Implant Extraction Set - Stryker

Implant Extraction Set - Stryker

Implant Extraction Set - Stryker

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

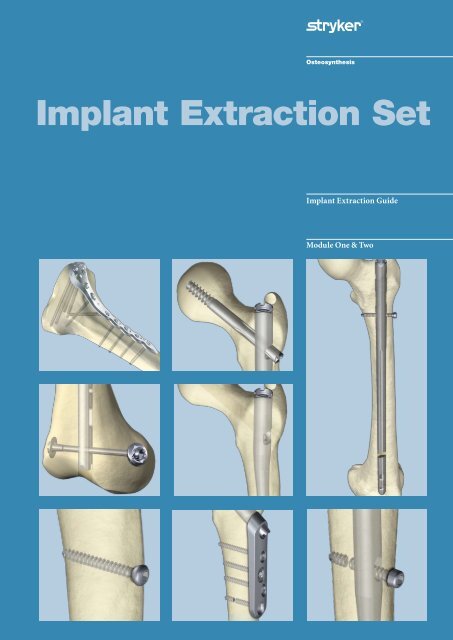

<strong>Implant</strong> <strong>Extraction</strong> <strong>Set</strong><br />

1<br />

<strong>Implant</strong> <strong>Extraction</strong> Guide<br />

Module One & Two

Contents<br />

This publication sets forth detailed<br />

recommended procedures for using<br />

<strong>Stryker</strong> Osteosynthesis devices and<br />

instruments.<br />

It offers guidance that you should<br />

heed, but, as with any such technical<br />

guide, each surgeon must consider<br />

the particular needs of each patient<br />

and make appropriate adjustments<br />

when and as required. A workshop<br />

training is required prior to first<br />

surgery.<br />

See package insert (L22000007) for<br />

a complete list of potential adverse<br />

effects, contraindications, warnings<br />

and precautions. The surgeon must<br />

discuss all relevant risks, including the<br />

finite lifetime of the device, with the<br />

patient, when necessary.<br />

Warning:<br />

All bone screws referenced in<br />

this document here are not<br />

approved for screw attachment or<br />

fixation to the posterior elements<br />

(pedicles) of the cervical, thoracic<br />

or lumbar spine.<br />

1. Introduction 3<br />

2<br />

Introduction 3<br />

Features and Benefits 3<br />

Contraindications 3<br />

2. Product Description 4<br />

3. Technical Details 6<br />

Screws 6<br />

Condyle Screws 6<br />

Cannulated Screws 7<br />

Damaged Screw Head 7<br />

Broken Screws 8<br />

Plates 9<br />

Broken Cannulated Screws 10<br />

Lag Screw 11<br />

IM Nails 13<br />

Broken IM Nails 14<br />

4. Additional Information 15<br />

Hydro<strong>Set</strong> 15<br />

References 15<br />

Page<br />

Ordering Information – Instruments 16

Introduction<br />

Introduction<br />

Hardware removal occurs for<br />

four reasons:<br />

1. Elective removal.<br />

2. Removal secondary to symptoms.<br />

3. Removal for infection.<br />

4. During revision procedures.<br />

The most challenging are typically<br />

points 3 and 4 as the hardware maybe<br />

broken and / or tissue planes distorted.<br />

In addition, there is frequently no<br />

bail out because the hardware must<br />

be removed in order to revise the<br />

fixation for a non-union or to address<br />

infection.<br />

Although considered easy and<br />

straightforward by patients, hardware<br />

removal is almost always more<br />

challenging than the insertion of the<br />

implants ¹.<br />

Specialty instruments can significantly<br />

facilitate hardware removal<br />

while minimizing damage to the<br />

surrounding bone/soft-tissue. <strong>Stryker</strong><br />

has developed a comprehensive set of<br />

instruments / techniques to assist the<br />

surgeon with these challenging issues,<br />

regardless of the indication or timing.<br />

Additionally, stripped screws and<br />

stripped IM Nails proximal threads<br />

(used for removal) may rise surgical<br />

difficulty and should be treated<br />

together.<br />

<strong>Stryker</strong> <strong>Extraction</strong> System is a set<br />

of instrumentation developed to<br />

meet the surgeons need for implant<br />

extraction.<br />

The System consist of two modules<br />

for the removal of almost any <strong>Stryker</strong><br />

Trauma implant, as well as many non-<br />

<strong>Stryker</strong> plates, nails, and screws*.<br />

It has evolved from our extensive<br />

clinical experience with trauma<br />

devices, as well as from the<br />

collaboration with experienced<br />

surgeons worldwide.<br />

Module One includes<br />

instrumentation for the removal<br />

of internal fixation systems and<br />

