section - Ahmedabad Municipal Corporation

section - Ahmedabad Municipal Corporation

section - Ahmedabad Municipal Corporation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

AMDAVAD MUNICIPAL CORPORATION<br />

Tender Documents<br />

for<br />

SITC of Hydraulically operated Grit Mechanism with related Electrical work at<br />

E, E3, W & W5 sites with one year of Operation & Maintenance period for<br />

Sabarmati River Front Development <strong>Corporation</strong> Ltd.<br />

of Amdavad <strong>Municipal</strong> <strong>Corporation</strong><br />

TENDER NO : AMC/_______________________/2011<br />

NOTICE NO. : _________________________________<br />

Volume I: - Technical Bid<br />

Part – I : General Specifications<br />

Part – II : Technical Specifications<br />

Part – III : Drawings<br />

(1) Last date of Tender Submission :<br />

30/08/2011 Upto 14:00 Hours.<br />

By RPAD / Speed post / Hand delivery / Courier<br />

(2) Date of Tender Opening : 30/08/2011 at 16:00 Hours.<br />

<strong>Municipal</strong> Commissioner<br />

Amdavad <strong>Municipal</strong> <strong>Corporation</strong><br />

Sardar Patel Bhavan<br />

<strong>Ahmedabad</strong> - 380 001.<br />

Gujarat<br />

India<br />

IN ASSOCIATION WITH<br />

4th Floor, Krishna Complex- A, Opp Devashish School, off. S. G. Highway, Bodakdev, <strong>Ahmedabad</strong> - 15<br />

PH: 0091-079-40222999, FAX: 0091-079-40222998<br />

EMAIL: stcpl@shethtechno.com<br />

AUGUST - 2011<br />

1

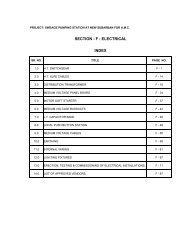

PROJECT :<br />

DOCUMENT : INDEX<br />

VOLUME - I : TECHNICAL BID<br />

SITC OF HYDRAULICALLY OPERATED GRIT MECHANISM WITH<br />

RELATED ELECTRICAL WORK AT E, E3, W & W5 SITES WITH ONE<br />

YEAR OF OPERATION & MAINTENANCE PERIOD FOR<br />

SABARMATI RIVER FRONT DEVELOPMENT CORPORATION LTD.<br />

OF AMDAVAD MUNICIPAL CORPORATION<br />

SECTION TITLE PAGE NO.<br />

PART - I : GENERAL SPECIFICATIONS<br />

[ A ] GENERAL 4 - 43<br />

[ B ] GENERAL CONDITIONS OF CONTRACT 44 - 97<br />

[ C ] SPECIFICATIONS - NON TECHNICAL 98 - 119<br />

PART - II : TECHNICAL SPECIFICATIONS<br />

[ D ] TECHNICAL SPECIFICATIONS FOR MECHANICAL WORK 121 - 147<br />

[ E ] TECHNICAL SPECIFICATIONS FOR ELECTRICAL WORK 148 - 184<br />

[ F ] CONDITIONS OF CONTRACT FOR OPERATION &<br />

MAINTENANCE WORK<br />

185 - 196<br />

2

PART – I<br />

GENERAL SPECIFICATIONS<br />

3

SECTION: A<br />

A-1: NOTICE INVITING TENDER<br />

A-2: MEMORANDUM OF WORKS IN BRIEF<br />

A-3: SCOPE OF WORKS<br />

A-4: INSTRUCTIONS TO TENDERERS<br />

A-5: QUALIFICATION CRITERIA FOR TENDERER<br />

4

Section<br />

No.<br />

SECTION - A : GENERAL<br />

CONTENTS<br />

Description Page No.<br />

A-1 Notice Inviting Tender 7<br />

A-2 Memorandum of work in brief 13<br />

A-3 Scope of Work 28<br />

A-4 Instructions to Tenderers<br />

A.4.1. Note 32<br />

A.4.2. Invitation to Tender 32<br />

A.4.3. Tender Validity Period 32<br />

A.4.4. Language of Tender 32<br />

A.4.5. Documents 32<br />

A.4.6. Earnest Money 33<br />

A.4.7. Income-tax Return 34<br />

A.4.8. Submission of Tender 34<br />

A.4.9. General Performance Data 35<br />

A.4.10. Signing of Tender Document 35<br />

A.4.11. Interpretation of Documents 36<br />

A.4.12. Errors and Discrepancies in Tender 36<br />

A.4.13. Modification of Documents 37<br />

A.4.14. Evaluation of Tenders 37<br />

A.4.15. Policy for tenders under consideration 37<br />

A.4.16. Alternatives (Deleted) 37<br />

A.4.17. Cost of tendering 38<br />

A.4.18. Award of Contract 38<br />

A.4.19. Signing of Contract 38<br />

A.4.20. Stamp Duty and Legal Charges 38<br />

A.4.21. Solvency Certificate 38<br />

A.4.22. Documents / Information to be submitted along with Volume- I 38<br />

A.4.23. Forms<br />

Bank Guarantee 40<br />

Performance Bond 42<br />

5

Section<br />

No.<br />

SECTION - A : GENERAL<br />

CONTENTS<br />

A-5 Qualification criteria for Tenderers<br />

Description Page No.<br />

A.5.1 Eligibility Criteria 45<br />

A.5.2 General Experience 45<br />

A.5.3 Financial Position 45<br />

A.5.4 Litigation History 45<br />

A.5.5 Solvency Certificate 46<br />

A.5.6 Bidding Capacity 46<br />

A.5.7 Personnel 46<br />

A.5.8 Equipment 46<br />

A.5.9 Joint Ventures 47<br />

6

SECTION: A-1<br />

NOTICE INVITING TENDER<br />

7

To,<br />

SECTION – A: GENERAL<br />

A - 1 : NOTICE INVITING TENDER<br />

Sub: SITC OF HYDRAULICALLY OPERATED GRIT MECHANISM WITH RELATED<br />

ELECTRICAL WORK AT E, E3, W & W5 SITES WITH ONE YEAR OF<br />

OPERATION & MAINTENANCE PERIOD FOR SABARMATI RIVER FRONT<br />

DEVELOPMENT CORPORATION LTD. OF AMDAVAD MUNICIPAL<br />

CORPORATION.<br />

Dear Sirs,<br />

A.1.1 The <strong>Municipal</strong> Commissioner, Amdavad <strong>Municipal</strong> <strong>Corporation</strong> (AMC) invites the item<br />

rate tenders (two-bid system) from the Grit Mechanism Manufacturers or Authorized<br />

Dealers who qualify to the eligibility criteria, as mentioned in Section–A.5 of the tender<br />

document for the SITC of Hydraulically operated Grit Mechanism with related Electrical<br />

work at E, E3, W & W5 Sites with One year of Operation & Maintenance Period for<br />

Sabarmati River Front Development <strong>Corporation</strong> Ltd. of Amdavad <strong>Municipal</strong> <strong>Corporation</strong>.<br />

A.1.2 One set of tender documents consisting of –<br />

Volume – I : Technical Bid<br />

Part – I :<br />

Section – A General<br />

Section – B General Conditions of Contract etc.<br />

Section – C Specifications – Non Technical<br />

Section – D Technical Specifications - Mechanical Items<br />

Part – II : Section – E Technical Specifications - Electrical Items<br />

Part – III : Section – F Drawings<br />

Volume – II : Financial Bid<br />

Section – G Schedule of Quantities & Rates<br />

A.1.3 Tender along with conditions of contract will be available from the website<br />

www.egovamc.com. Tenderer shall have to present D.D. in favour of <strong>Municipal</strong><br />

Commissioner payable at <strong>Ahmedabad</strong> of Rs. 1500/- as tender fee along with the tender<br />

submission.<br />

The tenderer is required to check the AMC website for Addendum if any before 72<br />

hours of tender submission date and time. The tenderer who quotes the tender<br />

without attaching the addendum will be rejected.<br />

A.1.4 Earnest Money Deposit shall be in the form of Demand Draft / Bank Guarantee of any<br />

Nationalized Bank, located at <strong>Ahmedabad</strong> and payable to <strong>Municipal</strong> Commissioner, AMC<br />

for Rs. 32,000/-. All the tenderers have to submit the earnest money as specified in the<br />

tender document.<br />

A.1.5 The successful tenderer shall have to pay security deposit in Indian Rupees in approved<br />

Form ‘A’ enclosed with the tender document in Section A4, clause. A.4.23.<br />

8

A.1.6 The Earnest Money Deposit of all the bidders except first lowest, second lowest and third<br />

lowest will be returned within 20 days.<br />

A.1.7 The tender shall be accompanied with the copy of Similar type of work carried, Works<br />

on hands, Financial capacity and required details in Schedules (Format) given in<br />

Section – A2 & “Memorandum of work in brief” of Technical bid, Volume-I. & blank<br />

data sheets of Technical Specifications of Volume- I”.<br />

A.1.8 Two sets (One Original + One Xerox copy) of tender documents (Volume – I, Part-I, II<br />

