAR® PoweRgear s Inch-po

- Page 301 and 302:

299 POWERGEAR® PoweRgear s Inch-po

- Page 303 and 304:

301 POWERGEAR® PoweRgear s Inch-po

- Page 305 and 306:

303 POWERGEAR® PoweRgear s Inch-po

- Page 307 and 308:

305 POWERGEAR® PoweRgear 1.00 Serv

- Page 309 and 310:

POWERGEAR ® V Series The VX models

- Page 311 and 312:

Example No. 2 - Torque Method Selec

- Page 313 and 314:

Up to 3-10 Over APPLICATION 3 Hrs.

- Page 315 and 316:

Worm Gear Reducers DV and DVX Serie

- Page 317 and 318:

Lubricating Instructions - Reducers

- Page 319 and 320:

317 POWERGEAR® PoweRgear 1.00 Serv

- Page 321 and 322:

319 POWERGEAR® PoweRgear s Inch-po

- Page 323 and 324:

321 POWERGEAR® PoweRgear 1.00 Serv

- Page 325 and 326:

323 POWERGEAR® PoweRgear 1.00 Serv

- Page 327 and 328:

80VX Net wt. 895 lbs. 8.0" C.D. RAT

- Page 329 and 330:

327 POWERGEAR® PoweRgear s Inch-po

- Page 331 and 332:

POWERGEAR ® G Series The GC models

- Page 333 and 334:

Example No. 2 - Torque Method Selec

- Page 335 and 336:

POWERGEAR® (Service factors shown

- Page 337 and 338:

Model GC Type T Model GC Type V Sha

- Page 339 and 340:

Worm Gear Reducers GCDB, and GCDV S

- Page 341 and 342:

Worm Gear Reducers GDSA, and GDSF A

- Page 343 and 344:

Lubricating Instructions - Reducers

- Page 345 and 346:

Worm Gear Reducers GCDB and GCDV Se

- Page 347 and 348:

Worm Gear Reducers GCDB and GCDV Se

- Page 349 and 350:

Worm Gear Reducers GDSA and GDSF Se

- Page 351 and 352:

Worm Gear Reducers GCDB and GCDV Se

- Page 353 and 354:

Worm Gear Reducers GDSA and GDSF Se

- Page 355 and 356:

Worm Gear Reducers GCDB and GCDV Se

- Page 357 and 358:

Worm Gear Reducers GDSA and GDSF Se

- Page 359 and 360:

56C MOTOR FRAME A-.627 - .628 DIA.

- Page 361 and 362:

30GDSA Net wt. 72 lbs. 3.0" C.D. 30

- Page 363 and 364:

56C MOTOR FRAME A-.627 - .628 DIA.

- Page 365 and 366:

Worm Gear Reducers GDSA and GDSF Se

- Page 367 and 368:

56C MOTOR FRAME A-.627 - .628 DIA.

- Page 369 and 370:

Worm Gear Reducers GDSA and GDSF Se

- Page 371 and 372:

56C MOTOR FRAME A-.627 - .628 DIA.

- Page 373 and 374:

Worm Gear Reducers GDSA and GDSF Se

- Page 375 and 376:

182TC & 184TC MOTOR FRAME 56C MOTOR

- Page 377 and 378:

Worm Gear Reducers GDSA and GDSF Se

- Page 379 and 380:

17 5/8 11 1/8 Worm Gear Reducers 9

- Page 381 and 382:

22 7/8 15 1/8 Worm Gear Reducers 12

- Page 383 and 384:

POWERGEAR ® S Series The SA and SF

- Page 385 and 386:

Example No. 2 - Torque Method Selec

- Page 387 and 388:

Up to 3-10 Over APPLICATION 3 Hrs.

- Page 389 and 390:

MODEL DS TYPE A MODEL DS TYPE F No

- Page 391 and 392:

Lubricating Instructions - Reducers

- Page 393 and 394:

391 POWERGEAR® PoweRgear s Inch-po

- Page 395 and 396:

393 POWERGEAR® PoweRgear 1.00 Serv

- Page 397 and 398:

395 POWERGEAR® PoweRgear sInch-pou

- Page 399 and 400:

397 POWERGEAR® PoweRgear s Inch-po

- Page 401 and 402:

IRA Gearmotors 1. Innovative self-l

- Page 403 and 404:

General Presentation Type IRA Gener

- Page 405 and 406:

