PUMPING PERFORMANCE - Wood Group

PUMPING PERFORMANCE - Wood Group

PUMPING PERFORMANCE - Wood Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Newsfront<br />

<strong>PUMPING</strong> <strong>PERFORMANCE</strong><br />

Vertiflo Pump<br />

Energy efficiency,<br />

protection against plant<br />

upsets, and ease of<br />

maintenance are key<br />

improvements in the<br />

latest generation of<br />

process pumps<br />

Recent strong activity in the<br />

global chemical process industries<br />

(CPI) has brought good<br />

news for pump manufacturers,<br />

among other equipment vendors.<br />

“There’s tremendous growth in the<br />

chemical, petrochemical and oil and<br />

gas markets, and business for us is<br />

good,” says Dave Flinton, product &<br />

marketing manager with ITT Goulds<br />

Pumps (Seneca Falls, N.Y.).<br />

But both engineering contractors<br />

and pump end-users are demanding<br />

more for their money in terms of<br />

reduced pump-lifecycle costs, Flinton<br />

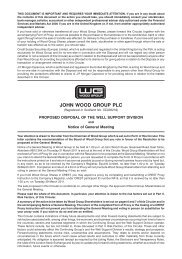

points out. For API 610 centrifugal<br />

pumps such as Goulds’ Model<br />

3700 (photo), one way to do this is to<br />

broaden the range of impeller and casing<br />

sizes so that the best efficiency<br />

point (BEP) of each pump can be more<br />

closely matched to the actual operating<br />

conditions.<br />

Accordingly, Goulds has recently<br />

made available eight new hydraulic<br />

combinations for the Model 3700,<br />

with a further 17 or so to come later<br />

this year. “Energy is a big portion of<br />

the cost of owning a centrifugal pump,<br />

especially the high-horsepower machines<br />

found in the oil and gas market,”<br />

Flinton says. “By dramatically<br />

increasing the density of our coverage,<br />

we will more often be able to provide<br />

our customers with the optimum selection<br />

for efficiency.”<br />

For engineers seeking a similarly<br />

wide range of hydraulics in ISO<br />

pumps for chemical service, the CPX<br />

Opti-Valve<br />

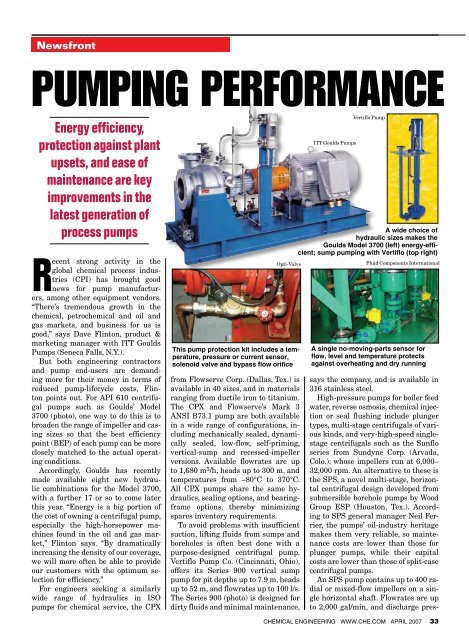

This pump protection kit includes a temperature,<br />

pressure or current sensor,<br />

solenoid valve and bypass flow orifice<br />

from Flowserve Corp. (Dallas, Tex.) is<br />

available in 40 sizes, and in materials<br />

ranging from ductile iron to titanium.<br />

The CPX and Flowserve’s Mark 3<br />

ANSI B73.1 pump are both available<br />

in a wide range of configurations, including<br />

mechanically sealed, dynamically<br />

sealed, low-flow, self-priming,<br />

vertical-sump and recessed-impeller<br />

versions. Available flowrates are up<br />

to 1,680 m 3 /h, heads up to 300 m, and<br />

temperatures from –80°C to 370°C.<br />

All CPX pumps share the same hydraulics,<br />

sealing options, and bearingframe<br />

options, thereby minimizing<br />

spares inventory requirements.<br />

To avoid problems with insufficient<br />

suction, lifting fluids from sumps and<br />

boreholes is often best done with a<br />

purpose-designed centrifugal pump.<br />

Vertiflo Pump Co. (Cincinnati, Ohio),<br />

offers its Series 900 vertical sump<br />

pump for pit depths up to 7.9 m, heads<br />