& III The tenderer shall clearly state in the forwarding letter (in duplicate) to be enclosed<br />

with the tender documents, the deviations from General Terms and Conditions, if any<br />

with cross references. If no such letter is received, it will be presumed that the<br />

tenderer agrees entirely with the General Terms and Conditions.<br />

A.1.9 Earnest Money Deposit in the form of Demand Draft (in favour of <strong>Municipal</strong><br />

Commissioner payable at <strong>Ahmedabad</strong>) / Bank Guarantee should be sealed in separate<br />

envelope and the same shall be enclosed along with Volume – I and drawings in Envelope<br />

– ‘A’ only (Technical Bid) (One Original + One Xerox copy).<br />

A.1.10 Volume – II (One Original + One Xerox copy) should be sealed in another separate<br />

envelope, marked envelope ‘B’ (Financial Bid).<br />

A.1.11 Both envelopes ‘A’ and ‘B’ should then be sealed in one large envelope. On all these<br />

envelopes, the name of tenderer, name of work as well as date of opening of the bid<br />

shall be written invariably.<br />

A.1.12 The first envelope ‘A’ containing technical bids from the bidders received, will be opened<br />

in the presence of the bidder’s representatives; who choose to attend at the office of the<br />

City Engineer 2 nd floor, Sardar Patel Bhavan, Khamasa Gate, Amdavad <strong>Municipal</strong><br />

<strong>Corporation</strong> at the time and date mentioned in tender notice and the technical bids will be<br />

scrutinized by AMC for satisfying various eligibility criteria prescribed for the bidders for<br />

this work.<br />

A.1.13 After this, the financial bids – Volume – II (envelope ‘B’) of the technically responsive<br />

tenderers only will be opened. The actual date of opening of financial bids will be<br />

communicated to technically responsive tenderers at a later date.<br />

A.1.14 Tenders received without Earnest Money will be considered as Non-Responsive and will<br />

be rejected outright.<br />

A.1.15 The conditional tender will not be accepted and will be rejected outright, unless, the<br />

nature of condition(s) put up by the bidder is acceptable to AMC. Any suggestions /<br />

alterations from the tender, if suggested in specifications, must be mentioned in the<br />

main forwarding letter.<br />

A.1.16 The tender shall be item rate tender. Tenderer shall be offered the rate for each item in<br />

figures. Sub total of each item and grand total shall be indicated both in figures and<br />

words in Volume-II of the tender document (Financial Bid). The tenderer shall also<br />

work out the total tender amount and shall write this tender amount in words and<br />

figures as per the item rate.<br />

A.1.17 Tenderer shall have to attach the following documents in duplicate with tender:<br />

9

Schedules of Section A-2 “Memorandum of work in brief” of Volume I.<br />

Other documents, as per A.4.8.5, A.4.9 & A.4.22 of Section A-4, Volume – I, Arbitration /<br />

Litigation history if applicable.<br />

It is mandatory for all the tenderers to fill the format as mentioned in A2 <strong>section</strong> (from A<br />

2.1 to A 2.8) of Technical bid, Volume-I. All the financial and technical guaranteed<br />

parameters along with required supportive documents (mentioned in format) to be<br />

submitted with prescribed format only. It is mandatory to submit all the documents in spiral<br />

binding. There shall not be any loose paper. Proper index shall be made for all submitted<br />

documents i.e. format and supportive documents. This is mandatory. In case of not filling<br />

and submitting of documents as mentioned in tender at the time of technical bid (all<br />

technical & commercial documents) and price bid ( cost of each item and any discount- if<br />

applicable) opening then no further correspondence shall be done and the same time tender<br />

will be rejected. Technical details shall be filled in the blank data sheet mentioned in<br />

Technical bid, Volume- “Technical Specifications”.<br />

A.1.18 Incomplete tender which does not fulfill any of the above conditions will be liable for<br />

rejection and Volume – II including addendum if any), duly completed in all respects shall<br />

be submitted as described further, so as to reach at the following address on or before the<br />

date and time mentioned in tender notice.<br />

Assistant Manager (Project)<br />

Amdavad <strong>Municipal</strong> <strong>Corporation</strong><br />

2 nd floor, <strong>Corporation</strong> Bank Building,<br />

Sardar Patel Bhavan,<br />

Khamasa Gate,<br />

<strong>Ahmedabad</strong> – 380 001<br />

Gujarat (INDIA)<br />

A.1.19 Tender will also be liable to be rejected if –<br />

i) The tenderer proposes any alteration in the work specified or in the time allowed in<br />

carrying out the works or make corrections in Schedule of Quantities.<br />

ii) Any of the page or pages in the tender is / are removed or replaced.<br />

iii) The rate of each item is not entered in ink, in figures in Financial Bid. Also the rate of<br />

sub total of each item and grand total is not written in word and figure and signed.<br />

iv) All corrections, additions or pasted slips are not initialed by the tenderer.<br />

v) Any erasure is made in the tender.<br />

vi) The tenderer or in the case of a firm, each partner or the person holding the power of<br />

attorney thereof does not sign or the signature(s) is (are) not attested by the witness,<br />

wherever it is required.<br />

vii) Earnest money for required amount is not paid with the tender.<br />

viii) The tenderer returns the tender document without signing relevant pages of the bid<br />

and amendments, if any.<br />

10

ix) Information vide Section A.2 must be furnished.<br />

x) Data sheet by the bidder in Section ‘D’ & ‘E’ must be furnished.<br />

A.1.20 Acceptance of the tenders will rest with the competent authority, who does not bind<br />

himself to accept the lowest tender and reserves the right to reject any or all tenders without<br />

assigning any reason thereof.<br />

A.1.21 It must be clearly and distinctly understood that the conditions of contract and<br />

specifications shall be rigidly enforced and no relaxation on the grounds of customs<br />

prevailing shall be allowed.<br />

A.1.22 The quoted rates in the Financial Bid (Volume – II) shall be inclusive of all taxes,<br />

duties, octroi, etc. and no claim in this context shall be entertained. Contractor shall<br />

not be paid any extra due to increase in any type of Government Taxes including<br />

excise duty during implementation of contract. Any variations in taxes etc. shall be<br />

borne by the contractor.<br />

A.1.23 It is considered that the tenderer has visited the site of work, fully acquainted himself with<br />

the local situations regarding materials, labour and other factors pertaining to work and<br />

studied the plans and estimates before submitting the tender.<br />

A.1.24 It will be the responsibility of the bidder to arrange for necessary import license and<br />

clearance of Govt. of India in time, if required, so that the imported plant or equipment<br />

could be utilized for the proposed work. The bidder has to assure AMC that he is in a<br />

position to import the plant or equipment at the time of commencement of proposed work.<br />

A.1.25 In the event of a discrepancy between description in words and figures in total offered<br />

amount by the tenderer, the description in words shall prevail.<br />

A.1.26 In the event of any calculation error found in the bid of submission, the rate will be<br />

considered as final and accordingly the amount will be corrected. Also in case of<br />

calculation error like error in summation, subtraction, etc., the actual calculation will be<br />

considered as final.<br />

A.1.27 The tender for the work shall remain open for a period of 120 days from the date of<br />

opening of price bid of the tender and the tenderer shall not be allowed to withdraw or<br />

modify the offer on his own during this period any modifications or additions in terms and<br />

conditions of his tender not acceptable to the <strong>Municipal</strong> Commissioner, AMC, <strong>Ahmedabad</strong>.<br />

The <strong>Municipal</strong> Commissioner shall without prejudice to any right or remedy, be at liberty<br />

to forfeit in full the said earnest money absolutely.<br />

A.1.28 The AMC reserves the right to reject all the tenders of the lowest or any other tender which<br />

is the judgment of the AMC and also does not appear to be in its best interest and the<br />

tenderers shall have no cause of action or claim against the AMC of its officers, employees,<br />

successors for assignees for rejection of its tender. The <strong>Municipal</strong> Commissioner does not<br />

bind himself to accept the lowest or any tender. If the tenderer wishes to offer discount in<br />

the event of this entire work being awarded to him, he shall state so in the tender. Tender<br />

documents are not transferable.<br />

A.1.29 (a) The Contractor shall furnish to the Additional Chief Engineer – (S.O. E & M), AMC<br />

every week during the progress of the works, classified weekly returns of the number of the<br />

11

people employed on the work during the week. The report of skilled and unskilled labour<br />

shall be given in the prescribed forms.<br />

(b) Details of machineries deployed on site shall be furnished by the Contractor, every week.<br />

A.1.30 The tenderer, if directed by the Engineer in charge; shall increase or decrease the strength<br />

of the labour both skilled and unskilled. The Contractor shall also furnish the following<br />

returns:<br />

(a) A weekly medical report showing the health of the Contractor’s labours and the number<br />

and the nature of their illness, and<br />

(b) A report of any accident which may have occurred within 24 hours of its occurrence.<br />