TEFC - Three Phase Corro-Duty TEFC

- Page 407 and 408:

Example IRA A right angle, foot mou

- Page 409 and 410:

Selection Example IRA A foot mounte

- Page 411 and 412:

MOTOR TYPE DESIGN S Single Phase TE

- Page 413 and 414:

AGMA Application Classification IRA

- Page 415 and 416:

F-1 STANDARD U-3* Mounting Position

- Page 417 and 418:

The IRA gearbox is filled at the fa

- Page 419 and 420: General Specifications: Totally enc

- Page 421 and 422: General Specifications: Totally enc

- Page 423 and 424: General Specifications: Totally enc

- Page 425 and 426: General Specifications: Totally enc

- Page 427 and 428: M7 Insulation Standard 3 phase TEFC

- Page 429 and 430: Overall dimensions Worm-Helical (GW

- Page 431 and 432: Single Phase Gearmotor Alternate Mo

- Page 433 and 434: DC FCR Brake (IP55) O P2 ØP AC AB

- Page 435 and 436: IRA Worm and Helical Reducers These

- Page 437 and 438: "C" Face Input Worm Gear Configurat

- Page 439 and 440: Type Gear Frame IRA 6 20 Based on S

- Page 441 and 442: AGMA Application Classification IRA

- Page 443 and 444: AGMA Application Classification IRA

- Page 445 and 446: Availability Gear Frame Footed Univ

- Page 447 and 448: Exact ratio rpm, hp and Torque: IRA

- Page 449 and 450: Exact ratio rpm, hp and Torque: IRA

- Page 451 and 452: IRA Reducers Modifications Gear Mod

- Page 453 and 454: Overall dimensions Standard W-3 Ass

- Page 455 and 456: HB and HSB Bevel and Spiral Bevel 1

- Page 457 and 458: 455 Bevel Red. Cast Iron Load Class

- Page 459 and 460: 457 Bevel Red. Cast Iron Reducer Se

- Page 461 and 462: 459 Bevel Red. Cast Iron **The Inpu

- Page 463 and 464: 461 Bevel Red. Cast Iron Ratios, Ty

- Page 465 and 466: ARA Aluminum Right Angle Bevel 1. L

- Page 467 and 468: .630 P* U* SIZE 3ARA2 ONLY P1* .344

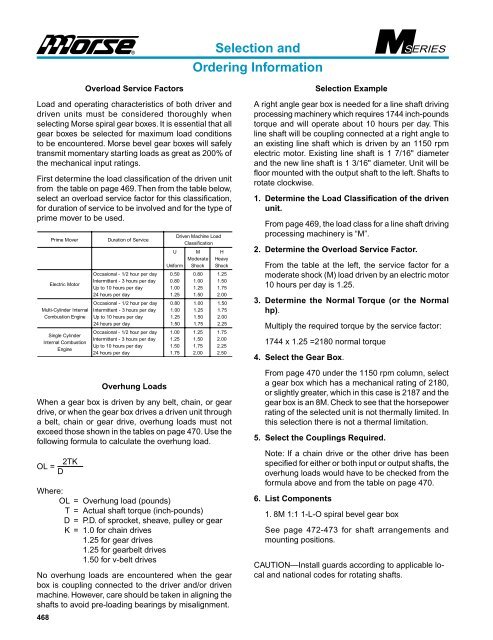

- Page 469: M Series Spiral Bevel 1. Corrosion

- Page 473 and 474: Horizontal Mount W A C K H B Vertic

- Page 475 and 476: Shaft Arrangements U - LR U - LR -O

- Page 477 and 478: Emerson Industrial Automation Heavy

- Page 479 and 480: Stainless Steel Motors 1. 1/2 - 2 H

- Page 481 and 482: State-of-the-Art Features Built int

- Page 483 and 484: C-Face IntelliGear Plus Innovative

- Page 485 and 486: 483 C-Face IntelliGear IntelliGear

- Page 487 and 488: Color and state of indicator lamp S

- Page 489 and 490: AZ C AG IntelliGear Plus C-Face Foo

- Page 491 and 492: Decimal - Millimeter Equivalents F

- Page 493 and 494: Put it all together. Our family of

- Page 495 and 496: One Source Emerson Has the Industry

- Page 497 and 498: All sales are made on our STANDARD

- Page 499 and 500: EPT Edge Online is our online techn