KALTE FEDDER E - KFR-Fedder GmbH

KALTE FEDDER E - KFR-Fedder GmbH

KALTE FEDDER E - KFR-Fedder GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

R <strong>KALTE</strong><br />

EFRIGERATION<br />

<strong>FEDDER</strong> <strong>GmbH</strong><br />

INDUSTRIAL COOLING AND FREEZING SYSTEMS<br />

LIQUEFIER<br />

in Split and compact model<br />

E<br />

<br />

<strong>FEDDER</strong><br />

SINCE 1954<br />

The individual adaptation of our<br />

installations to the requirements of your<br />

products is our primary goal. Setting<br />

this goal and the flexible technical<br />

model of our systems' solutions<br />

according to your wishes and<br />

economical interests, our units are<br />

becoming costs saving components<br />

of your product lines.<br />

Split model<br />

High capacities<br />

Noise reduction<br />

Compact model<br />

Less installation works<br />

No separate machine hall<br />

®

SPLIT - liquefier<br />

Liquifier<br />

Axial liquifier<br />

TK - STORAGE<br />

or<br />

PRODUCTION'S FROSTER<br />

=<br />

+<br />

Options<br />

Oil cooler to be used in head recovery field<br />

till water temperatures of 55°C.<br />

Equipment with the refrigerating agent R22<br />

for the export. But the performance data of<br />

the units R22 are lightly different from those<br />

of the table.<br />

Special constructions are possible<br />

In case of operation with other refrigerating agents, please<br />

send us your detailed inquiry.<br />

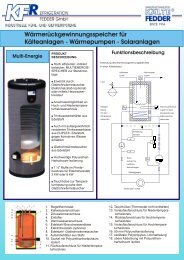

The Split liquefier of the series QSLS are<br />

previously factory assembled cooling<br />

machines. Equipped with hermetically screw<br />

compressors. They are mainly used for industrial<br />

purpose in frost storing field or in combination<br />

with froster installations. So doing, in case of<br />

installation series QSLA, the conception plans<br />

that the condensators will be installed outside<br />

the building.<br />

The condensators are weather resistant and<br />

protected against corrosion, they can be<br />

installed without additional weather protecting<br />

measures. Due to regulated rotary frequency,<br />

the installations satisfy to quiet all requirements<br />

of noise emissions and so, they can be installed<br />

in all industrial areas.<br />

The intern unit consists of factory constructed<br />

cooling machine. It is already equipped with<br />

the complete installation switch cabinet, wired<br />

and electrically connected. Big dimensioned oil<br />

separation guarantees short-oil refrigerating<br />

agent that is leaded to the refrigerator and so it<br />

guarantees high efficiency of refrigerator. The<br />

complete delivery of machines and<br />

condensors in one delivery allows a quick<br />

installation and swift start-up of the whole<br />

installation. Standard capacity sizes are<br />

described in the tables beside.<br />

The standard capacity sizes are described in the table in page 6.<br />

Standard equipment<br />

Conceived to be used with refrigerating<br />

agents free of fluorocarbon and chloric gas<br />

Winter start and operation devices<br />

Economic operation of screw compressors.

CONSTRUCTION GROUPS<br />

& CAPACITY DOMAINS SERIES QSLS<br />

SPLIT-Verflüssigereinheiten<br />

Capacity data depending on type of machine and operation conditions<br />

at t=15k<br />

TYP <strong>KFR</strong>V47- <strong>KFR</strong>V102<br />

<br />

Nominal capacity [kW] 18,5 - 635<br />

Air volume stream<br />

Sound pressure level<br />

3<br />

[m /h] 5080 - 14420<br />

[dB/A ] /Y 47/35 - 66/61<br />

5m<br />

Lp [dB(A)]<br />

TYP QSLS 5016 AA - QSLS 5053 AA<br />

Refrigerating capacity:<br />

15.500 Watt - 84.600 Watt<br />

TYP QSLS 5070 BA - QSLS 5106 BA<br />

Refrigerating capacity:<br />

70.000 Watt - 169.000 Watt<br />

TYP QSLS 5140 - QSLS 5159<br />

Refrigerating capacity:<br />

<br />

140.000 Watt - 253.000 Watt<br />

TYP QSLS 5186 - QSLS 5212<br />

Refrigerating capacity:<br />

186.000 Watt - 338.400 Watt<br />

Sound pressure level depending on the capacity<br />

Q [kW]