A.1.31 The tenderer shall strictly observe all the requirements laid down in the Contract Labour<br />

(Regulation and abolition) Act, 1970 and the Contract Labour (Regulation and Abolition)<br />

(Gujarat) Rules, 1972 and other acts as amended from time to time so far as applicable. The<br />

tenderer should obtain necessary permission, license and registration from the labour<br />

commissioner, as per labour law.<br />

A.1.32 The work is to be completed in all respects within 6 (Six months) inclusive of monsoon,<br />

reckoned from the date of written order to be commence the work. Out of 6 months, the<br />

contractor shall take approval of all documents & drawings and as per tender specification<br />

and refer to the approval given by AMC within 1 (One) month. In 4 month the contractor<br />

shall supply & deliver at site, & within 1 month for execution, testing and commissioning<br />

of all mechanical & electrical work related to the job. This duration shall also include<br />

inspection at manufacturer’s works for the Grit Mechanism as per technical specification.<br />

A.1.33 The tenderer shall carefully read the eligibility criteria, furnish the details and satisfy the<br />

same; otherwise the tender will be rejected without assigning any reason.<br />

A.1.34 The tenderer is required to check the AMC website for Addendum if any before 72<br />

hours of tender submission/ due or cut off date and time. The tenderer who quotes the<br />

tender without attaching the addendum will be rejected.<br />

A.1.35 This notice will form part of the Contract.<br />

A.1.36 Tender documents can be downloaded from AMC website www.egovamc.com and tender<br />

fees Rs.1500/- by DD (in favour of <strong>Municipal</strong> Commissioner Payable at <strong>Ahmedabad</strong>)<br />

submitted along with the tender submission.<br />

Last date of tender submission will be on 30/08/2011 up to 14.00 hours. Tender (only<br />

technical bid) will be opened on same date: 30/08/2011 at 16.00 hours at the office of the<br />

City Engineer 2 nd floor, Sardar Patel Bh1avan, Khamasa Gate, Amdavad <strong>Municipal</strong><br />

<strong>Corporation</strong>.<br />

Signature of Tenderer: Additional Chief Engineer (S.O.E. & M.)<br />

Name : Amdavad <strong>Municipal</strong> <strong>Corporation</strong><br />

Company’s seal :<br />

Date : Date<br />

12

SECTION: A-2<br />

MEMORANDUM OF WORKS<br />

IN BRIEF<br />

13

A.2.1 Name of Work:<br />

A - 2 : MEMORANDUM OF WORK IN BRIEF<br />

SITC of Hydraulically operated Grit Mechanism with related Electrical work at E, E3, W<br />

& W5 Sites with One year of Operation & Maintenance Period for Sabarmati River Front<br />

Development <strong>Corporation</strong> Ltd. of Amdavad <strong>Municipal</strong> <strong>Corporation</strong>.<br />

A.2.2 Earnest Money : Rs. 32, 000/- (Rs. Thirty Two Thousand only)<br />

EMD shall be in the form of Demand Draft (in favour of <strong>Municipal</strong> Commissioner Payable at<br />

<strong>Ahmedabad</strong>) / Bank Guarantee.<br />

A.2.3 Validity Period : 120 Days from the date of price bid opening<br />

A.2.4 Security Deposit : 5% of the contract value in the form of Bank Guarantee<br />

from any Nationalized Bank<br />

A.2.5 Performance Guarantee Bond: 5 % of the contract value in form of Bank Guarantee for<br />

period of 12 months beyond time limit i.e.6 Months.<br />

A.2.6 Solvency Certificate : Not Applicable<br />

A.2.7 Time – Limit : 6 Months (Including monsoon season). Within 1 month for<br />

documents, drawings approval, within 4 month for<br />

Inspection, supply & delivery of goods at site, within 1<br />

month for Execution, Testing & Commissioning at site.<br />

A.2.8 O & M period : One Year<br />

A.2.9 i) Last date of submission<br />

of the tender : 30/08/2011 up to 14.00 hours<br />

ii) Mode of Sending<br />

iii) Description essential to<br />

: a) In sealed cover in (One Original + One Xerox copy)<br />

copies by Registered Post A.D. or Speed Post or Hand<br />

delivery or Courier.<br />

b) Tender sent by ordinary post will be rejected out right.<br />

be made on sealed cover :<br />

iv) Mode of quoting rates in<br />

a) Name of Work and Tender No.,<br />

Name of Contractor<br />

b) Last date of receiving tender by the AMC.<br />

Schedule of rates : Rate of each item shall be mentioned in figure and rate of<br />

sub total of each item and total of each work and grand total<br />

shall be mentioned in figures as well as in words.<br />

A.2.10 Performance Guarantee : The security deposit paid will be converted in the<br />

performance guarantee and will be released after Operation<br />

& Maintenance Period of one year.<br />

A.2.11 EMD : BG / D.D. No. _______________ Dt. ________,<br />

Drawn on ______________ Bank ________<br />

14

Payable to <strong>Municipal</strong> Commissioner, at <strong>Ahmedabad</strong> is<br />

enclosed herewith representing the earnest money, the full<br />

value of which is to be absolutely forfeited by AMC, should<br />

I / We not deposit the full amount of security deposit<br />

specified above.<br />

A.2.12 Excess Item : It is mandatory for the successful tenderer to give excess<br />

item (up to 40 % of tender qty) at the quoted rate up to<br />

project completion limit.<br />

A.2.13 Important Instruction : i) It is mandatory for all the tenderer to fill the Format as<br />

