(khamir) produced from sorghum in Gizan region, Saudi Arabia

(khamir) produced from sorghum in Gizan region, Saudi Arabia

(khamir) produced from sorghum in Gizan region, Saudi Arabia

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Journal of Applied Microbiology 1999, 86, 221–225<br />

Study of the micro-organisms associated with the fermented<br />

bread (<strong>khamir</strong>) <strong>produced</strong> <strong>from</strong> <strong>sorghum</strong> <strong>in</strong> <strong>Gizan</strong> <strong>region</strong>, <strong>Saudi</strong><br />

<strong>Arabia</strong><br />

INTRODUCTION<br />

M.A.A. Gassem<br />

Department of Food Science and Nutrition, College of Agriculture, K<strong>in</strong>g Saud University, Riyadh, <strong>Saudi</strong> <strong>Arabia</strong><br />

6707/04/98: received 22 April 1998, revised 21 August 1998 and accepted 26 August 1998<br />

M.A.A. GASSEM. 1999. Traditional bread (<strong>khamir</strong>) was made <strong>from</strong> <strong>sorghum</strong> flour of two<br />

local varieties, Bayadh and Hamra. The bread was prepared by mix<strong>in</strong>g the<br />

<strong>sorghum</strong> flour with water and spices (onion, garlic, lemon juice and fenugreek) <strong>in</strong> a<br />

1:0·8 (w/w) ratio and fermented for 24 h at 30 °C. Two other fermentations were carried out<br />

us<strong>in</strong>g an <strong>in</strong>oculum <strong>from</strong> the previous fermentation. The micro-organisms were isolated<br />

<strong>from</strong> different plates and identified us<strong>in</strong>g different characterization systems. Both total<br />

bacterial populations and lactic acid bacteria <strong>in</strong>creased with fermentation time and<br />

reached the highest number at 16 h (first fermentation) and at 8 h (second and third<br />

fermentation). The content of lactic acid was <strong>in</strong>creased with time to reach 1·2%, but<br />

the <strong>in</strong>crease was higher for the second and third fermentations (1·6% each). The<br />

pH dropped with time <strong>from</strong> 6·77 to 4·35 <strong>in</strong> the first fermentation and <strong>from</strong> 6·65 to<br />

4·18, and 6·57–3·93, <strong>in</strong> the second and third fermentations, respectively. The microorganisms,<br />

which were isolated and characterized dur<strong>in</strong>g the 24 h fermentation,<br />

<strong>in</strong>cluded: bacteria (Pediococcus pentosaceus, Lactobacillus brevis, Lact. lactis subsp.<br />

lactis, Lact. cellobiosus, Klebsiella oxytoca, Kl. pneumoniae, Enterobacter aerogenes, Ent.<br />

sakazakii, Serratia marcescens and Ser. odourifera), moulds (Penicillium sp.,<br />

Rhizopus sp., Aspergillus niger, Alternaria sp., Fusarium sp. and Mucor sp.) and yeasts<br />

(Candida parapsilosis, C. orvegnsis and Rhodotorula glut<strong>in</strong>is).<br />

Sorghum (Sorghum bicolor L. Moench) is a staple food for<br />

the people of the arid and semi-arid tropical <strong>region</strong>s of Africa<br />

and Asia (Chavan et al. 1988). Graham et al. (1986) reported<br />

that millions of people <strong>in</strong> the semi-arid <strong>region</strong>s of the world,<br />

and especially <strong>in</strong> Africa and the Asian subcont<strong>in</strong>ent, depend<br />

on <strong>sorghum</strong> as a major source of dietary prote<strong>in</strong> and energy.<br />

Sorghum is cultivated <strong>in</strong> different parts of the world; gra<strong>in</strong><br />

<strong>sorghum</strong> is considered to be the fifth most extensively grown<br />

crop <strong>in</strong> the world and the third largest crop harvest <strong>in</strong> the<br />

