Grade 8625

Grade 8625

Grade 8625

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

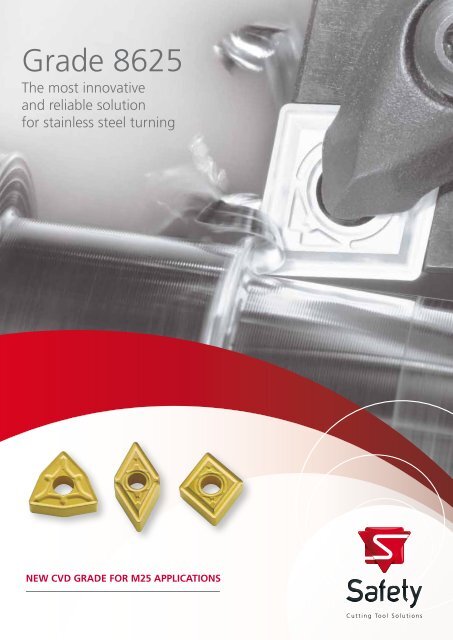

<strong>Grade</strong> <strong>8625</strong><br />

The most innovative<br />

and reliable solution<br />

for stainless steel turning<br />

NEW CVD GRADE FOR M25 APPLICATIONS

2<br />

FIRST CHOICE FOR STAINLESS STEEL TURNING<br />

M25 applications are the most important stainless steel turning area.<br />

It means different parts, sizes, materials and machining conditions.<br />

It is both a roughing and semi-finishing area, very critical for all market segments.<br />

Safety has developped the new <strong>8625</strong> grade to meet this industrial demand<br />

with the higher productivity and reliability. A good balance of toughness<br />

and wear resistance makes this new grade matching high speed machining<br />

whatever the conditions.<br />

<strong>8625</strong> is based on both a new coating technology and a new substrate<br />

recently developped for this area.<br />

Our <strong>8625</strong> grade will be the RIGHT SOLUTION for your further success!<br />

FEATURES AND ADVANTAGES<br />

❯ RELIABLE SUBSTRATE:<br />

The substrate has increased resistance to plastic deformation at high temperatures and whatever<br />

the conditions: semi-finishing, roughing, continuous and intermittent cutting.<br />

❯ OPTIMIZED CVD COATING:<br />

New multilayers CVD coating to improve notch wear, flaking and build-up edge resistance which are<br />

the main wear mechanism in stainless steel turning.<br />

❯ COMPLEMENTARY AREA:<br />

<strong>8625</strong> is a second choice to machine low carbon steel, low alloyed steel and exotic alloys<br />

(Nickel and Cobalt base).

Customer Service - Tel.: +33(0)1.46.10.54.00 Fax: +33(0)1.46.10.54.54<br />

APPLICATION AREAS<br />

ISO group<br />

Wear resistance<br />

M<br />

Toughness<br />

M01<br />

M05<br />

M10<br />

M15<br />

M20<br />

M25<br />

M30<br />

M35<br />

M40<br />

9605<br />

GRADE <strong>8625</strong><br />

PVD<br />

8620<br />

Coated grades<br />

Carbide<br />

CVD<br />

8515<br />

<strong>8625</strong><br />

INDUSTRIES<br />

AUTOMOTIVE<br />

DIE & MOLD<br />

OIL/GAS<br />

AEROSPACE<br />

POWER GENERATION<br />

OFF HIGHWAY<br />

MEDICAL<br />

MARINE<br />

NEW<br />

8535<br />

3

4<br />

GRADE <strong>8625</strong><br />

GRADE DESCRIPTION<br />

<strong>Grade</strong> Description Performance<br />

<strong>8625</strong> MTCVD coated carbide<br />

APPLICATION AREA<br />

Multilayers TiCN/AI203/TiN<br />

High cobalt substrate<br />

Thin coating<br />

High resistant build-up edge<br />

MACHINING CONDITIONS<br />

General machining grade<br />

Enhanced plastic deformation<br />

resistance<br />

High toughness<br />

Chipping resistance<br />

Enhanced build-up resistance<br />

Notch wear resistance<br />

Flaking resistance<br />

ISO<br />

material<br />

M25<br />

P30<br />

S15<br />

Applications<br />

Stainless steels: ferritic, austenitic, PH & duplex<br />

General machining & roughing<br />

Continuous & interrupted cuts<br />

Steels: low carbon, alloy<br />

General machining ; interrupted cuts<br />

High temperature alloys<br />

Semi-finishing ; continuous cuts<br />

Materials:<br />

1st choice for ferritic, austenitic, martensitic stainless steel, duplex, super-duplex, precipitation hardening stainless steel<br />

