Adhesives for the Filter Industry, LT-6471 (04/2012)

Adhesives for the Filter Industry, LT-6471 (04/2012)

Adhesives for the Filter Industry, LT-6471 (04/2012)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

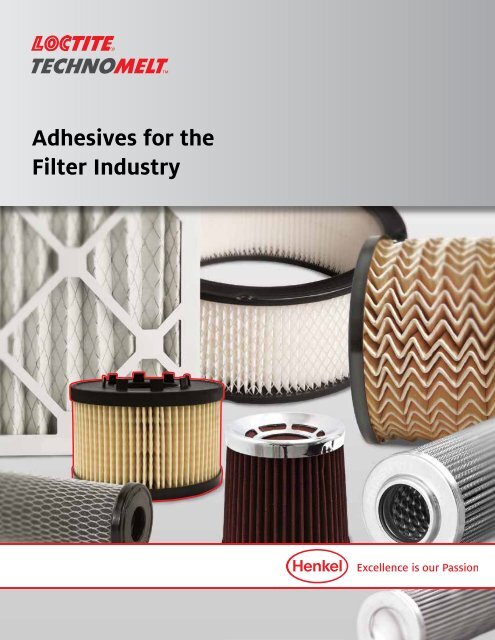

<strong>Adhesives</strong> <strong>for</strong> <strong>the</strong><br />

<strong>Filter</strong> <strong>Industry</strong>

Table of Contents<br />

<strong>Adhesives</strong> <strong>for</strong> Liquid <strong>Filter</strong> Assembly<br />

<strong>Adhesives</strong> <strong>for</strong> Industrial Air <strong>Filter</strong>s<br />

High Per<strong>for</strong>mance <strong>Adhesives</strong> <strong>for</strong> High Efficiency <strong>Filter</strong>s<br />

Process-Matched <strong>Adhesives</strong> <strong>for</strong> HVAC Air <strong>Filter</strong>s<br />

<strong>Adhesives</strong> <strong>for</strong> Water <strong>Filter</strong> Assembly<br />

Index<br />

pg.<br />

pg.<br />

pg.<br />

pg.<br />

pg.<br />

pg.<br />

3<br />

7<br />

13<br />

17<br />

21<br />

25<br />

Henkel was ranked by Forbes as one of <strong>the</strong><br />

World’s 100 Most Innovative Companies<br />

www.henkelna.com/filters

Want to Produce a Better <strong>Filter</strong> or<br />

Improve Your Manufacturing Operations?<br />

Effective filtration is becoming increasingly<br />

important in today’s world. Whe<strong>the</strong>r it’s <strong>the</strong> air<br />

inside your residence, <strong>the</strong> drinking water in an<br />

urban metropolis or <strong>the</strong> fuel in a heavy-duty<br />

vehicle, filters are being asked to do more.<br />

In turn, filter manufacturers contact Henkel<br />

when <strong>the</strong>y need to accomplish more with <strong>the</strong>ir<br />

filter adhesives.<br />

Striving <strong>for</strong> Innovation<br />

Henkel approaches your filter assembly needs<br />

with more than a selection of adhesive products<br />

— we offer solutions. We recognize that filter<br />

manufacturers are constantly looking to improve<br />

<strong>the</strong>ir finished products, as well as <strong>the</strong>ir operations,<br />

in order to remain competitive. We not only think<br />

that each filter manufacturer is unique, but we also<br />

believe innovation comes from understanding.<br />

Raising <strong>the</strong> Standard<br />

As a global leader in <strong>the</strong> adhesive industry, Henkel<br />

offers a wide range of adhesive products that have<br />

a proven history in filter applications. Adhesive<br />

per<strong>for</strong>mance is dependent on <strong>the</strong> process where<br />

it is used, so our technical teams spend time in<br />

<strong>the</strong> field, as well as in <strong>the</strong> labs. This hands-on<br />

market experience and dedication allows our<br />

experts to select <strong>the</strong> optimum product solutions<br />

from our broad adhesive portfolio to meet your<br />

requirements.<br />

But a standard product is not always <strong>the</strong> best<br />

approach. When you are challenged with bonding<br />

difficult substrates or withstanding even tougher<br />

conditions, <strong>the</strong> Henkel team will work with<br />

you to customize new products and engineer<br />

cost-effective application processes that deliver<br />

per<strong>for</strong>mance, quality and value.<br />

Consistent, Reliable Per<strong>for</strong>mance<br />

As a global supplier, we can deliver <strong>the</strong> same<br />

product from multiple plants to accommodate<br />

your needs. You get <strong>the</strong> per<strong>for</strong>mance you expect<br />

in every batch. By working with Henkel, you<br />

receive products designed specifically <strong>for</strong> filter<br />

applications.<br />

Partners in <strong>the</strong> Field, Experts in <strong>the</strong> Lab<br />

Henkel is not just about products; it’s about people.<br />

Our adhesive experts team up with you to find<br />

solutions to <strong>the</strong> toughest process and product<br />

issues. They will continue to explore areas of<br />

possible improvement <strong>for</strong> as long as you work with<br />

us. Plus, <strong>the</strong>y’re backed by <strong>the</strong> full resources of our<br />

industry-leading research team. If you would like<br />

to accomplish more with your filter products and<br />

improve production operations, now is <strong>the</strong> time to<br />

call Henkel. Our filter team will help you analyze<br />

your situation and develop a solution based<br />

on your unique needs.<br />

www.henkelna.com/filters

ADHESIVES FOR LIQUID FI<strong>LT</strong>ER ASSEMBLY<br />

Today’s engineers are faced with <strong>the</strong> need to develop filters that satisfy increasing<br />

operating and processing requirements. Liquid filters are used in everything from<br />

automobiles to refineries to aircraft, and must withstand exposure to <strong>the</strong> most intense<br />

operating conditions. Despite continuous exposure to hot oils or solvents, <strong>the</strong>se filters<br />

must remove particulates to keep <strong>the</strong> equipment running effectively.<br />

<strong>Adhesives</strong> are required to not only be compatible with your substrates<br />

and your manufacturing process, but to also meet <strong>the</strong> extreme<br />

demands of end-use working environments.<br />

<strong>Adhesives</strong> That Satisfy <strong>the</strong> Extremes<br />

If your application requires an adhesive to withstand constant exposure to aggressive solvents like glycols,<br />

fuels or oils, we can supply it.<br />

Chemical and Temperature Resistance<br />

Henkel’s polyamide hot melt adhesives and our one- and two-part epoxies are compatible with a wide range<br />

of operating conditions. Our adhesives <strong>for</strong> liquid filter assembly are <strong>for</strong>mulated to have superior chemical and<br />

heat resistance properties by providing a durable, shock-resistant seal between <strong>the</strong> end cap and <strong>the</strong> media.<br />

We recognize <strong>the</strong> importance of efficient processing, so our adhesive products provide controlled exo<strong>the</strong>rms<br />

that limit <strong>the</strong> amount of distortion and bond shrinkage after cure.<br />

With Henkel, you get just what you need.<br />

CHEMICALLY RESISTANT ADHESIVES FOR LIQUID FI<strong>LT</strong>ER ASSEMBLY<br />

EPOXY ADHESIVES – Typical Properties<br />

One-Part Heat Cured Epoxies<br />

Application<br />

End Cap Bonding &<br />

First Pleat/Last Pleat<br />

Product Name<br />

LOCTITE ® 3985<br />

LOCTITE ® 9432NA<br />

Product<br />

Number<br />

40870<br />

34731<br />

83217<br />

83216<br />

Package Size/<br />

Type<br />

Liter<br />

Pail<br />

2lb Can<br />

Pail<br />

Premier<br />

Distribution<br />

Color<br />

Viscosity<br />

(cPs)<br />

Cure Time at<br />

160°C (min.)<br />

Service Temperature (°C)<br />

Black 50,000 30 -40 155<br />

Grey 250,000 15 -40 200<br />

LOCTITE ® A 316-30 1521<strong>04</strong>0 1 Gallon - Grey 250,000 5 -40 190<br />

Chemical Resistance<br />

Min Max Oil Trans Fluid Gas, Diesel Solvents<br />

Contact<br />

Henkel<br />

Acids<br />

Bases<br />

Contact<br />

Henkel<br />

Description<br />

General-Purpose, Low Viscosity<br />

High Temp. Resistance, High Strength, Surface<br />

Insensitive<br />

High Temperature and High Chemical Resistance<br />

(Skydrol Resistance)<br />

LOCTITE ® A 3<strong>04</strong>-10-1 1215362 Pail - Grey 52,000 30 -40 155 High Chemical Resistance (Skydrol Resistance)<br />