up to 52 m, and flowrates up to 100 l/s.<br />

The Series 900 (photo) is designed for<br />

dirty fluids and minimal maintenance,<br />

ITT Goulds Pumps<br />

A wide choice of<br />

hydraulic sizes makes the<br />

Goulds Model 3700 (left) energy-efficient;<br />

sump pumping with Vertiflo (top right)<br />

Fluid Components International<br />

A single no-moving-parts sensor for<br />

flow, level and temperature protects<br />

against overheating and dry running<br />

says the company, and is available in<br />

316 stainless steel.<br />

High-pressure pumps for boiler feed<br />

water, reverse osmosis, chemical injection<br />

or seal flushing include plunger<br />

types, multi-stage centrifugals of various<br />

kinds, and very-high-speed singlestage<br />

centrifugals such as the Sunflo<br />

series from Sundyne Corp. (Arvada,<br />

Colo.), whose impellers run at 6,000–<br />

32,000 rpm. An alternative to these is<br />

the SPS, a novel multi-stage, horizontal<br />

centrifugal design developed from<br />

submersible borehole pumps by <strong>Wood</strong><br />

<strong>Group</strong> ESP (Houston, Tex.). According<br />

to SPS general manager Neil Ferrier,<br />

the pumps’ oil-industry heritage<br />

makes them very reliable, so maintenance<br />

costs are lower than those for<br />

plunger pumps, while their capital<br />

costs are lower than those of split-case<br />

centrifugal pumps.<br />

An SPS pump contains up to 400 radial<br />

or mixed-flow impellers on a single<br />

horizontal shaft. Flowrates are up<br />

to 2,000 gal/min, and discharge pres-<br />

ChemiCal engineering www.Che.Com april 2007 33

Newsfront<br />

sures up to 6,000 psi. “We did think the<br />

length of the pumps might be a problem,”<br />

Ferrier admits, “but there has<br />

been a lot of interest from refineries,<br />

even if they have to be installed along<br />

walkways.” So far, six refineries have<br />

bought the pumps. Fluids pumped include<br />

wash water for desalting, and<br />

light hydrocarbons.<br />

Although many manufacturers<br />

these days offer magnetically coupled<br />

and canned-motor pumps, one of the<br />

pioneers in this market is Hermetic-<br />

Pumpen (Gundelfingen, Germany and<br />

Humble, Tex.), which has delivered<br />

more than 120,000 such units. At the<br />

beginning of March Hermetic took<br />

over sister company Lederle (Gundelfingen,<br />

Germany), which specializes<br />

in liquid-ring vacuum pumps and<br />

rotary piston pumps.<br />

Another canned-motor specialist,<br />

Hayward Tyler Inc. (Colchester, Vt.),<br />

recently delivered a canned-motor<br />

pump and spare motor together worth<br />

DON’T DISCOVER THAT YOUR<br />

PROTECTION IS INADEQUATE —<br />

DEPEND ON FIKE for engineered,<br />

proven solutions.<br />

Blackmer<br />

34 ChemiCal engineering www.Che.Com april 2007<br />

$520,000 to a U.S. specialty chemical<br />

manufacturer. The pump will handle<br />

1,4-dimethyl cyclohexanedicarboxylate<br />

(DMCD) saturated with hydrogen<br />

at 1,850 psi and up to 500°F, and will<br />

run continuously for 18 months between<br />

catalyst changes.<br />

Wanner Engineering (Minneapolis,<br />