(as 15-5Ph, 17-4Ph)<br />

Complementary grade for low carbon steel, low alloy steel, high temp alloys (Nickel, cobalt base)<br />

Applications:<br />

Semi-finishing to roughing<br />

Longitudinal turning, facing, profiling<br />

Continuous and intermittent cutting<br />

Continuous cutting Run-out Light Medium High<br />

8515<br />

8620<br />

<strong>8625</strong><br />

NEW<br />

8535<br />

Customer Service - Tel.: +33(0)1.46.10.54.00 Fax: +33(0)1.46.10.54.54

COATING<br />

Customer Service - Tel.: +33(0)1.46.10.54.00 Fax: +33(0)1.46.10.54.54<br />

GRADE <strong>8625</strong><br />

New multilayers CVD coating:<br />

Optimized edge preparation<br />

to provide accurate control of<br />

cutting edge<br />

Special post treatment of the TiN<br />

layer to have an ultra smooth surface<br />

reducing adhesion and build-up edge<br />

Yellow coating for easy wear detection<br />

Ultra smooth TiN for easy wear detection and increasing adhesion resistance<br />

TiN/Al2O3 multilayers recently developped for stainless steel machining<br />

to increase flaking, build-up edge and temperature resistance<br />

TiCN for abrasive wear resistance<br />

New tough tungsten carbide substrate:<br />

High cobalt substrate with increased plastic deformation<br />

resistance at high speed<br />

5

6<br />

GRADE <strong>8625</strong><br />

CUTTING DATA<br />

MTCVD<br />

coated<br />

P<br />

Steels<br />

<strong>8625</strong><br />

M<br />

Stainless steels<br />

MTCVD<br />

coated<br />

<strong>8625</strong><br />

S<br />

High temp alloys<br />

MTCVD<br />

coated<br />

<strong>8625</strong><br />

Operation<br />

ap<br />

Depth of<br />

cut<br />

mm<br />

f<br />

Feed<br />

mm/rev<br />

Free machining & low<br />

carbon steels<br />

vc<br />

m/min<br />

Geo.<br />

1st 2nd<br />

Cutting speed / Chipbreaker designation<br />

Medium carbon & high<br />

carbon steels<br />

vc<br />

m/min<br />

Geo.<br />

1st 2nd<br />

Alloy steels & easy to<br />

machine tool steels<br />

vc<br />

m/min<br />

Geo.<br />

1st 2nd<br />

Tool steels & die steels<br />

vc<br />

m/min<br />

R 2.0-7.6 0.25-0.64 137 M7 M5 107 M7 M5 - - - -<br />

GP 1.0-3.8 0.2-0.4 213 M5 M4 152 M5 M4 - - - -<br />

F - - - - - - - - - -<br />

Operation<br />

ap<br />

Depth of<br />

cut<br />

mm<br />

f<br />

Feed<br />

mm/rev<br />

Cutting speed / Chipbreaker designation<br />

Ferritic & martensitic Austenitic PH & duplex<br />

vc<br />

m/min<br />

Geo.<br />

1st 2nd<br />

vc<br />

m/min<br />

Geo.<br />

1st 2nd<br />

vc<br />

m/min<br />

Geo.<br />

1st 2nd<br />

Geo.<br />

1st 2nd<br />

R 2.0-6.4 0.2-0.64 61-168 M7 M5 61-137 M7 M5 61-122 M7 M5<br />

GP 1.0-3.8 0.15-0.38 76-198 M5 M4 76-183 M5 M4 61-137 M5 M4<br />

F 0.25-1.3 0.13-0.25 91-229 M4 F5 76-213 M4 F5 61-152 M4 F5<br />

Operation<br />

ap<br />

Depth of<br />

cut<br />

mm<br />

f<br />

Feed<br />

mm/rev<br />

Iron base alloys<br />

A-286 discalloy, incoloy<br />

vc<br />

m/min<br />

Geo.<br />

1st 2nd<br />

Cutting speed / Chipbreaker designation<br />

Nickel base alloys<br />

monel, hastelloy,<br />

inconel, waspaloy<br />

vc<br />

m/min<br />

Geo.<br />

1st 2nd<br />

Cobalt base alloys<br />

haynes stellite<br />

vc<br />

m/min<br />

Geo.<br />

1st 2nd<br />

Titanium alloys<br />

6Al-4V<br />

vc<br />