LOCTITE ® A 329-14 1215376 Pail - Grey Paste 3 -40 155<br />

LOCTITE ® A 316-43<br />

1215357<br />

1215358<br />

Pail<br />

Drum - Beige 25,000 3 -40 155<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

High Viscosity (Thixo), High Strength<br />

Thermal Shock Resistance, High Chemical Resistance<br />

(Skydrol Resistance)<br />

LOCTITE ® A 3<strong>04</strong>-26 1215343 Pail - Grey 19,500 5 -40 155 General-Purpose, Low Viscosity<br />

LOCTITE ® A 3<strong>04</strong>-29 1215370 Pail - Grey 100,000 5 -40 155 General-Purpose, High Viscosity<br />

LOCTITE ® E 359 1215364 Pail - Grey Paste 10 -40 180<br />

Contact<br />

Henkel<br />

High Temp. Resistance, High Strength, Low Off Gas<br />

3 www.henkelna.com/filters<br />

4

CHEMICALLY RESISTANT ADHESIVES FOR LIQUID FI<strong>LT</strong>ER ASSEMBLY<br />

EPOXY ADHESIVES – Typical Properties<br />

Application<br />

Product Name<br />

Product<br />

Number<br />

Package Size/<br />

Type<br />

Premier<br />

Distribution<br />

Color<br />

Mixed<br />

Viscosity<br />

(cPs)<br />

Work Life at 25°C (min) Service Temperature (°C) Chemical Resistance<br />

Description<br />

Min Max Oil Trans Fluid Gas, Diesel Solvents Acids Bases<br />

Two-Part Epoxies<br />

End Cap Bonding<br />

& First Pleat/Last Pleat<br />

LOCTITE ® E-40EXP<br />

1511653<br />

1511896A/<br />

1511897B<br />

200ml Cart<br />

Pail<br />

Grey 25,000 35 -40 177<br />

LOCTITE ® E-40HT 1086081 400ml Cart Blue Paste 45 -40 2<strong>04</strong><br />

LOCTITE ® E-30CL<br />

LOCTITE ® E-60NC<br />

LOCTITE ® E-05MR<br />

29329<br />

29331<br />

29332A/29333B<br />

29326<br />

29327A/ 29328B<br />

1086599<br />

1087602A/<br />

1087603B<br />

50ml Cart<br />

400ml Cart<br />

Pail - MTO<br />

400ml Cart<br />

Pail<br />

400ml Cart<br />

Pail<br />

Clear 6,000 30 -40 177<br />

Black 10,000 60 -40 177<br />

Clear 21,000 10 -40 177<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Medium Setting, Excellent Chemical<br />

Resistance, Meets UL 674 and UL 1203<br />

Medium Setting, High Temperature<br />

Resistance, Good Metal Adhesiion<br />

Medium Setting, Multi-use,<br />

Excellent Metal & Plastic Adhesion<br />

Long Setting, Versatile,<br />

Good Metal Adhesion<br />

Very Fast Setting, Multi-use,<br />

Good Metal Adhesion<br />

LOCTITE ® E-00CL 29291 400ml Cart Clear 5,000 3.5 -40 177<br />

Contact<br />

Henkel<br />

Very Fast Setting, Versatile,<br />

Good Metal & Plastic Adhesion<br />

LOCTITE ® H3101<br />

1510317<br />

83013A/ 83010B<br />

400ml Cart<br />

Pail<br />

Cream 70,000 15 -40 121<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Fast Setting, Thixo, Wide Substrate<br />

Compatibile, Adhesive to Metals &<br />

Plastics, NSF Approved<br />

HOT ME<strong>LT</strong> ADHESIVES – Typical Properties<br />

Application<br />

Product Name<br />

Product<br />

Number<br />

Package Size/<br />

Type<br />

Premier<br />

Distribution<br />

Color<br />

Viscosity<br />

@ 464°F<br />

Open Time<br />

Temperature Resistance<br />

Softening Point<br />

(ºC)/ (ºF)<br />

Oil<br />

Trans<br />

Fluid<br />

Chemical Resistance<br />

Gas,<br />

Diesel<br />

Solvents<br />

Acids<br />

Bases<br />

Description<br />

MACROME<strong>LT</strong> ® 2692 1415054<br />

Bag<br />

(40 lbs)<br />

-<br />

Translucent<br />

Light Amber<br />

4,200<br />

Short<br />

10-20 Seconds<br />

Very High 206 / 403<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

High Temperature Resistance, Excellent Creep<br />

Resistance. Good Chemical Resistance<br />

- FDA 175.105 Approved<br />

MACROME<strong>LT</strong> ® 6300 1398258<br />

Bag<br />

(40 lbs)<br />

-<br />

Translucent<br />

Light Amber<br />

3,700<br />

Short<br />

10-20 Seconds<br />

Very High 190 / 374<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

High Temperature Resistance, Excellent Creep<br />

Resistance, good Chemical Resistance<br />

- FDA 175.105 approved<br />

Pleating & End Cap<br />

Replacement & End Cap<br />

Bonding & Spiral Bead<br />

MACROME<strong>LT</strong> ® 2192B 1396374<br />

Bag (40 lbs)<br />

Sack (880 lbs)<br />

-<br />

Dark<br />

Amber<br />

4,200 at<br />

410°F<br />

Short-Moderate<br />

20-40 Seconds<br />

High 167 / 333<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

High Temperature Resistance, Excellent Creep<br />

Resistance & Moisture Resistance with Excellent<br />

Chemical Resistance - FDA 175.105 Approved<br />

MACROME<strong>LT</strong> ® 9069 1398400<br />

Bag<br />

(40 lbs)<br />

- Amber<br />

3,700 at<br />

410°F<br />

Short<br />

10-20 Seconds<br />

Very High 185 / 365<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Good Chemical Resistance and Adhesion to Plastic,<br />

Metals and Media - FDA 175.105<br />

PURME<strong>LT</strong> ® QR 9016 1223000<br />

Pail<br />

(40 lbs)<br />

Translucent<br />

Light Amber<br />

7,500 at<br />

250°F<br />

Short<br />

10-20 Seconds<br />

Very High<br />

NA<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Extrusion, Spray or Roll Coatable, 250°F<br />

temperature Resistance, Very Fast Setting, High<br />

Defection Resistance<br />

PURME<strong>LT</strong> ® QR 246CLV<br />

1100203<br />

97<strong>04</strong>46<br />

Pail (40 lbs)<br />

Drum (429 lbs)<br />

Translucent<br />

Light Amber<br />

18,000 at<br />

180°F<br />

Moderate<br />

40-60 Seconds<br />

Very High<br />

NA<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Excellent Adhesion to Difficult-to-Bond<br />

Substrates with Low Dispense Temperatures<br />

TWO-PART POLYURETHANE SYSTEMS – Typical Properties<br />

Application<br />

Product Name<br />

Product<br />

Number<br />

Package<br />

Size/Type<br />

Premier<br />

Distribution<br />

Polyol/Iso<br />

Vol. Mix<br />

Ratio (A:B)<br />

Mass Mix<br />

Ratio (A:B)<br />

Viscosity (cPs)<br />

Density<br />

(lbs/gal)<br />

Color<br />

Mixed<br />

Viscosity<br />

Shore<br />

Hardness<br />

Gel Time<br />

(25g at 77ºF)<br />

Tack-Free<br />

Time<br />

Tensile<br />

Strength<br />

(psi)<br />

%<br />

Elongation<br />

Description<br />

End Cap Replacement<br />

US 0151 A 1085676 Drum - Iso 1:3 1:3.57 200 10.4 Brown 1,600 75 (D) 2.5 min. 6-8 min. 2,100 50<br />

US 0151 B 1085656 Drum - Polyol 1:3 1:3.57 3,200 12.3 White 1,600 75 (D) 2.5 min. 6-8 min. 2,100 50<br />

Oil, Diesel Fuel, Hydraulic Fluid,<br />

Transmission Fluid, Anti-Freeze Compatible<br />

- Flame Retardant 94V-0<br />

5 www.henkelna.com/filters<br />

6

RELIABLE ADHESIVES FOR INDUSTRIAL AIR FI<strong>LT</strong>ERS<br />

Industrial filters must consistently deliver clean air under severe operating conditions.<br />

