1. What must be done to ensure electrical safety in schools? 2 ...

1. What must be done to ensure electrical safety in schools? 2 ...

1. What must be done to ensure electrical safety in schools? 2 ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

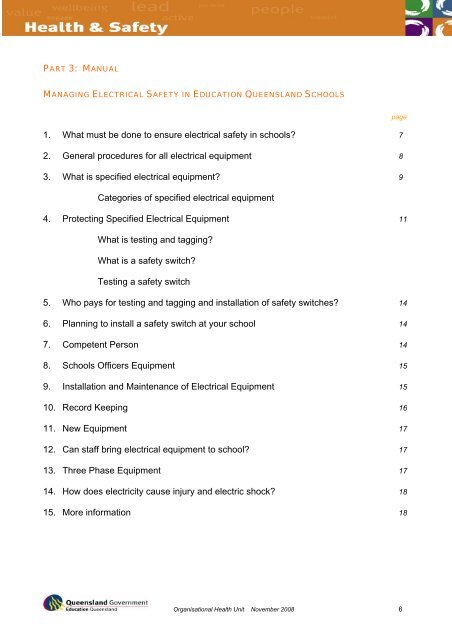

PART 3: MANUAL<br />

MANAGING ELECTRICAL SAFETY IN EDUCATION QUEENSLAND SCHOOLS<br />

<strong>1.</strong> <strong>What</strong> <strong>must</strong> <strong>be</strong> <strong>done</strong> <strong>to</strong> <strong>ensure</strong> <strong>electrical</strong> <strong>safety</strong> <strong>in</strong> <strong>schools</strong>? 7<br />

2. General procedures for all <strong>electrical</strong> equipment 8<br />

3. <strong>What</strong> is specified <strong>electrical</strong> equipment? 9<br />

Categories of specified <strong>electrical</strong> equipment<br />

4. Protect<strong>in</strong>g Specified Electrical Equipment 11<br />

<strong>What</strong> is test<strong>in</strong>g and tagg<strong>in</strong>g?<br />

<strong>What</strong> is a <strong>safety</strong> switch?<br />

Test<strong>in</strong>g a <strong>safety</strong> switch<br />

5. Who pays for test<strong>in</strong>g and tagg<strong>in</strong>g and <strong>in</strong>stallation of <strong>safety</strong> switches? 14<br />

6. Plann<strong>in</strong>g <strong>to</strong> <strong>in</strong>stall a <strong>safety</strong> switch at your school 14<br />

7. Competent Person 14<br />

8. Schools Officers Equipment 15<br />

9. Installation and Ma<strong>in</strong>tenance of Electrical Equipment 15<br />

10. Record Keep<strong>in</strong>g 16<br />

1<strong>1.</strong> New Equipment 17<br />

12. Can staff br<strong>in</strong>g <strong>electrical</strong> equipment <strong>to</strong> school? 17<br />

13. Three Phase Equipment 17<br />

14. How does electricity cause <strong>in</strong>jury and electric shock? 18<br />

15. More <strong>in</strong>formation 18<br />

page<br />

Organisational Health Unit Novem<strong>be</strong>r 2008 6

<strong>1.</strong> <strong>What</strong> <strong>must</strong> <strong>be</strong> <strong>done</strong> <strong>to</strong> <strong>ensure</strong> <strong>electrical</strong> <strong>safety</strong> <strong>in</strong> <strong>schools</strong>?<br />

The protection of students, staff and others from <strong>in</strong>jury relat<strong>in</strong>g <strong>to</strong> electricity is of primary<br />

importance. Ensur<strong>in</strong>g <strong>electrical</strong> <strong>safety</strong> can also prevent property damage. Education Queensland<br />

<strong>schools</strong> <strong>must</strong>;<br />

<strong>1.</strong> Follow general procedures <strong>to</strong> <strong>ensure</strong> the <strong>electrical</strong> <strong>safety</strong> of all <strong>electrical</strong> equipment<br />

2. Protect specified <strong>electrical</strong> equipment accord<strong>in</strong>g <strong>to</strong> the requirements of the Electrical Safety<br />

Regulation 2002<br />

3. Record and notify <strong>electrical</strong> <strong>in</strong>cidents as required by the Electrical Safety Act and Regulation<br />

2002. These requirements are provided <strong>in</strong> departmental procedure HLS-PR-005: Health and<br />

Safety Incident Record<strong>in</strong>g and Notification. Refer <strong>to</strong> respond<strong>in</strong>g <strong>to</strong> an <strong>electrical</strong> <strong>in</strong>cident flow<br />

chart for summary of steps.<br />

4. Ensure all staff, students and others us<strong>in</strong>g <strong>electrical</strong> equipment have the appropriate skills,<br />

<strong>in</strong>formation and tra<strong>in</strong><strong>in</strong>g <strong>to</strong> perform the task safely.<br />

Education Queensland Approach<br />

There are regula<strong>to</strong>ry requirements that <strong>must</strong> <strong>be</strong> followed <strong>in</strong> relation <strong>to</strong> <strong>electrical</strong> <strong>safety</strong>. These are<br />

def<strong>in</strong>ed <strong>in</strong> the Electrical Safety Regulation 2002 (the Regulation) and state the m<strong>in</strong>imum standards<br />

<strong>to</strong> <strong>be</strong> implemented. Due <strong>to</strong> the diverse range of activities <strong>in</strong> <strong>schools</strong> that <strong>in</strong>volve <strong>electrical</strong><br />

equipment these requirements can <strong>be</strong> <strong>in</strong>terpreted <strong>in</strong> different ways and may <strong>be</strong> confus<strong>in</strong>g. Our<br />

department has liaised with the Electrical Safety Office, Department of Employment and Industrial<br />

Relations <strong>to</strong> develop this guide <strong>to</strong> meet the requirements and help <strong>schools</strong> ma<strong>in</strong>ta<strong>in</strong> <strong>electrical</strong><br />

<strong>safety</strong>.<br />

This guide for Education Queensland <strong>schools</strong>:<br />

acknowledges that more rigorous controls for <strong>electrical</strong> <strong>safety</strong> may <strong>be</strong> needed <strong>to</strong> due <strong>to</strong> the<br />

characteristics of young people that may affect their (and others) health and <strong>safety</strong>; e.g.<br />

physical and <strong>in</strong>tellectual maturity, experience and <strong>be</strong>haviour, confidence and judgement; and<br />

outl<strong>in</strong>es a consistent approach that provides a standard of <strong>electrical</strong> <strong>safety</strong> that meets, and <strong>in</strong><br />

some cases exceeds, regula<strong>to</strong>ry requirements.<br />

The Department of Education, Tra<strong>in</strong><strong>in</strong>g & the Arts has, <strong>in</strong> some cases, implemented guidance that<br />

exceeds the regula<strong>to</strong>ry requirements <strong>to</strong> further m<strong>in</strong>imise the risk of <strong>in</strong>jury <strong>to</strong> our students, staff and<br />

visi<strong>to</strong>rs.<br />

Overview of <strong>electrical</strong> <strong>safety</strong> requirements<br />