mentioned in Schedule A-2 (A2.1 to A2.8) of Technical bid,<br />

Volume-I.<br />

ii) All the financial and technical guaranteed parameters along<br />

with required supportive documents (mentioned in format)<br />

to be submitted with prescribed format only.<br />

iii) It is mandatory to submit all the documents spiral binding<br />

having proper checklist index indicating the page no. as per<br />

format and supportive documents.<br />

iv) Loose paper or left out paper later submitted will not be<br />

accepted.<br />

v) In case of not filling and submitting of documents as<br />

mentioned in tender at the time of tendering then no further<br />

correspondence shall be done with bidders for further<br />

submission of either technical or commercial documents or<br />

any discount, and at the same time tender will be rejected.<br />

vi) Technical details shall be filled in the blank data sheet<br />

mentioned in Technical bid, Volume-I “Technical<br />

Specifications”.<br />

Signature of Tenderer : Additional Chief Engineer (S.O.E & M)<br />

Name : Amdavad <strong>Municipal</strong> <strong>Corporation</strong><br />

Company’s seal :<br />

Date :<br />

15

INDEX FOR SCHEDULES<br />

Sch. No. Description Page No.<br />

A-2.1<br />

INFORMATION REGARDING FINANCIAL CAPACITY FOR<br />

THE TENDERER<br />

1. Earnest Money Deposit<br />

2. Solvency certificates<br />

3.<br />

Certificate of Grit Mechanism Manufacturer / Authorised dealer of<br />

Grit Mechanism of approved make specified in the tender &<br />

Qualifying to the Qualification Criteria<br />

4. Annual Average Turn Over<br />

5. An overall schedule of the work plan of the project<br />

6.<br />

7.<br />

Experience of execution of water supply or sewage application for<br />

electrical and mechanical work<br />

Blank data sheet to be furnished as mentioned in technical bid Part<br />

II<br />

8. A certified copy of power of attorney<br />

9. Agreement in case of joint Venture<br />

10. Income Tax return copy of last three financial year<br />

A.2.2 BID CAPACITY<br />

A.2.3<br />

A.2.4<br />

A.2.5<br />

A.2.6<br />

A.2.7<br />

INFORMATION REGARDING TECHNICAL PARAMETERS<br />

BY THE TENDERER – NOT APPLICABLE<br />

DETAILS OF THE WORKS OF SIMILAR TYPE &<br />

MAGNITUDE CARRIED OUT BY THE TENDERER DURING<br />

LAST 5 YEARS PERIOD<br />

DETAILS OF THE WORKS IN HAND AND WORKS<br />

TENDERED FOR AS ON DATE OF SUBMISSION OF THE<br />

TENDER.<br />

DETAILS OF TECHNICAL PERSONNEL WITH TENDERER<br />

WHO ARE PROPOSED FOR THIS CONTRACT – NOT<br />

APPLICABLE<br />

DETAILS OF THE EQUIPMENT IN POSSENSSION OF THE<br />

CONTRACOTR AND THE EQUIPMENT HE PROPOSES TO<br />

BRING TO THE SITE FOR THIS WORK – NOT APPLICABLE<br />

A.2.8 STRUCTURE AND ORGANISATION OF FIRM<br />

16

Sr.<br />

No.<br />

1. Earnest Money Deposit<br />

A – 2: SCHEDULES<br />

SCHEDULE - A.2.1<br />

INFORMATION REGARDING FINANCIAL CAPACITY OF THE TENDERER.<br />

Details Amount in Lacs<br />

Details to be<br />

furnished<br />

Submitted<br />

Yes / No<br />

Min EMD value shall be<br />

Rs. 32,000/-<br />

2. Solvency Certificates Not Applicable<br />

3.<br />

4.<br />

5.<br />

6.<br />

7.<br />

Certificate of Grit<br />

Mechanism Manufacturer /<br />

Authorized Dealer of Grit<br />

Mechanism of approved make<br />

Annual average turnover for<br />

last three years:<br />

Year :<br />

2008 – 2009<br />

2009 – 2010<br />

2010 – 2011<br />

Average:<br />

An overall schedule of the<br />

‘Work Plan’ of the project<br />

Experience of execution of<br />

Grit Mechanism with<br />

electrical and mechanical<br />

work<br />

Blank Data sheet to be<br />

furnished as mentioned in<br />

technical bid Part II<br />

Remarks<br />

Certificate of Grit Mechanism Manufacturer /<br />

Authorized dealer of Grit Mechanism of<br />

approved make shall be attached.<br />

Minimum average Annual Turnover for last three<br />

financial years shall be Rs. 20,00,000/-<br />

Certificates duly signed and stamped from C.A.<br />

shall be attached with this schedule along with<br />

the audited balance sheets for the last three years<br />

showing long term profitability.<br />

Separate chart to be enclosed with this schedule<br />

considering project completion period<br />

Separate sheet to be enclosed with this schedule<br />

as supportive documents.<br />

Blank Data sheet to be filled in format attached in<br />

technical specification and shall be attached with<br />

this schedule<br />

17

Sr.<br />

No.<br />

8.<br />

9.<br />

10.<br />

Details Amount in Lacs<br />

A certified copy of power of<br />

attorney<br />

Agreement in case of Joint<br />

Venture<br />

Income Tax return copy of<br />

last three financial year<br />

Details to be<br />

furnished<br />

Submitted<br />

Yes / No<br />

Not Applicable<br />

Note: No Deviation with respect to technical guaranteed parameters and commercial terms shall be acceptable.<br />

Signature of the Tenderer with stamp: Company’s seal:<br />

Name: Date:<br />

Remarks<br />

Copy shall be attached with this schedule<br />

18

SCHEDULE - A.2.2<br />

BID CAPACITY:<br />

The Contractor shall furnish the schedule for capacity in the following format for this work<br />

I. Annual average turnover for last three financial years (A):<br />

Year :<br />

2008 – 2009<br />

2009 – 2010<br />

2010 – 2011<br />

II. Value of work the existing commitments and on-going works to be completed during the next one year (B) :<br />

Name of work in progress<br />

II. Qualification Criteria<br />

Date of issue of work order<br />

along with its tendered cost<br />

(Rs. Lacs)<br />

Actual Tentative Date of<br />

Completion of work<br />

Minimum Annual Turnover<br />

for last three financial years<br />

shall be<br />

Rs. 20,00,000/-<br />

Amount of existing<br />

commitment as well as<br />

ongoing work to be done<br />

in next 12 months<br />

The bidder should be original manufacturer of Grit Mechanism or authorised dealer of the Grit Mechanism (for approved make refer to the technical<br />

specifications, Make of Material). In case of Authorization, the Bidder should be Authorised dealer for current year and should hold the same authorization since<br />

last one year. The certification for the same shall be submitted.<br />

III. Completion period / 12 = 6/12 = 0.5 (N) :<br />

Bid Capacity<br />

Bid Capacity = (2AN – B) = __________________________ (Shall be minimum Rs. 10, 00, 000/- (Rs. Ten lacs only))<br />

Where, A = Annual average turnover of last three years<br />

B = Value of work the existing commitments and on-going works to be completed during the next one year<br />

N = Completion period / 12 = 6/12 = 0.5<br />

Signatures of the Tenderer with stamp Name:<br />

Company’s Seal: Date:<br />

19

SCHEDULE - A.2.3<br />

NOT APPLICABLE<br />

20

Sr.<br />

No.<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

SCHEDULE - A.2.4<br />

DETAILS OF THE WORKS OF SIMILAR TYPE AND MAGNITUDE CARRIED OUT BY THE TENDERER<br />

DURING LAST 5 YEARS PERIOD<br />

Name of Work<br />

Place and<br />

Country<br />

Tendered<br />

Cost<br />

Date of start Prescribed date<br />

of completion<br />

Note :<br />

Date of Completion<br />

Actual date of<br />

completion<br />

Principal Features<br />

1) Experience of execution of at least ONE similar (Hydraulic type) Grit Mechanism SITC work with related electrical & mechanical work completed<br />

during last five years each having costing not less than Rs. 7,50,000 (Rs. 7.5 Lacs Only) & satisfactory working at least one year.<br />

2) Certificate of satisfactory completion of the work from the owner shall be submitted for each work which is mandatory. If required separate sheet can be<br />

used for more details.<br />

Signatures of the Tenderer with stamp Company’s seal:<br />

Name: Date:<br />

21

Sr.<br />

No<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

SCHEDULE - A.2.5<br />

DETAILS OF THE WORKS IN HAND AND WORKS TENDERED FOR AS ON THE DATE OF SUBMISSION OF THE TENDER<br />

Name of<br />

Work<br />

Place and<br />

Country<br />

Tendered<br />

Cost<br />

WORKS IN HAND WORKS TENDERED FOR<br />

Cost of work<br />

remaining to<br />

be executed as<br />

on date<br />

Anticipated<br />

Date of<br />

Completion<br />

Note:<br />

Tender<br />

Cost<br />

Date when<br />

decision is<br />

expected<br />

Stipulated date &<br />

period of<br />

Completion<br />

Main features of<br />

the work<br />

1. Correct details of work on hand to be furnished. In case of hiding / not showing of the details of work on hand, contractor shall not be considered<br />

technically qualified and their price bid will not be opened.<br />

2. If required separate sheet can be used for more details.<br />

Signature of the Tenderer with stamp Company’s seal:<br />

Name: Date:<br />

22

Sr.<br />

No<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

SCHEDULE - A.2.6 : NOT APPLICABLE<br />

DETAILS OF TECHNICAL PERSONNEL WITH TENDERER WHO ARE PROPOSED FOR THIS CONTRACT<br />

Description of Category Name Qualification<br />

Professional<br />

experience and<br />

details of works<br />

carried out<br />

Since how long in<br />

service with<br />

tenderer<br />

Note: The complete biodata of each personnel with qualification and experience shall be furnished separately alongwith this schedule.<br />

Signature of the Tenderer with stamp<br />

Name:<br />

Company’s seal:<br />

Date:<br />

Remarks<br />

23

SCHEDULE - A.2.7 : NOT APPLICABLE<br />

DETAILS OF THE QUIPMENT IN POSSESSION OF THE CONTRACTOR AND THE EQUIPMENT HE PROPOSES TO<br />

BRING TO THE SITE FOR THIS WORK<br />

Sr. No.<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

6.<br />

7.<br />

8.<br />

9.<br />

10.<br />

Type and Description of the<br />

Equipment & Capacity<br />

Age and Approximate Value<br />

Numbers the Tenderer<br />

has in possession<br />

Numbers he proposes to<br />

bring on to site.<br />

Tenderer hereby confirms that quantity and type of tools he will employ for execution will not be less than those listed in para A.5.8 and agree to bring more<br />

equipment, if so warranted in the opinion of the Engineer.<br />

Signatures of the Tenderer with stamp Company’s seal:<br />

Name: Date:<br />

24

1. Name of Applicant<br />

2. Nationality of Applicant<br />

3. Office Address<br />

Telegraphic Address<br />

Telephone No.<br />

Telex No.<br />

Fax No.<br />

E-mail Address<br />

4. Year and location of establishment<br />

5. The Applicant is<br />

a) An individual<br />

b) A proprietary firm<br />

c) A firm in partnership<br />

d) A limited company or Corp.<br />

(if a firm in partnership)<br />

SCHEDULE - A.2.8<br />

STRUCTURE AND ORGANISATION OF FIRM<br />

6. Attach the organization chart showing the<br />

structure of the organization including the<br />

names of the Directors and position of<br />

officers.<br />

7. Number of years of experience<br />

8. Give details of your experience in Grit<br />

Mechanism manufacturing and quality<br />

control.<br />

9. Give details of equipments, if any.<br />

Signature of Tenderer<br />

Name<br />

Company’s Seal<br />

Date<br />

25

A - 3<br />

SECTION: A-3<br />

SCOPE OF WORKS<br />

26

A.3: SCOPE OF WORK<br />

A.3. 1 Scope for Mechanical work shall include design, manufacture, testing of Hydraulically<br />

Operated Grit Mechanism at manufacturer’s works by third party inspecting (TPI) agency<br />

jointly with AMC representatives’ inclusive of all the expenses incurred towards the<br />

inspection like commercial fees, to & fro charges, lodging & boarding, etc., delivery of<br />

equipment at site, unloading & storage at site, installation, testing at E, E3, W & W5 sites<br />

of Sabarmati River Front Development <strong>Corporation</strong> Ltd. for STP Department of<br />

