Loctite® Nordbak® Crusher Backing Materials

Loctite® Nordbak® Crusher Backing Materials

Loctite® Nordbak® Crusher Backing Materials

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Number of Kits per Application<br />

Approximate number of 2 gallon kits (21.5 lbs. / 10 kg) of Nordback ® <strong>Backing</strong> Material required for crushers<br />

NORDBERG ® PRIMARY GYRATORY CRUSHERS<br />

<strong>Crusher</strong> Size HD 42-70 HD 54-80 HD 60-102<br />

Mantle<br />

Concave<br />

24<br />

69<br />

39<br />

119<br />

49<br />

177<br />

NORDBERG ® WATER FLUSH SYSTEMS<br />

<strong>Crusher</strong> Type WF 500 WF 800<br />

Mantle<br />

Bowl<br />

Bowl – using<br />

fi ller blocks<br />

SYMONS<br />

5<br />

14<br />

—<br />

8<br />

40<br />

20<br />

® CONE CRUSHERS<br />

<strong>Crusher</strong> Size<br />

Standard Cone <strong>Crusher</strong><br />

2' 3' 4' 4¼' 5' 5½' 7'<br />

Mantle<br />

1 2½ 3½ 4 3½ 7½ 12<br />

Bowl Liner<br />

1 1½ 3½ 4½ 5<br />

7½ 15<br />

Short-Head ® Cone <strong>Crusher</strong><br />

Mantle<br />

Bowl Liner<br />

1<br />

1<br />

1½<br />

1½<br />

2<br />

3<br />

2<br />

2½<br />

2½<br />

5<br />

3½<br />

6<br />

6½<br />

9<br />

Note: These fi gures are based on cone crushers with a fi ne bowl and fi ne liner. The condition of liners and bowls may vary due to wear.<br />

Locking compound requirements: All sizes of Symons ® Cone <strong>Crusher</strong>s up to 5.5-foot – 1 kit. For 5.5-foot Symons ® Cone <strong>Crusher</strong>s – 2 kits.<br />

TELSMITH GYRASPHERE ® CRUSHERS<br />

<strong>Crusher</strong> Size<br />

Style S<br />

24 36 367 48 489 66 6614 1100 1100SX 1300 1500 1500SX<br />

Mantle<br />

Concave Ring<br />

Medium<br />

Coarse<br />

Style FC<br />

1½<br />

1<br />

2<br />

1¾<br />

2<br />

1¾<br />

4½<br />

4<br />

4½<br />

4<br />

4<br />

5½<br />

9½<br />

17½<br />

2<br />

—<br />

4½<br />

4<br />

2<br />

—<br />

4½<br />

4<br />

4<br />

—<br />

—<br />

4<br />

5<br />

5<br />

—<br />

—<br />

6<br />

—<br />

65<br />

Mantle<br />

Concave Ring<br />

Medium<br />

Coarse<br />

1¾<br />

1<br />

2<br />

1¾<br />

—<br />

—<br />

2<br />

3½<br />

—<br />

—<br />

9½<br />

12<br />

—<br />

—<br />

2<br />

—<br />

43<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

5<br />

5<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

ALLIS-CHALMERS CRUSHERS<br />

Superior<br />

<strong>Crusher</strong> Size 13-36 16-50 24-60 30-55 30-70 36-55 42-65 48-74 54-74 60-89 60-109<br />

Mantle<br />

5 17 18 16 24 27<br />

37<br />

46<br />

46<br />

66<br />

90<br />

Concave Ring<br />

Hydrocone<br />

5 26 41 48 46 70<br />

95 110 173 190 220<br />

<strong>Crusher</strong> Size 36" 45" 51" 60" 84"<br />

Mantle<br />

1 4½ 5<br />

6 22<br />

Concave Ring — 9 14 36 43<br />

EL-JAY ROLLERCONE ® CRUSHERS<br />

<strong>Crusher</strong> Size 2' 3' 4' 4¼' 5' 5½'<br />

Mantle<br />

Bowl Liner<br />

PIONEER CONE CRUSHERS<br />

1<br />

1<br />

2½<br />

1½<br />

3½<br />

3½<br />

<strong>Crusher</strong> Size 36" Standard 36" Fine Head 45" Standard 45" Fine Head 54" Standard 54" Fine Head<br />

