Delivery program "One-Piece Heads" - Dillinger Hütte GTS

Delivery program "One-Piece Heads" - Dillinger Hütte GTS

Delivery program "One-Piece Heads" - Dillinger Hütte GTS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

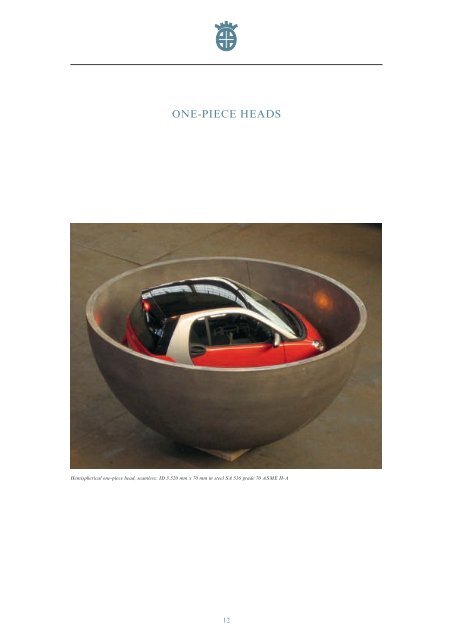

ONE-PIECE HEADS<br />

Hemispherical one-piece head, seamless: ID 3.520 mm x 70 mm in steel SA 516 grade 70 ASME II-A<br />

12

<strong>One</strong>-piece heads serve for example<br />

as end pieces for pressure<br />

vessels and power boilers. The<br />

widest range of shapes is available:<br />

spherical, torispherical,<br />

elliptical, etc. The flat heads i.e.<br />

flanged only within the proposed<br />

dimensional range are mainly<br />

used for the fabrication of ladles<br />

involved in metallurgical<br />

processes.<br />

Manufacturing process<br />

<strong>One</strong>-piece heads in Dillingen are<br />

always hot formed by deepdrawing,<br />

the circular blanks being<br />

free of any weld seam. They<br />

are dished by the means of<br />

hydraulic presses up to 2.500 tons<br />

fitted with the proper tooling i.e.<br />

ring and die, the shape of which<br />

suits the inside contour of the<br />

head. The edges are generally<br />

worked by flame cutting; the<br />

machining of the weld-edge<br />

preparation can be also agreed<br />

upon for heads with wall thicknesses<br />

above 30 mm.<br />

Heavy Fabrication Division <strong>Dillinger</strong> <strong>Hütte</strong> <strong>GTS</strong>, <strong>One</strong>-piece heads [1/7], 2008<br />

13<br />

Scope of supply<br />

Seamless heads can be supplied<br />

spherical-shaped in outside<br />

diameters up to 3.650 mm, torispherical<br />

or elliptical-shaped up<br />

to 4.450 mm or flanged only up<br />

to 4.750 mm. The "Dimensional<br />

Program" table provides information<br />

concerning the standard<br />

shapes, diameters and wall<br />

thicknesses to which the heads<br />

can be manufactured:<br />

intermediate dimensions and<br />

other head shapes must be<br />

agreed upon. Please refer also to<br />

the Technical <strong>Delivery</strong> Conditions<br />

on page 32.

Dimensional <strong>program</strong><br />

Wall thickness related to the external diameter for the different shapes<br />

Outside diameter Thickness (mm)<br />

(mm)<br />

Elliptical 1) & Spherical 3) Flanged only 4)<br />

torispherical 2)<br />

from up to from up to from up to<br />

1.000 & 1.050 6 90 12 90 - -<br />

1.100 & 1.150 6 90 13 100 - -<br />

1.200 & 1.250 6 100 14 120 - -<br />

1.300 & 1.350 6 100 15 130 - -<br />

1.400 & 1.450 6 110 16 140 - -<br />

1.500 & 1.550 7 120 17 150 - -<br />

1.600 & 1.650 7 120 18 170 - -<br />

1.700 & 1.750 7 130 19 180 - -<br />

1.800 & 1.850 7 130 20 200 - -<br />

1.900 & 1.950 8 140 22 200 - -<br />

2.000 & 2.050 8 140 24 200 - -<br />

2.100 & 2.150 9 150 26 200 - -<br />

2.200 & 2.250 9 150 28 200 - -<br />

2.300 & 2.350 10 160 30 200 20 75<br />

2.400 & 2.450 10 160 32 200 20 75<br />

2.500 & 2.550 11 170 34 200 20 80<br />

2.600 & 2.650 11 170 36 180 20 80<br />

2.700 & 2.750 12 170 38 180 22 85<br />

2.800 & 2.850 12 170 40 180 22 85<br />

2.900 & 2.950 13 170 40 160 22 90<br />

3.000 & 3.050 14 170 40 160 22 90<br />

3.100 & 3.150 15 170 40 150 22 100<br />

3.200 & 3.250 16 160 40 150 24 100<br />

3.300 & 3.350 17 160 40 140 24 100<br />

3.400 & 3.450 18 150 40 140 24 100<br />

3.500 & 3.550 19 150 40 130 24 100<br />

3.600 & 3.650 20 140 40 120 24 100<br />

3.700 & 3.750 21 140 - - 24 100<br />

3.800 & 3.850 22 120 - - 24 100<br />

3.900 & 3.950 23 120 - - 24 100<br />

4.000 & 4.050 24 110 - - 26 100<br />

4.100 & 4.150 25 110 - - 26 100<br />

4.200 & 4.250 26 110 - - 26 100<br />

4.300 & 4.350 27 110 - - 28 100<br />

4.400 & 4.450 28 110 - - 28 100<br />

4.500 & 4.550 - - - - 30 100<br />

4.600 & 4.650 - - - - 30 100<br />

4.700 & 4.750 - - - - 30 100<br />

The data on wall thicknesses apply for steel with 355 N/mm 2 yield<br />

strength. The flange height complies with the applicable standard or<br />

the customer's requirements but - due to the tool design - is normally<br />

restricted to 150 mm. Please inquire for other head shapes and intermediate<br />