Minn.), a firm noted for its Hydra-Cell<br />

positive displacement pumps, recently<br />

introduced magnetically coupled versions<br />

of its Stan-Cor non-metallic<br />

ANSI centrifugal pumps. The Stan-<br />

Cor MK pumps feature an impeller<br />

that can be replaced or trimmed without<br />

replacing the magnetic drive. All<br />

Stan-Cor pumps have casings made<br />

1 - 8 6 6 - 7 5 8 - 6 0 0 4<br />

from thick, carbon-fiber-filled Kynar,<br />

which eliminates the permeation that<br />

can occur with plastic-lined metal casings,<br />

the company says.<br />

Protecting valuable assets<br />

While good pump design is the foundation<br />

for low lifetime costs and reliability,<br />

suitable control systems can go<br />

a long way to aid both these objectives.<br />

Version 5.0 of the PumpSmart PS200<br />

variable-speed drive system from ITT<br />

Monitoring and Control (Seneca Falls,<br />

N.Y.) can cut pump energy use by up to<br />

65%, the company says, through intelligent<br />

control. After calibration based<br />

on just four data points — flowrate<br />

The IMPACT of an EXPLOSION<br />

is COSTLY.<br />

ProVane sliding-vane pump (left) for economical pumping at low<br />

flowrates; the Viking RTP20 (right) for transport applications<br />

• Engineering and application specialists<br />

• Over 60 years of experience in safety<br />

• Process and code compliance knowledge<br />

• Total Explosion Protection Solutions:<br />

- Testing - Isolation<br />

- Venting - Suppression<br />

V I S I T W W W . F I K E . C O M<br />

P R O V E N S A F E T Y S O L U T I O N S F O R O V E R 6 0 Y E A R S<br />

Circle 28 on p. 82 or go to adlinks.che.com/6894-28<br />

Viking Pump

Larox Flowsys Moyno Watson-Marlow Bredel<br />

Larox calls the LPP80 peristaltic pump<br />

“the first real change in 30 years”<br />

and power at the BEP, rated speed, provides two levels of alarm: the first<br />

and shut-off power — the system uses when the flowrate falls below a preset<br />

the current and frequency supplied value in the range 0.01–3 ft/s, and the<br />

to the motor to predict flowrate to a second when the pump inlet actually<br />

claimed accuracy of ±5% without the runs dry. The FlexSwitch FLT has no<br />

need for pressure or flow sensors. The moving parts.<br />

result is improved controllability, en- Detecting problem conditions is<br />

ergy savings, and low-flow protection only useful, of course, if protective ac-<br />

for both centrifugal and positive-distion follows. To make this as easy as<br />

placement pumps.<br />

possible, Opti-Valve LLC (Broomfield,<br />

For applications that simply require Colo.) offers a package of equipment<br />

protection against overheating, Fluid including sensor, bypass valve and<br />

Components International (FCI; San flow-restriction orifice (photo, p. 33).<br />

Marcos, Calif.) offers the FlexSwitch The sensor detects low flow caused by<br />

FLT pump protection device (photo, a closed downstream valve through<br />

p. 33). By detecting flow, level and rises in temperature or pressure, a<br />

8152MIPad.qxd temperature, the 9/5/06 FlexSwitch 2:40 PM FLT Page drop 1 in motor current, or a combina-<br />

