You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

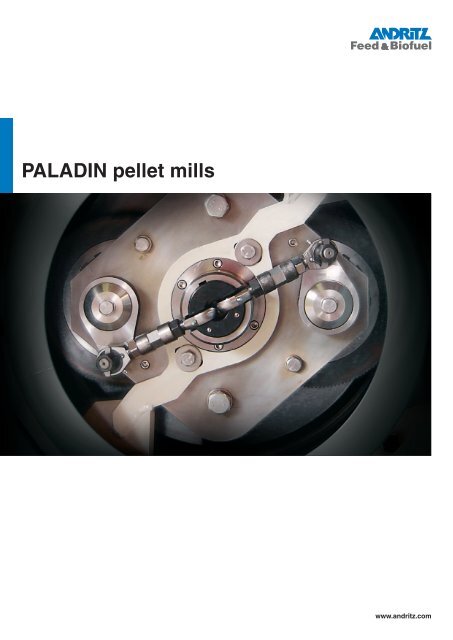

<strong>PALADIN</strong> <strong>pellet</strong> <strong>mills</strong><br />

www.andritz.com

Well-proven design concept<br />

Developed from a design concept proven on more than 2,000 operating machines sold throughout the world, the Paladin<br />

<strong>pellet</strong> mill series continues to advance and offer reliability, maximum efficiency and ease of operation and maintenance.<br />

Standard features on most Paladin <strong>pellet</strong> <strong>mills</strong>:<br />

• Rigid, durable construction for a variety of applications.<br />

• All parts in contact with products are of wear-resistant<br />

stainless steel.<br />

• Two or three rolls.<br />

• Manual roll adjustment.<br />

• Taper fit die with auto-piloting effect for easy die change.<br />

• Left-hinged or right-hinged door provides access to the<br />

entire <strong>pellet</strong> chamber.<br />

• Rugged roller main shaft in monoblock cast design,<br />

manufactured from high-quality stainless steel to withstand<br />

the harshest applications.<br />

• Hydraulic overload protection is standard for all models.<br />

• Safety systems interrupt the <strong>pellet</strong> mill immediately in case<br />

of irregularities.<br />

• Multiple options.<br />

Optional features for most Paladin <strong>pellet</strong> <strong>mills</strong>:<br />

• Pellet chamber in double-wall sandwich construction with<br />

heat and noise insulation.<br />

• Automatic roll adjustment is available for certain models.<br />

The system allows additional distance between die and<br />

rolls. No hydraulic or electronic components inside the die<br />

cavity.<br />

• The inlet screw and Centri-feeder® options provide<br />

uniform distribution of material to the press rolls for the<br />

<strong>pellet</strong>ing of low-density and other difficult raw or expanded<br />

materials<br />

• Automatic grease lubrication systems.<br />

• Built-in hoist with lifting tools for easy and safe die change<br />

and maintenance.<br />

• Computerized process control for the monitoring of all key<br />

parameters.<br />

• A series of conditioner chambers provides optimum<br />

retention time for specific capacity requirements.

Features which make the difference<br />

Highly skilled design engineering teams working in close contact with the customers ensure that the Paladin <strong>pellet</strong><br />

<strong>mills</strong> fulfil every need, using state-of-the-art technology.<br />

2<br />

2<br />

Roll adjustment system<br />

The system makes roll adjustment fast,<br />

easy and very accurate.<br />

Standard Paladin <strong>pellet</strong> <strong>mills</strong> can have<br />

two or three rolls.<br />

With the optional automatic roll<br />

adjustment system, roll gaps can<br />

be adjusted from the control desk,<br />

which gives the advantage of fast die<br />

change, fully step-less readjustment<br />

during operation and resetting without<br />

risking to roll over the die.<br />

2<br />

1 1<br />

Die hoist<br />

An integrated hoist facilitates the<br />

handling of dies, rolls, front plate<br />

and rotary feed cone. The die hoist<br />

on the Paladin 2000 and 3000<br />

series is hydraulic.<br />

3<br />

Pellet chamber<br />

The stainless steel <strong>pellet</strong> chamber<br />

door can be left-hinged or righthinged<br />

to suit the installation.<br />

Adjustable, calibrated knives<br />

provide the required <strong>pellet</strong> length.<br />

4<br />

Door<br />

The door is fitted with safety<br />

switches to prevent opening of a<br />

running machine.