Whe<strong>the</strong>r <strong>the</strong> filters are used in automotive engines, heavy-duty equipment, dust<br />

collectors or even vacuum cleaners, buyers demand high per<strong>for</strong>mance and reliability.<br />

To meet <strong>the</strong>se demands, you not only need adhesives that are<br />

compatible with your media and your production equipment,<br />

but also meet <strong>the</strong> ultimate end-use filter requirements.<br />

With Henkel, you get just what you need.<br />

<strong>Adhesives</strong> That Match Your Product Profile<br />

If your application requires adhesives to bond special media or low surface energy substrates, to resist extreme<br />

temperature conditions or to remain flexible <strong>for</strong> radial designs, we can supply it.<br />

Heavy-Duty Applications<br />

For example, cartridge filters used in dust collection or gas turbine applications are often exposed to vibration and high<br />

air velocities. Whe<strong>the</strong>r serving as <strong>the</strong> end cap or <strong>the</strong> potting compound, Henkel’s polyurethanes are specifically designed<br />

to meet <strong>the</strong> demands of industrial filtration.<br />

High Temperature Applications<br />

Pleated filters used in industrial vacuums or engines are often exposed to higher temperatures <strong>for</strong> extended periods.<br />

Our hot melt adhesives are <strong>for</strong>mulated to not only improve equipment processing and produce superior quality filters,<br />

but also to withstand <strong>the</strong> requirements of <strong>the</strong> end-use application. But a standard product is not always <strong>the</strong> best solution.<br />

When you need a custom adhesive, Henkel can <strong>for</strong>mulate it to match your specific process, design and application.<br />

RELIABLE ADHESIVES FOR INDUSTRIAL AIR FI<strong>LT</strong>ERS<br />

TWO-PART POLYURETHANE SYSTEMS – Typical Properties<br />

Application<br />

Product Name<br />

Product<br />

Number<br />

Package<br />

Size/Type<br />

Premier<br />

Distribution<br />

Polyol/Iso<br />

Vol. Mix<br />

Ratio<br />

(A:B)<br />

Mass Mix<br />

Ratio (A:B)<br />

Viscosity<br />

(cPs)<br />

Density<br />

(lbs/gal)<br />

Color<br />

Mixed<br />

Color<br />

Mixed<br />

Viscosity<br />

(cPs)<br />

Shore<br />

Hardness<br />

Gel Time<br />

(100g at 77ºF)<br />

Tack Free<br />

Time<br />

Tensile<br />

Strength<br />

%<br />

Elongation<br />

Description<br />

MACROPLAST ® UK 201A 1219075 Drum - Polyol 2:1 1.65:1 1,300 8.1 Blue Blue 1,200 60 (A) 1.5 min. 120 sec. 400 psi 100%<br />

MACROPLAST ® UK 180B 1219067 Drum - Iso 2:1 1.65:1 1,100 9.7 Amber Blue 1,200 60 (A) 1.5 min. 120 sec. 400 psi 100%<br />

Fast De-molding, Low Wicking and<br />

Minimal Bubbling w/ Potting High<br />

Moisture Containing <strong>Filter</strong> Media<br />

End Cap Replacement<br />

& End Cap Bonding<br />

MACROPLAST ® UK 072A 1219038 Drum Polyol 3.2:1 3.5:1 30,000 11.3 White Off-White 23,500 90 (A) 2.5 min. 150 sec. Good Good<br />

MACROPLAST ® UK 072B 1219<strong>04</strong>0 Drum Iso 3.2:1 3.5:1 200 10.3 Amber Off-White 23,500 90 (A) 2.5 min. 150 sec. Good Good<br />

Controlled Penetration, Low<br />

Temperature Flexibility, Excellent<br />

Adhesion to Metal, Plastic, Wood,<br />

Media, etc.<br />

HYSOL ® US 5501A 876402 Tote - Iso 1:3.53 1:3.94 200 10.3 Amber Off-White 2,600 90 (A) 6 min. NA Good Moderate<br />

HYSOL ® US 5501B 1708482 Tote - Polyol 1:3.53 1:3.94 3,320 11.2 White Off-White 2,600 90 (A) 6 min. NA Good Moderate<br />

Low VOC, Flame Retardant,<br />

Thixotropic (1.0), Approvable UL<br />

94V-1 / UL 900<br />

7 www.henkelna.com/filters<br />

8

RELIABLE ADHESIVES FOR INDUSTRIAL AIR FI<strong>LT</strong>ERS<br />

HOT ME<strong>LT</strong> ADHESIVES – Typical Properties<br />

Application<br />

Product Name<br />

Product<br />

Number<br />

Package Size/<br />

Type<br />

Premier<br />

Distribution<br />

Type<br />

Pleating<br />

Speeds<br />

Flexibility<br />

Temp.<br />

Resistance<br />

Color<br />

Softening Point<br />

(ºC)/(ºF)<br />

Viscosity (cPs)<br />

Open Time (sec.)<br />

275°F 300°F 325°F 350°F 300°F 325°F 350°F<br />

Description<br />

MACROME<strong>LT</strong> ® 6240 1397818<br />

Bag<br />

(40 lbs)<br />

- Polyamide Moderate Moderate High Light Amber 142 / 287 7,000 cPs at 437°F Moderate: 40-60<br />

Superior Adhesion to Polar Plastics<br />

like ABS & PVC; UL 94 V-2 Flame<br />

Rating<br />

MACROME<strong>LT</strong> ® 2692 1415054<br />

Bag<br />

(40 lbs)<br />

- Polyamide High Moderate Very High<br />

Translucent<br />

Amber<br />

206 / 403 4,200 cPs at 464°F Short-Moderate: 20-40<br />

High Temperature Resistance, with<br />

Excellent Creep Resistance Good<br />

Chemical Resistance - FDA 175.105<br />

MACROME<strong>LT</strong> ® 6300 1398258<br />

Bag<br />

(40 lbs)<br />

- Polyamide High High Very High<br />

Translucent<br />

Amber<br />

190 / 374 3,700 cPs at 464°F Short: 10-20<br />

High Temperature Resistance, with<br />

Excellent Creep Resistance, Good<br />

Chemical Resistance - FDA 175.105<br />

MACROME<strong>LT</strong> ® 6202 1398265<br />

Bag<br />

(40 lbs)<br />

- Polyamide Moderate Moderate Moderate Light Amber 133 / 271 5,000 cPs at 375°F Moderate: 40-60<br />

Good Adhesion to Plastics, Metals<br />

and Media - FDA 175.105<br />

MACROME<strong>LT</strong> ® 2157 1398263 Bag - Polyamide Moderate Moderate High Clear Amber 165 / 329 750 cPs at 375°F Long: 60-80<br />

Excellent Heat Resistance, Good<br />

Adhesion to Metals, Elastomers and<br />

Polyesters - FDA 175.105, 94 V-0<br />

MACROME<strong>LT</strong> ® 9069 1398400<br />

Bag<br />

(40 lbs)<br />

- Polyamide High Moderate Very High Amber 185 / 365 3,700 cPs at 410°F Short: 10-20<br />

Good Chemical Resistance and<br />

Adhesion to Plastic, Metals and<br />

Media - FDA 175.105<br />

MACROME<strong>LT</strong> ® 6238 78967<br />

Bag<br />

(40 lbs)<br />

- Polyamide Moderate Moderate High Clear Amber 133 / 271 5,000 cPs at 410°F Moderate: 40-60<br />

Good Adhesion to Rigid and Flexible<br />

Plastics, Metal and Media - FDA<br />

175.105<br />

Pleating &<br />

First Pleat/Last Pleat<br />

MACROME<strong>LT</strong> ® 6239 515023<br />

Bag<br />

(40 lbs)<br />

- Polyamide Moderate Moderate High Light Amber 133 / 271 7,000 cPs at 437°F Moderate: 40-60<br />

Good High and Low Temperature<br />

Resistance (Creep), Good Adhesion<br />

to Plastic, Metal & Media - FDA<br />

175.105<br />

MACROME<strong>LT</strong> ® 2192B<br />

1396374<br />

1396799<br />

Bag (40 lbs)<br />

Sack (80 lbs)<br />

- Polyamide High Moderate High Dark Amber 167 / 333 4,200 cPs at 410°F Short-Moderate: 20-40<br />