All <strong>electrical</strong> equipment<br />

<strong>1.</strong> Ensure ‘<strong>in</strong>-built’ <strong>safety</strong> features of <strong>electrical</strong> equipment rema<strong>in</strong> <strong>in</strong>tact<br />

2. General care and ma<strong>in</strong>tenance<br />

3. Make regular visual <strong>in</strong>spections<br />

4. A system is <strong>in</strong> place <strong>to</strong> <strong>ensure</strong> the <strong>safety</strong> of all<br />

<strong>electrical</strong> equipment<br />

Specified <strong>electrical</strong> equipment<br />

Ensure specified <strong>electrical</strong> equipment is<br />

tested and tagged and/or connected <strong>to</strong> a<br />

<strong>safety</strong> switch accord<strong>in</strong>g <strong>to</strong> the requirements<br />

of the Regulation.<br />

Organisational Health Unit Novem<strong>be</strong>r 2008 7

2. General procedures for all <strong>electrical</strong> equipment<br />

Legislation requires that the <strong>safety</strong> of all <strong>electrical</strong> items <strong>must</strong> <strong>be</strong> <strong>ensure</strong>d. The follow<strong>in</strong>g general<br />

procedures should <strong>be</strong> followed for the use of all <strong>electrical</strong> equipment:<br />

<strong>1.</strong> Ensur<strong>in</strong>g ‘<strong>in</strong>-built’ <strong>safety</strong> features of <strong>electrical</strong> equipment rema<strong>in</strong> <strong>in</strong>tact:<br />

Appropriately designed and manufactured <strong>electrical</strong> equipment has some ‘<strong>in</strong>-built’ <strong>safety</strong> features<br />

that protect the user from harm related <strong>to</strong> electricity. Importers, designers and manufacturers of<br />

<strong>electrical</strong> equipment have obligations <strong>to</strong> <strong>ensure</strong> equipment is <strong>electrical</strong>ly safe.<br />

To <strong>ensure</strong> these features rema<strong>in</strong> <strong>in</strong>tact and are effective;<br />

Use equipment accord<strong>in</strong>g <strong>to</strong> <strong>in</strong>structions<br />

Use appropriate equipment for the task – e.g. do not use domestic equipment for <strong>in</strong>dustrial<br />

purposes<br />

Do not remove any cas<strong>in</strong>gs or covers that enclose <strong>electrical</strong> parts<br />

Do not <strong>in</strong>sert <strong>in</strong>appropriate items (e.g. metal implements) <strong>in</strong><strong>to</strong> <strong>electrical</strong> equipment<br />

Do not attempt repairs - use a licensed <strong>electrical</strong> contrac<strong>to</strong>r (e.g. an electrician)<br />

2. General care and ma<strong>in</strong>tenance<br />

Protect leads and equipment from damage e.g. position leads and equipment where they are<br />

not likely <strong>to</strong> <strong>be</strong> damaged<br />

Remove faulty <strong>electrical</strong> items from use immediately <strong>to</strong> <strong>ensure</strong> the item is not used<br />

<strong>in</strong>advertently by someone else; clearly la<strong>be</strong>l them as ‘faulty’ or ‘out of service’<br />

Discard faulty <strong>electrical</strong> equipment or have it repaired by an electrician. Sometimes it is more<br />

economical <strong>to</strong> replace the item<br />

Use power boards <strong>in</strong>stead of double adap<strong>to</strong>rs; however, do not overload power boards<br />

3. Mak<strong>in</strong>g regular visual <strong>in</strong>spections<br />

More than 90% of defects are detectable by visual <strong>in</strong>spection. It only takes a few seconds <strong>to</strong> check<br />

the item <strong>be</strong>fore you use it.<br />

Check the lead, plug, socket and item for:<br />

cuts or other damage that exposes the <strong>in</strong>sulation of the <strong>in</strong>ner cores or conduc<strong>to</strong>rs<br />

melted or burnt areas<br />

damage <strong>to</strong> covers, guards and controls (e.g. switches)<br />

cracks and holes that may expose live parts<br />

obstructed ventilation <strong>in</strong>lets and exhausts<br />

deformed leads e.g. permanently twisted<br />

4. Electrical items that are not specified <strong>electrical</strong> equipment<br />

For <strong>electrical</strong> equipment that is not specified <strong>electrical</strong> equipment (e.g. fridges, computers) the<br />

Regulation does not prescri<strong>be</strong> the way <strong>to</strong> <strong>ensure</strong> <strong>electrical</strong> <strong>safety</strong>. This is <strong>be</strong>cause the risks are<br />

seen <strong>to</strong> <strong>be</strong> much lower for these types of equipment. For example, the risks (e.g. of electric shock)<br />

associated with us<strong>in</strong>g a refrigera<strong>to</strong>r <strong>in</strong> a staff room are much lower than the risks associated with<br />

students operat<strong>in</strong>g a power drill dur<strong>in</strong>g <strong>in</strong>dustrial technology.<br />

There is still the general obligation <strong>to</strong> <strong>ensure</strong> <strong>electrical</strong> <strong>safety</strong> for these items so, your school may<br />

choose <strong>to</strong> take extra precautions <strong>in</strong> addition <strong>to</strong> the 3 steps listed above.<br />

For example;<br />

identify if there are any <strong>electrical</strong> items that are exposed <strong>to</strong> damage (see Schedule for examples)<br />

implement a test & tag regime or <strong>in</strong>stall a <strong>safety</strong> switch <strong>to</strong> <strong>in</strong>crease the level of protection for<br />

users<br />

This approach shows a risk management process has <strong>be</strong>en used and is one method of prov<strong>in</strong>g that a<br />

system is <strong>in</strong> place <strong>to</strong> <strong>ensure</strong> <strong>electrical</strong> <strong>safety</strong> for all <strong>electrical</strong> equipment.<br />

Organisational Health Unit Novem<strong>be</strong>r 2008 8

3. <strong>What</strong> is ‘specified <strong>electrical</strong> equipment’?<br />

Specified <strong>electrical</strong> equipment is def<strong>in</strong>ed under the Electrical Safety Regulation 2002 as any equipment that<br />

meets any of the follow<strong>in</strong>g criteria:<br />

All extension leads (cord extension sets with a current rat<strong>in</strong>g of not more than 20 amps)<br />

All power boards (portable outlet devices with a current rat<strong>in</strong>g of not more than 20 amps)<br />

OR<br />

Electrical equipment that is connected by a flexible cord and plug <strong>to</strong> low voltage supply, has a<br />

current rat<strong>in</strong>g not more than 20 Amps 1 and is used <strong>to</strong> perform “manufactur<strong>in</strong>g work”. e.g. a<br />