COMPACT LIQUIFIERS<br />

LIQUIFIER<br />

Options<br />

TK - STORAGE<br />

or<br />

PRODUCTION'S FROSTER<br />

Oil cooler to be used in heat recovery<br />

field till to water temperatures of 55°C<br />

Equipment with refrigerating agent R22<br />

for the export area. But the capacity<br />

data of installations with R22 are slightly<br />

different from those in the tables.<br />

Special constructions are possible.<br />

In case of operation with other refrigerating agents, please<br />

give us your detailed inquiry. Special constructions are<br />

possible.<br />

The compact liquefiers of the series QSLA are<br />

previously factory assembled cooling machines<br />

ready for connection. They are equipped with<br />

air cooled condensators and hermetically<br />

screw compressors. The equipment of the<br />

machines are foreseen to be used in industrial<br />

purposes and are mainly used in deep frosting<br />

field as refrigerating machines for deep frosting<br />

store or production froster. The conception of<br />

the machine plans to place the refrigerating<br />

machine in the production building and to<br />

establish the connection to the refrigerator of<br />

the refrigerating warehouse or of the production<br />

froster to supply them with the refrigerating<br />

pipes. Generously dimensioned oil separation<br />

and condensators guarantee an economical<br />

low cost way of operation and short-oil<br />

refrigerating agent in the refrigerator.<br />

Due to the weather resistant house, the<br />

installation can be installed outside without<br />

additional weather protecting measures.<br />

Integrated switch cabinet for electric contains<br />

all necessary components to operate and safe<br />

the installation. It is wired, all machine's<br />

components are connected with the switch<br />

cabinet and the electrical functions of the<br />

installation is factory examined.<br />

The refrigerating cycle within the installation is<br />

piped and examined ready for connection. It is<br />

delivered with gas filling protection.<br />

The standard capacity sizes are described in the table in page 6.<br />

Standard equipment<br />

Conceived to be used with refrigerating<br />

agents free of fluorocarbon and chloric gas<br />

Winter start and operation devices<br />

Economic operation of screw compressors.<br />

House protected against corrosion and<br />

powder coated with RAL 7035

CONSTRUCTION GROUPS<br />

& CAPACITY DOMAINS SERIES QSLA<br />

SPLIT-Verflüssigereinheiten<br />

SPLIT-Verflüssigereinheiten<br />

Capacity data depending on type of machine and operation conditions<br />

TYP QSLA 5016 AA - QSLA 5046 AA<br />

Refrigerating capacity:<br />

15.500 Watt - 46.650 Watt<br />

TYP QSLA 5053 AA - QSLA 5070 AA<br />

Refrigerating capacity:<br />

53.000 Watt - 70.000 Watt<br />

TYP QSLA 5093 AA - QSLA 5106 AA<br />

Refrigerating capacity:<br />

93.300 Watt - 106.000 Watt

TECHNICAL DATA QSLS / QSLA<br />

QSLA<br />

compact machines<br />

QSLS<br />

Split machines<br />

condensators<br />

Type<br />

5016 AA<br />

5024 AA<br />

5035 AA<br />

5046 AA<br />

5053 AA<br />

5070 BA<br />

5093 BA<br />

5106 BA<br />

5016 AA<br />

5024 AA<br />

5035 AA<br />

5046 AA<br />

5053 AA<br />

5070 BA<br />

5093 BA<br />

5106 BA<br />

5140 CA<br />

5159 CA<br />

5186 DA<br />

5212 DA<br />

Type<br />

CON016<br />

CON024<br />

CON035<br />

CON046<br />

CON053<br />

CON070<br />

CON093<br />

CON106<br />

REFRIGERATING MACHINE<br />

R 507A<br />

to=-40/+40<br />

Q 0<br />

Watt<br />

15.500<br />

24.050<br />

35.000<br />

46.650<br />

53.000<br />