Good Chemical Resistance &<br />

Moisture Resistance, Excellent High<br />

Temperature Creep Resistance.<br />

- FDA 175.105<br />

MACROME<strong>LT</strong> ® 2333B 1396375<br />

Bag<br />

(40 lbs)<br />

- Polyamide Moderate Moderate High Light Amber 140 / 284 3,000 cPs at 375°F Short: 10-20<br />

Good Low Temperature Flexibility,<br />

Good Bond Strength to Plastic, Metal<br />

and Media - FDA 175.105<br />

TECHNOME<strong>LT</strong> ® 871B 1217873<br />

Box<br />

(50 lbs)<br />

- PO High High Moderate Off-White 152 / 305<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

3,800 2,000<br />

Short:<br />

10-15<br />

Short:<br />

10-15<br />

Short:<br />

15-20<br />

High Strength Adhesive to Multiple<br />

Substrates - FDA 175.105<br />

TECHNOME<strong>LT</strong> ® Q-5669* 1649575 Drum - EVA High Moderate Moderate White 100 / 212 17,000 10,500 8,000<br />

TECHNOME<strong>LT</strong> ® 80-8647*<br />

TECHNOME<strong>LT</strong> ® Q-1214 1217279<br />

*UL Class II Fire Retardant<br />

TECHNOME<strong>LT</strong> ® 8370<br />

*UL Class II Fire Retardant<br />

621750<br />

1<strong>04</strong>3481<br />

551969<br />

1591674<br />

1568631<br />

Box (35 lbs)<br />

Bin (400 lbs)<br />

Drum (1199 lbs)<br />

Box<br />

(40 lbs)<br />

Box (40 lbs)<br />

Sack (880 lbs)<br />

- EVA High Moderate Moderate Off-White 108 / 226 11,500 7,200<br />

Contact<br />

Henkel<br />

- EVA Moderate Very High Low Off-White 75 / 167 7,500 4,500 2,900 1,850<br />

- EVA High Low Moderate Light Yellow 110 / 230<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Short: 10-20<br />

4,700 Moderate: 40-60<br />

Moderate:<br />

40-45<br />

Moderate:<br />

40-45<br />

1,200 Short-Moderate: 20-40<br />

Moderate:<br />

40-45<br />

Flame Retardant, Rapid Running<br />

Speeds, Good Adhesion to Media<br />

Flame Retardant, Good Adhesion to<br />

Media - FDA 175.105<br />

Long Open Time (Roll Coatable),<br />

PSA Alternative - FDA 175.105<br />

Excellent Hot Tack <strong>for</strong> Low<br />

Compression Applications - FDA<br />

175.105<br />

9<br />

www.henkelna.com/filters<br />

10

RELIABLE ADHESIVES FOR INDUSTRIAL AIR FI<strong>LT</strong>ERS<br />

VARIOUS ADHESIVES – Typical Properties<br />

Application<br />

Product Name<br />

Product<br />

Number<br />

Package Size/<br />

Type<br />

Premier<br />

Distribution<br />

Type Set Speed Flexibility<br />

Temp.<br />

Resistance<br />

Color<br />

Softening Point<br />

(ºC)/(ºF)<br />

Viscosity (cPs)<br />

Open Time (sec.)<br />

Description<br />

275°F 300°F 325°F 350°F 300°F 325°F 350°F<br />

TECHNOME<strong>LT</strong> ® PS-8843X<br />

1679622<br />

884120<br />

Box (40 lbs)<br />

Drum (1190 lbs)<br />

- PO Long Moderate Moderate Amber 143 / 289 5,500 cPs at 350°F Long: 60-80<br />

Excellent Adhesion to Difficult-to-Bond<br />

Substrates, Wide Service Temperature<br />

Range - FDA 175.105<br />

Frame Assembly<br />

TECHNOME<strong>LT</strong> ® Q4222 266079 Box (40 lbs) PO Short Moderate High Amber 160 / 320 8,100 cPs at 350°F Short: 10-20<br />

TECHNOME<strong>LT</strong> ® Q4206 554668 Box (40 lbs) PO Moderate Moderate Moderate Amber 118 / 244 10,000 cPs at 350°F Moderate: 40-60<br />

High Creep Resistance, Excellent<br />

Adhesion to Difficult-to-Bond<br />

Substrates - FDA 175.105<br />

Excellent Adhesion to Difficult-to-Bond<br />

Substrates, Wide Service Temperature<br />

Range<br />

TECHNOME<strong>LT</strong> ® 269C 1280350 Sack (998 lbs) - EVA Moderate Moderate Low Yellow 80 / 176<br />

Contact<br />

Henkel<br />

1,820<br />

Contact<br />

Henkel<br />

800 Short-Moderate: 20-40<br />

Excellent Adhesion to Difficult-to-Bond<br />

Substrates, Excellent Cold Temperature<br />

Resistance - FDA 175.105<br />

TECHNOME<strong>LT</strong> ® 8848<br />

1351009<br />

1059364<br />

Box (29 lbs)<br />

Drum (350 lbs)<br />

PSA Moderate High Moderate<br />

Translucent<br />

White<br />

93 / 200 2,100 725<br />

Contact<br />

Henkel<br />

250 Moderate: 40-60<br />

Foam-in-Place Gaskets (Up to 60%),<br />

Temperatures Up to 175°F<br />

SUPERFLEX ® 593<br />

59375<br />

960994<br />

Cartridge<br />

Drum<br />

Silicone Long High Very High Black N/A Paste (100g/min. Extrusion Rate) Moderate: 30 min.<br />

Cure-in-Place Gasket, Temperatures<br />

Up to 400°F<br />

Gasketing<br />

SUPERFLEX ® 5900<br />

20166<br />

20167<br />

20168<br />

Cartridge<br />

Pail<br />

Drum<br />

Silicone Long High Very High Black N/A Paste (35g/min Extrusion Rate) Short: 5 min.<br />

Very Thick, Cure-in-Place Gasket,<br />

Temperatures Up to 400°F<br />

SUPERFLEX ® 587<br />

58775<br />

58791<br />

33421<br />

Cartridge<br />

Pail<br />

Drum<br />

Silicone Long High Very High Blue N/A Paste (300g/min Extrusion Rate) Long: 50 min.<br />

Oil Resistant, Cure-in-Place Gasket,<br />

Temperatures Up to 400°F<br />

Gasket Bonding<br />

LOCTITE ® 454<br />

LOCTITE ® 401<br />

454<strong>04</strong><br />

1337712<br />

23132<br />

34846<br />

17738<br />

3 g. Tube<br />

30 g. Syringe<br />

850 g. Cartridge<br />

20 g. Bottle<br />

1 lb. Bottle<br />

- CA Short Low Moderate Clear N/A Gel Fixtures 20 sec.<br />

- CA Short Low Moderate Clear N/A 110 cPs Fixtures 15 sec.<br />

Bonding Rubber or Foam Gaskets<br />

to Metal or Plastic End Caps, 250°F<br />

Temp resistance, Excellent Chemical<br />

Resistance<br />

Bonding Rubber or Foam Gaskets<br />

to Metal or Plastic End Caps, 250°F<br />

Temp. Resistance, Excellent Chemical<br />

Resistance<br />

LOCTITE ® 6001<br />

467119<br />

493621<br />

250mL<br />

Liter<br />

- Anaerobic Short Low High Rosy White N/A 3,000 cPs (Thixo) Fixtures 15 min.<br />

Surface Insensitive Retaining<br />

Compound, Provides Primerless<br />

Adhesion to Metal Substrates, Highly<br />

Thixo Liquid, Max Gap Fill 0.015 ”<br />

Diametral<br />

Crimp Sealing<br />

LOCTITE ® 620<br />

62<strong>04</strong>0<br />

62070<br />

50mL<br />

250mL<br />

Anaerobic Moderate Low High Green N/A 8,500 cPs Fixtures 1 hr.<br />

Provides Adhesion to Metal Substrates,<br />

High Temperature Resistance to 450°F,<br />

Max Gap Fill 0.015” Diametral<br />

LOCTITE ® 5182<br />

18010<br />

32214<br />

850mL<br />

1L - MTO<br />

- Anaerobic Moderate High Moderate Red N/A Gel Fixtures 25 min.<br />

Provides Adhesion to Metal Substrates,<br />

High Temperature Resistance to<br />

300°F, Max Gap Fill 0.050” Diametral,<br />

Deaerated <strong>for</strong> Gasketing<br />

11 www.henkelna.com/filters<br />

12

HIGH PERFORMANCE ADHESIVES FOR HIGH EFFICIENCY FI<strong>LT</strong>ERS<br />

The stakes are high <strong>for</strong> laboratory, clean room and industrial filters. Dust contaminants<br />

can compromise an entire electronic assembly or skew <strong>the</strong> results of a laboratory study.<br />