<strong>be</strong>nch gr<strong>in</strong>der<br />

OR<br />

Equipment that is;<br />

o connected by a flexible cord and plug <strong>to</strong> a low voltage supply and<br />

o is used <strong>to</strong> perform “service or office work” and<br />

o is moved dur<strong>in</strong>g its normal use for the purpose of its use.<br />

e.g. a hand held blow dryer, hot glue gun.<br />

Specified <strong>electrical</strong> equipment is also separated <strong>in</strong><strong>to</strong> categories (formerly “classes of work”) accord<strong>in</strong>g <strong>to</strong><br />

how the equipment is <strong>be</strong><strong>in</strong>g used. The way a piece of <strong>electrical</strong> equipment is used <strong>in</strong>fluences the likely wear<br />

and tear or damage <strong>to</strong> the equipment and consequently the level of risk of <strong>in</strong>jury <strong>to</strong> users.<br />

The level of protection required for the item depends on the category of work.<br />

e.g. higher risk environment = greater level of controls (protection for users) required.<br />

<strong>1.</strong> <strong>What</strong> is the item?<br />

e.g. is it specified <strong>electrical</strong><br />

equipment?<br />

<br />

2. How is the item <strong>be</strong><strong>in</strong>g used?<br />

e.g. what is the category of work? =<br />

3. Level of protection<br />

e.g. <strong>safety</strong> switch and/or test and tag<br />

Categories of specified <strong>electrical</strong> equipment<br />

The Regulation divides specified <strong>electrical</strong> equipment <strong>in</strong><strong>to</strong> 6 categories and prescri<strong>be</strong>s the ways <strong>to</strong> <strong>ensure</strong><br />

<strong>electrical</strong> <strong>safety</strong> for specified <strong>electrical</strong> equipment <strong>in</strong> each category. Our department has liaised with the<br />

Electrical Safety Office <strong>to</strong> clarify the categories of work relevant <strong>to</strong> school activities. Electrical equipment will<br />

predom<strong>in</strong>antly <strong>be</strong> used <strong>in</strong> “manufactur<strong>in</strong>g, service and office work” by school staff or students.<br />

<strong>1.</strong> construction work<br />

2. manufactur<strong>in</strong>g work<br />

3. service work<br />

4. office work<br />

5. amusement work (e.g. amusement rides)<br />

6. rural work<br />

<strong>1.</strong> Construction Work: Construction work (def<strong>in</strong>ed <strong>in</strong> the WHS Act 1995) or work <strong>done</strong> <strong>in</strong> conjunction<br />

with construction work.<br />

School application:<br />

Repair work around swimm<strong>in</strong>g pools<br />

Build<strong>in</strong>g reta<strong>in</strong><strong>in</strong>g walls<br />

Contrac<strong>to</strong>rs work<strong>in</strong>g around the school<br />

Organisational Health Unit Novem<strong>be</strong>r 2008 9

2. Manufactur<strong>in</strong>g Work: assembly, disassembly, fabrication, <strong>in</strong>stallation, ma<strong>in</strong>tenance, manufactur<strong>in</strong>g,<br />

refurbishment or repair, but does not <strong>in</strong>clude amusement work, construction work or rural <strong>in</strong>dustry work.<br />

School application:<br />

Industrial Technology / Manual Arts<br />

Ag Science/ Workshops.<br />

Schools Officer tasks such as refurbishment or repair work, <strong>in</strong>stallation of shelv<strong>in</strong>g etc.<br />

3. Service Work: Work that is not office, manufactur<strong>in</strong>g, construction, amusement or rural.<br />

School application:<br />

Teach<strong>in</strong>g – classrooms<br />

Teacher aide activities e.g. preparation for class activities<br />

Library<br />

Mak<strong>in</strong>g <strong>be</strong>verages/food<br />

Kitchenettes / tea rooms.<br />

Sell<strong>in</strong>g goods from a shop e.g. uniform shop<br />

Tuckshops<br />

Cook<strong>in</strong>g – home economics<br />

Kitchens at Outdoor Education Centres.<br />

Clean<strong>in</strong>g (however, specific controls are <strong>in</strong> place for school clean<strong>in</strong>g equipment see Schedule )<br />

4. Office Work:<br />

School application:<br />

Adm<strong>in</strong>istration tasks such as us<strong>in</strong>g computers, pho<strong>to</strong>copy<strong>in</strong>g or fax<strong>in</strong>g <strong>in</strong> an adm<strong>in</strong>istration area<br />

or staff room.<br />

5. Amusement work (e.g. amusement rides): this category is relevant for contrac<strong>to</strong>rs who supply<br />

and operate amusement rides for school fetes and functions – refer <strong>to</strong> the Checklist for School<br />

Fete/Event Organisers – Mobile Amusement Devices<br />

6. Rural <strong>in</strong>dustry work: for Education Queensland <strong>schools</strong>, Agricultural Science activities have <strong>be</strong>en<br />

<strong>in</strong>cluded <strong>in</strong> the category of manufactur<strong>in</strong>g work.<br />

Clean<strong>in</strong>g Equipment <strong>in</strong> Education Queensland <strong>schools</strong> and departmental offices<br />

Clean<strong>in</strong>g equipment is operated <strong>in</strong> a range of environments across <strong>schools</strong> and is subject <strong>to</strong> damage, wear<br />

and tear due <strong>to</strong> the high level of use. Mach<strong>in</strong>es are also sometimes operated on a wet surface or <strong>in</strong> wet/dry<br />

applications. Clean<strong>in</strong>g equipment is used all over school campuses and therefore <strong>safety</strong> switch protection<br />

may not always <strong>be</strong> provided over all circuits. Due <strong>to</strong> these fac<strong>to</strong>rs DETA has implemented specific <strong>electrical</strong><br />

control measures for clean<strong>in</strong>g equipment;<br />

• Daily visual checks as per <strong>in</strong>struction and tra<strong>in</strong><strong>in</strong>g and<br />

• Inspected, tested and tagged every 6 months<br />

OR<br />

• Daily visual checks as per <strong>in</strong>struction and tra<strong>in</strong><strong>in</strong>g and<br />

• Connected <strong>to</strong> a <strong>safety</strong> switch (e.g. portable or fixed).<br />

For <strong>schools</strong> that do not have <strong>safety</strong> switch protection on all circuits, pr<strong>in</strong>cipals are encouraged <strong>to</strong> purchase a<br />

portable <strong>safety</strong> switch for each school cleaner. This can <strong>be</strong> connected <strong>to</strong> each <strong>electrical</strong> item e.g. vacuum<br />

cleaner or polisher prior <strong>to</strong> use.<br />

See Schedule for full <strong>in</strong>formation.<br />

Organisational Health Unit Novem<strong>be</strong>r 2008 10

4. Protect<strong>in</strong>g Specified Electrical Equipment<br />

<strong>What</strong> is Test<strong>in</strong>g and Tagg<strong>in</strong>g of Electrical Equipment?<br />

The regulation prescri<strong>be</strong>s ways <strong>to</strong> <strong>ensure</strong> <strong>electrical</strong> <strong>safety</strong>. This <strong>in</strong>cludes the use of test<strong>in</strong>g and tagg<strong>in</strong>g<br />

and/or <strong>safety</strong> switches. (Regulation s 82)<br />

“In-service test<strong>in</strong>g and tagg<strong>in</strong>g” as the name suggests, <strong>in</strong>volves a competent person test<strong>in</strong>g the <strong>electrical</strong><br />

equipment <strong>to</strong> detect damage, wear or other conditions that may make it unsafe. The person <strong>must</strong> then la<strong>be</strong>l<br />