USA (Kazanas and Fields 1981). In <strong>Saudi</strong> <strong>Arabia</strong>, <strong>sorghum</strong><br />

is grown <strong>in</strong> different <strong>region</strong>s, but it is the ma<strong>in</strong> cereal crop <strong>in</strong><br />

the south-western <strong>region</strong> (Chaudhary 1989).<br />

Different traditional fermented foods and beverages are<br />

Correspondence to: Dr M.A.A. Gassem, Department of Food Science and<br />

Nutrition, College of Agriculture, K<strong>in</strong>g Saud University, PO Box 2460, Riyadh<br />

11451, <strong>Saudi</strong> <strong>Arabia</strong> (e-mail: MAGASSEM@KSU.EDU.SA).<br />

© 1999 The Society for Applied Microbiology<br />

prepared <strong>from</strong> the gra<strong>in</strong> <strong>sorghum</strong> <strong>in</strong> different parts of the<br />

world, for example, kisar, asida, merrissa and nasha <strong>in</strong> Sudan<br />

(Dirar 1978; El-T<strong>in</strong>ay et al. 1985; Graham et al. 1986;<br />

Mohammed et al. 1991), ogi and obiolar <strong>in</strong> Nigeria (Adeyemi<br />

1988; Acki 1990), feni <strong>in</strong> India (Chavan and Kadam 1989)<br />

and <strong>khamir</strong> and lahoh <strong>in</strong> <strong>Saudi</strong> <strong>Arabia</strong>.<br />

Fermentation of the <strong>sorghum</strong> was found to enhance its<br />

digestibility (Au and Fields 1981; Eggum et al. 1983;<br />

MacLean et al. 1983; Graham et al. 1986). Gra<strong>in</strong> <strong>sorghum</strong> is<br />

used <strong>in</strong> the <strong>Gizan</strong> <strong>region</strong> (south-western <strong>Saudi</strong> <strong>Arabia</strong>) for<br />

mak<strong>in</strong>g fermented bread called <strong>khamir</strong>. Traditionally, the<br />

bread is made by utiliz<strong>in</strong>g the natural microflora <strong>in</strong> <strong>sorghum</strong><br />

flour. No <strong>in</strong>formation is available regard<strong>in</strong>g <strong>khamir</strong> mak<strong>in</strong>g<br />

and its fermentation <strong>in</strong> <strong>Saudi</strong> <strong>Arabia</strong>. Therefore, it is necessary<br />

to understand the fermentation process and to identify the<br />

micro-organisms <strong>in</strong>volved. The aim of this study was to<br />

isolate and identify micro-organisms associated with <strong>sorghum</strong><br />

fermentation <strong>in</strong> order to obta<strong>in</strong> the necessary <strong>in</strong>formation

222 M.A.A. GASSEM<br />

for improv<strong>in</strong>g <strong>khamir</strong> production, and to study the changes<br />

occurr<strong>in</strong>g <strong>in</strong> pH and titratable acidity which might have a<br />

major role <strong>in</strong> microbial distribution dur<strong>in</strong>g fermentation.<br />

MATERIALS AND METHODS<br />

Two local varieties of <strong>sorghum</strong> gra<strong>in</strong>s (Baydah and Hamra)<br />

were obta<strong>in</strong>ed <strong>from</strong> a gra<strong>in</strong> market <strong>in</strong> Abu-Arish (south-west<br />

<strong>Saudi</strong> <strong>Arabia</strong>). The <strong>sorghum</strong> was milled at the local gra<strong>in</strong><br />

market to f<strong>in</strong>e flour us<strong>in</strong>g a Diamant mill, model 500-mm<br />

(Denmark). The flour was then transferred to the laboratory<br />

<strong>in</strong> Riyadh and stored at 25 °C until used. Sorghum fermentation<br />

was carried out <strong>in</strong> the traditional way by mix<strong>in</strong>g<br />

<strong>sorghum</strong> flour with sterile deionized water and spices (onion,<br />

garlic, lemon juice and fenugreek) <strong>in</strong> a 1:0·8 (w/w) ratio to<br />

make a dough (traditionally called ‘ajeen’). The mixture was<br />

<strong>in</strong>cubated at 30 °C for 24 h <strong>in</strong> a sterile covered flask; usually,<br />

at this time, the dough will have a good consistency and sour<br />

taste. Two consecutive fermentations were carried out us<strong>in</strong>g<br />