dimensions.<br />

14<br />

1) Elliptical heads to NF E 81-103 (axis ratio 1.9:1) und ASME<br />

Code (axis ratio 2:1)<br />

2) Torispherical heads to DIN 28 013 and SMS-482<br />

3) Depending on the required design, the available diameters for<br />

spherical heads can be restricted or enlarged<br />

4) Flat heads can be produced with a knuckle-radius between 50<br />

and 150 mm<br />

Heavy Fabrication Division <strong>Dillinger</strong> <strong>Hütte</strong> <strong>GTS</strong>, <strong>One</strong>-piece heads [2/7], 2008

Standard tolerances<br />

Edge-preparation flame-cut machined<br />

Bevel angle ± 2.0° ± 1.0°<br />

Land position 1) ± 2.0 mm ± 1.0 mm<br />

Land height ± 2.0 mm ± 1.0 mm<br />

Milling radius 2) ± 1.0 mm<br />

Cut face quality ISO 9013-33 ISO 1302-N9<br />

1) measured from the reference diameter Da or Di<br />

2) applicable just to U and DU edges only<br />

Diameter, out-of-roundness and shape according to applicable fabrication codes e.g. ASME I, ASME<br />

VIII-1, ASME VIII-2, PD 5500, BS 1113, CODAP or AD 2000.<br />

Heavy Fabrication Division <strong>Dillinger</strong> <strong>Hütte</strong> <strong>GTS</strong>, <strong>One</strong>-piece heads [3/7], 2008<br />

15

Information required<br />

Torispherical heads<br />

Shape<br />

(applicable standard or dishing radius r 1<br />

and knuckle radius r 2)<br />

Diameter Da or Di<br />

Minimum wall thickness after forming s<br />

Straight flange h 1<br />

Weld-edge preparation<br />

Elliptical heads<br />

Shape<br />

(applicable standard or axis ratio b : a)<br />

Diameter Da or Di<br />

Minimum wall thickness after forming s<br />

Straight flange h 1<br />

Weld-edge preparation<br />

Flat heads, flanged only<br />

Diameter Da or Di<br />

Minimum wall thickness after forming s<br />

Dishing radius or knuckle radius r 1<br />

Straight flange h 1 or depth h 3 (h 1+h 2)<br />

Weld-edge preparation<br />

Heavy Fabrication Division <strong>Dillinger</strong> <strong>Hütte</strong> <strong>GTS</strong>, <strong>One</strong>-piece heads [4/7], 2008<br />

16<br />

s<br />

s<br />

s<br />

a<br />

D i<br />

D a<br />

D i<br />

D a<br />

D i<br />

D a<br />

r 1<br />

b<br />

r 2<br />

r 2<br />

h 2<br />

h 1<br />

h 2<br />

h 1<br />

h 1<br />

h 3<br />

h 3<br />

h 3

Information required<br />

Hemispherical heads with straight flange<br />

Dishing radius r 1 or inside diameter Di<br />

Minimum wall thickness after forming s<br />

Straight flange h 1 or depth h 3 (h 1+h 2)<br />

Weld-edge preparation<br />

Hemispherical heads (r 1 = h 3)<br />

Dishing radius r 1 or inside diameter Di<br />

Minimum wall thickness after forming s<br />

Weld-edge preparation<br />

Spherical heads<br />

Dishing radius r 1<br />

Connecting inside diameter<br />

Dh or "negative" height h1 or<br />

depth h3<br />

Minimum wall thickness after forming s<br />

Weld-edge preparation<br />

Heavy Fabrication Division <strong>Dillinger</strong> <strong>Hütte</strong> <strong>GTS</strong>, <strong>One</strong>-piece heads [5/7], 2008<br />

17<br />

s<br />

s<br />

s<br />

D h<br />

D i<br />

D a<br />

D i<br />

D a<br />

r 1<br />

r 1<br />

r 1<br />

h 3<br />

h 1<br />

h 2<br />

h 1<br />

h 3<br />

h 3

HOT DISHING PROCESS OF<br />

ONE-PIECE HEADS<br />

OD 4.200 mm x 80 mm in steel SA 516 grade 70<br />

1. Circular blank being removed out of the furnace once heated at the proper temperature<br />

2. Circular blank being transferred to the 2500 t - hydraulic press by means of the overhead crane<br />

3. Circular blank being positioned onto the forming ring laying on the lateral transfer lorry<br />

Heavy Fabrication Division <strong>Dillinger</strong> <strong>Hütte</strong> <strong>GTS</strong>, <strong>One</strong>-piece heads [6/7], 2008<br />

18

6. Dished head being extracted out of the forming tools<br />

HOT DISHING PROCESS OF<br />

ONE-PIECE HEADS<br />

OD 4.200 mm x 80 mm in steel SA 516 grade 70<br />

4. Lateral transfer lorry being positioned within the operating area of the hydraulic press fitted with the forming die<br />

5. Circular blank being dished<br />

Heavy Fabrication Division <strong>Dillinger</strong> <strong>Hütte</strong> <strong>GTS</strong>, <strong>One</strong>-piece heads [7/7], 2008<br />

19