associated screws.<br />

Conical and Spreading Tip<br />

Screwdrivers are provided in<br />

varying sizes for the safe removal<br />

of torx, hex, and cannulated<br />

screws. Nail and Lag Screw<br />

removal is facilitated through<br />

the availability of different sized<br />

Adaptors and Conical <strong>Extraction</strong><br />

Rods that are easily assembled.<br />

Module Two contains extraction<br />

instruments for the removal of<br />

stripped and / or broken screws and<br />

implants.<br />

<strong>Stryker</strong> <strong>Extraction</strong> System is a single<br />

instrument platform that can be<br />

used for various extraction methods<br />

according to each individual case,<br />

in a minimally invasive operating<br />

procedure, allowing for the removal of<br />

almost any <strong>Stryker</strong> Trauma implants.<br />

It may also be compatible with non-<br />

<strong>Stryker</strong> implants*.<br />

Since broken hardware can often<br />

be identified on preoperative<br />

radiographs, but may also be<br />

encountered unexpectedly during<br />

an operation, <strong>Stryker</strong> recommends<br />

having both modules present in the<br />

operating room to facilitate surgical<br />

procedures and to reduce operative<br />

time.<br />

* <strong>Stryker</strong> can only recommend use of the extractor instruments with its own products. Application of the<br />

instruments to competitive products or to <strong>Stryker</strong> products that have been altered may be possible but has not<br />

been validated. Where competitive products are mentioned in this document this is solely to indicate where<br />

application of the extractor instruments appears possible due to similar design or dimensions, and <strong>Stryker</strong> does<br />

not guarantee that the extractor instruments demonstrated herein will work in any cases where competitive<br />

products are used, or in cases where <strong>Stryker</strong> products have been altered. As a precaution, make sure to have<br />

other standard instruments available in case the tolerances of the implants do not match the tolerances of the<br />

extractor tool.<br />

1. J Am Acad Orthop Surg 2006;14:113-120 Hardware Removal: Indications and Expectations<br />

Matthew L. Busam, MD, Robert J. Esther, MD, MSc, William T. Obremskey, MD,<br />

3<br />

Features and<br />

Benefits<br />

Versatility:<br />

• Removal of standard, broken<br />

and / or stripped nails, plates<br />

and screws<br />

• Multiple extraction methods<br />

Universal Instruments<br />

• Compatible for use with other<br />

manufactures’ implants*<br />

Single Instrument Platform<br />

• Simplified surgical technique<br />

Contraindications<br />

Cold welded screws require cutting<br />

tools for metal to remove the screws.<br />

The extraction set does not feature<br />

carbide drills or other cutting tools to<br />

remove cold welded screws.<br />

Screws<br />

Lag Screw<br />

Nails<br />

Hydro<strong>Set</strong><br />

Instruments

Product Description<br />

Article <strong>Stryker</strong> Systems<br />

Teardrop handle, AO-medium For AO medium bits:<br />

- Screwdriver bits<br />

- Crowndrills (Trephines)<br />

- Conical extractors male/female<br />

Screwdriver Bit 2.5 (conical) For 2.5mm Hex Screws:<br />

T2 Hum Compression; Asnis III 4.0;<br />

Numelock 4.5; ISO 2.7;<br />

ISO 3.5; ISO 4.0<br />

Screwdriver Bit 3.5 (conical) For 3.5mm Hex Screws:<br />

4 and 5mm Locking Screws (T2, S2, Gamma3, IC etc.);<br />

T2/S2 End Caps; T2/S2 Fem/Tib Compr. Screws;<br />

TLN all Screws; T2 Recon <strong>Set</strong> Screws 3.7 and 4.6mm Locking Screws G&K;<br />

Asnis III 5.0;<br />

Numelock 6.5; ISO 4.5; ISO 6.5<br />

Screwdriver Bit 4 (conical) <strong>Set</strong> Screws for Gamma, Gamma3, Gamma Ti, Dyax-A, AP, AP-J;<br />