3% <strong>in</strong>ocula (traditionally called ‘shetiah’) <strong>from</strong> the previous<br />

fermentation to start each subsequent batch. Each fermentation<br />

was performed <strong>in</strong> duplicate and sampled every 4 h<br />

for 24 h.<br />

Sampl<strong>in</strong>g<br />

At each sampl<strong>in</strong>g time, a 50 g sample was placed <strong>in</strong> a sterile<br />

stomacher bag and mixed with 450 ml sterile 0·1% peptone<br />

water (Oxoid) us<strong>in</strong>g a Stomacher Lab-Blender 400 (Seward<br />

Medical, London, UK). Appropriate serial dilutions <strong>in</strong> 0·1%<br />

peptone water were prepared and samples were plated on the<br />

different agar media.<br />

Microbiological analysis<br />

Total plate count was determ<strong>in</strong>ed on Plate Count Agar (PCA,<br />

Oxoid). The plates were <strong>in</strong>cubated at 32 °C for 24 h.<br />

Coliforms were enumerated on Violet Red Bile Agar<br />

(VRBA, Oxoid) and <strong>in</strong>cubated at 37 °C. Counts were taken<br />

at 24 and 48 h. Coliforms were isolated <strong>from</strong> VRBA plates,<br />

purified on PCA and identified us<strong>in</strong>g the API 20 system<br />

(BioMérieux, Marcy l’Etoile, France).<br />

Lactic acid bacteria were enumerated on de Man, Rogosa<br />

and Sharpe (MRS, Oxoid) agar. The plates were <strong>in</strong>cubated<br />

at 37 °C for 48 h under anaerobic conditions us<strong>in</strong>g GasPak<br />

(H 2 and CO 2) anaerobic systems (BBL Microbiology Systems,<br />

Cockeysville, MD, USA). Pure colonies <strong>from</strong> countable<br />

plates were Gram-sta<strong>in</strong>ed, ma<strong>in</strong>ta<strong>in</strong>ed <strong>in</strong> MRS broth,<br />

and fur-ther characterized us<strong>in</strong>g the API 50 CHL system<br />

(BioMérieux).<br />

Yeasts and moulds were enumerated on acidified potato<br />

dextrose agar (APDA, Oxoid). The plates were <strong>in</strong>cubated at<br />

25 °C for 3, 5 and 7 d. Isolated yeasts were purified on Sabou-<br />

raud medium (Difco) and characterized us<strong>in</strong>g the API AUX<br />

system (BioMérieux). Moulds were identified us<strong>in</strong>g 10 dayold<br />

cultures on potato dextrose agar (Oxoid). Cultural and<br />

microscopic characteristics were exam<strong>in</strong>ed and moulds were<br />

classified accord<strong>in</strong>g to Frazier and Westhoff (1988) and Barnett<br />

and Hunter (1972).<br />

Microbial identification<br />

Representatives <strong>from</strong> each colony type were selected <strong>from</strong><br />

plates used for viable counts at each sampl<strong>in</strong>g time accord<strong>in</strong>g<br />

to shape and/or colour. Isolates were purified by repeated<br />

streak<strong>in</strong>g on appropriate media and identified us<strong>in</strong>g appropriate<br />

identification systems.<br />

Measurement of pH and titratable acidity<br />

The pH of the fermented dough was measured us<strong>in</strong>g a pH<br />

meter (Jenway PHM10, Felsted, UK). Titratable acidity,<br />

expressed as percentage lactic acid, was determ<strong>in</strong>ed by<br />

titrat<strong>in</strong>g the samples with 0·1 mol l −1 NaOH to the phenolphthale<strong>in</strong><br />

