Loctite® Nordbak® Crusher Backing Materials

Loctite® Nordbak® Crusher Backing Materials

Loctite® Nordbak® Crusher Backing Materials

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PRODUCT<br />

BENEFITS:<br />

• Maximum<br />

protection<br />

• Positive support<br />

of wear liners<br />

• Low shrinkage<br />

during cure<br />

prevents<br />

voids and<br />

misalignment<br />

• Replace<br />

dangerous and<br />

costly molten<br />

zinc pours<br />

• Kit package<br />

allows easy<br />

mixing and<br />

pouring<br />

Loctite ® Nordbak ® <strong>Backing</strong> <strong>Materials</strong> —<br />

industry leaders with proven performance<br />

for over 30 years.<br />

<strong>Crusher</strong> <strong>Backing</strong> <strong>Materials</strong><br />

Loctite ® Nordbak ® <strong>Backing</strong> Material<br />

• 100% solids epoxy compound for backing wear<br />

plates in cone crushers and grinding mills<br />

• Provides high compressive strength and<br />

impact resistance<br />

• High volumetric stability eliminates gaps<br />

between liners<br />

• Nonfl ammable<br />

• Pourable compound requires no melting or<br />

special equipment<br />

Loctite ® Nordbak ® High Impact<br />

<strong>Backing</strong> Material<br />

• Excellent resilience while retaining high<br />

compression and tensile strengths<br />

• Maintains all other features of regular Loctite ®<br />

Nordbak ® <strong>Backing</strong> Material (heat distortion<br />

temperature, ease of mixing and pouring)<br />

Loctite ® Nordbak ® Accelerator<br />

for <strong>Backing</strong><br />

• Added to resin prior to mixing to speed the cure<br />

of the material when equipment and ambient<br />

temperatures are below 55°F<br />

• Can be used with the following products:<br />

– Loctite ® Nordbak ® <strong>Backing</strong> Material<br />

– Loctite ® Nordbak ® High Impact <strong>Backing</strong> Material<br />

– Loctite ® Nordbak ® High Performance<br />

<strong>Backing</strong> Material<br />

<strong>Loctite®</strong> <strong>Nordbak®</strong> High Performance<br />

<strong>Backing</strong> Material<br />

• For use in water fl ush systems and<br />

protecting wear plates under the most<br />

demanding conditions<br />

• Provides the highest compressive strength<br />

and impact resistance<br />

• High volumetric stability eliminates gaps<br />

between liners<br />

• Nonfl ammable<br />

• High hydrolytic stability provides low<br />

water absorption<br />

Loctite ® Nordbak ® Trowel Mix<br />

• <strong>Backing</strong> material in a trowelable, putty form<br />

• Used to back liners in all types of mills<br />

without dismantling the mill or removing the<br />

grinding charge<br />

• Recommended for backing head liners,<br />

division heads, diaphragms, and securing<br />

liner bolts<br />

• Unused portions may be resealed for<br />

future use<br />

Loctite ® Nordbak ® Locking Compound<br />

• Locks the inner and outer eccentric bushings in<br />

Symons ® Cone <strong>Crusher</strong>s<br />

• High impact system resists temperatures<br />

to 225°F<br />

• Safe and easy to use; saves time and money<br />

• One kit required for all sizes of Symons ® Cone<br />

<strong>Crusher</strong>s up to 5.5 foot<br />

• Two kits required for 5.5-foot Symons ®<br />

Cone <strong>Crusher</strong>s<br />

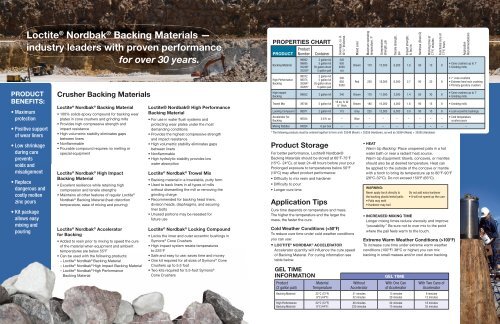