Proximal Plugs for Gamma, Gamma Ti, Dyax, Dyax-A, AP, AP-J<br />

Screwdriver Bit 5 For 5mm Hex Screws:<br />

6.28mm Locking Screws; Asnis III 6.5 and 8.0<br />

and T2/S2 Recon Lag Screws<br />

Screwdriver Bit 6.3 For 6.3mm Hex Screws: T2/S2 Condyle Screws<br />

Screwdriver Bit 8 G&K SCN Condyle Screws; Gamma3 End Caps<br />

Screwdriver Bit T 8 (Torx) AxSOS 3.0<br />

Screwdriver Bit T 15 (Torx) AxSOS 4.0<br />

Screwdriver Bit T 20 (Torx) ALTA 3.7mm Locking Screws; AxSOS 5.0<br />

Screwdriver Bit T 25 (Torx) ALTA 5mm Locking Screws, Lag Screws and Caps<br />

Conical Extractor, male, left hand, small<br />

Asnis III 4.0<br />

(left hand driving) for diameter range 1–2.5mm<br />

Conical Extractor, male, left hand, 2.5<br />

(left hand driving, for damaged hex 2.5mm<br />

and diameter range 2.3–4mm)<br />

Conical Extractor, male, left hand, 3.5<br />

(left hand driving, for damaged hex 3.5mm and<br />

diameter range 3.3–4mm)<br />

Conical Extractor, male, left hand, 4<br />

(left hand driving, for damaged hex 4mm and<br />

diameter range 3.8–4.4mm)<br />

Conical Extractor, male, left hand, 5<br />

(left hand driving, for damaged hex 5mm and<br />

diameter range 4.8–5.4mm)<br />

Crowndrill 3 (bonedrill for broken Screws with<br />

diameter range =< 3mm)<br />

Crowndrill 4 (bonedrill for broken Screws with<br />

diameter range =< 4mm)<br />

Crowndrill 5 (bonedrill for broken Screws with<br />

diameter range =< 5mm)<br />

Crowndrill 6.5 (bonedrill for broken Screws with<br />

diameter range =< 6.5mm)<br />

Crowndrill 8 (bonedrill for broken Screws with<br />

diameter range =< 8mm)<br />

Crowndrill 10 (bonedrill for broken Screws with<br />

diameter range =< 10mm)<br />

Crowndrill 12 (bonedrill for broken Screws with<br />

diameter range =< 12mm)<br />

Conical Extractor, female, left hand, 3<br />

(left hand driving, for broken Screws with diameter<br />

range =

Product Description<br />

Article <strong>Stryker</strong> Systems<br />

Teardrop handle, AO-medium, cannulated<br />

(including Rotation Rod)<br />

for AO medium bits:<br />

Spreading Screwdriver<br />

Spreading Screwdriver Bit 5 6.28mm Locking Screws; Asnis III 6.5 and 8.0<br />

and T2/S2 Recon Lag Screws<br />

Spreading Screwdriver Bit 6.3 T2/S2 Condyle Screws<br />

Spreading Screwdriver Bit 8 G&K SCN Condyle Screws; Gamma3 End Caps<br />

Punches 2.7 for broken Screws with diameter range =4mm<br />

Forceps, small for damaged Screws, broken Screws with diameter 9mm<br />

Conical <strong>Extraction</strong> Rod 6 <strong>Extraction</strong> of nails using proximal Nail End:<br />

T2 Humeral<br />

Conical <strong>Extraction</strong> Rod 8 <strong>Extraction</strong> of nails using proximal Nail End:<br />

Humerus Seidel, T2 Proximal Humeral, T2 Humeral, Alta Humeral,<br />

TLN (M7),SCN (M8), Alta Femoral & Tibial, Zickel, IC Femoral & Tibial,<br />

T2/S2 Tibial & Femoral Antegrade/Retrograde<br />

Conical <strong>Extraction</strong> Rod 10 <strong>Extraction</strong> of nails for the proxmal Nail End:<br />

Gamma3, Dyax-A, all G&K Nails (Fem, Tib, SFN, STN, SCN)<br />

Conical <strong>Extraction</strong> Rod 13 <strong>Extraction</strong> of nails using proximal Nail End:<br />

Gamma, Gamma Ti, Dyax, AP, AP-J<br />

<strong>Extraction</strong> Hook, small <strong>Extraction</strong> of cannulated nails with inner diameter 4.6–5.5mm:<br />

G&K, Gamma3 (Ti), Seidel, IC, SCN, TLN, T2/S2<br />

<strong>Extraction</strong> Hook, large <strong>Extraction</strong> of cannulated nails with inner diameter =>5.6mm:<br />

Gamma, Gamma3 (StSt), Dyax, Dyax-A, AP, AP-J, G&K, IC,<br />

SCN, Kuentscher Nails<br />

<strong>Extraction</strong> Instrument Lag Screw Consisting of Handle and <strong>Extraction</strong> Rod.<br />

To be used with the threaded rod and nut for the Lag screw extraction<br />

Nut Fastens the <strong>Extraction</strong> Rod to the threaded rods and Connectors<br />

Threaded Rod M7 Threaded into Lag screw (Gamma/Dyax-A), fastens connection between<br />

<strong>Extraction</strong> Rod and Connectors<br />

Threaded Rod M5 Threaded into Lag screw (Omega), fastens connection between <strong>Extraction</strong> Rod<br />

and Connectors<br />

Threaded Rod M4 Threaded into Lag screw (OHS/OCS), fastens connection between <strong>Extraction</strong><br />

Rod and Connectors<br />

Spanner SW17<br />

Connector, Gamma<br />

Connector, Gamma U-Blade<br />

Connector, Gamma3 U-Blade<br />

Serves for larger torque transmission of the <strong>Extraction</strong> Instrument Lag Screw<br />

Connector, Dyax-A<br />

Connector, Gamma3<br />

Connector, Omega and Omega plus<br />

Connector, OHS/OCS<br />

Fits onto the specific Lag Screws, over the threaded Rod, and connects<br />

with the <strong>Extraction</strong> Instrument Lag Screw<br />

Sharp Hook (Optional) Removes from bone material<br />

Osteotome (Optional) Removes from bone material<br />

Outer Introducer (Optional) Hansson Pin<br />

Inner Introducer (Optional) Hansson Pin<br />

Extractor (Optional) Hansson Pin<br />

Emergency Inner Extractor (Optional) Hansson Pin<br />

Extractor Handle (Optional) Hansson Twin Hook<br />

Outer Extractor (Optional) Hansson Twin Hook<br />

Inner Extractor (Optional) Hansson Twin Hook<br />

T-Handle, AO-medium (Optional) for AO medium bits: Screwdriver–Screw removal, conical - Crowndrill -<br />

Screw extraction, conical<br />

Screwdriver 2.5 Seidel Humerus Spreading Screw (Standard Seidel instrument)<br />