Amdavad <strong>Municipal</strong> <strong>Corporation</strong> as follows:<br />

I. The scope of Mechanical work may include but not limited to the following:<br />

A.3.1.1 Hydraulically operated Grit Mechanism with related Electrical & Civil work for various<br />

sites of SRFDCL.<br />

A.3.1.2 Carbon Steel with hot dipped galvanized Nuts, bolts, washers, gaskets, etc.<br />

A.3.1.3 Structural steel, square bar, etc. as required on site<br />

II. The scope of Electrical work may include but not limited to the following for AMC:<br />

A.3. 2.1 Connection from spare feeder of the MLTP to Grit mechanism through cable.<br />

A.3. 2.2 Power and control cables.<br />

A.3. 2.3 Earthing system<br />

A.3. 2.4 Cabling system<br />

A.3. 2.5 Control Panel<br />

A.3. 2 ADDITIONAL SCOPE:<br />

In addition to the above, following services are also included in the scope of the<br />

Contractor:<br />

A.3.3.1. Cable tray support<br />

A.3.3.2. Final painting of equipment at site after installation<br />

A.3.3.3. Drawings and Instruction Manuals<br />

A.3.3.4. Verifying the existing dimensions as relevant to the Contractors scope.<br />

A.3.3.5. Civil repairing and maintaining of damage done to the pump house during execution.<br />

Signature of Tenderer Additional Chief Engineer (S.O.E & M.)<br />

Name: Amdavad <strong>Municipal</strong> <strong>Corporation</strong><br />

Company’s seal:<br />

Date: Date:<br />

27

SECTION: A-4<br />

INSTRUCTIONS TO TENDERERS<br />

28

A.4.1. Note<br />

A – 4: INSTRUCTIONS TO TENDERERS<br />

A.4.1.1 These instructions are provided to assist tenderers while preparing their tenders. They do<br />

not form part of the Contract and they shall not be taken into consideration in interpreting<br />

or construing the Contract.<br />

A.4.2. Invitation to Tender<br />

A.4.2.1 The <strong>Municipal</strong> Commissioner, AMC for and on behalf of the Amdavad <strong>Municipal</strong><br />

<strong>Corporation</strong>, <strong>Ahmedabad</strong>, hereinafter referred to as the AMC, will receive tenders for the<br />

Supply, installation, testing & commissioning of pumping machinery with related electrical<br />

& mechanical works according to the specifications and Schedule of Quantities and Rates<br />

in the tender documents herewith attached.<br />

A.4.2.2 Tenders will not be accepted after the hour and date fixed for receiving of tenders.<br />

Telegraphic tenders will not be accepted under any circumstance. Tenders received after<br />

the hour and date so fixed will not be considered. Tenders will be received by RPAD /<br />

Speed Post / Hand delivery / Courier on or before due date and time as mentioned in<br />

tender notice. Tenderer’s authorized representatives may attend the tender opening. The<br />

tenders shall be opened at the date and time as mentioned in tender notice.<br />

A.4.2.3 However, the AMC reserves the right to reject all the tenders or the lowest or any other<br />

tender which in the judgment of the AMC does not appear to be in its best interest, and the<br />

tenderer shall have no cause of action or claim against the AMC or its officers, employees,<br />

successors or assignee for rejection of its tender.<br />

A.4.2.4 The <strong>Municipal</strong> Commissioner does not bind himself to accept the lowest or any tender. If<br />

the tenderer wishes to offer discount in the event of the entire work he shall state so in the<br />

tender.<br />

A.4.2.5 Tender documents are not transferable.<br />

A.4.2.6 Technical bid shall not contain any commercial detail or letter pertaining to commercial<br />

part (like discount letter, optional offer letter, etc.).<br />

A.4.3. Tender Validity Period<br />

A.4.3.1 The tender shall be kept valid for acceptance for a period of one hundred & twenty days<br />

(120) calendar days from the date of opening of price bid.<br />

A.4.4. Language of Tender<br />

A.4.4.1 Tenders shall be submitted in English, and all information in the tender shall be in English.<br />

Information in any other language shall be accompanied by its translation in English.<br />

Failure to comply with this may disqualify a tender. Only English text shall be governing.<br />

A.4.5. Documents<br />

A.4.5.1 Two sets (One Original + One Xerox copy) of tender documents (Part – I and II of<br />

Volume-I & Volume-II, drawings & addendum if any), comprehensively referred to as<br />

Tender Document, are issued to every tenderer. The details of the Tender Document<br />

referred above are as follows:<br />

29

(A) : Technical Bid<br />

(1) : Volume – I : Part – I (General)<br />

Section: A - Notice Inviting Tender, Scope of Work, Instructions to Tenderers etc.<br />

Section: B - General Conditions of Contract, Schedules etc.<br />

Section: C - Specifications : Non-Technical, Safety Provisions etc.<br />

(2) : Volume – I : Part – II (Technical Specification & Drawings)<br />

Section: D - Technical Specifications (Mechanical)<br />

Section: E - Technical Specifications (Electrical)<br />

Section: F - Drawings<br />

(B) : Financial Bid<br />

(3) : Volume – II :<br />

Section: G - Schedule of Quantities & Rates (Schedule B)<br />

A.4.6. Earnest Money<br />

A.4.6.1 Each tender must be accompanied by Earnest Money in the form of Demand Draft / Bank<br />

Guarantee of any Nationalized Bank, located at <strong>Ahmedabad</strong> (in favour of <strong>Municipal</strong><br />

Commissioner Payable at <strong>Ahmedabad</strong>).<br />

A.4.6.2 Tenders not accompanied by Earnest Money as required shall be rejected as nonresponsive.<br />

A.4.6.3 If during the tender validity period, the tenderer withdraws his tender or the successful<br />

tenderer fails to accept the contract within 15 calendar days after receiving notice of the<br />

award of contract and fails to submit security deposit, the earnest money shall be<br />

forfeited and the tenderer may be disqualified from tendering for further works with<br />

the Amdavad <strong>Municipal</strong> <strong>Corporation</strong>.<br />

A.4.6.4 After the awarding of contract has been finalized, the Earnest Money will be returned to the<br />

respective tenderers, with the exception of the successful tenderer.<br />

A.4.6.5 The successful tenderer’s earnest money will be retained as security after signing the<br />

contract and for making of the contract deposit.<br />

A.4.6.6 No interest will be paid on any tender deposit.<br />

A.4.7 Income Tax Return<br />

A.4.7.1 In case of domestic tenderers, the tender must be accompanied by an Income-Tax return<br />

copy of last three financial years. If a tender is submitted without complying with these<br />

requirements, it is liable to be rejected outright.<br />

A.4.8 Submission of Tenders<br />

30

A.4.8.1 Tenders shall be submitted together with the other documents that form the tender. In the<br />

event of a Contract, the tender and the documents attached there to shall be considered as<br />

forming part of the Contract Documents.<br />

A.4.8.2 Two sets (One Original + One Xerox copy) of tender documents (Vol. I, Part – I and II &<br />

Vol. II, drawings and addendum, if any) duly completed in all respects shall be submitted<br />

as described in notice inviting tender in a sealed envelope so as to reach by at the following<br />

address on or before the date and time as mentioned in tender notice without which the<br />

tender shall be considered non responsive.<br />

Assistant Manager (Project)<br />

Amdavad <strong>Municipal</strong> <strong>Corporation</strong><br />

2 nd floor, <strong>Corporation</strong> Bank Building,<br />

Sardar Patel Bhavan,<br />

Khamasa Gate,<br />

<strong>Ahmedabad</strong> – 380 001<br />

Gujarat (INDIA)<br />

A.4.8.3 The sealed envelopes ‘A’ & ‘B’ shall show on the outside, the name of the tenderer<br />

and his address. In addition, the lower left hand corner of the envelope or other container<br />

should indicate the Contract number if any given by AMC and the tender opening date.<br />

Tenders which are opened before the due date with no indication having been given on the<br />

outside of the envelope or container to indicate that it is a tender liable to be disqualified.<br />

A.4.8.4 The tender shall be considered non-responsive if Technical and Financial Bids<br />

(envelopes ‘A’ & ‘B’) are not sealed in separate envelope. Tenderers shall not be<br />

allowed to fill in or seal their tenders at the AMC Office. Tenderers are requested to<br />

present the tenders well in time before stipulated date and time of receipt; so as to<br />

avoid rush at the closing hours.<br />

A.4.8.5 Envelope ‘A’ of the tender document shall be accompanied by the following documents in<br />

duplicate:<br />

(a) Vol. I of the tender with duly signed.<br />

(b) Tenderer’s programme for the execution of the works.<br />

(c) A chart showing the estimated monthly labour force proposed for the execution of<br />

this contract.<br />

(d) List of plant and machinery in good working order available with the tenderer<br />

which he proposes to deploy on the works.<br />

(e) Details of schedule of <strong>section</strong> A-2, of Vol. I. In case of work completed by tenderer<br />

during last 5 years, he should submit completion certificate from the owner.<br />