PROPERTIES CHART<br />

PRODUCT<br />

<strong>Backing</strong> Material<br />

High Performance<br />

<strong>Backing</strong><br />

High Impact<br />

<strong>Backing</strong><br />

Product<br />

Number Container<br />

99692<br />

99695<br />

35248*<br />

35259*<br />

98072<br />

98075<br />

35264*<br />

35265*<br />

2 gallon kit<br />

5 gallon kit<br />

55 gallon drum<br />

5 gallon pail<br />

2 gallon kit<br />

5 gallon kit<br />

55 gallon drum<br />

5 gallon pail<br />

Product Storage<br />

For better performance, <strong>Loctite®</strong> <strong>Nordbak®</strong><br />

<strong>Backing</strong> <strong>Materials</strong> should be stored at 60°F-75°F<br />

(15ºC- 24ºC), at least 24-48 hours before your pour.<br />

Prolonged exposure to temperatures below 50°F<br />

(10ºC) may affect product performance:<br />

• Diffi culty to mix resin and hardener<br />

• Diffi culty to pour<br />

• Longer cure time<br />

Application Tips<br />

Coverage, cu. in.<br />

@ ¼" thickness<br />

340<br />

850<br />

9350<br />

n/a<br />

340<br />

850<br />

9350<br />

Cure time depends on temperature and mass.<br />

The higher the temperature and the larger the<br />

mass, the faster the cure.<br />

Cold Weather Conditions (100°F)<br />

To increase cure time under extreme warm weather<br />

conditions (100ºF/ 38ºC or higher) you can mix<br />

backing in small masses and/or cool down backing.<br />

Hardness (Shore D)<br />

Working time at<br />

77°F, minutes<br />

Functional cure at<br />

77°F, hours<br />

Brown 170 15,500 6,200 1.6 90 10 8<br />

Red 220 18,000 6,500 2.7 90 20 8<br />

99652 2 gallon kit 340 Brown 170 11,000 3,000 1.4 85 30 8<br />

Trowel Mix 39748 5 gallon kit<br />

18 sq. ft. @<br />

¼" thick<br />

Application<br />

Recommendations<br />

• Cone crushers up to 7'<br />

• Grinding mills<br />

• 7' cone crushers<br />

• Extreme hard rock crushing<br />

• Primary gyratory crushers<br />

• Cone crushers up to 7'<br />

• Grinding mills<br />

Brown 180 16,000 4,000 1.6 90 15 8 • Grinding mills<br />

Locking Compound 98971 2 gallon kit 115 Grey 225 12,000 6,000 3.0 90 10 8 • Lock eccentric bushings<br />

Accelerator for<br />

<strong>Backing</strong><br />

96554 2.8 fl . oz. – Blue – – – – – – –<br />

• Cold temperature<br />

crusher pours<br />

Mixing Paddles 94024 6 per box – – – – – – – – – –<br />

* The following products must be ordered together to form a kit: 35248 (Resin) + 35259 (Hardener), as well as 35264 (Resin) + 35265 (Hardener)<br />

GEL TIME<br />

INFORMATION GEL TIME<br />

Product<br />

(2 gallon pail)<br />

Material<br />

Temperature<br />

<strong>Backing</strong> Material 22°C (72°F)<br />

8°C (44°F)<br />

High Performance<br />

<strong>Backing</strong> Material<br />

22°C (72°F)<br />

8°C (44°F)<br />

Without<br />

Accelerator<br />

21 minutes<br />

32 minutes<br />

46 minutes<br />

220 minutes<br />

WARNING:<br />

Never apply torch directly to<br />

the backing plastic/metal pails:<br />

• Pails may melt<br />

• Hardener may boil<br />

With One Can<br />

of Accelerator<br />

13 minutes<br />

28 minutes<br />

24 minutes<br />

75 minutes<br />

Do not add extra hardener<br />

• It will not speed up the cure<br />

With Two Cans of<br />

Accelerator<br />

9 minutes<br />

12 minutes<br />

18 minutes<br />

55 minutes