Caution:<br />

<strong>Implant</strong>s can be subject to change. This can impact the compatibility of extraction<br />

instruments. It is therefore required to start the implant extraction with a complete<br />

<strong>Extraction</strong> <strong>Set</strong> in order to have access to alternative instruments.<br />

5

Screws<br />

Technical Details<br />

Screws<br />

After identifying screw type and<br />

diameter, extract the screws with the<br />

appropriate screwdriver bit by turning<br />

the screwdriver counterclockwise.<br />

To avoid damaging the screw, make<br />

sure the screwdriver is in line with the<br />

screw axis and fully inserted.<br />

Condyle Screws<br />

For T2/S2 Condyle Screw removal,<br />

assemble the necessary screwdrivers:<br />

The 6.3hex Screwdriver Bit<br />

with the Solid Teardrop Handle<br />

(for the nut) and the 6.3hex<br />

Spreading Screwdriver bit with<br />

the Cannulated Teardrop Handle<br />

(in combination with the Rotation<br />

Rod) as shown in the illustration.<br />

6<br />

Screwdriver Bits (hex)<br />

Screwdriver Bits (torx)<br />

Solid Teardrop<br />

Handle<br />

Screwdriver Bit<br />

Solid Teardrop Handle<br />

Spreading Screwdriver Bit<br />

Teardrop Handle (cannulated)<br />

Rotation Rod<br />

Partially threaded screw removal<br />

(e.g. Asnis III screws, T2 Recon<br />

Lag Screws) is facilitated by<br />

using the spreading screwdriver<br />

bits and cannulated handle.<br />

For spreading screwdriver<br />

instructions see Condyle<br />

Screw removal below.<br />

<strong>Stryker</strong> offers a wide variety of<br />

hex (standard, conical, spreading)<br />

and torx screwdrivers. Check the<br />

available type and size on the<br />

Ordering Information page.<br />

Make sure to tighten the Rotation<br />

Rod until the tip of the screwdriver<br />

spreads firmly and fully into the<br />

screw head.<br />

A screwdriver needs to be inserted<br />

from each side of the Condyle Screw<br />

using one to stabilize the Nut and the<br />

Spreading Screwdriver to loosen and<br />

extract the Condyle Screw.<br />

If necessary, use the Spreading<br />

Screwdriver to remove the Nut in a<br />

second step.<br />

The Condyle Screw is extracted<br />

by turning the Screwdriver in a<br />

counterclockwise direction.

