Chip on Board Encapsulant Materials

Chip on Board Encapsulant Materials

Chip on Board Encapsulant Materials

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

40<br />

ASSEMBLY<br />

MATERIALS<br />

MICRO-ENCAPSULANTS<br />

(COB ENCAPSULANTS)<br />

<strong>Encapsulant</strong>s are used to provide envir<strong>on</strong>mental<br />

protecti<strong>on</strong> and add mechanical strength to<br />

wire b<strong>on</strong>ded devices. Two different applicati<strong>on</strong><br />

technologies are employed for the protective<br />

encapsulati<strong>on</strong> of wire b<strong>on</strong>ded die:<br />

<br />

a fine-tuned rheology, as the flow capabilities<br />

must allow the wires to be covered without the<br />

encapsulant flowing bey<strong>on</strong>d the chip.<br />

<br />

to limit the flow of the low viscosity fill material,<br />

allowing its use with fine pitch wire leads.<br />

Henkel’s Hysol® and Eccob<strong>on</strong>d encapsulants<br />

are available as either thermal or ultraviolet cure<br />

materials and are designed for the highest reliability<br />

in that they offer low coefficient of thermal<br />

expansi<strong>on</strong>, high glass transiti<strong>on</strong> temperature, and<br />

low i<strong>on</strong>ic c<strong>on</strong>tent. These encapsulants have been<br />

engineered to provide protecti<strong>on</strong> to wire b<strong>on</strong>ds,<br />

leads, aluminium and silic<strong>on</strong> dies from harsh<br />

envir<strong>on</strong>ments, mechanical damage and corrosi<strong>on</strong>.<br />

Formulated from epoxy, polyurethane, acrylate (UV<br />

curable) and silic<strong>on</strong>e chemistries, these systems have<br />

proven reliability for electr<strong>on</strong>ic insulati<strong>on</strong>. Henkel<br />

encapsulants offer excellent elevated temperature<br />

stability and thermal shock resistance, outstanding<br />

electrical insulati<strong>on</strong> at both room and elevated<br />

temperatures, minimal shrinkage and low stress<br />

during cure, as well as excellent chemical resistance.<br />

Our encapsulants have been designed to offer high<br />

throughput and low-cost assembly processes.<br />

ASSEMBLY<br />

MATERIALS<br />

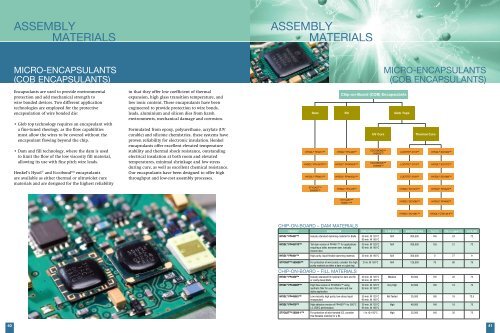

Dam Fill<br />

HYSOL ® FP4451<br />

<str<strong>on</strong>g>Chip</str<strong>on</strong>g>-<strong>on</strong>-<strong>Board</strong> (COB) <strong>Encapsulant</strong>s<br />

HYSOL ® FP4450<br />

ECCOBOND<br />

UV9052<br />

HYSOL ® HYSOL FP4450HF<br />

® FP4451TD LOCTITE ® ECCOBOND<br />

3119<br />

UV9085<br />

HYSOL ® FP6401<br />

STYCAST<br />

50500D<br />

HYSOL ® FP4450LV LOCTITE ® 3129<br />

HYSOL ® FP4470 HYSOL ® EO1016<br />

STYCAST<br />

50500-1<br />

CHIP-ON-BOARD – DAM MATERIALS<br />

MICRO-ENCAPSULANTS<br />

(COB ENCAPSULANTS)<br />

Glob Tops<br />

UV Cure Thermal Cure<br />

LOCTITE ® 3118 HYSOL ® EO1062<br />

HYSOL ® EO1060<br />

HYSOL ® EO1061<br />

HYSOL ® EO1072<br />

HYSOL ® EO1080<br />

HYSOL ® FP4323<br />

HYSOL ® FP4460<br />

HYSOL ® OT0149-3<br />

PRODUCT DESCRIPTION CURE SCHEDULES FLOW SPEED VISCOSITY (cPs) Tg (°C) CTE 1 (ppm/°C) % FILLER<br />

HYSOL ® FP4451 Industry standard damming material for BGAs. 30 min. @ 125°C<br />