(tag) the item if it complies with the test specifications.<br />

Test<strong>in</strong>g and tagg<strong>in</strong>g checks the <strong>in</strong>tegrity of the item at the time of test<strong>in</strong>g – it does not provide any “extra”<br />

protection <strong>be</strong>yond that of the item’s <strong>in</strong>-built <strong>safety</strong> features. It is important <strong>to</strong> remem<strong>be</strong>r that test<strong>in</strong>g and<br />

tagg<strong>in</strong>g can <strong>be</strong> rendered <strong>in</strong>effective if any part of the <strong>electrical</strong> item is damaged after the tagg<strong>in</strong>g is<br />

completed. Implement<strong>in</strong>g a test<strong>in</strong>g and tagg<strong>in</strong>g regime is one method that the legislation offers as a way <strong>to</strong><br />

<strong>ensure</strong> <strong>electrical</strong> <strong>safety</strong>.<br />

<strong>What</strong> is a Safety Switch?<br />

The la<strong>be</strong>l (tag) attached <strong>to</strong> the item specifies the<br />

next test date.<br />

Safety switches are easily identifiable by the ’T’ TEST but<strong>to</strong>n.<br />

Safety switches are also known as:<br />

Residual Current Devices (RCD),<br />

Earth Leakage Circuit Breakers (ELCB) or<br />

Earth Leakage Devices (ELD)<br />

Fixed, portable and ‘<strong>in</strong>-l<strong>in</strong>e’ options are available. Fixed <strong>safety</strong><br />

switches can <strong>be</strong> <strong>in</strong>stalled on <strong>electrical</strong> switch boards or on<br />

power po<strong>in</strong>ts. Portable <strong>safety</strong> switches can <strong>be</strong> connected <strong>to</strong><br />

the relevant piece of equipment and used outdoors or<br />

<strong>in</strong>doors. They are a convenient option where permanent<br />

<strong>safety</strong> switches are not available. ‘In-l<strong>in</strong>e’ devices are another<br />

portable option and are <strong>in</strong>corporated <strong>in</strong><strong>to</strong> a device similar <strong>to</strong><br />

an extension lead.<br />

Safety switches moni<strong>to</strong>r and compare the current flow <strong>in</strong> both<br />

active and neutral circuits of an <strong>electrical</strong> item. An imbalance<br />

of current flow <strong>in</strong>dicates that some of the current is not<br />

return<strong>in</strong>g via the neutral wire but is leak<strong>in</strong>g <strong>to</strong> earth – possibly<br />

via a person. When this occurs the unit detects the imbalance<br />

and au<strong>to</strong>matically cuts the <strong>electrical</strong> supply <strong>to</strong> discont<strong>in</strong>ue the<br />

flow of electricity <strong>in</strong> less than one thirtieth ( 1 /30) of a heart<br />

<strong>be</strong>at. This is sometimes referred <strong>to</strong> as the <strong>safety</strong> switch<br />

“tripp<strong>in</strong>g”.<br />

Organisational Health Unit Novem<strong>be</strong>r 2008 11

Safety switches cannot protect a person if they contact both active and neutral conduc<strong>to</strong>rs <strong>to</strong>gether. In this<br />

case the current may not flow <strong>to</strong> earth and the <strong>safety</strong> switch would not detect an imbalance (and therefore<br />

not “trip” (cut off the electricity).<br />

Complete protection under all circumstances is not possible from <strong>safety</strong> switches or any other devices.<br />

Proper care and ma<strong>in</strong>tenance of <strong>electrical</strong> equipment is still required.<br />

<strong>What</strong>’s so good about <strong>safety</strong> switches?<br />

Examples of portable <strong>safety</strong> switches<br />

Image from Code of Practice Electrical<br />

Equipment – Rural Industry<br />

Safety switches are designed <strong>to</strong> disconnect the power <strong>in</strong> less time than a heart <strong>be</strong>at; thus possibly<br />

prevent<strong>in</strong>g a tragedy<br />

Safety switches protect aga<strong>in</strong>st shocks from current pass<strong>in</strong>g through the body <strong>to</strong> earth which is the most<br />

frequent cause of electrocution<br />

An item of <strong>electrical</strong> equipment could <strong>be</strong> damaged shortly after test<strong>in</strong>g and tagg<strong>in</strong>g – which means that<br />

if the equipment is no longer <strong>electrical</strong>ly safe, the test<strong>in</strong>g and tagg<strong>in</strong>g is no longer accurate<br />

A function<strong>in</strong>g <strong>safety</strong> switch provides ongo<strong>in</strong>g protection; test<strong>in</strong>g and tagg<strong>in</strong>g checks the <strong>in</strong>tegrity of the<br />

item at the time of test<strong>in</strong>g only<br />

Staff and others may br<strong>in</strong>g faulty <strong>electrical</strong> equipment <strong>to</strong> school that is not <strong>electrical</strong>ly safe. A <strong>safety</strong><br />

switch provides a level of protection <strong>in</strong> these <strong>in</strong>stances and will assist with identify<strong>in</strong>g faulty equipment.<br />

Schools can <strong>in</strong>stall <strong>safety</strong> switches as an alternative <strong>to</strong> a test<strong>in</strong>g and tagg<strong>in</strong>g regime. This will<br />

provide;<br />

an added level of protection and<br />

ongo<strong>in</strong>g sav<strong>in</strong>gs due <strong>to</strong> reduced need for test<strong>in</strong>g and tagg<strong>in</strong>g.<br />

The <strong>in</strong>stallation of a <strong>safety</strong> switch reduces the num<strong>be</strong>r of items that need <strong>to</strong> <strong>be</strong> tested and tagged <strong>in</strong> <strong>schools</strong>.<br />

This is <strong>be</strong>cause many items of <strong>electrical</strong> equipment can <strong>be</strong> protected by either test<strong>in</strong>g and tagg<strong>in</strong>g or<br />

connection <strong>to</strong> a <strong>safety</strong> switch. For example, <strong>in</strong> an average primary school it is likely that the only specified<br />

<strong>electrical</strong> equipment that would need test<strong>in</strong>g and tagg<strong>in</strong>g <strong>in</strong> conjunction with connection <strong>to</strong> a <strong>safety</strong> switch<br />

would <strong>be</strong> <strong>electrical</strong> equipment used by the Schools Officer. Items <strong>in</strong> classrooms, library and office would <strong>be</strong><br />

adequately protected by the <strong>safety</strong> switch.<br />

Installation of <strong>safety</strong> switches should <strong>be</strong> discussed <strong>in</strong>itially with your Facilities Account Manager.<br />

Organisational Health Unit Novem<strong>be</strong>r 2008 12

How often <strong>must</strong> Safety Switches <strong>be</strong> tested?<br />