Technical Details<br />

Cannulated Screws<br />

Never use a worn or damaged<br />

screwdriver to remove Asnis screws.<br />

Reverse cutting flutes are present for<br />

this reason. It is recommended that the<br />

Solid Screwdriver be used for Screw<br />

removal. The Solid Screwdriver applies<br />

greater torque and will reduce the<br />

potential for damaging the hexagonal<br />

tip on the Screwdriver. Strong bone<br />

formation around the implant has<br />

been seen in the pediatric cases<br />

using partially threaded screws.<br />

Damaged Screw Head<br />

Screw stripping is commonly<br />

caused by slippage of a screwdriver<br />

that is not correctly aligned with<br />

the screw axis and/or fully seated.<br />

This can occur either during<br />

insertion or, more commonly,<br />

during attempted screw removal.<br />

The appropriate sized Conical<br />

Extractor (based on the size of the<br />

Spreading Screwdriver<br />

Bit<br />

Solid Teardrop Handle<br />

Screwdriver Bits (hex)<br />

Teardrop Handle (cannulated)<br />

Rotation Rod<br />

Conical Extractor (male)<br />

Solid Teardrop Handle<br />

Forceps for Screw Removal<br />

Slotted Hammer<br />

7<br />

This may lead to difficult implant<br />

removal with an increased risk of<br />

screw head breakage or stripping<br />

of screw hexagonal head.<br />

If the oblique direction of the screw<br />

(approximately 135° to the shaft) is<br />

not changed, then the reverse flutes<br />

are not in an opportune position<br />

to cut the cortex. If the screw head<br />

is placed under traction and the<br />

angle of the screw is brought to a<br />

perpendicular position relative to<br />

the bone, cutting the cortex will<br />

progress and facilitate screw removal.<br />

Caution:<br />

Be sure to use the Solid<br />

Screwdriver in combination with<br />

the appropriate sized screwdriver<br />

bits or the cannulated screwdriver<br />

with the Spreading Screwdriver<br />

Bits. Proceed as described above.<br />

screw head hex / torx) is inserted<br />

firmly into the screw head.<br />

Lightly tapping the Conical Extractor<br />

with a Slotted Hammer may be<br />

tried if purchase is not initially<br />

obtained with manual pressure. It<br />

is at the surgeons’ discretion if and<br />

how hard to use the hammer.<br />

Assemble the selected Conical Extractor<br />

(male) with the Teardop- Handle<br />

and turn it counter-clockwise while<br />

applying pressure in line with the<br />

screw axis, extracting the screw at the<br />

same time. If the screw does not come<br />

completely out, the Foreceps can be<br />

used to complete the extraction.<br />

Screws

Screws<br />

Technical Details<br />

Broken Screws<br />

In case of a Broken Screw Shaft:<br />

Step 1:<br />

Remove the screw head portion in<br />

order to gain access to the remaining<br />

part of the screw shaft. The screw head<br />

can be removed with the appropriate<br />

screwdriver as described on page 6.<br />

Step 2:<br />

Use the Drift Punch to extract the<br />

remaining part of the screw.<br />

If difficulties are encountered with<br />

the above process, overdrill the<br />

remaining part of the screw with<br />

a Crowndrill before proceeding<br />

with the Drift Punch.<br />

Broken screw shaft - Step 1<br />

Torn-off screw head - Step 1<br />

In case of a Torn off Screw Head:<br />

Step 1:<br />

Overdrill the remaining part of the<br />

screw with a Crowndrill.<br />

Use another Crowndrill, one size<br />

larger, in order to create space for<br />

the female Conical Extractor/Drift<br />

Punch. It may be necessary to start<br />

with light pressure on the crowndrill<br />

in order to avoid the drill walking<br />

on the cortex surface before applying<br />

additional pressure to penetrate the<br />

bone. Light tapping with the Slotted<br />

Hammer may be required. It remains<br />

at the surgeons` own discretion if and<br />

how hard to use the Slotted Hammer.<br />

8<br />

Broke screw shaft - Step 2<br />

Torn-off screw head - Step 2<br />

Alternatively, the optional Countersink<br />

(6 or 8mm) can be used to create a<br />

path for the Crowndrill.<br />

Step 2:<br />

Remove the remaining part of the<br />

screw with the Conical Extractor,<br />

(female) if the screw is broken close<br />

to the first cortex or with the help of<br />

a Drift Punch if the screw is broken<br />

close to the second cortex.<br />

This procedures can also be applied to<br />

broken IM locking screws.<br />

Screwdriver Bit<br />

Crowndrill<br />

(Trephine)<br />

Drift Punches<br />

Slotted Hammer<br />

Forceps for<br />

Screw Removal<br />

Conical Extractor<br />

(female)<br />

Solid<br />

Teardrop<br />

Handle

Technical Details<br />

Plates<br />

To remove any plate, first extract<br />

all screws by using the appropriate<br />

size Screwdriver Bits. Remove the<br />

plate by using a regular forceps.<br />

The development of locking plate<br />

technology has lead to “cold welding”<br />

of screws to the plates. In this case,<br />

cutting tools for metal have to be used<br />

for the removal of the screws. In order<br />

to protect the soft tissue from excessive<br />

heat and metal debris accumulation,<br />

irrigation and suction should be used<br />

in combination with cutting tools.<br />

Warning:<br />

If screws are cold welded to<br />

the plate, carbide drills may be<br />

required. The extraction set<br />

does not feature carbide drills<br />

or any other instruments to<br />

remove cold welded screws.<br />

Solid Teardrop<br />

Handle<br />

Screwdriver Bit<br />

9<br />

Crowndrill<br />

(Trephine)<br />

Solid Teardrop<br />

Handle<br />

Forceps<br />

Screws

Screws<br />

Technical Details<br />

Broken Cannulated Screws<br />

To remove the torn-off head:<br />

Step 1:<br />

Select the appropriate Spreading<br />

Screwdriver Bit. Attach Cannulated<br />

Teardrop Handle. Insert Rotation<br />

Rod through the top of the Teardrop<br />

Handle. Insert tip into the screw head<br />

and turn Rotation Rod to engage and<br />

remove screw head.<br />

To remove remaining screw body<br />

(parts):<br />

Step 2:<br />

Insert the Conical Extractor (male)<br />

and extract the remaining screw<br />

body turning the Conical Extractor<br />

in a counter-clockwise fashion.<br />

Cannulated Screw Removal - Method A - Step 1<br />

Cannulated Screw Removal - Method B - Step 1<br />

Spreading<br />

Screwdriver Bit<br />

Conical Extractor<br />

(male)<br />

Teardrop Handle<br />

(cannulated)<br />

10<br />

Crowndrill<br />

(Trephine)<br />

Conical Extractor<br />

(female)<br />

Rotation<br />

Rod<br />

If Steps 1 and 2 are unsuccessfully<br />

for screw removal:<br />

Step 3:<br />

Overdrill the shaft using the<br />

Crowndrill.<br />

Cannulated Screw Removal - Method A - Step 2<br />

Cannulated Screw Removal - Method B - Step 2<br />

Step 4:<br />

Use a Conical Extractor (female) for<br />

screw removal.<br />

If the attempt for screw removal is<br />

not successful, follow the standard<br />

procedure for broken screw removal<br />

describes on page 8.

