irradiation of dissolving pulp by electron beams - Lenzing

irradiation of dissolving pulp by electron beams - Lenzing

irradiation of dissolving pulp by electron beams - Lenzing

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Economical considerations. . The price <strong>of</strong><br />

irradiated <strong>of</strong> <strong>pulp</strong> is composed <strong>of</strong> high costs <strong>of</strong><br />

botlh investment and Operation, the latter one<br />

mainly depending on expenses for electric<br />

power. From this Point <strong>of</strong> view, the <strong>irradiation</strong> <strong>of</strong><br />

<strong>pulp</strong> would become an economically interesting<br />

innovation only if it is possible to carry out the<br />

viscose process with drastically reduced input<br />

chemicals (22% CS*, AR: 0.5) without any<br />

impairment <strong>of</strong> the fiber quality.<br />

Experimental<br />

For the experiments at lab plant and Pilot plant,<br />

50 sheets (isostack) <strong>of</strong> Solucell 450 were<br />

irraldiated at STUDER AG with a 1OMeV<br />

Rhodotron TT300 accelerator built <strong>by</strong> IBA.<br />

The viscose quality was evaluated <strong>by</strong> PVC and<br />

KWP filter value (constant pressure) and particle<br />

i<br />

-<br />

I<br />

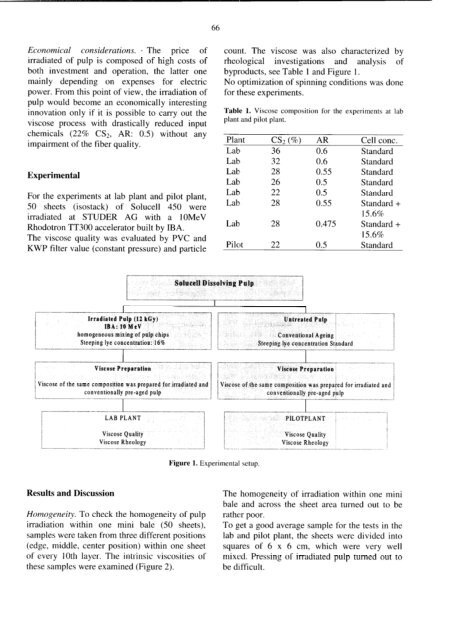

Irradiated Pulp fl2 kCy)<br />

BA: 10 MeV<br />

homogeneous nking <strong>of</strong> prllp chips<br />

Steeping lye concentratioe: 16%<br />

/ Viscose <strong>of</strong> the sanuz composition was prepared for irradiated and<br />

-.<br />

LAB PLANT<br />

Viscose Quality<br />

Viscose Rheology I<br />

- -----.~-~~--~ _-_- - - ---~~_<br />

66<br />

count. The viscose was also characterized <strong>by</strong><br />

rheological investigations and analysis <strong>of</strong><br />

<strong>by</strong>products, see Table 1 and Figure 1.<br />

No optimization <strong>of</strong> spinning conditions was done<br />

for these experiments.<br />

Table 1. Viscose composition for the experiments at lab<br />

plant and Pilot plant.<br />

Plant CS2 (%) AR Ce11 conc.<br />

Lab 36 0.6<br />

Lab 32 0.6<br />

Lab’ 28 0.55<br />

Lab 26 0.5<br />

Lab 22 0.5<br />

Lab 28 0.55<br />

Lab<br />

Pilot<br />

Figure 1. Experimental setup.<br />

--<br />

28<br />

22<br />

0.475<br />

0.5<br />

Standard<br />

Standard<br />

Standard<br />

Standard<br />

Standard<br />

Standard +<br />

15.6%<br />

Standard +<br />

15.6%<br />

Standard<br />

Con~entionai Ageiag<br />

Sieeping lye co~~~~~rati~a Standard<br />

-.--I--~ --.x .._““