m/min<br />

R - - - - - - - - - -<br />

GP 1.0-3.8 0.15-0.3 30-61 M5 M4 23-46 M5 M4 23-38 M5 M4 - -<br />

F 0.25-1.3 0.13-0.25 30-76 M4 F5 23-53 M4 F5 23-46 M4 F5 - -<br />

R = Roughing Bold print indicates first choice<br />

GP = General purpose<br />

F = Finishing<br />

FT = Flat top<br />

Negative top form geometry<br />

Cutting parameters provided for positive inserts are based on CCMT 12 04 08<br />

Cutting parameters provided for negative inserts are based on CNMG 12 04 12<br />

You may increase/decrease cutting parameters to optimize your application depending on many factors including: work piece type and hardness, surface finish<br />

required, insert size, shape and nose radius, lead angle, chipbreaker, cycle time required, desired tool life, desired failure mode and reason for indexing.<br />

Geo.<br />

1st 2nd<br />

Customer Service - Tel.: +33(0)1.46.10.54.00 Fax: +33(0)1.46.10.54.54

CUTTING DATA<br />

MTCVD<br />

coated<br />

P<br />

Steels<br />

<strong>8625</strong><br />

M<br />

Stainless steels<br />

MTCVD<br />

coated<br />

<strong>8625</strong><br />

S<br />

High temp alloys<br />

MTCVD<br />

coated<br />

<strong>8625</strong><br />

Operation<br />

ap<br />

Depth of<br />

cut<br />

mm<br />

f<br />

Feed<br />

mm/rev<br />

Customer Service - Tel.: +33(0)1.46.10.54.00 Fax: +33(0)1.46.10.54.54<br />

Free machining & low<br />

carbon steels<br />

vc<br />

m/min<br />

Geo.<br />

1st 2nd<br />

GRADE <strong>8625</strong><br />

Cutting speed / Chipbreaker designation<br />

Medium carbon & high<br />

carbon steels<br />

vc<br />

m/min<br />

Geo.<br />

1st 2nd<br />

Alloy steels & easy to<br />

machine tool steels<br />

vc<br />

m/min<br />

Geo.<br />

1st 2nd<br />

Tool steels & die<br />

steels<br />

vc<br />

m/min<br />

R 0.8-3.1 0.13-0.5 183 PM5 168 PM5 137 PM5 - -<br />

GP 0.8-3.1 0.13-0.5 213 PM4 152 PM4 122 PM4 - -<br />

F - - - - - - - - - -<br />

Operation<br />

ap<br />

Depth of<br />

cut<br />

mm<br />

f<br />

Feed<br />

mm/rev<br />

Positive top form geometry<br />

Cutting speed / Chipbreaker designation<br />

Ferritic & martensitic Austenitic PH & duplex<br />

vc<br />

m/min<br />

Geo.<br />

1st 2nd<br />

vc<br />

m/min<br />

Geo.<br />

1st 2nd<br />

vc<br />

m/min<br />

R - - - - - - - -<br />

Geo.<br />

1st 2nd<br />

Geo.<br />

1st 2nd<br />

GP 0.25-2.5 0.13-0.3 76-183 PM5 76-183 PM5 61-152 PM5<br />

F 0.25-2.0 0.13-0.25 91-244 PM4 76-213 PM4 61-183 PM4<br />

Operation<br />

ap<br />

Depth of<br />

cut<br />

mm<br />

f<br />

Feed<br />

mm/rev<br />

Iron base alloys<br />

A-286 discalloy, incoloy<br />

vc<br />

m/min<br />

Geo.<br />

1st 2nd<br />

Cutting speed / Chipbreaker designation<br />

Nickel base alloys<br />

monel, hastelloy,<br />

inconel, waspaloy<br />

vc<br />

m/min<br />

Geo.<br />

1st 2nd<br />

Cobalt base alloys<br />

haynes stellite<br />

vc<br />

m/min<br />

Geo.<br />

1st 2nd<br />

Titanium alloys<br />

6Al-4V<br />

vc<br />

m/min<br />

R - - - - - - - - - -<br />

GP 0.25-2.5 0.13-0.3 30-61 PM5 23-46 PM5 23-38 PM5 - -<br />

F - - - - - - - - - -<br />

R = Roughing Bold print indicates first choice<br />

GP = General purpose<br />

F = Finishing<br />

FT = Flat top<br />

Cutting parameters provided for positive inserts are based on CCMT 12 04 08<br />