Technical Details<br />

Lag Screw<br />

An incision is made over the proximal<br />

end of the nail.<br />

The End Cap, if used, is removed<br />

using the appropriate Screwdriver Bit<br />

followed by removal of the <strong>Set</strong> Screw<br />

using the 4.0mm Screwdriver as shown<br />

in the image below 1 .<br />

1<br />

Screwdriver Bit 4.0mm<br />

Threaded Rod<br />

Solid Teardrop Handle<br />

11<br />

Make a small incision through the old<br />

scar distal to the greater trochanter to<br />

expose the end of the Lag Screw.<br />

The Threaded Rod is then threaded<br />

and tightened into the end of the Lag<br />

Screw 2 .<br />

For Gamma <strong>Implant</strong>s:<br />

At first, position the K-Wire through<br />

the Lag Screw.<br />

Then, the Threaded Rod is inserted<br />

over the K-Wire (when used for<br />

Gamma) and tightened into the end of<br />

the Lag Screw.<br />

Remove the K-Wire, if used.<br />

2<br />

Lag Screw

Lag Screw<br />

Technical Details<br />

Lag Screw (continued)<br />

3<br />

6<br />

5<br />

4<br />

12<br />

Connector<br />

Threaded Rod<br />

<strong>Extraction</strong> Rod and Nut<br />

Wrench 8/10mm,<br />

standard<br />

Handle<br />

Spanner 17mm standard<br />

Check that ingrowth does not obstruct<br />

secure engagement of the <strong>Extraction</strong><br />

Device, otherwise the implant or the<br />

instrument may be damaged and<br />

extraction will be more difficult.<br />

Slide the appropriate Connector over<br />

the Threaded Rod before adding the<br />

<strong>Extraction</strong> Rod & Nut as shown in the<br />

picture 3 .<br />

Note:<br />

In this Technical Guide the<br />

Gamma3 Lag Screw is selected as<br />

an example to demonstrate Lag<br />

Screw removal.<br />

However, different Connectors<br />

are available for other implants<br />

including a Lag Screw. See details<br />

on the ordering information page.<br />

Finish assembly of the Lag Screw<br />

<strong>Extraction</strong> Device by tightening the<br />

Nut 4 and attaching the T-Handle 5<br />

in a final step as shown in the picture.<br />

The Lag Screw is extracted by turning<br />

counterclockwise direction 6 .<br />

Use the 17mm Spanner if<br />

higher forces are required for the<br />

removal of the Lag Screw.