(f) A covering letter (in duplicate) stating any other matter in relation to this tender<br />

which the tenderer considers should be drawn to the particular notice of the AMC<br />

or Consulting Engineers if any.<br />

In addition, the original tender shall be accompanied by:<br />

(g) DD for tender fee & DD or Bank Guarantee for EMD as detailed in item A.4.6,<br />

above.<br />

31

(h) In case of domestic contractor, an income-tax return copy of last three financial<br />

years as detailed in item A.4.7, above.<br />

A.4.8.6 Envelope ‘B’ of the Tender Documents shall be accompanied with Volume-II in<br />

duplicate.<br />

A.4.8.7 Erasures and other changes shall be noted over by the initials of the person signing<br />

the tender.<br />

A.4.9 General Performance Data<br />

A.4.9.1 Tenderers shall present the following information along with their tenders in duplicate:<br />

(a) Evidence of financial capacity to execute a contract of this magnitude in terms of<br />

annual turnover and price of biggest job carried out.<br />

(b) The bidders are requested to furnish requisite information as described in Section: A-5<br />

so as to enable the competent authority to decide the technical and financial capability<br />

of the bidder, based on which, the bidder shall be evaluated.<br />

(c) Experience of similar works with names of authorities for which the works were<br />

executed along with completion / performance certificate.<br />

(d) List of current jobs of comparable nature along with starting date and likely completion<br />

dates with their contract values.<br />

(e) The extent of responsibilities carried by Contractors associated with the tenderer.<br />

(f) General detail of tenderers’ organization, management, staff and personnel, Facilities<br />

for design and execution<br />

A.4.9.2 Tenders will not be considered if the above information is not provided or is considered to<br />

be unsatisfactory.<br />

A.4.10 Signing of Tender Document<br />

A.4.10.1 Tenderers are requested to quote the item rates and their total offered amount of the work<br />

and also sign the Schedule of Quantities in Volume–II etc. after making appropriate<br />

inquiries wherever necessary.<br />

A.4.10.2 If the tender is made by an individual, it shall be signed with his full name above his<br />

current address.<br />

A.4.10.3 If the tender is submitted by a proprietary firm, it shall be signed by the proprietor above<br />

his name and the name of his firm with its current address.<br />

A.4.10.4 If the tender is made by a firm in partnership, it shall be signed by all the partners of<br />

the firm above their full names and current addresses, or by a partner holding the<br />

power of attorney for the firm signing the tender in which case a certified copy of the<br />

power of attorney shall accompany the tender. A certified copy of the partnership<br />

deed, current address of the firm and the full name and the current address of all the<br />

partners of the firm shall also accompany the tender.<br />

A.4.10.5 If the tender is made by a limited company or a limited <strong>Corporation</strong>, it shall be signed by a<br />

duly authorized person holding the power of attorney for signing the tender, in which case,<br />

32

a certified copy of the power of attorney shall accompany the tender. Such limited<br />

Company or <strong>Corporation</strong> may be required to furnish satisfactory evidence of its existence<br />

before the contract is awarded.<br />

A.4.10.6 Not Applicable<br />

A.4.10.7 All witnesses and sureties shall be persons of status and probity and their full names,<br />

occupations and addresses shall be stated below their signatures.<br />

A.4.10.8 The tenders from Contractors shall be accompanied by an attested copy of income-tax<br />

return copy of last three financial years.<br />

A.4.10.9 All signatures in the tender documents shall be dated.<br />

A.4.11 Interpretation of Documents<br />

A.4.11.1 Tenderers shall carefully examine the Tender Documents and fully inform themselves as to<br />

all the conditions and matters which may in any way affect the work or the cost thereof.<br />

Should a tenderer find discrepancies in or omission from the specification or other<br />

documents, or should be in doubt as to their meaning, he should at once address a query to<br />

the Additional Chief Engineer (S.O.E &M), AMC. Any resulting interpretation of the<br />

Tender Documents will be issued to all tenderers as an Addendum. Verbal clarification<br />

and/or information given by the <strong>Municipal</strong> Commissioner, AMC shall not be binding on<br />

the AMC.<br />

A.4.12 Errors and Discrepancies in Tenders<br />

A.4.12.1 Should the Schedule of quantities and Rates (Vol. II) submitted with the tender be found to<br />

contain errors, or discrepancies, the owner / engineer will not permit any bidder to change<br />

the substance or price of his bid after the bid opening. In case of discrepancy in the quoted<br />

rate and the corresponding amount the rate quoted in words in all cases shall govern. Also<br />

the bidder will not be permitted to correct or withdraw material deviations or reservations<br />

once bids have been opened.<br />

A.4.13 Modification of Documents<br />

A.4.13.1 Modifications of specifications and extension of the closing date of the tender, if required,<br />

will be made by an Addendum. Copies of each Addendum will be put up on website.<br />

These shall be signed and returned by the tenderers and shall form a part of the tender<br />

document. The tenderer is required to check the AMC website for Addendum if any before<br />

72 hours of tender submission date and time. The tenderer who quotes the tender without<br />

attaching the addendum will be rejected.<br />

A.4.13.2 The tenderer shall not add to or amend the text of any of the documents except in so far as<br />

may be necessary to comply with the Addenda.<br />

A.4.14 Evaluation (Technical Bid & Price Bid) of Tenders<br />

A.4.14.1 For evaluation and comparison of bids, the following factors shall be considered in addition<br />

to the points mentioned in Clause A.4.22.1 of Section : A-4 of Volume-I.<br />

i) The costs of procurement of principal element of the work of similar magnitude<br />

executed earlier.<br />

ii) The time of completion of SITC job.<br />

33

iii) The reliability of the proposed execution of electrical and mechanical work.<br />

iv) Deviations, if any.<br />

v) Technical competence.<br />

vi) Relative quality of previous jobs.<br />

vii) Organization set up.<br />

viii) Financial Capability.<br />

ix) In case of joint venture, financial capacity of each partner.<br />

A.4.15 Policy for tenders under consideration<br />

A.4.15.1 Tenders shall be deemed to be under consideration from the opening of tenders, until such<br />

time as an official announcement of award is made.<br />

A.4.15.2 While tenders are under consideration, tenderers and their representatives, or other<br />

interested parties, are advised to refrain from contacting by any means any AMC personnel<br />

or representatives on matters relative to the tenders under study. The Engineer’s<br />

Representative, if necessary, will obtain clarification of tenders by requesting such<br />

information from any or all the tenderers either in writing or through personal contact, as<br />

may be necessary. The tenderer will not be permitted to change the substance of his tender<br />

after tenders have been opened. This includes any post tender price revision or major<br />

modification as defined in Clause No. A.4.13. Non-compliance with this provision is a<br />

cause for disqualification.<br />

A.4.16 Alternatives<br />

Deleted<br />

A.4.17 Cost of Tendering<br />

The AMC will not defray the expenses incurred by tenderers in tendering and will not be<br />

bound to accept the lowest or any tender.<br />

A.4.18 Award of Contract<br />

A.4.18.1 Notification of award will be made in writing to the successful tenderer.<br />

A.4.18.2 The contract will be awarded to the technically and financially qualified and responsive<br />

tenderer offering the lowest overall evaluated tender or tenders in conformance with<br />

specifications subject to the provisions in Clause No. A.4.14 and A.4.15 i.e. Evaluation of<br />

tenders and policy for tenders under considerations, mentioned earlier.<br />

A.4.18.3 A responsive tender is one which accepts all the terms and conditions of the Tender<br />

Documents without any major modifications. A major modification is one which affects in<br />

any way the price, quality, quantity or completion of works or which limits in any way, any<br />

responsibilities or liabilities of the tenderer or any rights of the AMC, as specified in the<br />

Tender Documents. The AMC may waive any minor informality in a tender which does<br />

not constitute a major modification. However, the failure of successful bidder to pay<br />

‘Security Deposit’ and signing the contract shall constitute sufficient grounds for<br />

annulment of the award of contract and forfeiture of the earnest money deposit, in which<br />

34

case the Owner/Engineer may award the contract to the next lowest evaluated responsive<br />

bidder. In the event of not finding any such bidders, the employer is empowered to call for<br />

new bids.<br />

A.4.18.4 In case, the tender is found technically responsive, tenderer will be intimated accordingly.<br />

Financial bid of only technically qualified tenderer will be opened. Financial bid of the<br />

technically unqualified tenderer will be retained un-opened.<br />

A.4.19 Signing of Contract<br />

A.4.19.1 The successful tenderer shall be required to execute the Contract within 15 days of receipt<br />

of intimation to execute the Contract. If the contractor will not pay security deposit and<br />

will not sign agreement within 15 days after issuing the first letter from the authority of<br />

