TIRET October 2012 Issue - MIDROC Ethiopia

TIRET October 2012 Issue - MIDROC Ethiopia

TIRET October 2012 Issue - MIDROC Ethiopia

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

A view of the forestry development<br />

The current product manufactured by the factory,<br />

particle board, can be used for furniture making,<br />

roofing, internal building, wall partition and also as<br />

packing material.<br />

The factory employs 130 professional and skilled<br />

employees on a permanent basis and 500 casual<br />

laborers. This will grow to 300 professional and skilled<br />

employees when it begins operating at full capacity<br />

(three shifts). The forestry development in Wolayta<br />

Sodo also employs 500 local residents during harvest<br />

seasons.<br />

Production Process<br />

Chipwood is composed of wood particles mixed with<br />

resin, as an adhesive, and wax and hardener; the mix is<br />

treated under various temperatures, moisture, pressing,<br />

curing and sanding conditions. The factory produces<br />

chipwood size 11.20m x 1.83m, which can be resized in<br />

to 2, 3, or 4 equal or different sizes.<br />

It uses four types of raw materials: chipwood particles<br />

(logs), urea formaldehyde resin (glue), wax and hardener<br />

(Ammonium Chloride), all of which, except logs, are<br />

imported at an annual cost of Birr 31 million.<br />

Chip wood has two outer layers (surfaces) and a core.<br />

The general steps used to produce particle wood include<br />

wood material chipping, flaking, drying, classifying by<br />

size, blending with resin, hardener and wax, forming<br />

the resinated (glued) material into a mat, hot pressing<br />

and finishing (cooling, trimming and sanding). The<br />

process involves the use of chipping, flaking and drying<br />

machines. A forming machine turns the glued material<br />

into a continuous mat, which is cut into the desired<br />

length. Furnace oil and wood dust are the energy<br />

sources used for the drying.<br />

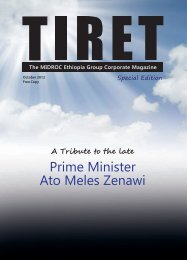

Wood transported to chipper machine<br />

Factory Input<br />

The consumption of wood per annum is 18,167 m3 at<br />

present, which will rise to 25,000 m3 in the near future.<br />

The factory can use any kind of wood, but the preferred<br />

wood type is Eucalyptus, because of its abundance and<br />

easier replacement. Accordingly contract agreement<br />

was entered with the Regional Government for the<br />

use and management of forest on 985hectares of land<br />

in Wolayta Sodo for the coming 20 years to ensure<br />

sustainable supply.<br />

Manpower Development and Training Schemes<br />

In order to ensure that quality remains the business’s top<br />

priority, the factory has adopted different approaches<br />

in recruiting and nurturing its employees, developing<br />

positive attitude towards learning, as part of the<br />

management’s commitment to equip and groom each<br />

individual.<br />

Accordingly, on the job training is given for 3-6<br />

months for new recruits to familiarize them with the<br />

different machines and operations. Inviting expatriate<br />

professionals to provide short-term training to employees<br />

is also part of this Manpower Development and Training<br />

Scheme. In addition, the factory is working with Hawassa<br />

University in the “University-Industry Linkage Program”<br />

for mutual benefit to train and familiarize students with<br />

the industry and exchange technology and knowledge<br />

with technologists of the University.<br />

Development Partners<br />

The factory’s development partners include Regional<br />

and Zonal offices of SNNPR, Dashen Bank, Nyala<br />

Insurance, the Commercial Bank of <strong>Ethiopia</strong>, <strong>MIDROC</strong><br />

Group Companies, Hawassa University, contractors,<br />

small scale distributors and furniture manufacturers.<br />

Special emphasis is due to <strong>MIDROC</strong> <strong>Ethiopia</strong> Head<br />

Office for the unrelented support in all aspects, for the<br />

TireT <strong>October</strong> <strong>2012</strong> 37