Technical Details<br />

IM Nails<br />

When removing an IM nail,<br />

it is helpful to identify the<br />

nail brand and its diameter<br />

in order to choose the<br />

correct instrumentation.<br />

Step 1 Step 2<br />

Conical <strong>Extraction</strong> Rod<br />

Universal Rod<br />

Strike Plate<br />

Sliding Hammer<br />

Slotted Hammer<br />

Universal Rod<br />

Sliding<br />

Hammer<br />

or use the<br />

Slotted<br />

Hammer<br />

Strike Plate<br />

Conical<br />

<strong>Extraction</strong> Rod<br />

13<br />

Caution:<br />

Special care must be taken to<br />

check if the nail moves offcenter<br />

from the entry point<br />

when screws are removed.<br />

Any attempt to remove a<br />

nail that is off-center may<br />

result in fractures of the<br />

distal condylar region.<br />

The End Cap, if used, is removed<br />

using a Screwdriver. If bone<br />

ingrowth obstructs access to the<br />

nail, use of either a Crowndrill,<br />

pick (not supplied), or currette (not<br />

supplied) may provide access.<br />

Remove the distal/proximal screw<br />

with the appropriate Screwdriver<br />

Bit. Do not take out the screws of<br />

the driving end until the Conical<br />

<strong>Extraction</strong> Rod is attached to the top<br />

of the nail in order to avoid rotation.<br />

Insert the Conical <strong>Extraction</strong> Rod<br />

into the driving end of the nail.<br />

Lightly hammer the Conical<br />

Extractor in order to fully<br />

engage the cutting flutes.<br />

Connect the Strike Plate and<br />

the Universal Rod either adding<br />

the Sliding or Slotted Hammer<br />

as shown in the picture.<br />

Remove now the remaining<br />

locking screws before using either<br />

Hammer to remove the nail.<br />

Nails

Nails<br />

Technical Details<br />

Broken IM Nails<br />

Removal of broken IM nails<br />

is particularly challenging.<br />

<strong>Stryker</strong> developed a system that<br />

can be used for the removal of<br />

many cannulated IM nails.<br />

Remove the distal screw with the<br />

appropriate Screwdriver Bit. Do<br />

not take out the proximal screws<br />

until you have attached the Conical<br />

<strong>Extraction</strong> Rod to the top of the<br />

nail in order to avoid rotation.<br />

Broken IM Nails -<br />

Step 1<br />

Broken IM Nails -<br />

Step 2<br />

14<br />

Conical <strong>Extraction</strong> Rod<br />

Universal Rod<br />

Sliding Hammer<br />

Strike Plate<br />

<strong>Extraction</strong> Hook<br />

Universal Rod<br />

Sliding<br />

Hammer<br />

Strike Plate<br />

<strong>Extraction</strong> Hook<br />

Broken IM Nails -<br />

Step 3<br />

An incision is made over the proximal<br />

end of the nail. The End Cap, if used,<br />

is removed using a Screwdriver.<br />

If bone ingrowth obstructs the<br />

access to the nail, the use of either<br />

a Chisel / Pick (not provided) or a<br />

Crowndrill will facilitate removal.<br />

Connect the Universal Rod and the<br />

Strike Plate to the <strong>Extraction</strong> Rod<br />

(center of page) either adding the<br />

Sliding or the Slotted Hammer.<br />

Step 1:<br />

Insert the nail <strong>Extraction</strong> Device<br />

into the proximal end of the nail,<br />

tightening it as firm as possible.<br />

Remove the proximal screws<br />

before using either Hammer<br />

to remove the nail end.<br />

Step 2:<br />

After removal of the proximal nail end,<br />

exchange the Conical <strong>Extraction</strong> Rod<br />

for the <strong>Extraction</strong> Hook (as shown to<br />

the left). Insert <strong>Extraction</strong> Hook into<br />

the cannulation of the nail fragment.<br />

Step 3:<br />

Under fluoroscopy, verify that the<br />

Hook has passed through the nail end.<br />

Make sure that the Hook takes<br />

a hold at the end of the nail<br />

before pulling to remove it.<br />

Step 4:<br />

Use the Sliding or the Slotted<br />

Hammer to pull out the<br />

remaining part of the nail.<br />

Broken IM Nails -<br />

Step 4

Additional Information<br />

Hydro<strong>Set</strong><br />

Hydro<strong>Set</strong> is an injectible self-setting<br />

calcium phosphate cement indicated<br />

to fill bony voids or gaps of the<br />

skeletal system (i.e. extremities,<br />

craniofacial, spine, and pelvis).<br />

These defects may be surgically<br />

created or osseous defects created<br />

from traumatic injury to the bone.<br />

Hydro<strong>Set</strong> is indicated only for bony<br />

voids or gaps that are not intrinsic to<br />

the stability of the bony structure.<br />

Hydro<strong>Set</strong> cured in situ provides<br />

an open void/gap filler that can<br />

augment provisional hardware<br />

(e.g. K-Wires, Plates, Screws) to<br />

help support bone fragments during<br />

the surgical procedure. The cured<br />

cement acts only as a temporary<br />

support media and is not intended<br />

to provide structural support<br />

during the healing process.<br />

Carefully read the IFU, the specific<br />

indications and the contraindications.<br />

REF Description<br />

397003 Hydro<strong>Set</strong> 3cc<br />

397005 Hydro<strong>Set</strong> 5cc<br />

397010 Hydro<strong>Set</strong> 10cc<br />

397015 Hydro<strong>Set</strong> 15cc<br />

References<br />

J Am Acad Orthop Surg 2006;<br />

14:113- 120 Hardware Removal: Indications and Expectations<br />

Matthew L. Busam, MD, Robert J. Esther, MD, MSc,<br />

William T. Obremskey, MD<br />

15<br />

Hydro<strong>Set</strong>

Instruments<br />

Ordering Information - Instruments<br />

REF Description<br />

1806-6150 Tray Module 1 (Generic Sterilization and Storage Tray)<br />

1806-6152 Module 1 Fully loaded<br />

Universal Screw <strong>Extraction</strong> Devices<br />

1806-6106 Screwdriver Bits conical, hex. 2.5mm<br />

1806-6108 Screwdriver Bits conical, hex. 3.5mm<br />

1806-6110 Screwdriver Bits conical, hex. 4.0mm<br />