AMC, his EMD shall be forfeited and such tenderer shall be disqualified for getting further<br />

any work in AMC. Also their registration will be kept in abeyance for three years.<br />

A.4.19.2 The person to sign the contract documents shall be the persons as detailed in Clause No.<br />

A.4.10 i.e. signing of tender documents.<br />

A.4.20 Stamp Duty and Legal Charges<br />

It shall be incumbent on the successful tenderer to pay stamp duty on the contract and legal<br />

charges for preparation of the contract agreement.<br />

A.4.21 Solvency Certificate: Refer <strong>section</strong> A2 “Memorandum of work” for solvency Certificate.<br />

A.4.22 Documents / Information to be submitted along with Volume – I (Technical Bid)<br />

A.4.22.1 The following documents/information must be submitted by the tenderer in duplicate along<br />

with Volume-I of the tender.<br />

i. Details of the work of similar type and magnitude carried out by the tenderer including<br />

names of the authorities for which works were executed, as per Schedule-A-2.1 to A-<br />

2.8 of Section A – (Volume-I) along with certificate of timely completion of work by<br />

owner.<br />

ii. Demand draft/ Bank Guarantee as earnest money as detailed in Clause No. A.4.6 of<br />

Instructions to Tenderers – (Volume-I).<br />

iii. An Income-tax return copy of last three financial years as detailed in Clause No. A.4.7,<br />

of Instructions to tenderers - (Volume-I).<br />

iv. If the tender is not submitted by an individual, the necessary certified copy of the power<br />

of attorney, a certified copy of the partnership deed and other relevant information in<br />

this connection as detailed in Clauses A.4.10.3 to A.4.10.7 of Instruction to Tenders –<br />

(Volume-I).<br />

v. General details of tenderer’s organization, facilities for design and execution.<br />

vi. Data asked wide blank data sheet shall be furnished in the given formats in the tender.<br />

A.4.22.2 Bidders not submitting the above mentioned information along with their tenders as per<br />

clause No. A.4.22.1 above, the tender will not be considered for evaluation and the bid will<br />

be outright rejected.<br />

35

A.4.23 Forms<br />

BANK GUARANTEE<br />

for<br />

EARNEST MONEY DEPOSIT / SECURITY DEPOSIT / PERFORMANCE BANK<br />

GUARANTEE<br />

In consideration of the <strong>Municipal</strong> <strong>Corporation</strong> of the city of <strong>Ahmedabad</strong> (hereinafter to as the<br />

corporation) having agreed to exempt ______________________________________ (hereinafter<br />

referred to as "the said Contract") from the demand of earnest money / security deposit in cash for the<br />

due fulfillment of the terms and conditions of the agreement made between the corporation and the<br />

said BIDDER on ____________________________________________ for<br />

________________________________________________________________________ (hereinafter<br />

referred to us "the said agreement") on production of Bank Guarantee for Rs._________________<br />

Rupees ____________________________________________ only.<br />

We ___________________________________________________________________ Bank<br />

(hereinafter referred to as "Bank") do hereby undertake to pay to the <strong>Corporation</strong> as a amount not<br />

exceeding Rs. _____________________________ Rupees<br />

_______________________________________________________________________ only on the<br />

demand from <strong>Corporation</strong>.<br />

Any such demand on the bank shall be conclusive as regards as amount due and payable by the bank<br />

under this guarantee. However, liability of the bank under this agreement shall restricted to as amount<br />

not exceeding Rs. ___________________________ Rupees<br />

______________________________________________________________________ only.<br />

We the bank further agree that the guarantee herein contain shall remain in full force and effect during<br />

the period that would be mentioned in the bid and that it shall continue to be enforceable till all the<br />

dues of the <strong>Corporation</strong> under or virtue of the said agreement have been paid and its claim satisfied or<br />

discharged and till a certificate to the effect has been received by the bank from the <strong>Corporation</strong>.<br />

However, unless the demand of claim under the guarantee is made to the bank in writing on or before<br />

the _____________________ (specify the date) the bank shall be discharged from all liabilities under<br />

this guarantee.<br />

36

With the bank further with <strong>Corporation</strong> shall have fullest liberty, without the concert of the bank<br />

without effecting in any manner it obligations herein under to vary any of the terms and conditions of<br />

the said agreement or extend time for validity by the said bid from time to time or to postpone for any<br />

time or from time to time any of the powers exercisable by the <strong>Corporation</strong> against the said Contractor<br />

and to forebear to enforced any of the terms and conditions relating to the said agreement and the bank<br />

shall not be relieved from liability by reason of any such variation, or extension granted to the<br />

contractor for any forbearance, at Contractor or by any such matter or thing whatsoever which under<br />

the law relating to sureties would, but this provision, have the effect of so relieving the Bank.<br />

We ________________________________________________________________ the bank<br />

undertake not to revoke the Guarantee during currency except with the previous concert of the<br />

<strong>Corporation</strong> in writing.<br />

Dated the ________________________ day of ________________________ of 20____.<br />

For ____________________________________ Bank<br />

Principal (Contractor)<br />

Surety (Bank)<br />

Contract No. and date of Contract<br />

37

PERFORMANCE BOND<br />

(The date of this bond must not be prior to the date of the instrument in connection with which it to<br />

given)<br />

Principal (Contractor)<br />

Surety (Bank)<br />

Sub of bond (Express in words and figures)<br />

Contract No. and date of Contract<br />

38

KNOW ALL MEN BY THESE PRESENTS, THAT WE,<br />

THE PRINCIPALS AND SURETY<br />

Above mentioned are held and firmly bound unto the <strong>Municipal</strong> Commissioner , AMC, owner of<br />

the work of “SITC of Hydraulically operated Grit Mechanism with related Electrical work at E,<br />

E3, W & W5 Sites with One year of Operation & Maintenance Period for Sabarmati River<br />

Front Development <strong>Corporation</strong> Ltd. of Amdavad <strong>Municipal</strong> <strong>Corporation</strong>”, hereinafter called<br />

the "employer" in the amount stated for payment of which sum, well and truly to be made, we<br />

bind ourselves, our heirs, executors, administrators and successors jointly and severally, firmly<br />

by these presents subject to the provisions of which the aforesaid contract on demand and<br />

without demand on a claim being made by the "employer".<br />

THE CONDITION OF THIS OBLIGATION IS SUCH that whereas the principals herein after<br />

called contractor viz. have entered into a contract with the Employer numbered and dates as shown<br />

above and hereto attached for the execution of work.<br />

NOW THEREFORE, if the principal shall well and truly perform and fulfill all the under takings,<br />

covenants, terms, conditions and agreements, of said contract during the original terms of the said<br />

contract and any extensions thereof, they may be granted by the employer with or without notice to the<br />

surety and during the lift of any guarantee required under the contract and shall also well and truly<br />

perform, and fulfill all the undertakings, contract, terms, conditions and agreements of any and all duly<br />

authorized modifications of said contract that may hereafter be made, notice of which modifications to<br />

the surety being hereby waived or shall pay over, make good and reimburse to the employer all losses<br />

and damages which the employer may sustain by reason of failure or default on the part of said<br />

principal so to do.<br />

We _____________________________________________ further agree that guarantee herein<br />

contained shall remain in full force and affect during the period that would be taken for the validity<br />

_______________________ of the said contract and that it shall continue to be enforceable till all the<br />

dues of the employer under or by virtue of the contract have been fully paid and its claims satisfied of<br />

discharged or till the Employer certifies that the terms and conditions of the contract have been fully<br />

and properly carried out by the said contractor and accordingly discharges the guarantee. Unless a<br />

demand or claim under this guarantee is made on us in writing on or before the<br />

___________________________________________<br />

_____________________________________________ we shall be discharged from all liability under<br />

this guarantee thereafter.<br />

IN WITNESS WHEREOF the above bounded parties have executed this instrument under their<br />

several on the date indicated above the name and corporate seal of each corporate party being hereto<br />

affixed and these presents duly signed by its undersigned representative, pursuant to authority of its<br />

governing body.<br />

In the presence of witness Individual Principal<br />

1. as to (Seal)<br />

2. as to (Seal)<br />

3. as to (Seal)<br />

4. as to (Seal)<br />

39

Affix<br />

By Corporate Seal<br />

Attested Corporate Surety<br />

Business Address<br />

Affix<br />

By Corporate Seal<br />

Title<br />

For and on behalf of the employer<br />

40

SECTION: A-5:<br />

QUALIFICATION CRITERIA<br />

FOR TENDERER<br />

41

A – 5 : QUALIFICATION CRITERIA FOR TENDERERS<br />

A.5.1 Eligibility Criteria<br />

A.5.1.1 Qualification will be based on meeting all the following minimum pass/fail criteria<br />

regarding the bidder’s general and particular experience, personnel and equipment<br />

capabilities, and financial position, as demonstrated by the bidder’s responses in the forms<br />

attached (specific requirements for joint ventures are given under Para A.5.9 below). The<br />

bidder should be original manufacturer of Grit Mechanism / Authorized dealer of<br />