Cutting parameters provided for negative inserts are based on CNMG 12 04 12<br />

You may increase/decrease cutting parameters to optimize your application depending on many factors including: work piece type and hardness, surface finish<br />

required, insert size, shape and nose radius, lead angle, chipbreaker, cycle time required, desired tool life, desired failure mode and reason for indexing.<br />

Geo.<br />

1st 2nd<br />

7

8<br />

GRADE <strong>8625</strong><br />

GEOMETRY APPLICATION<br />

Negative geometry Chipbreaker profile Applications Description<br />

F5<br />

M4<br />

M5<br />

M7<br />

5G<br />

Double<br />

sided<br />

1.0<br />

15°<br />

• Finishing to medium machining<br />

• High positive cutting angle<br />

• Low cutting forces - ideal for<br />

soft materials, work hardening<br />

materials<br />

15°<br />

0.9<br />

1.9<br />

• Multi-purpose geometry for<br />

machining of sticky materials<br />

0.8<br />

0.23<br />

7°<br />

13°<br />

• General machining<br />

• Wide range of materials<br />

• Positive cutting angle<br />

• Medium feed rates and medium<br />

depths of cut<br />

1.1<br />

0.2<br />

15°<br />

• Medium to light roughing<br />

• Smooth chipbreaker for soft<br />

materials<br />

• Neutral land for a good resistance<br />

1.23<br />

3.1<br />

r 1.9<br />

• Oriented (right or left)<br />

• Good support<br />

• Wide chip roller<br />

• Soft cutting<br />

15°<br />

P<br />

M<br />

S<br />

M<br />

S<br />

P<br />

M<br />

K<br />

P<br />

M<br />

K<br />

Depth of cut (mm)<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

r = 0.8<br />

4<br />

3<br />

2<br />

1 r = 0.4<br />

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1<br />

Depth of cut (mm)<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

r = 1.2<br />

4<br />

3<br />

r = 0.8<br />

2<br />

1<br />

Feed (mm/rev)<br />

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1<br />

Depth of cut (mm)<br />

10<br />

9<br />

8<br />

7<br />

6<br />

r = 1.2<br />

5<br />

r = 0.8<br />

4<br />

r = 0.4<br />

3<br />

2<br />

1<br />

Feed (mm/rev)<br />

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1<br />

Depth of cut (mm)<br />

10<br />

9<br />

8<br />

7<br />

6<br />

r = 1.6<br />

r = 1.2<br />

5<br />

r = 0.8<br />

4<br />

3<br />

2 r = 0.4<br />

1<br />

Feed (mm/rev)<br />

Continuous<br />

cutting<br />

Run-out Light Medium High<br />

Customer Service - Tel.: +33(0)1.46.10.54.00 Fax: +33(0)1.46.10.54.54<br />

F5<br />

Main application area:<br />

Depth of cut: ap = 0.3 - 5.0 mm<br />

Feed: f = 0.05 - 0.4 mm/rev<br />

Continuous<br />

cutting<br />

Run-out Light Medium High<br />

M4<br />

Main application area:<br />

Depth of cut: ap = 1 - 6 mm<br />

Feed: f = 0.15 - 0.5 mm/rev<br />

Continuous<br />

cutting<br />

Run-out Light Medium High<br />

M5<br />

Main application area:<br />

Depth of cut: ap = 0.5 - 6.0 mm<br />

Feed: f = 0.13 - 0.56 mm/rev<br />

Continuous<br />

cutting<br />

Run-out Light Medium High<br />

S Main application area:<br />

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 Depth of cut: ap = 0.8 - 6.5 mm<br />

Feed (mm/rev) Feed: f = 0.15 - 0.8 mm/rev<br />

P<br />

M<br />

Depth of cut (mm)<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

r = 0.8<br />

3 r = 0.4<br />

2<br />

1<br />

Continuous<br />

cutting<br />

M7<br />

Run-out Light Medium High<br />

S Main application area:<br />

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 Depth of cut: ap = 1.0 - 5.0 mm<br />