• Quiet, clean<br />

VFD controls<br />

• Non-pulsating<br />

flow<br />

• Closed piping<br />

system<br />

• Compact heavy duty<br />

Ultra-Drive ® gear joint design<br />

• Twin screw feeder<br />

• Optional slip injection system<br />

• High-efficiency Ultra-Feed ®<br />

rotor<br />

Unique gear joint on the Moyno 2000<br />

progressing-cavity pump<br />

Moves a higher<br />

percentage of solids<br />

longer distances than<br />

any other progressing<br />

cavity pump!<br />

Watson-Marlow Bredel’s SPX peristaltic<br />

handles corrosive and abrasive fluids<br />

tion of these. At this point, it opens the<br />

bypass valve, creating a flow of liquid<br />

large enough to stop the pump from<br />

overheating.<br />

To help pump users understand<br />

hydraulics, Pump Systems Matter<br />

(www.pumpsystemsmatter.org), an<br />

educational initiative backed by the<br />

Hydraulic Institute (Parsippany, N.J.;<br />

www.pumps.org) has made its Pump<br />

Systems Improvement Modeling Tool<br />

(PSIM) software freely available for<br />

download. PSIM allows users to model<br />

pumping systems using a drag-anddrop<br />

interface. PSIM models pump and<br />

system curves, pump efficiency, NPSH<br />

calculations, impeller trimming, and<br />

Patented<br />

1-877-4UMOYNO<br />

www.moyno.com<br />

Circle 61 on p. 82 or go to adlinks.che.com/6894-61<br />

ChemiCal engineering www.Che.Com april 2007 35

Newsfront<br />

automatic pump curve viscosity corrections,<br />

and calculates energy costs<br />

over time using net present value.<br />

Positive performers<br />

Positive displacement pumps may be<br />

preferred over centrifugals for viscous<br />

liquids, for low flowrates at moderate<br />

or high pressures, when self-prim-<br />

PumP exPerts<br />

Barnant Co. (Thermo<br />

Fisher Scientific) edlinks.che.com/6894-580<br />

Bio-Chem Valve edlinks.che.com/6894-581<br />

Bioengineering edlinks.che.com/6894-582<br />

Blackmer edlinks.che.com/6894-583<br />

BOC Edwards edlinks.che.com/6894-584<br />

Bran + Luebbe edlinks.che.com/6894-585<br />

CAT Pumps edlinks.che.com/6894-586<br />

Flowserve edlinks.che.com/6894-587<br />

ing is needed, and when flowrates<br />

or system conditions change widely.<br />

Blackmer (Grand Rapids, Mich.) recently<br />

launched a new sliding-vane<br />

Circle 29 on p. 82 or go to adlinks.che.com/6894-29<br />

36 ChemiCal engineering www.Che.Com april 2007<br />

Fluid Components<br />

International edlinks.che.com/6894-588<br />

Fluid Metering, Inc. edlinks.che.com/6894-589<br />

Hayward Tyler <strong>Group</strong> edlinks.che.com/6894-590<br />

Hermetic Pumpen<br />

(Lederle) edlinks.che.com/6894-591<br />

Hydraulic Institute edlinks.che.com/6894-592<br />

ITT Goulds Pumps edlinks.che.com/6894-593<br />

ITT Monitoring & Control edlinks.che.com/6894-594<br />

Jaeco edlinks.che.com/6894-595<br />

Larox Flowsys edlinks.che.com/6894-596<br />

pump, the SX3, that is suitable for<br />

many chemical duties, thanks to its<br />

stainless steel construction and Duravane<br />

carbon-filled resin vanes. External<br />

bearings provide durability and<br />

easy maintenance, says John Pepper,<br />

Blackmer’s VP of sales and marketing<br />

for North America; and the pump<br />

can run dry for short periods without<br />

damage. Capacity is 100–250 gal/min,<br />

at pressures up to 125 psi.<br />

Last year Blackmer launched a<br />

smaller pump, the ProVane, that has<br />

proved popular in biodiesel plants, says<br />

Tom Stone, the firm’s director of marketing.<br />

Available in ductile iron and<br />

stainless steel, five sizes of ProVane<br />

cover flowrates up to 100 gal/min. A<br />

small rotor diameter keeps vane tip<br />

speed down, allowing the pumps to<br />

operate reliably at full motor speed<br />

(1,200, 1,800 and 3,600 rpm), while<br />

the large diameter of the product-lubricated<br />

bearing ensures good performance<br />

even with “dry” fluids like<br />

methanol, pentane and liquid carbon<br />

dioxide, Pepper says (photo, p. 34).<br />

Waukesha Cherry-Burrell (Delavan,<br />

Wisc.) manufactures a wide range of<br />

pumps, including the Universal series<br />

of twin-rotor positive displacement<br />

pumps, which have hooked rotors;<br />

tri-lobe rotary pumps; and centrifugal<br />

pumps for sanitary applications.<br />

A recent development is the Tru-Fit<br />

gearbox, which the company says reduces<br />

baseplate length by 20–25% and<br />

eliminates shaft alignment problems.<br />

Viking Pump (Cedar Falls, Iowa) has<br />

launched a new tri-lobe positive displacement<br />

pump for OEM transport<br />

applications (photo, p. 34). The RTP20<br />

can transfer up to 264 gal/min at pressures<br />

up to 145 psi and viscosities to<br />

55,000 cSt. A longer sealing land at<br />