There<strong>for</strong>e, users are demanding better filtration to protect <strong>the</strong>ir operations.<br />

Air filters containing high ASHRAE ® efficiency or HEPA grade<br />

media come in all shapes and sizes. Henkel has a full range<br />

of adhesive products to meet <strong>the</strong>se challenges.<br />

<strong>Adhesives</strong> That Meet Your Standards<br />

If your application requires an adhesive to bond to metal frames, to keep mini-pleats evenly spaced or to have low<br />

volatiles to minimize outgassing, we can supply it.<br />

Improved Hot Melt <strong>Adhesives</strong> <strong>for</strong> Pleating<br />

Henkel’s hot melt adhesives are <strong>for</strong>mulated to produce superior quality filter pleat packs with both syn<strong>the</strong>tic and<br />

micro fiberglass media and can function in a wide range of pleating equipment.<br />

Superior Polyurethanes <strong>for</strong> Frame Bonding<br />

High efficiency air filters are not complete without a potting compound to seal <strong>the</strong> pleats. Our two-part liquid<br />

polyurethane adhesives are <strong>for</strong>mulated to achieve <strong>the</strong> desired cure rates, produce <strong>the</strong> specified hardness and per<strong>for</strong>m<br />

under turbulent environments.<br />

HIGH PERFORMANCE ADHESIVES FOR HIGH EFFICIENCY FI<strong>LT</strong>ERS<br />

HOT ME<strong>LT</strong> ADHESIVES – Typical Properties<br />

Application<br />

Product Name<br />

Product<br />

Number<br />

Package Size/<br />

Type<br />

Premier<br />

Distribution<br />

Type<br />

Pleating<br />

Speeds<br />

Flexibility<br />

Temp.<br />

Resistance<br />

Color<br />

Softening<br />

Point<br />

(ºC)/ (ºF)<br />

Viscosity (cPs) Open Time (sec.) Description<br />

275°F 300°F 325°F 350°F 300°F 325°F 350°F Open Time<br />

MACROME<strong>LT</strong> ® 2192B<br />

1396374<br />

1396799<br />

Bag<br />

Sack<br />

- Polyamide High High Moderate<br />

Dark<br />

Amber<br />

167 / 333 4200 CPs at 410°F Short-moderate: 20-40 Short<br />

Good Chemical Resistance<br />

& Moisture Resistance with<br />

Excellent High Temperature<br />

Creep Resistance.<br />

- FDA 175.105<br />

TECHNOME<strong>LT</strong> ® 80-8647*<br />

1649568<br />

1649569<br />

1655665<br />

Box<br />

Bin<br />

Drum<br />

- EVA Moderate High Moderate Off-White 108 / 226 11,500 7,200<br />

Contact<br />

Henkel<br />

4,700<br />

Moderate:<br />

40-60<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Moderate<br />

Flame Retardant, Good<br />

Adhesion to Media - FDA<br />

175.105<br />

Pleating<br />

TECHNOME<strong>LT</strong> ® Q-5669* 1649575 Drum - EVA Moderate High Moderate White 100 / 212 17,000 10,500 8,000<br />

Contact<br />

Henkel<br />

Short: 10-20<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Short<br />

Flame Retardant, Rapid<br />

Running Speeds, Good<br />

Adhesion to Media<br />

TECHNOME<strong>LT</strong> ® 870C<br />

1430067<br />

1217872<br />

Box<br />

Sack<br />

- EVA High High Moderate Off-White 109 / 228 3,350 2,175 1,475 1,050 10-15 10-15 15-20 Short<br />

Excellent Flexibility, Good<br />

Heat Resistance, Best<br />

Adhesion to Fiber<br />

Glass & Polyester Media<br />

TECHNOME<strong>LT</strong> ® Q-1214 1217279 Box - EVA Moderate Very High Low Off-White 75 / 167 7,500 4,500 2,900 1,850 40-45 40-45 40-45 Moderate<br />

Long Open Time<br />

(Roll Coatable),<br />

PSA Alternative -<br />

FDA 175.105<br />

*UL Class II Fire Retardant<br />

13 www.henkelna.com/filters<br />

14

HIGH PERFORMANCE ADHESIVES FOR HIGH EFFICIENCY FI<strong>LT</strong>ERS<br />

TWO-PART POLYURETHANE SYSTEMS – Typical Properties<br />

Application<br />

Product Name<br />

Product<br />

Number<br />

Package<br />

Size/Type<br />

Premier<br />

Distribution<br />

Polyol/Iso<br />

Vol. Mix<br />

Ratio (A:B)<br />

Mass Mix<br />

Ratio (A:B)<br />

Viscosity<br />

(cPs)<br />

Density<br />

(lbs./gal.)<br />

Color<br />

Mixed<br />

Color<br />

Mixed<br />

Viscosity (cps)<br />

Shore<br />

Hardness<br />

Gel Time<br />

(100 g. at<br />

77ºF)<br />

Tack-Free<br />

Time<br />

Tensile<br />

Strength<br />

% Elongation Description<br />

MACROPLAST ® UK 072A 1219038 Drum Polyol 3.2:1 3.5:1 30,000 11.3 White Off-White 23,500 90 (A) 2.5 min. 150 sec. Good Good Controlled Penetration,<br />

Low Temperature<br />

Flexibility, Excellent<br />

Adhesion to Metal,<br />

MACROPLAST ® UK 072B 1219<strong>04</strong>0 Drum Iso 3.2:1 3.5:1 200 10.3 Amber Off-White 23,500 90 (A) 2.5 min. 150 sec. Good Good Plastic, Wood, Media, etc.<br />

End Cap Replacement<br />

& Face Welding & End<br />

Cap Bonding<br />

Hysol ® US 5501A<br />

Hysol ® US 5501B<br />

876402<br />

1708482<br />

Tote<br />

Tote<br />

-<br />

-<br />

Iso<br />

Polyol<br />

1:3.53<br />

1:3.53<br />

1:3.94<br />

1:3.94<br />

200<br />

3,320<br />

10.3<br />

11.2<br />

Amber<br />

White<br />

Off White<br />

Off White<br />

2,600<br />

2,600<br />

90 (A)<br />

90 (A)<br />

6 min<br />

6 min<br />

NA<br />

NA<br />

Good<br />

Good<br />

Moderate<br />

Moderate<br />

Low VOC, Flame<br />

Retardent, Thixotropic<br />

(1.0), Approvable UL<br />

94V-1 / UL 900<br />

MACROPLAST ® UK 413A 1219110 Tote - Polyol 2.5:1 2.08:1 2,200 8.3 White Tan 1,600 80 (A) 4 min. 5 min. Moderate Moderate Controlled Penetration,<br />

Low Temperature<br />

Flexibility, Excellent<br />

Adhesion to Metal,<br />

MACROPLAST ® UK 413B 1219111 Tote - Iso 2.5:1 2.08:1 100 10.3 Brown Tan 1,600 80 (A) 4 min. 5 min. Moderate Moderate Plastic, Wood, Media, etc.<br />

15 www.henkelna.com/filters<br />

16

PROCESS-MATCHED ADHESIVES FOR HVAC AIR FI<strong>LT</strong>ERS<br />

Home owners want filters that clean <strong>the</strong> air without costing a <strong>for</strong>tune. Commercial buyers<br />

are looking <strong>for</strong> filters that deliver per<strong>for</strong>mance, durability and reliability. To meet <strong>the</strong><br />

growing demand <strong>for</strong> quality and economy, you must keep improving your product and<br />

assembly process. It’s a real challenge, but Henkel can help.<br />

<strong>Adhesives</strong> Optimized <strong>for</strong> Your Process<br />

Whe<strong>the</strong>r you are bonding to fiberglass or syn<strong>the</strong>tic media, Henkel can provide adhesives with exactly <strong>the</strong> properties<br />

you need <strong>for</strong> economical, fast, reliable filter assembly.<br />

Efficient Operations<br />

We work with you to identify your process and assembly line requirements, including <strong>the</strong> desired level of adhesion to<br />

substrates and <strong>the</strong> open time needed <strong>for</strong> manual filter assembly.<br />