Noth<strong>in</strong>g is failsafe. Safety switches <strong>must</strong> <strong>be</strong> checked regularly <strong>be</strong>cause, just like a smoke detec<strong>to</strong>r or any<br />

other <strong>safety</strong> device, it can not protect you if it is not operat<strong>in</strong>g properly.<br />

All fixed and portable <strong>safety</strong> switches <strong>must</strong> <strong>be</strong> tested immediately after they are <strong>in</strong>stalled or connected<br />

There are two types of tests for your <strong>safety</strong> switch. For frequency of each ‘test’ please refer <strong>to</strong> the<br />

Part 1: Schedule or Part 2: Quick Reference Table of this guide:<br />

<strong>1.</strong> Regularly test<strong>in</strong>g your <strong>safety</strong> switch us<strong>in</strong>g the TEST but<strong>to</strong>n. This “user test” is <strong>done</strong> by someone at your<br />

school<br />

AND<br />

2. Test<strong>in</strong>g of the <strong>safety</strong> switch by a competent person. This is a time/current test performed by a competent<br />

person – it is necessary that an appropriately tra<strong>in</strong>ed and equipped person performs this test (e.g.<br />

electrician).<br />

How do I perform the regular “user” test<strong>in</strong>g of my <strong>safety</strong> switch us<strong>in</strong>g the TEST but<strong>to</strong>n?<br />

<strong>1.</strong> Note: some <strong>electrical</strong> equipment may malfunction (e.g. lose data, start or s<strong>to</strong>p unexpectedly) if the<br />

power supply is <strong>in</strong>terrupted. Consider this equipment when plann<strong>in</strong>g your tests e.g. you may need <strong>to</strong><br />

“shut down” computers <strong>be</strong>fore push<strong>in</strong>g the TEST but<strong>to</strong>n.<br />

2. Press the <strong>in</strong>built TEST but<strong>to</strong>n – this simulates a problem <strong>in</strong> the system.<br />

3. This should au<strong>to</strong>matically “engage”, “trip” or “operate” the <strong>safety</strong> switch and cause it <strong>to</strong> flick <strong>to</strong> the OFF<br />

position.<br />

4. Then simply press the RESET but<strong>to</strong>n.<br />

5. If press<strong>in</strong>g the TEST but<strong>to</strong>n does not cause the <strong>safety</strong> switch <strong>to</strong> flick <strong>to</strong> OFF then call an electrician<br />

immediately <strong>to</strong> have it checked. Seek advice from the electrician on the use of the <strong>electrical</strong> items <strong>in</strong> the<br />

<strong>in</strong>terim and note the advice. Higher risk items such as power <strong>to</strong>ols <strong>in</strong> <strong>in</strong>dustrial technology should not <strong>be</strong><br />

used until the switch is operat<strong>in</strong>g properly.<br />

6. Record the date of the test on a register.<br />

<strong>What</strong> do we do if the <strong>safety</strong> switch trips dur<strong>in</strong>g normal activities?<br />

<strong>1.</strong> If a <strong>safety</strong> switch trips and disconnects power, it may <strong>be</strong> due <strong>to</strong> a faulty appliance. You may have <strong>be</strong>en<br />

us<strong>in</strong>g a faulty appliance or your <strong>electrical</strong> wir<strong>in</strong>g may have <strong>be</strong>come faulty.<br />

2. Reset the <strong>safety</strong> switch by press<strong>in</strong>g the RESET but<strong>to</strong>n.<br />

3. If it trips aga<strong>in</strong>, unplug the last appliance used. If everyth<strong>in</strong>g works okay, la<strong>be</strong>l that item as faulty and<br />

arrange <strong>to</strong> have the item checked by an electrician.<br />

4. If the <strong>safety</strong> switch cont<strong>in</strong>ues <strong>to</strong> trip, disconnect all appliances on the circuit and plug them <strong>in</strong>, one at a<br />

time, until you locate the faulty one.<br />

5. Avoid <strong>to</strong>uch<strong>in</strong>g the appliances while carry<strong>in</strong>g out this process.<br />

6. Contact your electrician if problems persist.<br />

Safety switches are often confused with circuit breakers. Circuit breakers and fuses protect<br />

aga<strong>in</strong>st overload faults and high current short circuits. These do not replace <strong>safety</strong> switches.<br />

Safety switches protect people – circuit breakers protect equipment.<br />

Organisational Health Unit Novem<strong>be</strong>r 2008 13

5. Who pays for test<strong>in</strong>g and tagg<strong>in</strong>g and the <strong>in</strong>stallation of <strong>safety</strong> switches?<br />

Test<strong>in</strong>g and tagg<strong>in</strong>g of specified <strong>electrical</strong> equipment (School Funds)<br />

Schools are responsible for engag<strong>in</strong>g and fund<strong>in</strong>g contrac<strong>to</strong>rs (or competent person) <strong>to</strong> complete test<strong>in</strong>g and<br />

tagg<strong>in</strong>g of specified <strong>electrical</strong> equipment. There is no obligation for <strong>schools</strong> <strong>to</strong> engage Q Build <strong>to</strong> perform<br />

these functions.<br />

Test<strong>in</strong>g of Fixed Safety Switches by a Competent person (Centrally funded)<br />

Test<strong>in</strong>g of fixed <strong>safety</strong> switches is covered under the ‘Service Ma<strong>in</strong>tenance Allocation’ and is centrally funded<br />

by the department. This work is performed by Q Build.<br />

Test<strong>in</strong>g of Portable Safety Switches by a Competent person (School Funds)<br />

Test<strong>in</strong>g of portable <strong>safety</strong> switches is covered by school funds. There is no obligation for <strong>schools</strong> <strong>to</strong> engage<br />

Q Build <strong>to</strong> perform these functions.<br />

6. Plann<strong>in</strong>g <strong>to</strong> <strong>in</strong>stall a <strong>safety</strong> switch at your school<br />

<strong>1.</strong> Check your switch boards for exist<strong>in</strong>g <strong>safety</strong> switches. It may <strong>be</strong> useful <strong>to</strong> have a map of your school<br />

<strong>in</strong>dicat<strong>in</strong>g locations of switchboards and <strong>safety</strong> switches. This could <strong>be</strong> used <strong>to</strong> keep records of tests.<br />

Many manual arts, home economics, science and art blocks already have <strong>safety</strong> switches <strong>in</strong>stalled.<br />

2. Seek advice from your Facilities Account Manager about the <strong>in</strong>stallation of <strong>electrical</strong> <strong>safety</strong> switches and<br />

future planned work at your school.<br />

3. Your school will probably need multiple <strong>safety</strong> switches with costs vary<strong>in</strong>g dependant on your school<br />

location, num<strong>be</strong>r of <strong>safety</strong> switches <strong>to</strong> <strong>be</strong> <strong>in</strong>stalled, size and age of your exist<strong>in</strong>g distribution board.<br />