Feed (mm/rev) Feed: f = 0.2 - 0.5 mm/rev<br />

5G

GEOMETRY APPLICATION<br />

TEST RESULTS<br />

Customer Service - Tel.: +33(0)1.46.10.54.00 Fax: +33(0)1.46.10.54.54<br />

GRADE <strong>8625</strong><br />

Positive geometry Chipbreaker profile Applications Description<br />

PM4<br />

PM5<br />

0.75<br />

0.10<br />

18°<br />

• Semi-finishing to medium<br />

machining<br />

• Low to medium feed rates<br />

• Medium depths of cut<br />

• Good chip control<br />

5°<br />

1<br />

0.25<br />

20°<br />

• Semi-finishing to light roughing<br />

• Medium feed rates<br />

• Medium depths of cut<br />

P<br />

M<br />

K<br />

P<br />

5<br />

4<br />

3<br />

2<br />

1<br />

Depth of cut (mm)<br />

r = 0.4<br />

r = 0.8<br />

0 0.1 0.2 0.3 0.4 0.5<br />

5<br />

4<br />

3<br />

2<br />

1<br />

Depth of cut (mm)<br />

r = 0.4<br />

r = 0.8<br />

Feed (mm/rev)<br />

0 0.1 0.2 0.3 0.4 0.5<br />

Feed (mm/rev)<br />

Material: AISI 304 Material: AISI 316<br />

SAFETY insert CNMG 12 04 08 M4<br />

Speed (m/min) 110<br />

Feed (mm/rev) 0.22<br />

DOC (mm) 2<br />

Application Roughing<br />

Condition Intermittent cutting<br />

Coolant Emulsion<br />

TOOL LIFE<br />

<strong>8625</strong> 8 parts<br />

Competitor 4 parts<br />

IMPROVEMENT 100%<br />

M<br />

K<br />

Continuous<br />

cutting<br />

Run-out Light Medium High<br />

PM4<br />

Main application area:<br />

Depth of cut: ap = 0.6 - 4.0 mm<br />

Feed: f = 0.1 - 0.36 mm/rev<br />

Continuous<br />

cutting<br />

Run-out Light Medium High<br />

PM5<br />

Main application area:<br />

Depth of cut: ap = 0.6 - 4.0 mm<br />

Feed: f = 0.12 - 0.4 mm/rev<br />

SAFETY insert CNMG 12 04 08 M5<br />

Speed (m/min) 90<br />

Feed (mm/rev) 0.15<br />

DOC (mm) 1<br />

Application Semi-finishing<br />

Condition Intermittent cutting<br />

Coolant Emulsion<br />

TOOL LIFE<br />

<strong>8625</strong> 126 parts<br />

Competitor 70 parts<br />

IMPROVEMENT 80%<br />

9

10<br />

GRADE <strong>8625</strong><br />

PRODUCT OFFERING<br />

CCMT<br />

PM4<br />

CCMT<br />

PM5<br />

CNMG<br />

F5<br />

CNMG<br />

M4<br />

CNMG<br />

M5<br />

CNMG<br />

M7<br />

DCMT<br />

PM4<br />

DNMG<br />

5G<br />

Chipbreaker Reference<br />

✓: Standard stocked<br />

Dimensions<br />

(mm)<br />

CVD<br />

grade<br />

I.C. Thickness Radius <strong>8625</strong><br />

CCMT 09T308-PM4 09 T3 08 ✓<br />

CCMT 120408-PM4 12 04 08 ✓<br />

CCMT 060202-PM5 06 02 02 ✓<br />

CCMT 060204-PM5 06 02 04 ✓<br />

CCMT 080304-PM5 08 03 04 ✓<br />

CCMT 080308-PM5 08 03 08 ✓<br />

CCMT 09T304-PM5 09 T3 04 ✓<br />

CCMT 09T308-PM5 09 T3 08 ✓<br />