5<br />

V-belt drive transmission<br />

Shock-absorbing V-belts form the first<br />

stage of the Paladin drive transmission<br />

with a hydraulic or mechanical system<br />

for constant maintenance of the<br />

correct tension. Therefore, slippage is<br />

eliminated, and the operational life of<br />

the V-belts is prolonged.<br />

8<br />

Automatic lubrication<br />

The Paladin series includes an<br />

automatic pneumatic grease<br />

lubrication system to ensure that press<br />

rolls and main shaft bearings are<br />

lubricated with the correct amount of<br />

grease.<br />

7<br />

8<br />

8<br />

6<br />

6<br />

Two-stage twin drive<br />

The patented Paladin two-stage<br />

drive system forms the basis of ideal<br />

transmission ratios. The combination<br />

of resilient V-belts and a high-torque<br />

toothed belt reduces the noise<br />

level and makes it possible to use<br />

standard electric motors and select<br />

a variety of die speeds.<br />

7<br />

Overload protection<br />

The die and roll assembly is<br />

protected by a hydraulic or<br />

mechanical overload system,<br />

which stops the main motors in<br />

case an overload situation occurs.<br />

Re-setting is quick and easy.

<strong>PALADIN</strong> <strong>pellet</strong> mill series<br />

Paladin 1600 Paladin 600<br />

Paladin 2400<br />

Paladin 2000<br />

Pellet mill type Die press dimensions Press rolls Speed-50 Hz Max. power 50 Hz<br />

Twin belt driven Width Diam. Cm 2 In 2 Qty. Diam. Qty. Diam. M/sec. kW<br />

Paladin 600B-130 130 550 2246 348 3 248 2 248 4.5 - 6.0 90 - 150<br />

Paladin 600B-170 170 550 2937 455 3 248 2 248 4.5 - 6.0 110 - 150<br />

Paladin 800-141 141 650 2879 446 3 298 2 298 4.5 - 6.5 110 - 150<br />

Paladin 800-175 175 650 3574 554 3 298 2 298 4.5 - 6.5 110 - 150<br />

Paladin 1200D-141 141 650 2879 446 3 298 2 298 5.1 - 6.5 150 - 180<br />

Paladin 1200D-175 175 650 3574 554 3 298 2 298 5.1 - 6.5 150 - 180<br />

Paladin 1600D-175 175 850 4673 725 3 396 2* 396 4.7 - 7.0 180 - 220<br />

Paladin 1600D-210 210 850 5608 870 3 396 2* 396 4.7 - 7.0 180 - 220<br />

Paladin 1600ES-210 210 850 5608 870 3 396 2* 396 4.7 - 7.0 180 - 220<br />

Paladin 2000-250 250 880 6912 1072 3 404 2* 420 4.9 - 7.5 220 - 264<br />

Paladin 2000-300 300 880 8294 1285 3 404 2* 420 4.9 - 7.5 220 - 264<br />

Paladin 2400-250 250 880 6912 1072 2 420 4.8 - 7.8 320<br />

Paladin 3000-300 300 1000 9425 1461 2* 490 5.0 - 7.0 320 - 500<br />

Paladin 3000-350 350 1000 10990 1703 2* 490 5.0 - 6.0 320 - 500<br />

Paladin 3000-380 380 1100 13125 2034 2* 510 5.0 - 6.0 320 - 500<br />

*The automatic roll adjustment system is optional.<br />

Paladin 3000

ANDRITZ FEED & BIOFUEL service<br />

Excellent support for aquatic feed and petfood plants. Being able to<br />

supply equipment for an entire feed <strong>pellet</strong> production is one thing,<br />