Mantle<br />

Bowl Liner<br />

TRAYLOR “TY” CRUSHERS<br />

1<br />

1½<br />

1<br />

1½<br />

1½<br />

3<br />

<strong>Crusher</strong> Size 2' 3' 4' 4¼' 5' 5½'<br />

Mantle<br />

Bowl Liner<br />

TRAYLOR “TC” CRUSHERS<br />

1<br />

1<br />

2½<br />

1½<br />

3½<br />

3½<br />

<strong>Crusher</strong> Size 2' 3' 4' 4¼' 5' 5½'<br />

Mantle<br />

Bowl Liner<br />

Henkel Corporation<br />

Engineering Adhesives<br />

www.henkelna.com/industrial<br />

www.loctite.com<br />

1<br />

1<br />

2½<br />

1½<br />

3½<br />

3½<br />

U.S.A.<br />

Henkel Corporation<br />

Engineering Adhesives<br />

1001 Trout Brook Crossing<br />

Rocky Hill, Connecticut 06067<br />

Tel: 860.571.5100<br />

Fax: 860.571.5465<br />

1½<br />

3<br />

1½<br />

3<br />

1½<br />

3<br />

1½<br />

3<br />

2<br />

4<br />

2<br />

4<br />

2<br />

4<br />

2<br />

4<br />

Canada<br />

Henkel Canada Corporation<br />

2225 Meadowpine Blvd.<br />

Mississauga, Ontario, Canada<br />

L5N 7P2<br />

Tel: 1.800.263.5043<br />

Tel: 905.814.6511<br />

Fax: 905.814.6522<br />

<strong>Loctite®</strong> and <strong>Nordbak®</strong> are trademarks of Henkel Corporation in the U.S. and its affiliates elsewhere. ® denotes a trademark registered in the U.S. Patent and Trademark Office.<br />

All other trademarks are the property of their respective owners. © Henkel Corporation, 2008. All rights reserved. 5151/LT-3387 (05/08).<br />

2<br />

4<br />

2<br />

4<br />

2<br />

4<br />

2<br />

4<br />

Chile<br />

Henkel Chile Ltda.<br />

Ave. Laguna Sur 9551<br />

Pudahuel, Santiago, Chile<br />

C.P. 9060987<br />

Tel: 800.223.005<br />

Tel: 56.2.381.7200<br />

Fax: 56.2.601.1670<br />

Loctite ® Nordbak ®<br />

<strong>Crusher</strong> <strong>Backing</strong> <strong>Materials</strong><br />

Cone and Gyratory <strong>Crusher</strong>s<br />

Water Flush Systems<br />

Grinding Mills<br />

Locks and Dams

PRODUCT<br />

BENEFITS:<br />

• Maximum<br />

protection<br />

• Positive support<br />

of wear liners<br />

• Low shrinkage<br />

during cure<br />

prevents<br />

voids and<br />

misalignment<br />

• Replace<br />

dangerous and<br />

costly molten<br />

zinc pours<br />

• Kit package<br />

allows easy<br />

mixing and<br />

pouring<br />

Loctite ® Nordbak ® <strong>Backing</strong> <strong>Materials</strong> —<br />

industry leaders with proven performance<br />

for over 30 years.<br />

<strong>Crusher</strong> <strong>Backing</strong> <strong>Materials</strong><br />