Reliable Per<strong>for</strong>mance<br />

Improving <strong>the</strong> efficiency and quality of operations is critical, but <strong>the</strong> right adhesive must also ensure <strong>the</strong> finished<br />

air filter product per<strong>for</strong>ms. Our hot melt and water-based adhesives are <strong>for</strong>mulated to satisfy residential, commercial<br />

and industrial requirements, including extended heat and moisture resistance.<br />

PROCESS-MATCHED ADHESIVES FOR HVAC AIR FI<strong>LT</strong>ERS<br />

WATER-BASED ADHESIVES – Typical Properties<br />

Application Product Name Product Number<br />

Package Size /<br />

Type<br />

Premier<br />

Distribution<br />

Open Time (sec.) Set Speed Tack Viscosity (cPs) Solids (%) pH Density (lbs./gal.) Description<br />

PERM-ATTACH ® 395C 854328 Pail<br />

Moderate<br />

120-300 Seconds<br />

Moderate<br />

90 - 250 secs<br />

High 5,000 38 7.1 8.7 High Per<strong>for</strong>mance Cross Linking PU, Heat Reactivatable<br />

ADHESIN ® 45-7348H<br />

512143<br />

556205<br />

Barrel<br />

Tote<br />

-<br />

Long<br />

300+ Seconds<br />

Moderate<br />

90 - 250 secs<br />

Low 6,000 50 8.5 8.8<br />

Bonds Difficult-to-Bond Substrates, Excellent Water<br />

Resistance - FDA 175.105<br />

AQUENCE LA 774B 1647314 Tote -<br />

Short<br />

90-120 Seconds<br />

Fast<br />

250+ secs<br />

High 2,300 61 7.5 9<br />

High Quality, Very Fast Setting, Good Water Resistance,<br />

Re-tack Capable - FDA 175.105<br />

Frame Assembly -<br />

Cold Glue<br />

ADHESIN ® 51-3130<br />

VETAK ® V797<br />

5131<strong>04</strong><br />

513103<br />

513096<br />

1059677<br />

751092<br />

Pail<br />

Drum<br />

Tote<br />

Pail<br />

Drum<br />

-<br />

Moderate<br />

120-300 Seconds<br />

Moderate<br />

120-300 Seconds<br />

Fast<br />

250+ secs<br />

Moderate<br />

90 - 250 secs<br />

Moderate 2,000 57 5 9<br />

High 4,000 56 5 8.8<br />

Well Balanced Per<strong>for</strong>mance, Good Water Resistance<br />

- FDA 175.105<br />

Bonds Difficult-to-Bond Substrates, Excellent Water<br />

Resistance - FDA 175.105<br />

ADHESIN ® 51-3093<br />

512116<br />

512114<br />

Barrel<br />

Tote<br />

-<br />

Short<br />

90-120 Seconds<br />

Fast<br />

250+ secs<br />

High 5,500 64 7 9<br />

Media to Wire Mesh Bonding, Excellent Wet Tack - FDA<br />

175.105<br />

ADHESIN ® 56-5112<br />

513787<br />

513786<br />

513783<br />

Pail<br />

Drum<br />

Tote<br />

-<br />

Moderate<br />

120-300 Seconds<br />

Fast<br />

250+ secs<br />

High 1,800 55 4.5 9<br />

General-Purpose, Excellent Wet Tack & Fast Setup, Good<br />

Water Resistance - FDA 175.105<br />

ADHESIN ® 32-724A<br />

1216490<br />

1216493<br />

Pail<br />

Tote<br />

-<br />

Short<br />

90-120 Seconds<br />

Fast<br />

250+ secs<br />

High 2,000 48 3.5 9<br />

High Quality, Very Fast Setting, Good Water Resistance,<br />

Re-tack Capable - FDA 175.105<br />

17 www.henkelna.com/filters<br />

18

PROCESS-MATCHED ADHESIVES FOR HVAC AIR FI<strong>LT</strong>ERS<br />

HOT ME<strong>LT</strong> ADHESIVES – Typical Properties<br />

Application<br />

Product Name<br />

Product<br />

Number<br />

Package Size/<br />

Type<br />

Premier<br />

Distribution<br />

Assembly<br />

Time<br />

Temperature<br />

Resistance<br />

Open Time<br />

Color<br />

Softening<br />

Point<br />

(ºC)/ (ºF)<br />

Viscosity Profile (cPs)<br />

250ºF 275ºF 300ºF 325ºF 350ºF<br />

Description<br />

DORUS ® MS 3210 1700025 Box (24 lbs) Moderate Very High<br />

Long<br />

60-80 Sec.<br />

Off-White 135 / 275 10,000 cPs at 350ºF<br />

Excellent Heat Resistance, Bonds to Hard-to-Bond<br />

Substrates - Class I Smoke Approvable<br />

Frame Assembly<br />

TECHNOME<strong>LT</strong> ® 80-8572<br />

1342349<br />

1342372<br />

Box (40 lbs)<br />

Sack (880 lbs)<br />

- Moderate High<br />

TECHNOME<strong>LT</strong> ® 2635 1222925 Box - Fast High<br />

Long<br />

60-80 Sec.<br />

Short<br />

10-20 Sec.<br />

Light Amber 74 / 165<br />

Light Yellow 108 / 226<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

9,960 5,690 3,900 2,400 PSA, High Peel Strength, Very Aggressive Tack<br />

Contact<br />

Henkel<br />

2,650 1,700 1,150 Versatile - FDA 175.205<br />

TECHNOME<strong>LT</strong> ® 2631 1217410 Box - Moderate High<br />

Moderate<br />

40-60 Sec.<br />

Medium Yellow 108 / 226<br />

Contact<br />

Henkel<br />

4,900 3,150 1,750 1,250 Versatile - FDA 175.205<br />

Pre-applied Reactivatable TECHNOME<strong>LT</strong> ® Cool 889A 1217888 Box - Fast Moderate<br />

Short<br />

10-20 Sec.<br />

Light Yellow 76 / 169 1,200 850 550<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Thermal Stability to Reduce Char, Low Energy Costs,<br />

Exceptional Adhesion to Difficult-to-Bond Substrates<br />

- FDA 175.105<br />

Wire Mesh/Scrim Attachment<br />

TECHNOME<strong>LT</strong> ® 2787 1469016 Drum (880 lbs) - Moderate Moderate<br />

TECHNOME<strong>LT</strong> ® EM-4955 1222980 Box - Moderate Moderate<br />

Moderate<br />

40-60 Sec.<br />

Moderate<br />

40-60 Sec.<br />

Yellow 90 / 194<br />

Medium<br />

Amber<br />

72 / 162<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

3,950 2,300 1,500 975<br />

4,800 3,800 Bonds PET, Metal & Media - FDA 175.105<br />

Good Adhesion to Glass, Metal, PET & Media - FDA<br />

175.105<br />

Pleat Separator<br />

TECHNOME<strong>LT</strong> ® 80-8647*<br />

TECHNOME<strong>LT</strong> ® 8370<br />

1649568<br />

1649569<br />

1655665<br />

1554389<br />

1568639<br />

Box<br />

Bin<br />

Drum<br />

Box<br />

Sack<br />

- Moderate High<br />

- Fast High<br />

Moderate<br />

40-60 Sec.<br />

Short<br />

10-20 Sec.<br />

Off-White 108 / 226 19,500 11,500 7,200<br />

Light Yellow 110 / 230<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

4,700<br />

1,000<br />

Flame Retardant, Good Adhesion to Media - FDA<br />

175.105<br />

Super Hot Tack <strong>for</strong> Low Compression Applications<br />

- FDA 175.105<br />

Stich Seal/Pleat Separator<br />

TECHNOME<strong>LT</strong> ® 8448<br />

1629993<br />

1329233<br />

Box<br />

Drum<br />

- Fast High<br />

TECHNOME<strong>LT</strong> ® 80-8361 514380 Sack (880 lbs) - Fast High<br />

Moderate<br />

40-60 Sec.<br />

Short<br />

10-20 Sec.<br />

Tan 110 / 230<br />

Translucent<br />

White<br />

96 / 205<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

Contact<br />

Henkel<br />

1,100<br />

Outstanding Hot Tack, Good Thermal Stability<br />

Extending Pot Life - FDA 175.105<br />

1,350 Heat Reactivatable - FDA 175.105<br />

*UL Class II Fire Retardant<br />

19 www.henkelna.com/filters<br />

20

ADHESIVES FOR WATER FI<strong>LT</strong>ER<br />

ASSEMBLY<br />

Today, municipalities, businesses and households use<br />

membrane and carbon block filtration elements to<br />

separate contaminants from water and o<strong>the</strong>r liquids. As<br />

<strong>the</strong> use of <strong>the</strong>se filters continues to expand into new<br />

end-use applications, <strong>the</strong> per<strong>for</strong>mance requirements<br />

can change and <strong>the</strong> elements can be exposed to harsher<br />

operating conditions. These changes often require <strong>the</strong><br />

development of new filters and improved adhesives.<br />

Polyurethanes and Epoxies<br />

The cost and per<strong>for</strong>mance of filtration elements are critical <strong>for</strong> expansion into new markets. As such, new and innovative<br />

adhesives are required to keep pace with <strong>the</strong> changing substrates, process automation upgrades and more demanding<br />

filtration requirements. Henkel has <strong>the</strong> technical expertise to <strong>for</strong>mulate custom adhesives to meet your changing needs.<br />

