ATMOS Premium Tissue I Energy efficiency â A challenge for ... - Voith

ATMOS Premium Tissue I Energy efficiency â A challenge for ... - Voith

ATMOS Premium Tissue I Energy efficiency â A challenge for ... - Voith

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TECHNOLOGY<br />

22<br />

Bowater Calhoun PM 4 rebuild –<br />

Realignment to more profitable markets<br />

The declining demand <strong>for</strong> newsprint above all in North America is<br />

<strong>for</strong>cing papermakers to look <strong>for</strong> other ways of using their production<br />

lines. In many cases existing newsprint machines can be<br />

converted <strong>for</strong> producing other grades. This is often a very attractive<br />

option <strong>for</strong> increasing value-added – the secret of success in today’s<br />

changing markets.<br />

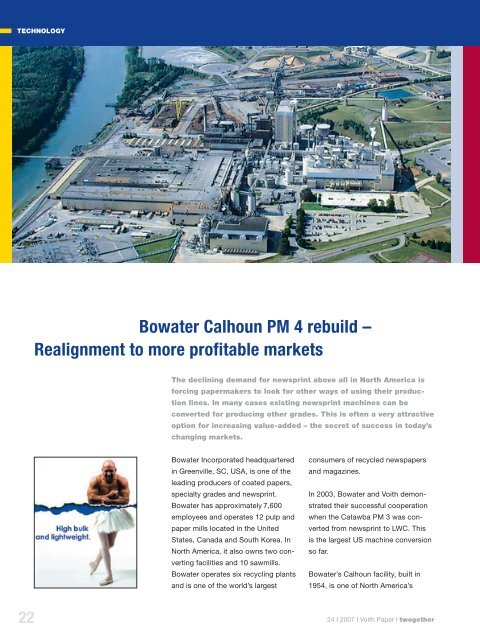

Bowater Incorporated headquartered<br />

in Greenville, SC, USA, is one of the<br />

leading producers of coated papers,<br />

specialty grades and newsprint.<br />

Bowater has approximately 7,600<br />

employees and operates 12 pulp and<br />

paper mills located in the United<br />

States, Canada and South Korea. In<br />

North America, it also owns two converting<br />

facilities and 10 sawmills.<br />

Bowater operates six recycling plants<br />

and is one of the world’s largest<br />

consumers of recycled newspapers<br />

and magazines.<br />

In 2003, Bowater and <strong>Voith</strong> demonstrated<br />

their successful cooperation<br />

when the Catawba PM 3 was converted<br />

from newsprint to LWC. This<br />

is the largest US machine conversion<br />

so far.<br />

Bowater’s Calhoun facility, built in<br />

1954, is one of North America’s<br />

24 I 2007 I <strong>Voith</strong> Paper I twogether