1806-6112 Screwdriver Bits, hex. 5.0mm<br />

1806-6114 Screwdriver Bits, hex. 6.3mm<br />

1806-6116 Screwdriver Bits, hex. 8.0mm<br />

1806-6118 Screwdriver Bits, Torx T 8.0<br />

1806-6119 Screwdriver Bits, Torx T 15.0<br />

1806-6120 Screwdriver Bits, Torx T 20.0<br />

1806-6121 Screwdriver Bits, Torx T 25.0<br />

1806-6113 Spreading Screwdriver Bit, hex. 5.0mm<br />

1806-6115 Spreading Screwdriver Bit, hex. 6.3mm<br />

1806-6117 Spreading Screwdriver Bit, hex. 8.0mm<br />

1806-6102 Teardrop Handle, solid<br />

1806-6104 Cannulated Teardrop Handle<br />

Rotation Rod used with Cannulated Teardrop Handle<br />

Universal Nail <strong>Extraction</strong> Device<br />

1806-0353 Conical <strong>Extraction</strong> Rod, standard 6mm<br />

1806-0350 Conical <strong>Extraction</strong> Rod, standard 7/8mm<br />

1806-6125 Conical <strong>Extraction</strong> Rod, 10mm<br />

1806-6130 Conical <strong>Extraction</strong> Rod, male, 13mm<br />

1806-0130 Wrench 8 /10mm, standard<br />

1806-0150 Strike Plate, standard<br />

1806-6100 Sliding Hammer<br />

1806-0110 Universal Rod<br />

1806-0170 Slotted Hammer, standard<br />

Universal Lag Screw <strong>Extraction</strong> Device<br />

1806-6140 Connector Gamma<br />

1806-6141 Connector Gamma U-Blade<br />

1806-6142 Connector Gamma3 U-Blade<br />

1806-6144 Connector Gamma3<br />

1806-6143 Connector Dyax-Asiatic<br />

1806-6146 Connector Omega<br />

1806-6148 Connector OHS /OCS<br />

16<br />

1806-6136 Threaded Rod Gamma etc.<br />

1806-6137 Threaded Rod Omega<br />

1806-6138 Threaded Rod OHS /OCS<br />

1114-5002 Spanner 17mm standard<br />

1806-6135 <strong>Extraction</strong> Instrument Lag Screw<br />

1806-6139 Nut

Ordering Information - Instruments<br />

REF Description<br />

Universal Emergency Screw <strong>Extraction</strong> Devices<br />

1806-6151 Tray Module 2 (Generic Sterilization and Storage Tray)<br />

1806-6153 Module 2 Fully Loaded<br />

1806-6169 Conical Extractor, male, small<br />

1806-6170 Conical Extractor, male, 2.5mm<br />

1806-6171 Conical Extractor, male, 3.5mm<br />

1806-6172 Conical Extractor, male, 4.0mm<br />

1806-6173 Conical Extractor, male, 5.0mm<br />

1806-6165 Crowndrill (Trephine), 3.0mm<br />

1806-6166 Crowndrill (Trephine), 4.0mm<br />

1806-6167 Crowndrill (Trephine), 5.0mm<br />

1806-6168 Crowndrill (Trephine), 6.5mm<br />

1806-6180 Crowndrill (Trephine), 8.0mm<br />

1806-6181 Crowndrill (Trephine), 10.0mm<br />

1806-6182 Crowndrill (Trephine), 12.0mm<br />

1806-6183 Conical Extractor, female, 3.0mm<br />

1806-6184 Conical Extractor, female, 4.0mm<br />

1806-6185 Conical Extractor, female, 5.0mm<br />

1806-6186 Conical Extractor, female, 6.3mm<br />

1806-6175 Drift Punch, 2.7mm<br />

1806-6176 Drift Punch, 3.7mm<br />

1806-6177 Drift Punch, 5.0mm<br />

1806-6102 Teardrop Handle, solid<br />

1806-6160 <strong>Extraction</strong> Hook (can also be stored in Module 1), small<br />

1806-6162 <strong>Extraction</strong> Hook (can also be stored in Module 1), large<br />

1806-6178 Forceps for Screw Removal, small<br />

1806-6179 Forceps for Screw Removal, large<br />

Optional Instruments Module 1 & 2<br />

700151 Sharp Hook, Removal from bone material<br />

700225 Osteotome, Removal from bone material<br />

702811 Countersink 6mm, Preparing the cortex<br />

702812 Countersink 8mm, Preparing the cortex<br />

704515 Outer Introducer, Hansson Pin<br />

704516 Inner Introducer, Hansson Pin<br />

704518 Extractor, Hansson Pin<br />

704540 Emergency Inner Extractor, Hansson Pin<br />

704607 Extractor Handle, Hansson Twin Hook<br />

704608 Outer Extractor, Hansson Twin Hook<br />

704609 Inner Extractor, Hansson Twin Hook<br />

702628 T-Handle, AO-medium, for AO medium bits:<br />

screwdriver - screw removal, conical - crowndrill - screw extraction, conical<br />

0106-3043 Screwdriver 2.5, Seidel Humerus Spreading Screw<br />

1806-6206 Gamma3 U-Blade Extractor<br />

* Please ask your <strong>Stryker</strong> sales representative for further information.<br />

17<br />

Instruments

Notes<br />

18

Notes<br />

19

This document is intended solely for the use of healthcare professionals. A surgeon must always rely on his or her<br />

own professional clinical judgment when deciding whether to use a particular product when treating a particular<br />

patient. <strong>Stryker</strong> does not dispense medical advice and recommends that surgeons be trained in the use of any<br />

particular product before using it in surgery. The information presented in this brochure is intended to demonstrate a<br />

<strong>Stryker</strong> product. Always refer to the package insert, product label and/or user instructions including the instructions<br />

for Cleaning and Sterilization (if applicable) before using any <strong>Stryker</strong> products. Products may not be available in all<br />

markets. Product availability is subject to the regulatory or medical practices that govern individual markets. Please<br />

contact your <strong>Stryker</strong> representative if you have questions about the availability of <strong>Stryker</strong> products in your area.<br />

<strong>Stryker</strong> Corporation or its divisions or other corporate affiliated entities own, use or have applied for the following<br />

trademarks or service marks: <strong>Stryker</strong>, Alta, Asnis, AxSOS, G&K, Gamma, IC Nails, Küntscher Nails, Numelock,<br />

OHS&OCS, S2, SCN, Seidel, T2, TLN, Zickel.<br />

All other trademarks are trademarks of their respective owners or holders.<br />

The products listed above are CE marked.<br />

Swemac Orthopaedics AB owns the following trademark: Hansson.<br />

Wacker-Chemie GmbH owns the following trademark: Elastosil.<br />

Literature Number : B1000057<br />

LOT D4809<br />

Copyright © 2009 <strong>Stryker</strong><br />

<strong>Stryker</strong> Trauma GmbH<br />

Prof.-Küntscher-Strasse 1–5<br />

D - 24232 Schönkirchen<br />

Germany<br />

www.osteosynthesis.stryker.com