Oldsmobile & Pontiac - Crane Cams

Oldsmobile & Pontiac - Crane Cams

Oldsmobile & Pontiac - Crane Cams

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CAMSHAFTS<br />

<strong>Oldsmobile</strong> and <strong>Pontiac</strong> V8 Tech Tips & Notes<br />

<strong>Oldsmobile</strong> V8 1967-1984 260-307 (5.0L) – 350<br />

(5.7L) – 400-403-425-455 cu.in.<br />

This popular <strong>Oldsmobile</strong> V8 engine family actually began<br />

in 1964, as a 330 cu.in. version. There are no “small block” or<br />

“big block” Olds V8’s in this series, as the same basic engine<br />

architecture is used from the 260 to the 455 versions. Two<br />

different deck heights were used, depending upon displacement.<br />

There were a number of changes from 1964 to 1967 that<br />

can complicate obtaining the correct camshaft and lifters,<br />

due to differing lifter bank angles and lifter diameters. The<br />

chart below will explain these by year and displacement.<br />

The 45 and 39 degree lifter bank angle camshafts will physically<br />

interchange, but the improper application will cause<br />

incorrect valve timing from bank to bank. To be certain that<br />

you have the proper camshaft in your block, check the cam<br />

timing on each bank of the engine. A cranking compression<br />

test will also be an indication, especially if one side varies<br />

consistently from the other. Our 79-prefix designates the 45<br />

degree bank angle camshafts (available on special order),<br />

while the 80-prefix is for the more common 39-degree bank<br />

angle applications. All of these engines have inline lifter<br />

bores and are equipped with 1.6:1 ratio non-adjustable<br />

rocker arms.<br />

1966-1967 400 cu.in. and 425 cu.in. Toronado engines had<br />

.921” diameter lifters, while the others had .842” diameter<br />

hydraulic lifters. The .921” lifters can be difficult to obtain,<br />

and many folks will sleeve their lifter bores so that the .842”<br />

items can be used.<br />

We offer complete lines of hydraulic, retrofit hydraulic roller,<br />

mechanical, and roller lifter camshafts and valve train<br />

components for these engines.<br />

The carburized steel retrofit hydraulic roller and street roll-<br />

270<br />

CRANECAMS.COM<br />

er camshafts are equipped with a cast iron distributor drive<br />

gear and rear journal. These are noted by an IG suffix (Iron<br />

Gear), allowing the use of a standard type distributor gear<br />

for long term reliability.<br />

There were also 260D and 350D cu.in. Diesel versions<br />

offered from 1978 to 1985, featuring more robust block and<br />

head castings. These engines had 39 degree bank angle<br />

camshafts and .842” flat faced lifters, with the exception of a<br />

few very early blocks intended for racing that were bored<br />