4. Get at least 3 quotes <strong>to</strong> <strong>ensure</strong> a competitive price.<br />

Install<strong>in</strong>g <strong>safety</strong> switches will offer the <strong>be</strong>st protection from electrocution and will also reduce your<br />

test<strong>in</strong>g and tagg<strong>in</strong>g costs.<br />

5. When the work is completed <strong>ensure</strong> that your electrician provides –<br />

a. <strong>in</strong>formation on the circuits that are protected by the <strong>safety</strong> switch and<br />

b. a demonstration of how <strong>to</strong> test the <strong>safety</strong> switch<br />

6. Advise your regional QBuild contact about the <strong>in</strong>stallation of your new <strong>safety</strong> switches. QBuild can add<br />

this <strong>in</strong>formation <strong>to</strong> their records about your school which will assist <strong>in</strong> ongo<strong>in</strong>g test<strong>in</strong>g and ma<strong>in</strong>tenance<br />

programs.<br />

7. Competent Person<br />

Some <strong>schools</strong> have decided <strong>to</strong> tra<strong>in</strong> a mem<strong>be</strong>r of staff as a competent person <strong>to</strong> perform test<strong>in</strong>g and tagg<strong>in</strong>g<br />

activities rather than engage a licensed electrician. Pr<strong>in</strong>cipals should <strong>be</strong> aware of their responsibilities when<br />

their own staff mem<strong>be</strong>r does work as the “competent person”.<br />

The Pr<strong>in</strong>cipal is responsible for determ<strong>in</strong><strong>in</strong>g that the person who carries out <strong>in</strong>spection, test<strong>in</strong>g and tagg<strong>in</strong>g of<br />

<strong>electrical</strong> equipment has the required competencies. Pr<strong>in</strong>cipals should <strong>be</strong> aware of this responsibility and<br />

that they are accountable for the ongo<strong>in</strong>g actions of the 'competent person'.<br />

For more <strong>in</strong>formation please refer <strong>to</strong> the Competent Person Fact Sheet.<br />

Organisational Health Unit Novem<strong>be</strong>r 2008 14

8. Schools Officers Equipment<br />

Schools Officers <strong>must</strong> have <strong>safety</strong> switch protection on the <strong>electrical</strong> equipment they use for work, whether<br />

they are work<strong>in</strong>g <strong>in</strong> their shed or around the school. Currently this may <strong>be</strong> via either a fixed <strong>safety</strong> switch or<br />

a portable <strong>safety</strong> switch.<br />

In the future, <strong>to</strong> meet legislative requirements, a fixed <strong>safety</strong> switch will need <strong>to</strong> <strong>be</strong> <strong>in</strong>stalled <strong>to</strong> protect circuits<br />

<strong>in</strong> the <strong>schools</strong> officer’s shed or workshop. The Electrical Safety Regulation 2002 requires that <strong>electrical</strong><br />

equipment used <strong>in</strong> ‘manufactur<strong>in</strong>g work’ <strong>be</strong> protected by a fixed <strong>safety</strong> switch by 1 March 2008.<br />

The legislation does not affect work undertaken by Schools Officers around the school so portable <strong>safety</strong><br />

switches can still <strong>be</strong> used <strong>in</strong> classrooms and other areas. If there is fixed <strong>safety</strong> switch protection cover<strong>in</strong>g all<br />

the outlets <strong>in</strong> the school there is no requirement <strong>to</strong> cont<strong>in</strong>ue us<strong>in</strong>g the portable <strong>safety</strong> switch.<br />

It is recognised that a fixed <strong>safety</strong> switch will not <strong>be</strong> <strong>in</strong>stalled <strong>in</strong> every <strong>schools</strong> officer’s shed or workshop prior<br />

<strong>to</strong> 1 March 2008.<br />

A portable <strong>safety</strong> switch MUST <strong>be</strong> used until confirmation that all circuits have fixed<br />

<strong>safety</strong> switches <strong>in</strong>stalled.<br />

Safety switch protection <strong>must</strong> <strong>be</strong> <strong>in</strong> operation at all times when the Schools Officer is us<strong>in</strong>g specified<br />

<strong>electrical</strong> equipment (e.g. electric <strong>be</strong>nch gr<strong>in</strong>der, drill or electric sander) <strong>in</strong> their shed or around the school.<br />

this may <strong>be</strong> via a fixed or portable <strong>safety</strong> switch and<br />

if there is not <strong>safety</strong> switch coverage over all circuits, the school is <strong>to</strong> provide a portable <strong>safety</strong><br />

switch for the Schools Officer’s use.<br />

<strong>1.</strong> If us<strong>in</strong>g a portable <strong>safety</strong> switch – press the “TEST” but<strong>to</strong>n <strong>be</strong>fore use each day <strong>to</strong> confirm it is<br />

operational.<br />

2. Schools are sometimes visited or audited by Inspec<strong>to</strong>rs from the Electrical Safety Office or Workplace<br />

Health and Safety Queensland. The Pr<strong>in</strong>cipal or WHSO should seek advice and support from their<br />

Regional Senior H&S Consultant and/or Regional Facilities Account Manager if issues with <strong>safety</strong> switch<br />

<strong>in</strong>stallation are identified and these cannot <strong>be</strong> easily resolved at the school level.<br />

9. Installation and Ma<strong>in</strong>tenance of Electrical Equipment<br />

Only a licensed electrician or <strong>electrical</strong> contrac<strong>to</strong>r can do <strong>electrical</strong> work at your school. This <strong>in</strong>cludes repairs<br />

of <strong>electrical</strong> equipment.<br />

A school can purchase but cannot <strong>in</strong>stall:<br />

<strong>electrical</strong> accessories e.g. light switches, plugs, power po<strong>in</strong>ts, light fitt<strong>in</strong>gs without a cord; or<br />

fixed wire <strong>electrical</strong> appliances e.g. ceil<strong>in</strong>g fans, some light fitt<strong>in</strong>gs, s<strong>to</strong>ves, ovens, split system air<br />

condition<strong>in</strong>g.<br />

The follow<strong>in</strong>g repair work <strong>must</strong> <strong>be</strong> undertaken by your electrician or <strong>electrical</strong> contrac<strong>to</strong>r:<br />

replac<strong>in</strong>g plugs or leads<br />

repair<strong>in</strong>g damaged wir<strong>in</strong>g – e.g. do not dismantle <strong>electrical</strong> equipment<br />

replac<strong>in</strong>g power po<strong>in</strong>ts<br />

modify<strong>in</strong>g <strong>electrical</strong> equipment<br />

repair<strong>in</strong>g <strong>safety</strong> switches<br />

Organisational Health Unit Novem<strong>be</strong>r 2008 15

The follow<strong>in</strong>g activities are not <strong>electrical</strong> work and do not have <strong>to</strong> <strong>be</strong> undertaken by a licensed electrician or<br />