Whe<strong>the</strong>r you are assembling carbon block, spiral wound, hollow fiber, tubular or cassette membranes, Henkel can satisfy<br />

your application needs. Our polyurethane adhesives are <strong>for</strong>mulated to resist a wide range of pH, chemicals, temperatures<br />

and pressures. In some applications you may need <strong>the</strong> adhesive to do a little extra, and our epoxies are designed to<br />

provide this added per<strong>for</strong>mance.<br />

It’s a real challenge, but Henkel can help.<br />

APPLICATION SPECIFIC ADHESIVES FOR WATER / DAIRY / FOOD & BEVERAGE FI<strong>LT</strong>ER ASSEMBLY<br />

TWO-PART POLYURETHANE SYSTEMS – – Typical Properties<br />

Application<br />

Product Name<br />

Product<br />

Number<br />

Package<br />

Size/Type<br />

Premier<br />

Distribution<br />

Type<br />

Vol. Mix<br />

Ratio (A:B)<br />

Mass Mix<br />

Ratio (A:B)<br />

Viscosity (cPs)<br />

Density<br />

(lbs./gal.)<br />

Color<br />

Mixed<br />

Viscosity (cPs)<br />

Shore<br />

Hardness<br />

Gel Time<br />

Open Time<br />

Tensile<br />

Strength (psi)<br />

Tear Strength<br />

(lbs/in)<br />

Description<br />

End Cap Molding<br />

MACROPLAST ® UK 180A<br />

MACROPLAST ® UK 180B<br />

1219066<br />

1219067<br />

Drum<br />

Drum<br />

Polyol<br />

Iso<br />

1.34:1<br />

1.34:1<br />

1.11:1<br />

1.11:1<br />

1,500<br />

1,100<br />

8.3<br />

9.7<br />

Blue<br />

Amber<br />

1,200<br />

1,200<br />

85-95 (A)<br />

85-95 (A)<br />

2 min<br />

2 min<br />

-<br />

-<br />

2,400<br />

2,400<br />

140<br />

140<br />

Self-Leveling, Fast de-molding,<br />

Low Wicking & Excellent<br />

Chemical Resistance -NSF<br />

Approvable<br />

Membrane Bonding<br />

(Spiral Wound)<br />

MACROPLAST ® UK 178A<br />

MACROPLAST ® UK 178B<br />

1579616<br />

1219060<br />

1219058<br />

1579615<br />

1219063<br />

1219061<br />

Pail<br />

Tote<br />

Drum<br />

Pail<br />

Tote<br />

Drum<br />

Polyol 1:1 0.9:1 18,000 8.3 Amber 18,000 85-90 (A) - 40-60 min Moderate Moderate<br />

Iso 1:1 0.9:1 18,000 9.1 Amber 18,000 85-90 (A) - 40-60 min Moderate Moderate<br />

MACROPLAST ® UK 231A 1219089 Drum - Polyol 1:1 0.9:1 35,000 8.2 Amber Thixotropic 90-95 (A) - 60-70 min Moderate Moderate<br />

MACROPLAST ® UK 231B 1219090 Drum - Iso 1:1 0.9:1 6,000 9.3 Amber Thixotropic 90-95 (A) - 60-70 min Moderate Moderate<br />

FDA 175.105 / NSF 61<br />

FDA 175.105<br />

21 www.henkelna.com/filters<br />

22

APPLICATION-SPECIFIC ADHESIVES FOR<br />

WATER / DAIRY / FOOD & BEVERAGE FI<strong>LT</strong>ER ASSEMBLY<br />

TWO-PART EPOXY SYSTEMS – Typical Properties<br />

Application Product Name Product Number<br />

Package Size/<br />

Type<br />

Premier<br />

Distribution<br />

Type<br />

Vol. Mix Ratio<br />

(A:B)<br />

Mass Mix<br />

Ratio (A:B)<br />

Viscosity<br />

(cPs)<br />

SG<br />

Color<br />

Mixed Viscosity<br />

(cPs)<br />

Shore Hardness<br />

Gel Time<br />

(100g at 77ºF)<br />

Tensile Strength<br />

(psi)<br />

Tear Strength<br />

(lbs/in)<br />

Description<br />

LOCTITE ® E-30CL<br />

29329<br />

29331<br />

29332A/29333B<br />

50mL Cart<br />

400mL Cart<br />

Pail - MTO<br />

Resin<br />

100 10,500 1.1 Clear<br />

2:1<br />

Hardener 46 2,000 1 Clear<br />

6,000 85 (D) 160 min. High High Controlled Viscosity<br />

LOCTITE ® M-31CL<br />

30673<br />

30674<br />

50mL Cart<br />

200mL Cart<br />

Resin<br />

100 10,500 1.1 Clear<br />

2:1<br />

Hardener 46 2,000 1 Clear<br />

6,000 85 (D) 160 min. High High<br />

Controlled Viscosity<br />

& ISO 10993 approval<br />

LOCTITE ® E3346<br />

1294260<br />

1294291<br />

Pail<br />

Pail -<br />

Resin<br />

100 4,000 N/A Blue<br />

2:1<br />

Hardener 43 2,500 N/A Yellow<br />

3,500 85 (D) 60 min. 16,324 High<br />

Controlled Viscosity<br />

& High Elongation (46%)<br />

LOCTITE ® 193316 1094638 (Can)-MTO - Resin 2.44:1 100 3,500 1.15 Clear 3,000 85 (D) 180 min. High High Controlled Viscosity<br />

Hollow Fiber Potting<br />

LOCTITE ® 193317 1094639 (Can)-MTO - Hardener 2.44:1 34.5 500 0.97 Amber 3,000 85 (D) 180 min. High High Controlled Viscosity<br />

LOCTITE ® 36369 209989 Pail - Resin 2:1 100 5,750 1.15 Clear 4,900 78 (D) 30 min. High High<br />

LOCTITE ® 36370 209990 Pail - Hardener 2:1 46.1 3,250 1.06 Clear 4,900 78 (D) 30 min. High High<br />

LOCTITE ® 37734 210268 Tote - Resin 2:1 100 3,500 1.14 Clear 3,200 78 (D) 30 min. High High<br />

LOCTITE ® 37735 210269 Tote - Hardener 2:1 46.5 2,500 1.06 Clear 3,200 78 (D) 30 min. High High<br />

Controlled Viscosity<br />

& Low Exo<strong>the</strong>rm (85°C)<br />

Controlled Viscosity<br />

& Low Exo<strong>the</strong>rm (85°C)<br />

Controlled Viscosity<br />

& Low Exo<strong>the</strong>rm (85°C)<br />

Controlled Viscosity<br />

& Low Exo<strong>the</strong>rm (85°C)<br />

LOCTITE ® 9412 83107 1 Gal<br />

Resin<br />

100 15,000<br />

Off-White<br />

3.5:1<br />

N/A<br />

Hardener 25 40 Pink<br />

750 75 (D) 65 min. High High<br />

Low Viscosity and<br />

High Peel Strength<br />

ADHESIVES FOR CARBON BLOCK FI<strong>LT</strong>ERS<br />

Application Product Name Product Number<br />

Package Size/<br />

Type<br />

Premier<br />

Distribution<br />

Type Assembly Time Open Time Color Softening Point (ºC)/(ºF) Viscosity (cPs)<br />