for .921” lifters.<br />

From 1985 to 1990, this engine family continued with a<br />

307 cu.in. powerplant, equipped with a 39 degree bank<br />

angle hydraulic roller camshaft and .921” diameter hydraulic<br />

roller lifters. Our 80-prefix camshafts can be used in these<br />

engines if a thrust spacer is fabricated, and the appropriate<br />

lifters are used.<br />

The production cylinder heads can be machined for screwin<br />

rocker arm studs and pushrod guideplates, permitting<br />

adjustable stud mounted rocker arms to be installed. Heat<br />

treated pushrods will be required for guideplate compatibility.<br />

This will provide more accurate lifter preload adjustment<br />

for hydraulic lifter applications, and are necessary to<br />

achieve lash adjustment for mechanical and roller lifter<br />

equipped engines. A number of aftermarket cylinder heads<br />

have been offered over the years, in iron and aluminum versions,<br />

with most of them having provisions for adjustable<br />

rockers already incorporated.<br />

In the late 70’s and early 80’s, General Motors interchanged<br />

engines throughout the product offerings. <strong>Pontiac</strong>s could<br />

have <strong>Oldsmobile</strong> engines, Buicks with Chevy engines, etc.<br />

Make sure of exactly what engine you have before proceeding<br />

with your service or modifications.<br />

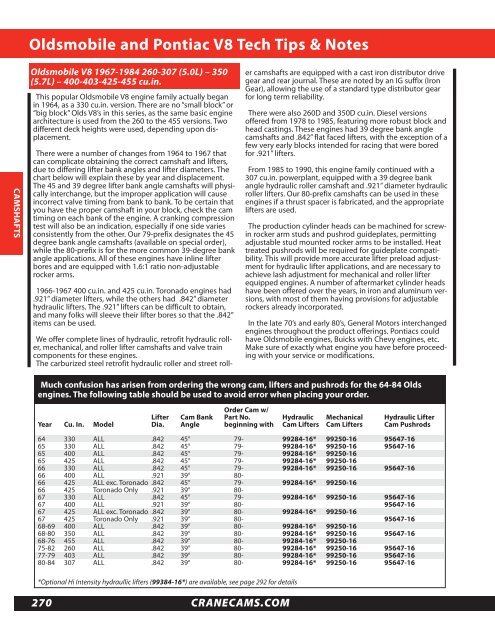

Much confusion has arisen from ordering the wrong cam, lifters and pushrods for the 64-84 Olds<br />

engines. The following table should be used to avoid error when placing your order.<br />

Order Cam w/<br />

Lifter Cam Bank Part No. Hydraulic Mechanical Hydraulic Lifter<br />

Year Cu. In. Model Dia. Angle beginning with Cam Lifters Cam Lifters Cam Pushrods<br />

64 330 ALL .842 45° 79- 99284-16* 99250-16 95647-16<br />

65 330 ALL .842 45° 79- 99284-16* 99250-16 95647-16<br />

65 400 ALL .842 45° 79- 99284-16* 99250-16<br />

65 425 ALL .842 45° 79- 99284-16* 99250-16<br />

66 330 ALL .842 45° 79- 99284-16* 99250-16 95647-16<br />

66 400 ALL .921 39° 80-<br />

66 425 ALL exc. Toronado .842 45° 79- 99284-16* 99250-16<br />

66 425 Toronado Only .921 39° 80-<br />

67 330 ALL .842 45° 79- 99284-16* 99250-16 95647-16<br />

67 400 ALL .921 39° 80- 95647-16<br />

67 425 ALL exc. Toronado .842 39° 80- 99284-16* 99250-16<br />

67 425 Toronado Only .921 39° 80- 95647-16<br />

68-69 400 ALL .842 39° 80- 99284-16* 99250-16<br />

68-80 350 ALL .842 39° 80- 99284-16* 99250-16 95647-16<br />

68-76 455 ALL .842 39° 80- 99284-16* 99250-16<br />

75-82 260 ALL .842 39° 80- 99284-16* 99250-16 95647-16<br />

77-79 403 ALL .842 39° 80- 99284-16* 99250-16 95647-16<br />

80-84 307 ALL .842 39° 80- 99284-16* 99250-16 95647-16<br />

*Optional Hi Intensity hydraullic lifters (99384-16*) are available, see page 292 for details