<strong>electrical</strong> contrac<strong>to</strong>r:<br />

Some <strong>electrical</strong> equipment requires ma<strong>in</strong>tenance or servic<strong>in</strong>g that is unrelated <strong>to</strong> its <strong>electrical</strong><br />

components; for example chang<strong>in</strong>g blades or fitt<strong>in</strong>gs on manual arts equipment. Be sure <strong>to</strong> turn off the<br />

power and, if possible, unplug the equipment prior <strong>to</strong> undertak<strong>in</strong>g these activities. Follow the<br />

manufacturer’s <strong>in</strong>structions for these activities.<br />

As with other general ma<strong>in</strong>tenance procedures, the power <strong>must</strong> <strong>be</strong> turned off prior <strong>to</strong> chang<strong>in</strong>g light<br />

bulbs, tu<strong>be</strong>s and starters. If the switch is some distance, or out of sight, post a sign or tape the switch <strong>in</strong><br />

some way <strong>to</strong> <strong>ensure</strong> it is not <strong>in</strong>advertently switched on while the bulb is <strong>be</strong><strong>in</strong>g changed.<br />

For <strong>electrical</strong> work <strong>in</strong>volv<strong>in</strong>g computers please refer <strong>to</strong> the Safety Alert - Electrical Incident – Computer Work.<br />

10. Record Keep<strong>in</strong>g<br />

Records are essential <strong>to</strong> review how your own systems are work<strong>in</strong>g and <strong>to</strong> moni<strong>to</strong>r compliance with<br />

departmental and legislative requirements. In the event of an <strong>electrical</strong> <strong>in</strong>cident records will <strong>be</strong> checked <strong>to</strong><br />

determ<strong>in</strong>e if these requirements were fulfilled. Without records it will <strong>be</strong> difficult <strong>to</strong> demonstrate that systems<br />

were <strong>in</strong> place <strong>to</strong> <strong>ensure</strong> compliance. Departmental Senior Audit Officers may also ask <strong>to</strong> check these<br />

records. The Australian/New Zealand Standard 3760 states that documentation <strong>must</strong> <strong>be</strong> kept for seven<br />

years.<br />

Keep records of the follow<strong>in</strong>g;<br />

<strong>1.</strong> Electrical Equipment - a register (list) of all <strong>electrical</strong> equipment<br />

For example:<br />

a spreadsheet that tracks the item and location<br />

School Management System (SMS) can <strong>be</strong> used <strong>to</strong> create a register<br />

2. Specified <strong>electrical</strong> equipment – identify items and frequency of test<strong>in</strong>g and tagg<strong>in</strong>g dates (if required)<br />

For example:<br />

Can <strong>be</strong> <strong>in</strong>corporated with list above<br />

Note: SMS does not have accurate time frames for test<strong>in</strong>g and tagg<strong>in</strong>g; enter your own timeframes<br />

accord<strong>in</strong>g <strong>to</strong> the <strong>in</strong>formation <strong>in</strong> this guide e.g. see Part 1: Schedule or Part 2: Quick Reference Table<br />

3. Safety switches<br />

For example:<br />

Record push but<strong>to</strong>n tests of <strong>safety</strong> switch (e.g. <strong>in</strong>itial and date)<br />

Record tests by competent person (e.g. date and contrac<strong>to</strong>r)<br />

The record can <strong>be</strong> as simple as a card <strong>in</strong> the switch board with date, name and signature<br />

As <strong>be</strong>st practice – a record of the location of all <strong>safety</strong> switches and circuits they cover<br />

4. Repair or ma<strong>in</strong>tenance work<br />

For example:<br />

A log or register where staff can identify repair work required for <strong>electrical</strong> equipment<br />

Details of service or ma<strong>in</strong>tenance work for specific items – an example form is available at:<br />

http://education.qld.gov.au/health/docs/health<strong>safety</strong>/blower-vacuum-elecal.doc . The first page of this<br />

example document could <strong>be</strong> modified <strong>to</strong> use with items of <strong>electrical</strong> equipment that require regular<br />

checks or servic<strong>in</strong>g.<br />

5. Any risk assessments related <strong>to</strong> the use of <strong>electrical</strong> equipment<br />

example: test<strong>in</strong>g register on sticker <strong>in</strong> switch board<br />

Organisational Health Unit Novem<strong>be</strong>r 2008 16

1<strong>1.</strong> New Equipment<br />

In Australia, when the equipment is new, the supplier is deemed responsible for the <strong>in</strong>itial <strong>electrical</strong><br />

<strong>safety</strong> of the new equipment. New equipment need not <strong>be</strong> <strong>in</strong>spected or tested, however it <strong>must</strong> <strong>be</strong> <strong>in</strong>cluded<br />

<strong>in</strong> the regime of test<strong>in</strong>g and tagg<strong>in</strong>g (or used with a <strong>safety</strong> switch) as per other <strong>electrical</strong> equipment. This will<br />

<strong>ensure</strong> it is protected accord<strong>in</strong>g <strong>to</strong> the type of work for which it is used and captured with the next ‘round’ of<br />

test<strong>in</strong>g and tagg<strong>in</strong>g if appropriate.<br />

12. Can staff br<strong>in</strong>g <strong>electrical</strong> items <strong>to</strong> school?<br />

Pr<strong>in</strong>cipals have the discretion <strong>to</strong> allow staff <strong>to</strong> br<strong>in</strong>g personal <strong>electrical</strong> items on<strong>to</strong> the school site.<br />

Electrical equipment brought from home should <strong>be</strong> managed the same way as <strong>electrical</strong> items owned by<br />

school.<br />

If your school allows staff <strong>to</strong> br<strong>in</strong>g <strong>electrical</strong> equipment from home, the pr<strong>in</strong>cipal should <strong>be</strong> advised <strong>in</strong><br />

advance and the item <strong>must</strong> <strong>be</strong> visually <strong>in</strong>spected for defects by a nom<strong>in</strong>ated staff mem<strong>be</strong>r. Electrical items<br />

should then <strong>be</strong> managed accord<strong>in</strong>g <strong>to</strong> this Guide i.e. where and how it is used. Some <strong>schools</strong> implement<br />

additional processes such as requir<strong>in</strong>g items <strong>to</strong> <strong>be</strong> tested and tagged prior <strong>to</strong> them <strong>be</strong><strong>in</strong>g brought <strong>to</strong> school.<br />

13. Three phase equipment / Hard wired equipment<br />

The power available from a domestic power outlet <strong>in</strong> Australia is<br />

normally 240V of AC. The electricity available from these outlets is<br />

called s<strong>in</strong>gle phase power. This is a s<strong>in</strong>gle voltage that alternates <strong>in</strong><br />

polarity <strong>be</strong>tween positive and negative, hence the term ‘AC’ mean<strong>in</strong>g<br />

Alternat<strong>in</strong>g Current. Figure 1 shows a typical AC voltage pass<strong>in</strong>g<br />

through the positive and negative stages of one cycle, which takes onefiftieth<br />

of a second <strong>to</strong> complete. Figure 1<br />

Most small domestic appliances use s<strong>in</strong>gle phase power <strong>be</strong>cause it is easy <strong>to</strong> work with and requires only<br />

two wires, active and neutral, (plus a protective earth wire) <strong>to</strong> deliver energy <strong>to</strong> a load. However, there are<br />

some limitations <strong>to</strong> s<strong>in</strong>gle phase power. As the voltage passes through a ‘zero’ po<strong>in</strong>t twice for each cycle,<br />

there are po<strong>in</strong>ts <strong>in</strong> time when no energy is available <strong>to</strong> drive loads. This can <strong>be</strong> a problem for heavy and<br />