end po<strong>in</strong>t.<br />

RESULTS<br />

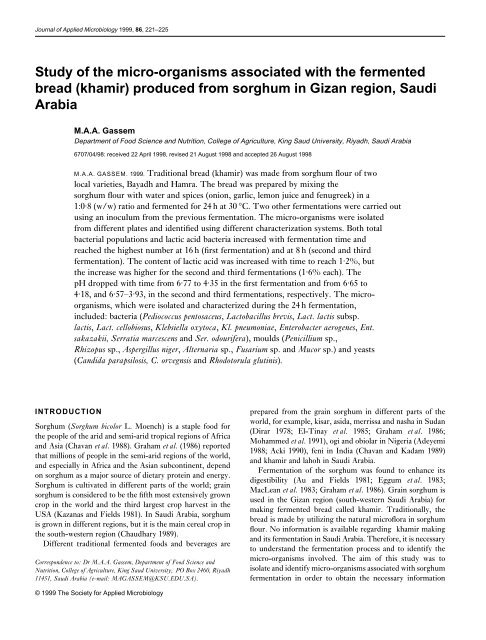

Microbial counts<br />

Microbial counts of the <strong>in</strong>itial fermentation of <strong>sorghum</strong> (Bayadh<br />

variety) are presented <strong>in</strong> Fig. 1. The microflora of the<br />

naturally fermented <strong>sorghum</strong> flour consisted of different<br />

micro-organisms, such as lactic acid bacteria, coliforms,<br />

moulds and yeasts. Both the total bacteria and lactic acid<br />

bacteria counts <strong>in</strong>creased with <strong>in</strong>creas<strong>in</strong>g fermentation time<br />

until they reached stationary phase at 16 h (Fig. 1a). The yeast<br />

and mould counts rema<strong>in</strong>ed constant dur<strong>in</strong>g the fermentation.<br />

The coliform counts decreased until 12 h, then<br />

<strong>in</strong>creased, and thereafter decreased.<br />

When <strong>sorghum</strong> was fermented us<strong>in</strong>g an <strong>in</strong>oculum <strong>from</strong><br />

the previously fermented <strong>sorghum</strong>, the microbial counts also<br />

<strong>in</strong>creased with time. However, the total bacterial populations<br />

and lactic acid bacteria reached maximal growth <strong>in</strong> half the<br />

time of the <strong>in</strong>itial fermentation (Fig. 1c). No changes <strong>in</strong> mould<br />

and yeast counts were noticed dur<strong>in</strong>g fermentation. The coliforms<br />

decreased and were not detected after 12 h of fermentation.<br />

Data for the third fermentation (not shown) which was<br />

carried out us<strong>in</strong>g an <strong>in</strong>coulum <strong>from</strong> the previous fermentation<br />

were similar to those obta<strong>in</strong>ed for the second fermentation<br />

except for the coliforms, which were not detected after 8 h.<br />

For the Hamra variety, similar results were obta<strong>in</strong>ed for<br />

total bacterial counts, lactic acid bacteria, and yeasts and<br />

moulds <strong>in</strong> the <strong>in</strong>itial, second and third fermentations.<br />

However, for coliforms, <strong>in</strong>itial fermentation counts <strong>in</strong>creased<br />

© 1999 The Society for Applied Microbiology, Journal of Applied Microbiology 86, 221–225

Log cfu g –1<br />

Log cfu g –1<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

0<br />

0<br />

(a)<br />

(c)<br />

5 10 15<br />

Time (h)<br />

20 25<br />

5 10 15<br />

Time (h)<br />

20 25<br />

30<br />

30<br />

MICRO-ORGANISMS IN FERMENTED SORGHUM BREAD 223<br />

% Lactic acid<br />

% Lactic acid<br />

1·8<br />

1·5<br />

1·2<br />

0·9<br />

0·6<br />

0·3<br />

0·0 0<br />

1·8<br />

1·5<br />

1·2<br />

0·9<br />

0·6<br />

0·3<br />

0·0 0<br />

(b)<br />

(d)<br />

5 10 15<br />

Time (h)<br />

20 25<br />

5 10 15<br />

Time (h)<br />

20 25<br />

Fig. 1 Microbial counts, percentage lactic acid, and pH dur<strong>in</strong>g the fermentation of <strong>khamir</strong> bread us<strong>in</strong>g the Bayadh variety. (a), (b) 24 h<br />

of <strong>in</strong>itial fermentation (natural); (c), (d) 24 h of the second fermentation with the addition of <strong>in</strong>oculum. ( ), Total plate count; (ž),<br />

lactic acid bacteria; (t), coliforms; (T), yeasts and moulds; ( ), pH; (Ž), percentage lactic acid<br />

until 8 h, then decreased, and persisted thereafter (data not<br />

shown). For the second and third fermentations, the results<br />

were similar to those for the Bayadh variety (Fig. 1c).<br />

Acidity and pH<br />

In the <strong>in</strong>itial fermentation, pH decreased with a concomitant<br />