Grit Mechanism of approved make refer to the technical specifications, Make of<br />

Material). The AMC reserves the right to waive minor deviations, if they do not materially<br />

affect the capability of a bidder to perform the contract. Sub-contractor’s experience and<br />

resources shall not be taken into account in determining the bidder’s compliance with the<br />

qualifying criteria.<br />

A.5.2 General Experience<br />

A.5.2.1 The bidder shall meet the following minimum criteria:<br />

(1) The bidders shall have financial capability and having annual average turnover<br />

not less than value of Rs. 20, 00,000/- during last 3 years.<br />

(2) Execution of atleast one similar SITC work of an Amount of Rs.7,50,000<br />

Hydraulic type Grit Mechanism (Grab Bucket type) Mechanism with related<br />

electrical & civil work during last five years and in satisfactory operation for at<br />

least one year.<br />

A.5.3 Financial Position<br />

A.5.3.1 The audited balance sheets for the last three financial years should be submitted and must<br />

demonstrate the soundness of the bidder’s financial position, showing long-term<br />

profitability. Where necessary, the Employer will make enquiries with the bidder’s<br />

bankers.<br />

A.5.4 Litigation History<br />

A.5.4.1 The bidder should provide accurate information on any litigation history or arbitration<br />

resulting from contracts completed or under execution by him over the last ten years.<br />

This should also include such cases, which are in process/progress. A consistent history of<br />

awards against the bidder or any partner of a joint venture may result in failure of the bid.<br />

In case the bidder has not provided such information and has come to the notice of the<br />

Authority, the tender will be rejected at whatsoever stage and in such case all the losses<br />

that will arise out of this issue will be recovered from the tenderer/contractor and he<br />

will not have any defence for the same.<br />

A.5.5 Solvency Certificate : Not Applicable<br />

A.5.5.1 Solvency Certificate for all bidder of current financial year from the collector of the district<br />

within which he resides or a Banker’s Certificate. Minimum amount of solvency certificate<br />

shall be of an amount up to 20% of the tendered cost plus the amount of Works on hand still<br />

to be executed. This certificate shall be enclosed with Envelope “A”. If he fails to produce<br />

such certificate his tender will not be considered.<br />

42

A.5.5.2 Solvency certificate for successful bidder: It is mandatory for successful tenderer to submit<br />

the fresh solvency certificate (of an amount up to 20% of the tendered cost plus the amount<br />

of Works on hand still to be executed) of his financial stability from the collector of the<br />

district within which he resides or a Banker’s Certificate for the current financial year.<br />

A.5.6 Bidding Capacity: Not Applicable<br />

Even though the bidders meet the above criteria, they are subject to be rejected, if they<br />

have:<br />

• Made misleading or false representation in the form, statements and attachments<br />

submitted, false or hiding the value of work on hand, and / or<br />

• Record of poor performance such as abandoning the work, not properly completing<br />

the contract, inordinate delays in completion, litigation history, or financial failures<br />

etc.<br />

A.5.7 Personnel<br />

A.5.7.1 The bidder shall furnish the organization chart<br />

A.5.8 Equipment<br />

A.5.8.1 The Bidder should have own, or have assured access to (through hire, lease, purchase<br />

agreement, availability of manufacturing capacity or other means), for the following key<br />

items of equipment in full working order, and must demonstrate that, based on known<br />

commitments, they will be available for use in the proposed contract. The Bidder may also<br />

list alternative equipment which he would propose for the Contract, together with an<br />

explanation of the proposal.<br />

A.5.9 Joint Ventures – Not Applicable<br />

43

SECTION: B<br />

B-1: SPECIAL INSTRUCTIONS TO TENDERERS<br />

B-2: GENERAL CONDITIONS OF CONTRACT<br />

B-3: SCHEDULE - 'B'<br />

B-4: GENERAL INSTRUCTIONS<br />

B-5: ANNEXURES<br />

B-6: SCHEDULES<br />

44

Sr.<br />

No.<br />

CONTENTS<br />

Description Page No.<br />

B.1 Special instructions to tenderers 54<br />

B.1.1 Special instructions to persons tendering 55<br />

B.1.2 Additional Instructions to Persons Tendering 57<br />

B.1.3 Payment 57<br />

B.1.4 Declaration Form 58<br />

B.1.5 General Rules and Directions for the Guidance of Tenderers 58<br />

B.1.6 Tender for works 61<br />

B.2 General Conditions of Contract<br />

B.2.1 Clause – 1 63<br />

B.2.2 Clause – 2 63<br />

B.2.3 Clause – 3 64<br />

B.2.4 Clause – 4 64<br />

B.2.5 Clause – 5 65<br />

B.2.6 Clause – 6 65<br />

B.2.7 Clause – 7 65<br />

B.2.8 Clause – 8 66<br />

B.2.9 Clause – 9 66<br />

B.2.10 Clause – 10 66<br />

B.2.11 Clause – 11 67<br />

B.2.12 Clause – 12 67<br />

B.2.13 Clause – 13 68<br />

B.2.14 Clause – 14 69<br />

B.2.15 Clause – 15 69<br />

B.2.16 Clause – 16 70<br />

B.2.17 Clause – 17 70<br />

B.2.18 Clause – 18 71<br />

B.2.19 Clause – 19 72<br />

B.2.20 Clause – 20 72<br />

B.2.21 Clause – 21 72<br />

B.2.22 Clause – 22 73<br />

B.2.23 Clause – 23 73<br />

B.2.24 Clause – 24 73<br />

45

Sr.<br />

No.<br />

Description Page No.<br />

B.2.25 Clause – 25 73<br />

B.2.26 Clause – 26 73<br />

B.2.27 Clause – 27 74<br />

B.2.28 Clause – 28 74<br />

B.2.29 Clause – 29 74<br />

B.2.30 Clause – 30 74<br />

B.2.31 Clause – 31 75<br />

B.2.32 Clause – 32 75<br />

B.2.33 Clause – 33 76<br />

B.2.34 Clause – 34 76<br />

B.2.35 Clause – 35 76<br />

B.2.36 Clause – 36 76<br />

B.2.37 Clause – 37 76<br />

B.2.38 Clause – 38 77<br />

B.2.39 Clause – 39 77<br />

B.2.40 Clause – 40 77<br />

B.2.41 Clause – 41 77<br />

B.2.42 Clause – 42 77<br />

B.2.43 Clause – 43 77<br />

B.2.44 Clause – 44 78<br />

B.2.45 Clause – 45 78<br />

B.2.46 Clause – 46 78<br />

B.2.47 Clause – 47 79<br />

B.2.48 Clause – 48 79<br />

B.2.49 Clause – 49 79<br />

B.2.50 Clause – 50 79<br />

B.2.51 Clause – 51 79<br />

B.2.52 Clause – 52 79<br />

B.2.53 Clause – 53 79<br />

B.2.54 Clause – 54 80<br />

B.2.55 Clause – 55 80<br />

B.2.56 Clause – 56 80<br />

B.2.57 Clause – 57 83<br />

B.2.58 Clause – 58 83<br />

B.2.59 Clause – 59 83<br />

46

Sr.<br />

No.<br />

Description Page No.<br />

B.2.60 Clause – 60 83<br />

B.2.61 Clause – 61 83<br />

B.2.62 Clause – 62 83<br />

B.2.63 Clause – 63 84<br />

B.2.64 Clause – 64 84<br />

B.2.65 Clause – 65 84<br />

B.2.66 Clause – 66 85<br />

B.2.67 Clause – 67 85<br />

B.2.68 Clause – 68 85<br />

B.2.69 Clause – 69 85<br />

B.2.70 Clause – 70 85<br />

B.2.71 Clause – 71 85<br />

B.2.72 Clause – 72 86<br />

B.2.73 Clause – 73 87<br />

B.2.74 Clause – 74 87<br />

B.2.75 Clause – 75 87<br />

B.2.76 Clause – 76 87<br />

B.2.77 Clause – 77 87<br />

B.2.78 Clause – 78 87<br />

Annexure – 1 88<br />

B.3 Schedules<br />

Schedules – A 90<br />

Schedules – B 91<br />

B.4 General instructions 93<br />

B.5 Annexures<br />

B.5.A Rules for grant of advance against machinery etc. (Deleted) 96<br />

B.5.B Rules for grant of mobilization advance (Deleted) 97<br />

B.5.C Cause for Arbitration (Deleted) 98<br />

B.5.D Price escalation (Deleted) 99<br />

B.5.E Liquidated damages 100<br />

B.5.F Star Rate (Deleted) 101<br />

B.6 Schedules<br />

Schedules 103<br />

47

SECTION: B-1<br />

SPECIAL INSTRUCTIONS TO TENDERERS<br />

48

SECTION – B: GENERAL CONDITIONS OF CONTRACT<br />

B – 1: SPECIAL INSTRUCTIONS TO TENDERERS (FORM B – 2)<br />

AMDAVAD MUNICIPAL CORPORATION<br />