90 min. @ 165°C<br />

HYSOL ® FP4451TD Tall dam versi<strong>on</strong> of FP4451 for applicati<strong>on</strong>s<br />

requiring a taller, narrower dam. I<strong>on</strong>ically<br />

cleaner also.<br />

30 min. @ 125°C<br />

90 min. @ 165°C<br />

N/A 900,000 145 24 72<br />

N/A 300,000 150 21 73<br />

HYSOL ® FP6401 High purity, liquid flexible damming material. 30 min. @ 165°C N/A 300,000 0 77 9<br />

STYCAST 50500D For protecti<strong>on</strong> of wire b<strong>on</strong>ds, c<strong>on</strong>sider this high<br />

purity material as either a dam or a glob top.<br />

CHIP-ON-BOARD – FILL MATERIALS<br />

HYSOL ® FP4450 Industry standard fill material for dam and fill<br />

or cavity down BGAs.<br />

HYSOL ® FP4450HF High flow versi<strong>on</strong> of FP4450LV using<br />

synthetic filler for use in fine wire and low<br />

alpha applicati<strong>on</strong>.<br />

HYSOL ® FP4450LV Low viscosity, high purity, low stress liquid<br />

encapsulant.<br />

HYSOL ® FP4470 High adhesi<strong>on</strong> versi<strong>on</strong> of FP4450 for 260°C<br />

L3 JEDEC performance.<br />

STYCAST 50500-1 For protecti<strong>on</strong> of wire-b<strong>on</strong>ded ICS, c<strong>on</strong>sider<br />

this flowable material for a fill.<br />

2 hrs. @ 150°C N/A 125,000 70 80 75<br />

30 min. @ 125°C<br />

90 min. @ 165°C<br />

30 min. @ 125°C<br />

90 min. @ 165°C<br />

30 min. @ 125°C<br />

90 min. @ 165°C<br />

30 min. @ 125°C<br />

90 min. @ 165°C<br />

Medium 50,000 155 22 73<br />

Very High 32,000 160 19 73<br />

Not Tested 35,000 160 18 72.5<br />

High 48,000 148 18 75<br />

1 hr. @ 150°C High 35,000 140 20 75<br />

41

42<br />

ASSEMBLY<br />

MATERIALS<br />

MICRO-ENCAPSULANTS<br />

(COB ENCAPSULANTS)<br />

GLOB TOP MATERIALS – UV CURE<br />

PRODUCT DESCRIPTION CURE SCHEDULES VISCOSITY (cPs)<br />

ECCOBOND UV9052 A <strong>on</strong>e-comp<strong>on</strong>ent, dual cure (UV<br />

& moisture) adhesive designed<br />

as a lead encapsulant.<br />

ECCOBOND UV9085 Designed as a faster curing, high<br />

thixotropic adhesive that gives<br />

good flow c<strong>on</strong>trol and adhesi<strong>on</strong><br />

for a thick b<strong>on</strong>dline.<br />

5 sec. using a<br />

300 W/in D bulb<br />

Moisture cure @<br />

ambient temperature<br />

5 sec. using a<br />

300 W/in D bulb<br />

GLOB TOP MATERIALS – THERMAL CURE<br />

Hardness after UV &<br />

Moisture Cure (Shore D)<br />

STORAGE TEMP<br />

6,400