CCMT 120408-PM5 12 04 08 ✓<br />

CCMT 120412-PM5 12 04 12 ✓<br />

CNMG 120404-F5 12 04 04 ✓<br />

CNMG 120408-F5 12 04 08 ✓<br />

CNMG 120404-M4 12 04 04 ✓<br />

CNMG 120408-M4 12 04 08 ✓<br />

CNMG 120412-M4 12 04 12 ✓<br />

CNMG 160612-M4 16 06 12 ✓<br />

CNMG 190612-M4 19 06 12 ✓<br />

CNMG 120404-M5 12 04 04 ✓<br />

CNMG 120408-M5 12 04 08 ✓<br />

CNMG 120412-M5 12 04 12 ✓<br />

CNMG 120404-M7 12 04 04 ✓<br />

CNMG 120408-M7 12 04 08 ✓<br />

CNMG 120412-M7 12 04 12 ✓<br />

CNMG 160608-M7 16 06 08 ✓<br />

CNMG 160612-M7 16 06 12 ✓<br />

CNMG 190612-M7 19 06 12 ✓<br />

CNMG 190616-M7 19 06 16 ✓<br />

DCMT 070204-PM4 07 02 04 ✓<br />

DCMT 11T304-PM4 11 T3 04 ✓<br />

DCMT 11T308-PM4 11 T3 08 ✓<br />

DCMT 11T312-PM4 11 T3 12 ✓<br />

DNMG 150604L-5G 15 06 04 ✓<br />

DNMG 150604R-5G 15 06 04 ✓<br />

DNMG 150608L-5G 15 06 08 ✓<br />

DNMG 150608R-5G 15 06 08 ✓<br />

DNMG<br />

F5<br />

DNMG<br />

M4<br />

DNMG<br />

M5<br />

ECMT<br />

PM4<br />

KNUX<br />

22<br />

KNUX<br />

32<br />

SCMT<br />

PM4<br />

SNMG<br />

F5<br />

SNMG<br />

M4<br />

Chipbreaker Reference<br />

Dimensions<br />

(mm)<br />

CVD<br />

grade<br />

I.C. Thickness Radius <strong>8625</strong><br />

DNMG 150604-F5 15 06 04 ✓<br />

DNMG 150608-F5 15 06 08 ✓<br />

DNMG 150608-M4 15 06 08 ✓<br />

DNMG 150612-M4 15 06 12 ✓<br />

DNMG 110404-M5 11 04 04 ✓<br />

DNMG 110408-M5 11 04 08 ✓<br />

DNMG 150604-M5 15 06 04 ✓<br />

DNMG 150608-M5 15 06 08 ✓<br />

DNMG 150612-M5 15 06 12 ✓<br />

ECMT 060204-PM4 06 02 04 ✓<br />

ECMT 080304-PM4 08 03 04 ✓<br />

ECMT 080308-PM4 08 03 08 ✓<br />

KNUX 160405L-22 16 04 05 ✓<br />

KNUX 160405R-22 16 04 05 ✓<br />

KNUX 160405L-32 16 04 05 ✓<br />

KNUX 160405R-32 16 04 05 ✓<br />

SCMT 09T304-PM4 09 T3 04 ✓<br />

SCMT 09T308-PM4 09 T3 08 ✓<br />

SNMG 120408-F5 12 04 08 ✓<br />

SNMG 120408-M4 12 04 08 ✓<br />

SNMG 120412-M4 12 04 12 ✓<br />

Customer Service - Tel.: +33(0)1.46.10.54.00 Fax: +33(0)1.46.10.54.54

PRODUCT OFFERING<br />

SNMG<br />

M5<br />

SNMG<br />

M7<br />

TCMT<br />

PM4<br />

TCMT<br />

PM5<br />

TNMG<br />

F5<br />

TNMG<br />

M4<br />

TNMG<br />

M5<br />

TNMG<br />

M7<br />

Chipbreaker Reference<br />

Dimensions<br />

(mm)<br />

Customer Service - Tel.: +33(0)1.46.10.54.00 Fax: +33(0)1.46.10.54.54<br />

CVD<br />

grade<br />

I.C. Thickness Radius <strong>8625</strong><br />

SNMG 120404-M5 12 04 04 ✓<br />

SNMG 120408-M5 12 04 08 ✓<br />

SNMG 120412-M5 12 04 12 ✓<br />

SNMG 090308-M7 09 03 08 ✓<br />

SNMG 120404-M7 12 04 04 ✓<br />

SNMG 120408-M7 12 04 08 ✓<br />

SNMG 120412-M7 12 04 12 ✓<br />