<strong>in</strong>crease <strong>in</strong> acidity as lactic acid accumulated. Lactic acid<br />

content (Fig. 1b) <strong>in</strong>creased with fermentation time <strong>from</strong> 0·19<br />

to 1·22%, and <strong>from</strong> 0·21 to 1·13%, dur<strong>in</strong>g 24 h for Bayadh<br />

and Hamra varieties, respectively. This resulted <strong>in</strong> a pH drop<br />

© 1999 The Society for Applied Microbiology, Journal of Applied Microbiology 86, 221–225<br />

7<br />

6<br />

5<br />

4<br />

3<br />

30<br />

7<br />

6<br />

5<br />

4<br />

3<br />

30<br />

<strong>from</strong> 6·77 to 4·35 (Bayadh), and <strong>from</strong> 6·73 to 4·29 (Hamra).<br />

When add<strong>in</strong>g an <strong>in</strong>oculum, the amount of lactic acid <strong>in</strong> the<br />

Bayadh variety <strong>in</strong>creased <strong>from</strong> 0·27 to 1·40% <strong>in</strong> 16 h and by<br />

the end of 24 h, the amount of the acid was 1·60% (Fig. 1d).<br />

In the Hamra variety, the amount of acid was lower than <strong>in</strong><br />

the Bayadh, <strong>in</strong>creased <strong>from</strong> 0·26 to 1·2% <strong>in</strong> 16 h, and reached<br />

1·36% at 24 h (data not shown). In the third fermentation<br />

(data not shown), the pH decreased <strong>from</strong> 6·57 to 4·18 <strong>in</strong> 12 h<br />

and reached 3·92 <strong>in</strong> 24 h for the Bayadh variety, while for the<br />

Hamra variety, the pH dropped <strong>from</strong> 6·57 to 4·06 <strong>in</strong> 12 h and<br />

at the end of 24 h, was 3·85. The amount of lactic acid<br />

pH<br />

pH

224 M.A.A. GASSEM<br />

(Bayadh) <strong>in</strong>creased <strong>from</strong> 0·32 to 1·2% <strong>in</strong> 12 h and at the end<br />

of 24 h fermentation, it was 1·60%. Similar results were<br />

obta<strong>in</strong>ed for the Hamra variety.<br />

Classification of micro-organisms<br />

Different micro-organisms were isolated at different fermentation<br />

times and are presented <strong>in</strong> Table 1. Two species<br />

of lactic acid bacteria (Lactobacillus and Pediococcus) were<br />

identified. Three stra<strong>in</strong>s of Lactobacillus were isolated, Lact.<br />

lactis subsp. lactis, Lact. brevis and Lact. cellobiosus. Lactobacillus<br />

lactis subsp. lactis was isolated and identified <strong>from</strong><br />

both <strong>sorghum</strong> varieties (Bayadh and Hamra), while Lact.<br />

brevis and Lact. cellobiosus were isolated and identified only<br />

<strong>from</strong> the Hamra variety. The Pediococcus isolates were identified<br />

as Ped. pentosaceus and were found <strong>in</strong> both <strong>sorghum</strong><br />

varieties. Pediococcus pentosaceus was dom<strong>in</strong>ant at the end of<br />

the fermentation and ma<strong>in</strong>ta<strong>in</strong>ed a high number.<br />

The coliforms are listed <strong>in</strong> Table 1. Klebsiella pneumoniae,<br />

Kl. oxytoca, Enterobacter aerogenes, Ent. sakazakii and Serratia<br />

marcescens were found <strong>in</strong> both <strong>sorghum</strong> varieties. Serratia<br />

odorifera was found <strong>in</strong> the Bayadh variety only.<br />

Yeasts (Table 1) were identified as Candida parapsilosis, C.<br />

norvegnsis and Rhotorula glut<strong>in</strong>is. Candida norvegnsis was<br />

found only <strong>in</strong> the Bayadh variety. Moulds (Table 1) were<br />

identified as Rhizopus sp., Penicillium sp., Alternaria sp., Apergillus<br />

niger, Mucor sp. and Fusarium sp.<br />

DISCUSSION<br />

There were several micro-organisms that are found naturally<br />

<strong>in</strong> <strong>sorghum</strong> flour. These micro-organisms <strong>in</strong>cluded coliforms,<br />

lactic acid bacteria, yeasts and moulds. Chavan and Kadam<br />

(1989) have <strong>in</strong>dicated that the micro-organisms <strong>in</strong>volved <strong>in</strong><br />