70.000<br />

93.300<br />

106.000<br />

15.500<br />

24.050<br />

35.000<br />

46.650<br />

53.000<br />

70.000<br />

93.300<br />

106.000<br />

140.000<br />

159.000<br />

186.600<br />

212.000<br />

Q C<br />

k W<br />

44,27<br />

64,7<br />

92,4<br />

123,2<br />

140,1<br />

184,8<br />

246,4<br />

280,2<br />

Ne<br />

kW<br />

16,52<br />

22,9<br />

32,1<br />

42,8<br />

48,6<br />

64,2<br />

85,6<br />

97,2<br />

16,52<br />

22,90<br />

32,10<br />

42,80<br />

48,6<br />

64,2<br />

85,6<br />

97,2<br />

128,4<br />

132,2<br />

171,2<br />

194,8<br />

V<br />

m3/h<br />

10.500<br />

16.600<br />

28.490<br />

34.100<br />

37.600<br />

51.400<br />

60.400<br />

77.500<br />

R 507A<br />

to=-30/+40<br />

Q0<br />

Watt<br />

25.400<br />

38.500<br />

55.800<br />

74.400<br />

84.600<br />

111.600<br />

148.800<br />

169.200<br />

25.400<br />

38.500<br />

55.800<br />

74.400<br />

84.600<br />

111.600<br />

148.800<br />

169.200<br />

223.400<br />

253.800<br />

297.600<br />

338.400<br />

Number<br />

of ventilators<br />

2<br />

2<br />

2<br />

2<br />

2<br />

2<br />

3<br />

3<br />

Ne<br />

kW<br />

18,87<br />

26,2<br />

36,6<br />

48,8<br />

55,5<br />

73,2<br />

97,6<br />

111<br />

18,87<br />

26,2<br />

36,6<br />

48,8<br />

55,5<br />

73,2<br />

97,6<br />

111<br />

146,4<br />

166,5<br />

195,2<br />

222<br />

Pegel<br />

dB(A)<br />

55<br />

57<br />

67<br />

57<br />

59<br />

65<br />

61<br />

67<br />

L x B x H<br />

3300/1100/1800<br />

3300/1100/1800<br />

3300/1100/2040<br />

3300/1100/2040<br />

3300/1100/2040<br />

3300/1100/2040<br />

4400/2200/2040<br />

4400/2200/2040<br />

1900/700/1500<br />

1900/700/1500<br />

1800/1200/2000<br />

1800/1200/2000<br />

1800/1200/2000<br />

2500/1200/2000<br />

2500/1200/2000<br />

2500/1200/2000<br />

2500/1200/2000<br />

3100/1200/2000<br />

3300/1200/2000<br />

3300/1200/2000<br />

L x B x H<br />

1700/795/895<br />

2650/895/950<br />

2250/1145/950<br />

2800/1185/1250<br />

3400/1185/1250<br />

3400/1185/1250<br />

6000/1185/1550<br />

5100/1185/1550<br />

G<br />

kg.<br />

1000<br />

1000<br />

1000<br />

1200<br />

1400<br />

2000<br />

2000<br />

2200<br />

510<br />

610<br />

690<br />

207<br />

1400<br />

1800<br />

1800<br />

1800<br />

1950<br />

2550<br />

3200<br />

3200<br />

Capacity<br />

per aerators<br />

Watt<br />

390<br />

780<br />

2200<br />

2000<br />

2000<br />

3600<br />

2000<br />

3600<br />

Number<br />

of compressor<br />

1<br />

1<br />

1<br />

1<br />

1<br />

2<br />

2<br />

2<br />

1<br />

1<br />

1<br />

1<br />

1<br />

2<br />

2<br />

2<br />

2<br />

3<br />

3/4<br />

3/4<br />

G<br />

kg.<br />

133<br />

179<br />

207<br />

402<br />

453<br />

499<br />

731<br />

705<br />

SUBJECT TO TECHNICAL CHANGES<br />

Comments:<br />

CON140 369,8 103.600 4 68 6800/1185/1550 3600 951 Refrigerating agent R507A:<br />

CON159 420,3 103.000 4 63 6800/1685/1550 2200 1172<br />

t c/t 0 = +40/-40°C<br />

t c/t 0 = +40/-30°C<br />

CON186 492,8 115.300 4 64 9200/1685/1550 2200 1563<br />

<br />

<br />

Condensators can be adjusted to all<br />

requirements of soundness! (in case<br />

of changed dimensions)<br />

CON212 560,4 137.800 5 65 10.000/1685/1550 2200 1733<br />

KF Refrigeration <strong>Fedder</strong> <strong>GmbH</strong> Industriestraße Industriestraße 10a D-48653 D-48653<br />

Coesfeld-Lette<br />

Tel.:++(49) 2546 7604-50 u. 51 Fax: Fax: ++(49) 2546 760452 www.kfr-fedder.de www.kfr-fedder.de e-Mail: e-Mail:<br />

mail@kfr-fedder.de