Loctite ® Nordbak ® <strong>Backing</strong> Material<br />

• 100% solids epoxy compound for backing wear<br />

plates in cone crushers and grinding mills<br />

• Provides high compressive strength and<br />

impact resistance<br />

• High volumetric stability eliminates gaps<br />

between liners<br />

• Nonfl ammable<br />

• Pourable compound requires no melting or<br />

special equipment<br />

Loctite ® Nordbak ® High Impact<br />

<strong>Backing</strong> Material<br />

• Excellent resilience while retaining high<br />

compression and tensile strengths<br />

• Maintains all other features of regular Loctite ®<br />

Nordbak ® <strong>Backing</strong> Material (heat distortion<br />

temperature, ease of mixing and pouring)<br />

Loctite ® Nordbak ® Accelerator<br />

for <strong>Backing</strong><br />

• Added to resin prior to mixing to speed the cure<br />

of the material when equipment and ambient<br />

temperatures are below 55°F<br />

• Can be used with the following products:<br />

– Loctite ® Nordbak ® <strong>Backing</strong> Material<br />

– Loctite ® Nordbak ® High Impact <strong>Backing</strong> Material<br />

– Loctite ® Nordbak ® High Performance<br />

<strong>Backing</strong> Material<br />

<strong>Loctite®</strong> <strong>Nordbak®</strong> High Performance<br />

<strong>Backing</strong> Material<br />

• For use in water fl ush systems and<br />

protecting wear plates under the most<br />

demanding conditions<br />

• Provides the highest compressive strength<br />

and impact resistance<br />

• High volumetric stability eliminates gaps<br />

between liners<br />

• Nonfl ammable<br />

• High hydrolytic stability provides low<br />

water absorption<br />

Loctite ® Nordbak ® Trowel Mix<br />

• <strong>Backing</strong> material in a trowelable, putty form<br />

• Used to back liners in all types of mills<br />

without dismantling the mill or removing the<br />

grinding charge<br />

• Recommended for backing head liners,<br />

division heads, diaphragms, and securing<br />

liner bolts<br />

• Unused portions may be resealed for<br />

future use<br />

Loctite ® Nordbak ® Locking Compound<br />

• Locks the inner and outer eccentric bushings in<br />

Symons ® Cone <strong>Crusher</strong>s<br />

• High impact system resists temperatures<br />

to 225°F<br />

• Safe and easy to use; saves time and money<br />

• One kit required for all sizes of Symons ® Cone<br />

<strong>Crusher</strong>s up to 5.5 foot<br />

• Two kits required for 5.5-foot Symons ®<br />

Cone <strong>Crusher</strong>s<br />

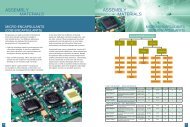

PROPERTIES CHART<br />

PRODUCT<br />

<strong>Backing</strong> Material<br />

High Performance<br />

<strong>Backing</strong><br />

High Impact<br />

<strong>Backing</strong><br />

Product<br />

Number Container<br />

99692<br />

99695<br />

35248*<br />

35259*<br />

98072<br />

98075<br />

35264*<br />

35265*<br />

2 gallon kit<br />

5 gallon kit<br />

55 gallon drum<br />

5 gallon pail<br />

2 gallon kit<br />

5 gallon kit<br />

55 gallon drum<br />

5 gallon pail<br />

Product Storage<br />

For better performance, <strong>Loctite®</strong> <strong>Nordbak®</strong><br />

<strong>Backing</strong> <strong>Materials</strong> should be stored at 60°F-75°F<br />

(15ºC- 24ºC), at least 24-48 hours before your pour.<br />

Prolonged exposure to temperatures below 50°F<br />

(10ºC) may affect product performance:<br />

• Diffi culty to mix resin and hardener<br />

• Diffi culty to pour<br />

• Longer cure time<br />

Application Tips<br />

Coverage, cu. in.<br />

@ ¼" thickness<br />

340<br />

850<br />

9350<br />

n/a<br />

340<br />

850<br />

9350<br />

Cure time depends on temperature and mass.<br />

The higher the temperature and the larger the<br />

mass, the faster the cure.<br />

Cold Weather Conditions (100°F)<br />

To increase cure time under extreme warm weather<br />

conditions (100ºF/ 38ºC or higher) you can mix<br />

backing in small masses and/or cool down backing.<br />

Hardness (Shore D)<br />

Working time at<br />

77°F, minutes<br />

Functional cure at<br />

77°F, hours<br />

Brown 170 15,500 6,200 1.6 90 10 8<br />

Red 220 18,000 6,500 2.7 90 20 8<br />

99652 2 gallon kit 340 Brown 170 11,000 3,000 1.4 85 30 8<br />

Trowel Mix 39748 5 gallon kit<br />

18 sq. ft. @<br />

¼" thick<br />

Application<br />

Recommendations<br />

• Cone crushers up to 7'<br />

• Grinding mills<br />

• 7' cone crushers<br />

• Extreme hard rock crushing<br />

• Primary gyratory crushers<br />

• Cone crushers up to 7'<br />

• Grinding mills<br />

Brown 180 16,000 4,000 1.6 90 15 8 • Grinding mills<br />

Locking Compound 98971 2 gallon kit 115 Grey 225 12,000 6,000 3.0 90 10 8 • Lock eccentric bushings<br />

Accelerator for<br />

<strong>Backing</strong><br />

96554 2.8 fl . oz. – Blue – – – – – – –<br />

• Cold temperature<br />

crusher pours<br />

Mixing Paddles 94024 6 per box – – – – – – – – – –<br />

* The following products must be ordered together to form a kit: 35248 (Resin) + 35259 (Hardener), as well as 35264 (Resin) + 35265 (Hardener)<br />

GEL TIME<br />

INFORMATION GEL TIME<br />

Product<br />

(2 gallon pail)<br />

Material<br />

Temperature<br />

<strong>Backing</strong> Material 22°C (72°F)<br />

8°C (44°F)<br />

High Performance<br />

<strong>Backing</strong> Material<br />

22°C (72°F)<br />

8°C (44°F)<br />

Without<br />

Accelerator<br />

21 minutes<br />

32 minutes<br />

46 minutes<br />

220 minutes<br />

WARNING:<br />

Never apply torch directly to<br />

the backing plastic/metal pails:<br />

• Pails may melt<br />

• Hardener may boil<br />

With One Can<br />

of Accelerator<br />

13 minutes<br />

28 minutes<br />

24 minutes<br />

75 minutes<br />

Do not add extra hardener<br />

• It will not speed up the cure<br />

With Two Cans of<br />

Accelerator<br />

9 minutes<br />

12 minutes<br />

18 minutes<br />

55 minutes