9605 with MICROFORM TECHNOLOGY It's Simple. The Toughest ...

9605 with MICROFORM TECHNOLOGY It's Simple. The Toughest ...

9605 with MICROFORM TECHNOLOGY It's Simple. The Toughest ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

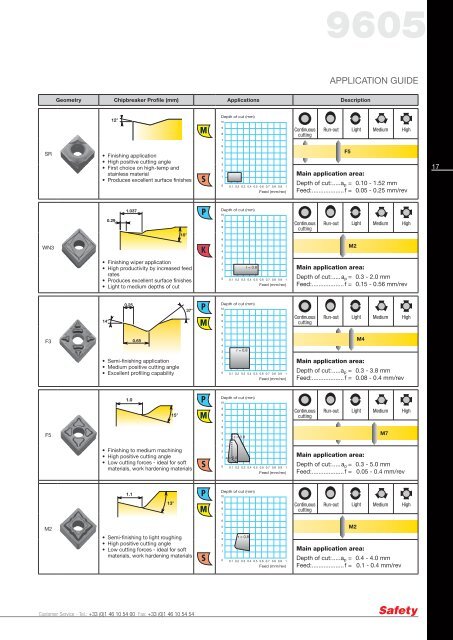

SR<br />

WN<br />

F<br />

F5<br />

M<br />

Geometry Chipbreaker Profile (mm) Applications Description<br />

12°<br />

• Finishing application<br />

• High positive cutting angle<br />

• First choice on high-temp and<br />

stainless material<br />

• Produces excellent surface finishes<br />

•<br />

•<br />

•<br />

•<br />

14°<br />

0.29<br />

1.037<br />

Customer Service - Tel.: +33 (0)1 46 10 54 00 Fax: +33 (0)1 46 10 54 54<br />

10°<br />

Finishing wiper application<br />

High productivity by increased feed<br />

rates<br />

Produces excellent surface finishes<br />

Light to medium depths of cut<br />

0.25<br />

0.65<br />

• Semi-finishing application<br />

• Medium positive cutting angle<br />

• Excellent profiling capability<br />

1.0<br />

15°<br />

37°<br />

• Finishing to medium machining<br />

• High positive cutting angle<br />

• Low cutting forces - ideal for soft<br />

materials, work hardening materials<br />

1.1<br />

13°<br />

• Semi-finishing to light roughing<br />

• High positive cutting angle<br />

• Low cutting forces - ideal for soft<br />

materials, work hardening materials<br />

M<br />

S<br />

P<br />

K<br />

P<br />

M<br />

P<br />

M<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1<br />

Feed (mm/rev)<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

r = 0.8<br />

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1<br />

Feed (mm/rev)<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

r = 0.8<br />

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1<br />

Feed (mm/rev)<br />

S<br />

1 r = 0.4<br />

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1<br />

Feed (mm/rev)<br />

P<br />

M<br />

Depth of cut (mm)<br />

Depth of cut (mm)<br />

Depth of cut (mm)<br />

Depth of cut (mm)<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

r = 0.8<br />

Depth of cut (mm)<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

r = 0.8<br />

1<br />

S 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1<br />

Feed (mm/rev)<br />

Continuous<br />

cutting<br />

SR<br />

<strong>9605</strong><br />

APPLICATION GUIDE<br />

Run-out Light Medium High<br />

F5<br />

Main application area:<br />

Depth of cut: .....a p = 0.10 - 1.5 mm<br />

Feed: ...................f = 0.05 - 0. 5 mm/rev<br />

Continuous<br />

cutting<br />

Run-out Light Medium High<br />

M2 WN3<br />

Main application area:<br />

Depth of cut: .....a p = 0. - .0 mm<br />

Feed: ...................f = 0.15 - 0.56 mm/rev<br />

Continuous<br />

cutting<br />

Run-out Light Medium High<br />

F3<br />

F5<br />

M2<br />

M4<br />

Main application area:<br />

Depth of cut: .....a p = 0. - . mm<br />

Feed: ...................f = 0.0 - 0. mm/rev<br />

Continuous<br />

cutting<br />

Run-out Light Medium High<br />

Main application area:<br />

M7<br />

Depth of cut: .....a p = 0. - 5.0 mm<br />

Feed: ...................f = 0.05 - 0. mm/rev<br />

Continuous<br />

cutting<br />

Run-out Light Medium High<br />

Main application area:<br />

Depth of cut: .....a p = 0. - .0 mm<br />

Feed: ...................f = 0.1 - 0. mm/rev<br />

1