<strong>in</strong>dustrial loads which use a lot of power. Another problem is that s<strong>in</strong>gle phase electric mo<strong>to</strong>rs do not know<br />

which way <strong>to</strong> rotate when they start, unless special wir<strong>in</strong>g methods or mo<strong>to</strong>r-start devices are used.<br />

Three Phase Power is three simultaneous AC signals,<br />

spaced one-third of a cycle apart <strong>in</strong> a s<strong>in</strong>gle 50 Hz<br />

cycle (see figure 2). For <strong>in</strong>dustrial applications three<br />

phase mo<strong>to</strong>rs are more reliable, less expensive, run<br />

more efficiently and last many years longer than their<br />

s<strong>in</strong>gle phase counterparts.<br />

Examples of equipment that use three phase power <strong>in</strong><br />

<strong>schools</strong> <strong>in</strong>clude lathes, mill<strong>in</strong>g mach<strong>in</strong>es, shapers,<br />

compressors and some large air condition<strong>in</strong>g systems.<br />

Figure 2<br />

These items are not ‘specified <strong>electrical</strong> equipment’ and are not covered under the requirements of the<br />

Electrical Safety Regulation 2002. However, it is important <strong>to</strong> <strong>ensure</strong> these items are used safely and the risk<br />

of electric shock is prevented or m<strong>in</strong>imised.<br />

Ensure that;<br />

the equipment is secured properly <strong>to</strong> the floor <strong>to</strong> prevent any damage <strong>to</strong> wir<strong>in</strong>g or cabl<strong>in</strong>g due <strong>to</strong> slow<br />

movement or vibration of the equipment<br />

items are visually checked regularly for firm connections, damage <strong>to</strong> panels or wir<strong>in</strong>g etc<br />

Regular checks by an electrician are also recommended.<br />

Although unusual, three phase, <strong>in</strong>clud<strong>in</strong>g hard wired equipment (no plug), can <strong>be</strong> connected <strong>to</strong> <strong>safety</strong> switches.<br />

Organisational Health Unit Novem<strong>be</strong>r 2008 17

14. How does electricity cause <strong>in</strong>jury and electric shock?<br />

Electricity is predictable <strong>in</strong> that it will:<br />

<strong>1.</strong> move <strong>in</strong> a circuit<br />

2. travel a path of least resistance and<br />

3. head for the ground.<br />

Electricity will not discrim<strong>in</strong>ate on how it achieves these three actions, that is, it will pass through a person <strong>to</strong><br />

flow <strong>to</strong> the earth if that is the easiest path of travel. A safe path <strong>to</strong> ground for electricity is away from your<br />

body and conf<strong>in</strong>ed with<strong>in</strong> whatever piece of <strong>electrical</strong> equipment you’re us<strong>in</strong>g. However, if an appliance is<br />

faulty or has a shorted wire, the electric current may try <strong>to</strong> f<strong>in</strong>d another path (e.g. through a person) <strong>to</strong> get <strong>to</strong><br />

ground.<br />

Aside from <strong>in</strong>juries susta<strong>in</strong>ed due <strong>to</strong> <strong>electrical</strong> current flow<strong>in</strong>g through the body, other <strong>in</strong>juries can result such<br />

as falls from ladders, contact with mov<strong>in</strong>g mach<strong>in</strong>ery or <strong>in</strong>juries <strong>to</strong> other people.<br />

Electric shock has the potential <strong>to</strong> cause fatal <strong>in</strong>jury. The term ‘electrocution’ implies death due <strong>to</strong> the action<br />

of electric current. Electric current pass<strong>in</strong>g through the body can cause:<br />

Muscle spasms<br />

Inhibition of the respira<strong>to</strong>ry centre of the bra<strong>in</strong><br />

Heart fibrillation (disturbance <strong>to</strong> heart <strong>be</strong>at)<br />

Tissue burns and nerve damage<br />

Confusion or memory loss<br />

Muscle spasm can prevent people from releas<strong>in</strong>g their grasp on <strong>electrical</strong>ly “live” parts and prevent breath<strong>in</strong>g<br />

or shout<strong>in</strong>g for help. This can cause the person <strong>to</strong> panic which <strong>in</strong> turn <strong>in</strong>duces sweat<strong>in</strong>g. A variable that<br />

affects current flow through the body is the <strong>in</strong>dividual’s “<strong>electrical</strong> resistance”. Almost all of the body’s<br />

resistance is <strong>in</strong> the sk<strong>in</strong> and sweat<strong>in</strong>g further reduces the person’s <strong>in</strong>herent resistance. (Greater resistance =<br />

<strong>in</strong>creased difficulty for electricity <strong>to</strong> pass through the body).<br />

Ventricular fibrillation is considered the ma<strong>in</strong> form of death by electric shock. Essentially, it is a condition of<br />

the heart caused by the disturbance of the heart’s own <strong>in</strong>ternal impulses. The heart rhythm fluctuates and<br />

cannot effectively pump blood <strong>to</strong> susta<strong>in</strong> life.<br />

First aid should <strong>be</strong> provided immediately after the person is isolated from the electric current. Always seek<br />

further medical assistance either;<br />

Immediately, by call<strong>in</strong>g the ambulance or<br />

as soon as possible, by attendance at a doc<strong>to</strong>r even if the person has received a mild shock or only a<br />

suspected shock. This is <strong>be</strong>cause disturbance <strong>to</strong> the heart <strong>be</strong>at may not <strong>be</strong> readily detected by the<br />

person or dur<strong>in</strong>g first aid.<br />

15. More <strong>in</strong>formation<br />

Creat<strong>in</strong>g Healthier Workplaces - Electrical Safety<br />

http://education.qld.gov.au/health/<strong>safety</strong>/hazards/<strong>electrical</strong>.html<br />

HLS-PR-005: Health and Safety Incident Record<strong>in</strong>g and Notification<br />

http://education.qld.gov.au/strategic/eppr/health/hlspr005/<br />

HLS-PR-003: First Aid http://education.qld.gov.au/strategic/eppr/health/hlspr003/<br />

Other <strong>safety</strong> tips can <strong>be</strong> found at: www.deir.qld.gov.au<br />

Don’t do <strong>electrical</strong> work yourself<br />

Don’t mix water and electricity<br />

Use a <strong>safety</strong> switch<br />

Look up and live<br />

Dial <strong>be</strong>fore you dig – phone 1100 or http://www.dial<strong>be</strong>foreyoudig.com.au/<br />

Are your <strong>electrical</strong> leads safe? http://www.deir.qld.gov.au/pdf/eso/safelead-brochure.pdf<br />

Organisational Health Unit Novem<strong>be</strong>r 2008 18