but being able to serve customers from nearby warehouses after the<br />

installation in terms of support and supply is yet another essential<br />

ANDRITZ FEED & BIOFUEL competence.<br />

Our worldwide presence is implemented through regional service centres<br />

that guarantee highly reliable process operations by means of close contact<br />

and support. ANDRITZ FEED & BIOFUEL engineers are available for plant<br />

audits and support in order to assist the customer in identifying and ensuring a<br />

possible production increase, locating cost-saving opportunities and fine-tuning<br />

the production process.<br />

Spare parts<br />

ANDRITZ FEED & BIOFUEL provides worldwide availability of spare parts,<br />

including dies and rolls. High-quality parts and consumables offer long life and<br />

good economy in the process plant.<br />

Service contracts, including products and support:<br />

• Spare parts<br />

• Wear parts<br />

• Regular service<br />

• On-line process support<br />

• Process optimization<br />

• Renovation and improvement<br />

• Recommendations for spare<br />

parts stock<br />

• Standby service technicians<br />

ANDRITZ FEED & BIOFUEL A/S<br />

Denmark.<br />

TeI. +45 72160 300<br />

andritz-fb.dk@andritz.com<br />

ANDRITZ FEED & BIOFUEL B.V.<br />

The Netherlands<br />

Tel. +31 40 2627777<br />

andritz-fb.nl@andritz.com<br />

ANDRITZ FEED & BIOFUEL,<br />

Division of <strong>Andritz</strong> S.A.S., France<br />

Tel. 33247506364<br />

andritz-fb.fr@andritz.com<br />

ANDRITZ FEED & BIOFUEL Ltd.<br />

England<br />

Tel. +44 1482825119 ·<br />

andritz-fb.uk@andritz.com<br />

ANDRITZ FEED & BIOFUEL<br />

eine Zweigniederlassung der <strong>Andritz</strong> GmbH.<br />

Germany<br />

Tel. +49 2104 9197-0<br />

andritz-fb.de@andritz.com<br />

ANDRITZ FEED & BIOFUEL<br />

Divsion Of <strong>Andritz</strong> Inc. USA<br />

Tel. +1 5705468211<br />

andritz-fb.us@andritz.com<br />

ANDRITZ FEED & BIOFUEL<br />

Rep. Office Venezuela<br />

Venezuela<br />

Tel. +58 241 8422515<br />

andritz-fb.ve@andritz.com<br />

ANDRITZ FEED & BIOFUEL,<br />

Division of <strong>Andritz</strong> Hydro S.A. de C.V.<br />

Mexico<br />

Tel. +52 (229) 178 3669<br />

andritz-fb.mx@andritz.com<br />

ANDRITZ FEED & BIOFUEL Brasil Ltda.<br />

Brasil<br />

Tel. +55 51 3333 0128 ·<br />

andritz-fb.br@andritz.com<br />

ANDRITZ FEED & BIOFUEL<br />

Division of <strong>Andritz</strong> Chile Ltda.<br />

Chile<br />

Tel.: +56 2214 5711<br />

andritz-fb.cl@andritz.com<br />

ANDRITZ FEED & BIOFUEL<br />

Divsion Of <strong>Andritz</strong> Pty Ltd.<br />

Australia<br />

Tel. +61 3 8795 9800<br />

andritz-fb.au@andritz.com<br />

ANDRITZ FEED & BIOFUEL<br />

Rep. office Vietnam<br />

Tel.: +84 8 6253 9434<br />

andritz-fb.vi@andritz.com<br />

ANDRITZ FEED & BIOFUEL<br />

Division Of <strong>Andritz</strong> Technologies Ltd.<br />

P.R. China<br />

Tel: +86 21 64670285<br />

andritz-fb.cn@andritz.com<br />

261 GB<br />

C.81.a.1.500.GB.11.09<br />

ADit Grafisk