<strong>Oldsmobile</strong> DRCE V8<br />

The DRCE (Drag Racing Corporate Engine) offered by Olds<br />

consisted of a block and cylinder heads based on big block<br />

Chevrolet dimensioning. The DRCE and DRCE2 engines<br />

were never vehicle installed, nor were they offered as an<br />

engine assembly. Directed towards Pro Stock racing, many<br />

improvements were made over the Chevy, with these components<br />

offered as basic building blocks for the particular<br />

engine builder. Different lifter bore angles and camshaft<br />

journal diameters were used, so if you obtain one of these<br />

engines, be certain of exactly what dimensioned version<br />

you have when requiring parts.<br />

<strong>Crane</strong> offers custom ground camshafts and other components<br />

for the DRCE series of engines. Please contact us<br />

directly for your specific requirements.<br />

<strong>Pontiac</strong> V8 1955-1981 265 (4.3L) – 287 301<br />

(4.9L) – 316-326-347-350-370-389-400 (6.6L) –<br />

421-428-455 cu.in.<br />

The fabled <strong>Pontiac</strong> V8 family is also based on a common<br />

dimensioned foundation. There are no “small block” or “big<br />

block” versions. The exceptions that might be noted are the<br />

1977-81 265 and 301 cu.in. lightweight engines, that<br />

require the use of Chevrolet lifters due to relocated oil galleries,<br />

and also have a different deck height (the cylinder<br />

heads and many other internal parts were also unique).<br />

These engines are designated by our 28-prefix. The blocks<br />

have inline lifter bores with .842” diameter lifters. The standard<br />

rocker arm ratio is 1.5:1, with the exception of the<br />

1959-63 Super Duty engines (cylinder head casting numbers<br />

540306, 544127, and 9771980) that were equipped<br />

with 1.65:1 ratio rockers.<br />

We offer complete lines of hydraulic, retrofit hydraulic roller,<br />

mechanical, and roller lifter camshafts and components<br />

for these engines. The carburized steel retrofit hydraulic<br />

roller and street roller camshafts are equipped with a cast<br />

iron distributor drive gear and rear journal. These are noted<br />

by an IG suffix (Iron Gear), allowing the use of a standard<br />

type distributor gear for long term reliability.<br />

The same camshafts are applicable to nearly all of these<br />

engines. One unique exception occurred in the 1973-74 455<br />

Super Duty, which had an undersize distributor drive gear<br />

on the camshaft, and an oversize gear on the distributor. A<br />

standard configuration camshaft can be installed in these<br />

engines, as long as a standard gear is also installed on the<br />

distributor. We did produce some of the small gear camshafts<br />

during that era, and they were designated by an “SD”<br />

suffix after the grind number.<br />

There was also a totally unique 1969 “Race Only” Ram Air V<br />

engine with tunnel port heads that incorporated a different<br />

valve layout, requiring a special camshaft. If you are fortunate<br />

to have one of these rare engines, we can custom<br />

manufacture a steel billet roller camshaft for it.<br />

There are also aftermarket cylinder blocks being offered<br />

today, which have options of different diameter cam bearing<br />

journals. We can also produce special steel billet roller<br />

camshafts for these applications.<br />

Although the <strong>Pontiac</strong> V8 engines had stud mounted<br />

stamped steel rocker arms with pivot balls, there were a<br />

number of variations. There were a few exceptions for special<br />

versions, but the basics are as follows: The 1955 engines<br />

had straight 3/8” studs, with a crimped locking nut used for<br />

adjustment. The 1956-60 engines had bottleneck 3/8” studs,<br />

with a 5/16” threaded top section. The nuts were torqued<br />

against the step, and were non-adjustable. The 1961-81<br />

engines had bottleneck 7/16” studs, with a 3/8” threaded<br />

top section, and were again non- adjustable. There were<br />

Super Duty heads equipped with straight 7/16’ studs, having<br />

an adjustable configuration. The bottleneck versions<br />

can be made adjustable with the appropriate sized positive<br />

locking adjusting nuts, providing the most accurate adjustment<br />

for hydraulic camshafts, and are a necessity for<br />

mechanical lifter camshafts. Today’s aftermarket aluminum<br />

cylinder heads have straight studs intended for an adjustable<br />

rocker configuration. We offer 1.5:1 and 1.65:1 ratio<br />

rocker arms for most popular combinations.<br />

In the late 70’s and early 80’s, General Motors interchanged<br />

engines throughout the product offerings. <strong>Pontiac</strong>s could<br />

have <strong>Oldsmobile</strong> engines, Buicks with Chevy engines, etc.<br />

Make sure of exactly what engine you have before proceeding<br />

with your service or modifications.<br />

866-388-5120 • 386-236-9983 FAX 271