SNMG 190612-M7 19 06 12 ✓<br />

SNMG 190616-M7 19 06 16 ✓<br />

TCMT 16T308-PM4 16 T3 08 ✓<br />

TCMT 16T304-PM5 16 T3 04 ✓<br />

TCMT 16T308-PM5 16 T3 08 ✓<br />

TNMG 160404-F5 16 04 04 ✓<br />

TNMG 160408-F5 16 04 08 ✓<br />

TNMG 160408-M4 16 04 08 ✓<br />

TNMG 160404-M5 16 04 04 ✓<br />

TNMG 160408-M5 16 04 08 ✓<br />

TNMG 160412-M5 16 04 12 ✓<br />

TNMG 160404-M7 16 04 04 ✓<br />

TNMG 160408-M7 16 04 08 ✓<br />

TNMG 160412-M7 16 04 12 ✓<br />

TNMG 220404-M7 22 04 04 ✓<br />

TNMG 220408-M7 22 04 08 ✓<br />

TNMG 220412-M7 22 04 12 ✓<br />

TNMG 270612-M7 27 06 12 ✓<br />

TNMG 270616-M7 27 06 16 ✓<br />

TNMG 270624-M7 27 06 24 ✓<br />

VBMT<br />

PM4<br />

VCGT<br />

PM5<br />

VNMG<br />

M5<br />

WNMG<br />

F5<br />

WNMG<br />

M4<br />

WNMG<br />

M5<br />

WNMG<br />

M7<br />

GRADE <strong>8625</strong><br />

Chipbreaker Reference<br />

✓: Standard stocked<br />

Dimensions<br />

(mm)<br />

CVD<br />

grade<br />

I.C. Thickness Radius <strong>8625</strong><br />

VBMT 160404-PM4 16 04 04 ✓<br />

VBMT 160408-PM4 16 04 08 ✓<br />

VCGT 130302-PM5 13 03 02 ✓<br />

VCGT 130304-PM5 13 03 04 ✓<br />

VCGT 130308-PM5 13 03 08 ✓<br />

VNMG 160404-M5 16 04 04 ✓<br />

VNMG 160408-M5 16 04 08 ✓<br />

WNMG 080404-F5 08 04 04 ✓<br />

WNMG 080408-F5 08 04 08 ✓<br />

WNMG 080408-M4 08 04 08 ✓<br />

WNMG 080412-M4 08 04 12 ✓<br />

WNMG 060404-M5 06 04 04 ✓<br />

WNMG 060408-M5 06 04 08 ✓<br />

WNMG 060412-M5 06 04 12 ✓<br />

WNMG 080404-M5 08 04 04 ✓<br />

WNMG 080408-M5 08 04 08 ✓<br />

WNMG 080412-M5 08 04 12 ✓<br />

WNMG 080408-M7 08 04 08 ✓<br />

WNMG 080412-M7 08 04 12 ✓<br />

11

Safety France<br />

51, rue de la Garenne<br />

92310 Sèvres - France<br />

Tel.: +33 (0)1 46 10 54 00<br />

Fax: +33 (0)1 46 10 54 54<br />

info.safety@safety-cuttingtools.com<br />

Impero Italia<br />

Via Bachelet - Località Crocetta<br />

29010 S. Polo (Piacenza) - Italia<br />

Tel.: +39 0523 55 19 11<br />

Fax: +39 0523 55 18 00<br />

info.impero@safety-impero.com<br />

Safety Deutschland<br />

Philipp - Reis - Str. 7<br />

D-63110 Rodgau - Deutschland<br />

Tel.: +49 (0)6106-26848-0<br />

Fax: +49 (0)6106-26848-22<br />

info.safety-deutschland@safety-cuttingtools.com<br />

Safety Ibérica<br />

Pol. Ind. Roca<br />

c./ Verneda s/n<br />

08107-Martorelles (Barcelona) - España<br />

Tel.: +34 935 71 77 22<br />

Fax: +34 935 71 77 65<br />

info.safety-iberica@safety-cuttingtools.com<br />

Safety China<br />

Tel.: +86 0316-2773500<br />

Fax: +86 0316-2773588<br />

info.safety-china@safety-cuttingtools.com<br />

www.safety-cuttingtools.com<br />

BROC-<strong>8625</strong>-08/11-ENG