the rotor tips improves efficiency with<br />

lower-viscosity products, says John<br />

Stillman, director, global OEM sales.<br />

Viking also makes internal and external<br />

gear pumps, and vane pumps.<br />

A specialist in progressing-cavity<br />

(PC) pumps is Moyno (Springfield,<br />

Ohio). The company’s Moyno 2000<br />

pump features a unique gear joint

MAAG Pump Systems<br />

Textron edlinks.che.com/6894-597<br />

Moyno, Inc. edlinks.che.com/6894-598<br />

MV Products edlinks.che.com/6894-599<br />

Neptune Chemical<br />

Pump Co. edlinks.che.com/6894-600<br />

Nikkiso Pumps edlinks.che.com/6894-601<br />

Opti-Valve LLC edlinks.che.com/6894-602<br />

Pulsafeeder edlinks.che.com/6894-603<br />

Pump Systems Matter edlinks.che.com/6894-604<br />

Seybert & Rahier edlinks.che.com/6894-605<br />

Bioengineering<br />

This dual-diaphragm pump is designed<br />

for aseptic feeding and metering in hygienic<br />

applications<br />

that provides excellent torque transmission<br />

and control of thrust, reducing<br />

the radial load on the drive shaft and<br />

bearings and simplifying maintenance<br />

(photo, p. 35). The Moyno 2000 HS system,<br />

meanwhile, uses a G4 pump with<br />

a twin-screw feeder as a cost-effective<br />

alternative to piston pumps for the<br />

transfer of semi-dry materials such as<br />

sewage sludge.<br />

The new LPP80 high-capacity<br />

peristaltic pump from Larox Flowsys<br />

(Lappeenranta, Finland) delivers<br />

up to 176 gal/min (photo, p. 35). The<br />

company’s design focus on minerals<br />

processing and metallurgical applications<br />

has resulted in a pump with exceptional<br />

performance and reliability,<br />

says Matti Riihimäki of Larox Flowsys<br />

Pump Products. The pump uses a<br />

patented roller design that is said to<br />

generate twice as much flow per revolution<br />

as a conventional pump, as well<br />

as increasing hose life and reducing<br />

energy consumption.<br />

The SPX peristaltic pump from<br />

Watson-Marlow Bredel (Wilmington,<br />

Mass.) is suitable for abrasive and<br />

corrosive fluids, thanks to its Bioprene<br />

hose material (photo, p. 35). The complete<br />

Watson-Marlow Bredel peristaltic<br />

range covers flowrates up to 350<br />

gal/min and pressures up to 230 psi.<br />

For demanding hygienic applications,<br />

Bioengineering (Waltham,<br />

Sulzer Pumps edlinks.che.com/6894-606<br />

Sundyne Corp. edlinks.che.com/6894-607<br />

Travaini Pumps USA edlinks.che.com/6894-608<br />

Tuthill Pump <strong>Group</strong> edlinks.che.com/6894-609<br />

Vertiflo Pump Co. edlinks.che.com/6894-610<br />

Viking Pump edlinks.che.com/6894-611<br />

Wanner Engineering edlinks.che.com/6894-612<br />

Watson-Marlow Bredel edlinks.che.com/6894-613<br />

Waukesha<br />

Cherry-Burrell edlinks.che.com/6894-614<br />

<strong>Wood</strong> <strong>Group</strong> ESP edlinks.che.com/6894-615<br />

Mass.) offers a dual-diaphragm pump<br />

(photo). For the pharmaceutical, food<br />

and cosmetic industries it offers accurate<br />

and controlled flow in either<br />

<strong>Wood</strong> <strong>Group</strong> ESP<br />

Surface Pumps<br />

www.woodgroup-esp.com<br />

direction, thanks in part to the use of<br />

positively actuated diaphragm valves.<br />

Made from mirror-polished 316L<br />

stainless steel and PTFE, the pump<br />

delivers pressures up to 6 bar, has zero<br />

dead volume, can be sterilized and<br />

cleaned-in-place, is self-priming, and<br />

can run dry without damage. ■<br />

Charles Butcher<br />

Low tolerance for pump problems?<br />

No problem.<br />

Pressure to lower ever-increasing maintenance<br />

costs and reduce environmental impact has paved<br />

the way to better surface pumping solutions.<br />

Our multi-stage centrifugal SPS Surface Pumping<br />

Systems provide versatile, low-maintenance<br />

alternatives to many split-case centrifugal,<br />

positive-displacement and vertical-turbine pump<br />

applications. The SPS is a cost-effective solution<br />

for processing, petroleum, mining, water and other<br />

industries that require high-volume movement of<br />

fluids. Proven benefits include:<br />

• Lower initial and whole-life cost<br />

• Short construction lead-time<br />

• Increased reliability and runtime<br />

• Low noise and vibration levels<br />

• Remote monitoring and control<br />

• Worldwide support.<br />

Call this number: 281.492.5160.<br />

Or e-mail sps@woodgroup.com.<br />

SPS APPLICATIONS:<br />

Booster<br />

Transfer<br />

Circulation<br />

Injection<br />

SP1000: rated 100 to 1000 HP<br />

(SP2000: rated 1000 to 2500 HP<br />

also available)<br />

Circle 30 on p. 82 or go to adlinks.che.com/6894-30<br />

ChemiCal engineering www.Che.Com april 2007 37<br />

WG SPS ad_CE_half_2-07.indd 1 3/1/07 11:03:02 AM