Router Fluting Jig Instructions - Rockler.com

Router Fluting Jig Instructions - Rockler.com

Router Fluting Jig Instructions - Rockler.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

8<br />

7<br />

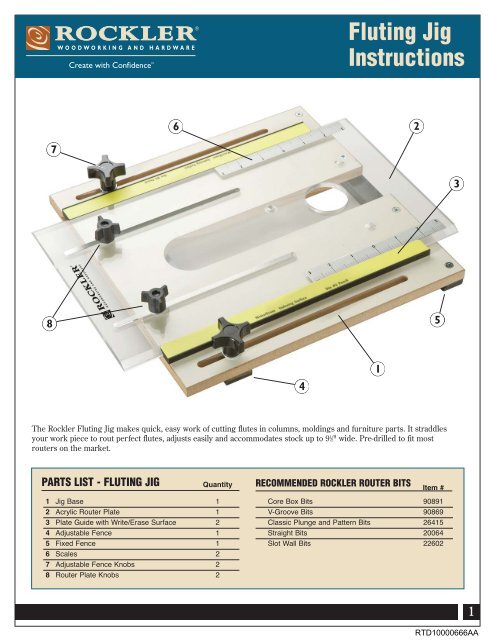

<strong>Fluting</strong> <strong>Jig</strong><br />

<strong>Instructions</strong><br />

The <strong>Rockler</strong> <strong>Fluting</strong> <strong>Jig</strong> makes quick, easy work of cutting flutes in columns, moldings and furniture parts. It straddles<br />

your work piece to rout perfect flutes, adjusts easily and ac<strong>com</strong>modates stock up to 9 1 ⁄2" wide. Pre-drilled to fit most<br />

routers on the market.<br />

PARTS LIST - FLUTING JIG<br />

Quantity<br />

1 <strong>Jig</strong> Base 1<br />

2 Acrylic <strong>Router</strong> Plate 1<br />

3 Plate Guide with Write/Erase Surface 2<br />

4 Adjustable Fence 1<br />

5 Fixed Fence 1<br />

6 Scales 2<br />

7 Adjustable Fence Knobs 2<br />

8 <strong>Router</strong> Plate Knobs 2<br />

6<br />

4<br />

RECOMMENDED ROCKLER ROUTER BITS<br />

5<br />

Item #<br />

Core Box Bits 90891<br />

V-Groove Bits 90869<br />

Classic Plunge and Pattern Bits 26415<br />

Straight Bits 20064<br />

Slot Wall Bits 22602<br />

1<br />

2<br />

3<br />

1<br />

RTD10000666AA

Fig. 1 Fig. 2<br />

Rev 5/09<br />

3<br />

Set Up <strong>Instructions</strong>:<br />

Distributed by <strong>Rockler</strong> Companies, Inc.<br />

©2009 <strong>Rockler</strong> Woodworking and Hardware<br />

1 1 ⁄2"<br />

1. Identify the distance from the center of the first flute to the<br />

edge of the work piece. Then adjust the acrylic router<br />

plate (Part 2) so this measurement lines up with the end of<br />

the yellow write/erase marking surface (Part 3). Fig. 1.<br />

2. Then using a pencil, mark the yellow write/erase (Part 3)<br />

marking surface at the ‘0’ mark for the first flute.<br />

3. To mark the second flute, measure to the left of ‘0’ on the<br />

scale the distance equal to the spacing between flutes and<br />

make a mark. Fig. 1.<br />

4. Move the acrylic router plate (Part 2) so the ‘0’ mark lines<br />

up with the second tic mark, and measure to the left of ‘0’<br />

on the scale the distance equal to the spacing between<br />

flutes and make a mark. Fig. 2.<br />

5. Repeat step 4 until all flutes are marked on the yellow<br />

write/erase surface (Part 3).<br />

6. Attach your router to the acrylic router plate (Part 2). You<br />

may have to drill new mounting holes depending on your<br />

router base configuration.<br />

7. Place the jig over your workpiece and adjust it to the width<br />

of your stock by moving the adjustable fence (Part 4).<br />

Tighten the fence knobs (Part 7), making sure the jig slides<br />

easily but is not loose or sloppy. The jig is adjustable for<br />

stock up to 9 1 ⁄2" wide. Fig. 3.<br />

8. Before routing the flutes, set the router bit to the desired<br />

depth of cut. Move the acrylic router plate so the ‘0’ on the<br />

scales lines up with the first tick mark on the writable<br />

marking surface, lock it in place and make the cut. Fig. 4.<br />

9. To rout the remaining flutes, once again move the acrylic<br />

router plate so ‘0’ on the scale lines up with the tick marks<br />

as shown in Fig. 5.<br />

Note: When making any kind of flute, remember to move the<br />

router in and out of the cuts quickly to prevent burning.<br />

2<br />

7<br />

Fig. 3<br />

Fig. 4<br />

Fig. 5<br />

4<br />

1st flute<br />

2nd flute<br />

28636<br />

2