325°F 350°F<br />

Description<br />

TECHNOME<strong>LT</strong> ® 2787<br />

1217459<br />

1469016<br />

Box<br />

Drum<br />

Copolymer Moderate Moderate Yellow 90 / 194 4,800 3,800 FDA 175.105<br />

End Cap Bonding<br />

TECHNOME<strong>LT</strong> ® 947C 1217927 Box - EVA Fast Long Off-White 78 / 172 7,400 4,500 FDA 175.105/NSF Approvable<br />

HYSOL ® 232 83239 Box EVA Moderate Long Clear 87 / 189 17,000 11,000 FDA 175.105 /NSF Approvable<br />

23 www.henkelna.com/filters<br />

24

INDEX<br />

PRODUCT PAGE PAGE<br />

A<br />

ADHESIN® 32-724A ........................................... 17<br />

ADHESIN® 45-7348H ......................................... 17<br />

ADHESIN® 51-3093 ............................................. 17<br />

ADHESIN® 51-3130 ............................................. 17<br />

ADHESIN® 56-5112 ............................................. 17<br />

AQUENCE 774B ...................................................... 17<br />

D<br />

DORUS® MS 3210 ............................................... 19<br />

H<br />

HYSOL® 232 ...................................................... 23<br />

HYSOL® US 5501A .......................................... 7, 15<br />

HYSOL® US 5501B .......................................... 7, 15<br />

L<br />

LOCTITE® 401 ......................................................11<br />

LOCTITE® 454 .....................................................11<br />

LOCTITE® 620 .....................................................11<br />

LOCTITE 3985 ..........................................................3<br />

LOCTITE® 3985 .....................................................3<br />

LOCTITE® 5182 ....................................................11<br />

LOCTITE® 6001 ....................................................11<br />

LOCTITE® 9412 .................................................. 23<br />

LOCTITE 9432NA .....................................................3<br />

LOCTITE® 9432NA ................................................3<br />

LOCTITE® 36369 ................................................ 23<br />

LOCTITE® 36370 ................................................ 23<br />

LOCTITE® 37734 ................................................ 23<br />

LOCTITE® 37735 ................................................. 23<br />

LOCTITE® 193316 ............................................... 23<br />

LOCTITE® 193317 ............................................... 23<br />

LOCTITE® A 3<strong>04</strong>-10-1 ........................................... 3<br />

LOCTITE® A 3<strong>04</strong>-26 ............................................. 3<br />

LOCTITE® A 3<strong>04</strong>-29 ............................................. 3<br />

LOCTITE® A 316-30 .............................................. 3<br />

LOCTITE® A 316-43 .............................................. 3<br />

LOCTITE® A 329-14 .............................................. 3<br />

LOCTITE® E-00CL ................................................ 5<br />

LOCTITE® E-05MR ............................................... 5<br />

LOCTITE® E-30CL .......................................... 5, 23<br />

LOCTITE® E-40EXP ............................................. 5<br />

LOCTITE® E-40HT ............................................... 5<br />

LOCTITE® E-60NC ............................................... 5<br />

LOCTITE® E 359 ................................................... 3<br />

LOCTITE® E3346 ................................................ 23<br />

LOCTITE® H3101 .................................................. 5<br />

LOCTITE® M-31CL .............................................. 23<br />

M<br />

MACROME<strong>LT</strong>® 2157 ............................................. 9<br />

MACROME<strong>LT</strong>® 2192B ..................................5, 9, 13<br />

MACROME<strong>LT</strong>® 2333B .......................................... 9<br />

MACROME<strong>LT</strong>® 2692 .........................................5, 9<br />

MACROME<strong>LT</strong>® 6202 ............................................ 9<br />

MACROME<strong>LT</strong>® 6238 ............................................ 9<br />

MACROME<strong>LT</strong>® 6239 ............................................ 9<br />

MACROME<strong>LT</strong>® 6240 ........................................... 9<br />

MACROME<strong>LT</strong>® 6300 ....................................... 5, 9<br />

MACROME<strong>LT</strong>® 9069 ....................................... 5, 9<br />

MACROPLAST® UK 072A .............................. 7, 15<br />

MACROPLAST® UK 072B ............................... 7, 15<br />

MACROPLAST® UK 178A .................................. 21<br />

MACROPLAST® UK 178B .................................. 21<br />

MACROPLAST® UK 180A ................................. 21<br />

MACROPLAST® UK 180B............................... 7, 21<br />

MACROPLAST® UK 201A .................................... 7<br />

MACROPLAST® UK 231A .................................. 21<br />

MACROPLAST® UK 231B .................................. 21<br />

MACROPLAST® UK 413A ................................... 15<br />

MACROPLAST® UK 413B ................................... 15<br />

P<br />

PERM-ATTACH® 395C ....................................... 17<br />

PURME<strong>LT</strong>® QR 246CLV ....................................... 5<br />

PURME<strong>LT</strong>® QR 9016 ............................................ 5<br />

S<br />

SUPERFLEX® 587................................................ 11<br />

SUPERFLEX® 593................................................ 11<br />

SUPERFLEX® 5900 ............................................. 11<br />

T<br />

TECHNOME<strong>LT</strong>® 80-8361.................................... 19<br />

TECHNOME<strong>LT</strong>® 80-8572 ................................... 19<br />

TECHNOME<strong>LT</strong>® 80-8647 .......................... 9, 13, 19<br />

TECHNOME<strong>LT</strong>® 269C ......................................... 11<br />

TECHNOME<strong>LT</strong>® 870C ....................................... 13<br />

TECHNOME<strong>LT</strong>® 871B ........................................... 9<br />

TECHNOME<strong>LT</strong>® 947C ....................................... 23<br />

TECHNOME<strong>LT</strong>® 2631 ......................................... 19<br />

TECHNOME<strong>LT</strong>® 2635 ......................................... 19<br />

TECHNOME<strong>LT</strong>® 2787 ................................... 19, 24<br />

TECHNOME<strong>LT</strong>® 8370..................................... 9, 19<br />

TECHNOME<strong>LT</strong>® 8448 ........................................ 19<br />

TECHNOME<strong>LT</strong>® 8848 ......................................... 11<br />

TECHNOME<strong>LT</strong>® COOL 889A .............................. 19<br />

TECHNOME<strong>LT</strong>® EM-4955 .................................. 19<br />

TECHNOME<strong>LT</strong>® PS-8843X .................................. 11<br />

TECHNOME<strong>LT</strong>® Q-1214 ..................................... 13<br />

TECHNOME<strong>LT</strong>® Q-1214 ........................................ 9<br />

TECHNOME<strong>LT</strong>® Q4206 ...................................... 11<br />

TECHNOME<strong>LT</strong>® Q4222 ....................................... 11<br />

TECHNOME<strong>LT</strong>® Q-5669 ................................ 9, 13<br />

U<br />

US 0151 A ............................................................. 5<br />

US 0151 B ............................................................. 5<br />

V<br />

VETAK® V797 ...................................................... 7<br />

25<br />

www.henkelna.com/filters

Building <strong>the</strong> Next Best Thing<br />

We realize that selecting <strong>the</strong> right adhesive is more than just a viscosity or open time value.<br />

It’s a combination of factors like adhesion to filter media, bond strength to metal end caps,<br />

or high temperature resistance. Moreover, it’s about working with suppliers who treat <strong>the</strong>ir<br />

customers like partners. At Henkel, we work with customers to help <strong>the</strong>m take <strong>the</strong> next step.<br />

For application assistance or additional in<strong>for</strong>mation, call 1.866.4HENKEL (443.6535).<br />

The Henkel filter team will help find a solution that’s right <strong>for</strong> you.

U.S.A.<br />

Henkel Corporation<br />

One Henkel Way<br />

Rocky Hill, CT 06067<br />

Tel: 866.781.4601<br />

Tel: 860.571.5100<br />

Canada<br />

Henkel Canada Corporation<br />

2515 Meadowpine Blvd.<br />

Mississauga, Ontario L5N 6C3<br />

Tel: 1.800.263.5<strong>04</strong>3 (within Canada)<br />

Tel: 905.814.6511<br />

Fax: 905.814.5391<br />

www.henkelna.com/filters<br />

Except as o<strong>the</strong>rwise noted, all marks used are trademarks and/or registered trademarks of Henkel and/or its affiliates in <strong>the</strong> U.S. and elsewhere.<br />

®<br />

= registered in <strong>the</strong> U.S. Patent and Trademark Office. © Henkel Corporation, <strong>2012</strong>. All rights reserved. 9636 / <strong>LT</strong>-<strong>6471</strong> (11/12)