Table 1 Micro-organisms isolated dur<strong>in</strong>g <strong>khamir</strong> fermentation<br />

—––––––––––––––––––––––––––––––––––––––––––––––––––– ––<br />

Bacteria Yeasts and moulds<br />

—––––––––––––––––––––––––––––––––––––––––––––––––––– ––<br />

Lactic acid bacteria n Yeasts n<br />

Pediococcus pentosaceus (8) Candida parapsilosis (10)<br />

Lactobacillus brevis (2) C. norvegnsis (1)<br />

Lact. lactis subsp. lactis (4) Rhodotorula glut<strong>in</strong>is (2)<br />

Lact. cellobiosus (3)<br />

Coliforms n Moulds n<br />

Klebsiella oxytoca (1) Penicillium sp. (4)<br />

Kl. pneumoniae (3) Rhizopus sp. (1)<br />

Enterobacter aerogenes (1) Aspergillus niger (1)<br />

Ent. sakazakii (4) Alternaria sp. (1)<br />

Serratia marcescens (2) Fusarium sp. (2)<br />

Ser. odorifera (1) Mucor sp. (1)<br />

—––––––––––––––––––––––––––––––––––––––––––––––––––– ––<br />

the natural fermentation of cereals are essentially the surface<br />

flora of seeds. The Enterobacteriaceae are common on plant<br />

material. Members of the Enterobacteriaceae were found <strong>in</strong><br />

natural fermentations of different products such as <strong>sorghum</strong><br />

(Nout 1991; Mohammed et al. 1991) and soybeans (Mulyowidarso<br />

et al. 1989). In the first <strong>sorghum</strong> fermentation, numbers<br />

of coliforms rema<strong>in</strong>ed constant. However, <strong>in</strong> the second<br />

and third fermentations, coliforms were not detected after<br />

12 h and 8 h, respectively. Similar results were reported by<br />

Mica (1955), Nout et al. (1989), Nout (1991) and Mohammed<br />

et al. (1991). Mohammed et al. (1991) suggested that Enterobacter<br />

may be <strong>in</strong>hibited by the growth of lactic acid bacteria<br />

which outnumber the Enterobacter and result <strong>in</strong> faster acid<br />

production.<br />

The numbers of lactic acid bacteria <strong>in</strong>creased with time and<br />

dom<strong>in</strong>ated the fermentation (Fig. 1a,c). Chavan and Kadam<br />

(1989) <strong>in</strong>dicated that lactic acid bacteria constitute the predom<strong>in</strong>ant<br />

flora <strong>in</strong> the natural fermentation of water/cereal<br />

meal mixture. Some of the lactic acid bacteria that were<br />

isolated and identified <strong>in</strong> this study were isolated <strong>from</strong> different<br />

fermented foods. Lactobacillus brevis has been isolated<br />

<strong>from</strong> ‘tef’ (Gashe 1987), ‘fufu and ogi’ (Adegoke and Babalola<br />

1988) and kisra (Mohammed et al. 1991). Lactobacillus cellobiosus<br />

was isolated <strong>from</strong> fermented corn meal (Fields et al.<br />

1981), and Ped. pentosaccus was isolated <strong>from</strong> kisra (Mohammed<br />

et al. 1991). The <strong>in</strong>crease <strong>in</strong> lactic acid bacteria resulted<br />

<strong>in</strong> <strong>in</strong>creased amounts of lactic acid <strong>produced</strong> and lower pH.<br />

Similarly, <strong>in</strong> the natural fermentation, there was an <strong>in</strong>crease<br />

<strong>in</strong> the amount of lactic acid <strong>produced</strong> and a decrease <strong>in</strong> pH.<br />

