ATMOS Premium Tissue I Energy efficiency â A challenge for ... - Voith

ATMOS Premium Tissue I Energy efficiency â A challenge for ... - Voith

ATMOS Premium Tissue I Energy efficiency â A challenge for ... - Voith

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TECHNOLOGY<br />

14<br />

Conversion package: C-bar screen basket/MultiFoil<br />

rotor with belt pulley <strong>for</strong> speed adjustment (patented)<br />

screened, to prevent plugging of the<br />

screen basket surface.<br />

By increasing capacity, this measure<br />

either saves about 20% of specific<br />

energy costs or improves screening<br />

quality with otherwise unchanged<br />

parameters.<br />

Throughput capacity increased<br />

by 20%, and bottleneck eliminated<br />

Problem 3: Increase in paper machine<br />

production cause higher rejects rates<br />

in the approach flow screens,<br />

and overloading of the last screening<br />

stage.<br />

Solution: Increase screen throughput<br />

capacity by fitting the screen with<br />

a MultiFoil rotor and a C-bar basket.<br />

Example (<strong>for</strong> a customer in Germany):<br />

Rebuilding Omega screens with<br />

MultiFoil rotors and C-bar baskets<br />

increased throughput of the final<br />

screening stage by 20% with the<br />

same slot width.<br />

By ensuring depend able operation of<br />

the first screening stage, this rebuild<br />

<br />

<br />

<br />

enabled a 30% production increase<br />

of the paper machine.<br />

A complete success right down<br />

the line<br />

Problem 4: A customer in Thailand<br />

wanted to optimize the approach flow<br />

screen <strong>for</strong> greater throughput capacity,<br />

and the customer also required<br />

better paper quality.<br />

<br />

<br />

<br />

<br />

<br />

<br />

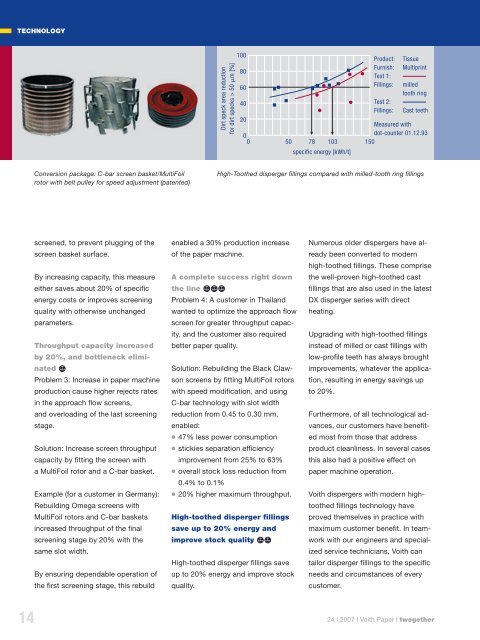

High-Toothed disperger fillings compared with milled-tooth ring fillings<br />

Solution: Rebuilding the Black Clawson<br />

screens by fitting MultiFoil rotors<br />

with speed modification, and using<br />

C-bar technology with slot width<br />

reduction from 0.45 to 0.30 mm,<br />

enabled:<br />

● 47% less power consumption<br />

● stickies separation <strong>efficiency</strong><br />

improvement from 25% to 63%<br />

● overall stock loss reduction from<br />

0.4% to 0.1%<br />

● 20% higher maximum throughput.<br />

High-toothed disperger fillings<br />

save up to 20% energy and<br />

improve stock quality<br />

High-toothed disperger fillings save<br />

up to 20% energy and improve stock<br />

quality.<br />

<br />

<br />

<br />

<br />

<br />

Numerous older dispergers have already<br />

been converted to modern<br />

high-toothed fillings. These comprise<br />

the well-proven high-toothed cast<br />

fillings that are also used in the latest<br />

DX disperger series with direct<br />

heating.<br />

Upgrading with high-toothed fillings<br />

instead of milled or cast fillings with<br />

low-profile teeth has always brought<br />

improvements, whatever the application,<br />

resulting in energy savings up<br />

to 20%.<br />

Furthermore, of all technological advances,<br />

our customers have benefited<br />

most from those that address<br />

product cleanliness. In several cases<br />

this also had a positive effect on<br />

paper machine operation.<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<strong>Voith</strong> dispergers with modern hightoothed<br />

fillings technology have<br />

proved themselves in practice with<br />

maximum customer benefit. In teamwork<br />

with our engineers and specialized<br />

service technicians, <strong>Voith</strong> can<br />

tailor disperger fillings to the specific<br />

needs and circumstances of every<br />

customer.<br />

24 I 2007 I <strong>Voith</strong> Paper I twogether