However, <strong>in</strong> the second and third fermentations, the amount<br />

of acid <strong>produced</strong> was higher and the drop <strong>in</strong> pH was faster.<br />

The faster drop <strong>in</strong> pH was probably due to the higher number<br />

of lactic acid bacteria <strong>in</strong> the <strong>in</strong>oculum than the <strong>in</strong>itial fermentation.<br />

Similar results were obta<strong>in</strong>ed by Nout (1991) and<br />

Mohammed et al. (1991). Therefore, the presence of lactic<br />

acid bacteria is important <strong>in</strong> <strong>khamir</strong> production.<br />

Numbers of yeasts and moulds rema<strong>in</strong>ed constant dur<strong>in</strong>g<br />

the fermentation for both varieties, except for a slight decrease<br />

dur<strong>in</strong>g the third fermentation. Candida parapsilosis and<br />

Rhodotorula glut<strong>in</strong>is were isolated <strong>from</strong> both Bayadh and<br />

Hamra. Candida norvegnsis was isolated <strong>from</strong> Bayadh only.<br />

Yeasts were isolated <strong>from</strong> different <strong>in</strong>digenous fermented<br />

foods such as kisra, ogi, fufu, tef, burukutu and merissa<br />

(Ste<strong>in</strong>kraus 1983; Gashe 1987; Adegoke and Babalola 1988;<br />

Chavan and Kadam 1989; Mohammed et al. 1991).<br />

In conclusion, this study has shown that there are some<br />

micro-organisms that are naturally present <strong>in</strong> <strong>sorghum</strong> flour.<br />

Dur<strong>in</strong>g <strong>khamir</strong> fermentation, these micro-organisms result<br />

<strong>in</strong> some microbial and biochemical changes. Changes <strong>in</strong> pH<br />

and acidity were due to the outgrowth of lactic acid bacteria<br />

which become the predom<strong>in</strong>ant organisms. Additional work<br />

is needed on the use of isolated micro-organisms for the<br />

development of starter cultures for <strong>khamir</strong> production.<br />

© 1999 The Society for Applied Microbiology, Journal of Applied Microbiology 86, 221–225

ACKNOWLEDGEMENTS<br />

The author gratefully acknowledges the valuable technical<br />

assistance of Mr Ibrahim Al-Za<strong>in</strong> throughout this work.<br />

REFERENCES<br />

Acki, O.K. (1990) Microbiology of ‘obiolor’: a Nigerian fermented<br />

non-alcoholic beverage. Journal of Applied Bacteriology 69, 321–<br />

325.<br />

Adegoke, G.O. and Babalola, A.K. (1988) Characteristics of microorganisms<br />

of importance <strong>in</strong> the fermentation of fufu and ogi –<br />

two Nigerian foods. Journal of Applied Bacteriology 65, 449–453.<br />

Adeyemi, I.A. (1988) Ogi quality of <strong>sorghum</strong> flour dry-milled <strong>from</strong><br />

fermented <strong>sorghum</strong> gra<strong>in</strong>s. Journal of Food Science 53, 641–642.<br />

Au, P.M. and Fields, M.L. (1981) Nutritive quality of fermented<br />

<strong>sorghum</strong>. Journal of Food Science 46, 652–654.<br />

Barnett, H.L. and Hunter, B.B. (1972) Illustrated Genera of Imperfect<br />

Fungi, 3rd edn, pp. 53–180. M<strong>in</strong>neapolis: Burgess Publish<strong>in</strong>g Co.<br />

Chaudhary, S.A. (1989) Grasses of <strong>Saudi</strong> <strong>Arabia</strong>. pp. 409–410.<br />

M<strong>in</strong>istry of Agriculture and Water, Riyadh, <strong>Saudi</strong> <strong>Arabia</strong>:<br />

National Herbarium.<br />

Chavan, U.D., Chavan, J.K. and Kadam, S.S. (1988) Effect of<br />

fermentation on soluble prote<strong>in</strong>s and <strong>in</strong> vitro prote<strong>in</strong> digestibility<br />

of <strong>sorghum</strong>, green gram and <strong>sorghum</strong>-green gram blends. Journal<br />

of Food Science 53, 1574–1575.<br />

Chavan, J.K. and Kadam, S.S. (1989) Nutritional improvement of<br />

cereals by fermentation. CRC Reviews <strong>in</strong> Food Science and<br />

Nutrition 28, 349–400.<br />

Dirar, H.A. (1978) A microbiological study of Sudanese merissa<br />

brew<strong>in</strong>g. Journal of Food Science 43, 1683–1686.<br />

Eggum, B.O., Monawar, L., Kundsen, K.E., Munk, L. and Axtell,<br />

J. (1983) Nutrition quality of <strong>sorghum</strong> and <strong>sorghum</strong> food <strong>from</strong><br />

Sudan. Journal of Cereal Science 1, 127–137.<br />

El-T<strong>in</strong>ay, A.H., El-Mahdi, Z.M. and Soubki, A. (1985) Supplementation<br />

of fermented <strong>sorghum</strong> kisra bread with legume<br />

prote<strong>in</strong> isolates. Journal of Food Technology 20, 679–687.<br />

© 1999 The Society for Applied Microbiology, Journal of Applied Microbiology 86, 221–225<br />

MICRO-ORGANISMS IN FERMENTED SORGHUM BREAD 225<br />

Fields, M.L., Hamad, A.M. and Smith, D.K. (1981) Natural lactic<br />

acid fermentation of corn meal. Journal of Food Science 46, 900–<br />

902.<br />

Frazier, W.C. and Westhoff, D.C. (1988) Food Microbiology, 4th<br />

edn, pp. 17–31. New York: McGraw-Hill Book Co.<br />

Gashe, B.A. (1987) Involvement of lactic acid bacteria <strong>in</strong> the fermentation<br />

of tef (Eragrostis tef) an Ethiopian fermented food.<br />

Journal of Food Science 50, 800–801.<br />

Graham, G.G., MacLean, W.C., Morales, E. et al. (1986) Digestibility<br />

and utilization of prote<strong>in</strong> and energy <strong>from</strong> ‘nasha’ a traditional<br />

Sudanese fermented <strong>sorghum</strong> wean<strong>in</strong>g food. Journal of<br />

Nutrition 116, 978–984.<br />

Kazanas, N. and Fields, M.L. (1981) Nutritional improvement of<br />

<strong>sorghum</strong> by fermentation. Journal of Food Science 46, 819–821.<br />

MacLean, W.C., de Romaña, J.L., Gastañaduy, A. and Gragam,<br />

G.G. (1983) The effect of decortication and extrusion on the<br />

digestibility of <strong>sorghum</strong> by preschool children. Journal of<br />

Nutrition 113, 2171–2177.<br />

Mica, J. (1955) Bacterial aspects of soda cracker fermentation. Cereal<br />

Chemistry 32, 125–131.<br />

Mohammed, S.I., Steenson, L.R. and Kirleis, A.W. (1991) Isolation<br />

and characterization of microorganisms associated with the traditional<br />

<strong>sorghum</strong> fermentation for production of Sudanese kisra.<br />

Applied and Environmental Microbiology 57, 2529–2533.<br />

Mulyowidarso, R.K., Fleet, G.H. and Buckle, K.A. (1989) The<br />

microbial ecology of soybean soak<strong>in</strong>g for tempe production. International<br />

Journal of Food Microbiology 8, 35–46.<br />

Nout, M.J.R. (1991) Ecology of accelerated natural lactic fermentation<br />

of <strong>sorghum</strong>-based <strong>in</strong>fant food formulas. International<br />

Journal of Food Microbiology 12, 217–224.<br />

Nout, M.J.R., Rombouts, F.M. and Hautvast, G.J. (1989) Effect of<br />

accelerated natural lactic fermentation of <strong>in</strong>fant food <strong>in</strong>gredients<br />

on some pathogenic microorganisms. International Journal of Food<br />

Microbiology 8, 351–361.<br />

Ste<strong>in</strong>kraus, K.H. (1983) Indigenous fermented foods <strong>in</strong>volv<strong>in</strong>g an<br />

acid fermentation. In Handbook of Indigenous Fermented Foods.<br />

pp. 95–299. New York: Marcel Dekker.