Koornfontein Mines achieves 1,000,000 fatality-free ... - Optimum Coal

Koornfontein Mines achieves 1,000,000 fatality-free ... - Optimum Coal

Koornfontein Mines achieves 1,000,000 fatality-free ... - Optimum Coal

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Autumn 2011

Contents<br />

2<br />

Optimizer Autumn 2011<br />

Editor’s notE<br />

Hello everyone!<br />

Welcome to the Autumn 2011 edition of the optimizer. this year is a momentous one for<br />

optimum <strong>Coal</strong> history: as a team we have much to celebrate and be proud of.<br />

Look out for our CEO’s message on the opposite page to learn more about our group performance.<br />

This is an important year for <strong>Optimum</strong> <strong>Coal</strong> with regards to new appointments – see pages 4, 5 and 18 for<br />

all the news.<br />

This year the <strong>Optimum</strong> <strong>Coal</strong> brand has received some prestigious accolades in the mining industry. Read<br />

about it on page 9. If you turn to pages 12, 13 and 14, you can read about <strong>Optimum</strong> Collieries’ safety achievements<br />

and the hard work and dedication from the <strong>Koornfontein</strong> team is evident on page 13.<br />

Please don’t forget that you really do not have to be a famous author to submit interesting information or<br />

news. Merely send the basics to me and I will rewrite it into a readable article.<br />

Thank you for your support! Keep your contributions coming in. Without you the Optimizer would not be<br />

as great as it is.<br />

Joyce<br />

Editor: Joyce Packery • Tel: +27 13 296 5025 • Email: joyce.packery@optimumcoal.com<br />

Typeset and designed by: Artworks Communications<br />

Optimizer is produced and published on behalf of <strong>Optimum</strong> <strong>Coal</strong>. All contributions to this publication are welcome and may be submitted to the editor.<br />

The contents of this publication do not necessarily reflect the views of <strong>Optimum</strong> <strong>Coal</strong>. No part of this publication may be reproduced or transmitted in any form<br />

or by any means without permission in writing from the editor.<br />

LEADERSHIP SPEAKS 3<br />

Mike’s message 3<br />

Mining flexibility and optimisation 4<br />

Vik Cogho speaks 5<br />

EMPOWERMENT 6<br />

<strong>Optimum</strong> <strong>Coal</strong> delivers last set of houses to community members 6<br />

<strong>Optimum</strong> <strong>Coal</strong> ends 18-month long water restrictions 7<br />

Tree planting at Cosmos Community Hall 8<br />

<strong>Optimum</strong> <strong>Coal</strong> hosts bursars for breakfast 8<br />

Award for Outstanding Contribution Towards Community Empowerment 9<br />

Award for most improved CsI Projects 9<br />

<strong>Optimum</strong> <strong>Coal</strong> hands over multi-purpose community centre 10<br />

AUDIT & VISIT 11<br />

<strong>Optimum</strong> Collieries’ Management system Audit 11<br />

Barnstone Outsourcing services visits <strong>Optimum</strong> <strong>Coal</strong> 11<br />

SAfETy 12<br />

Well done to the Kwagga section for achieving 600 safety weeks! 12<br />

<strong>Koornfontein</strong> <strong>Mines</strong>: 1,<strong>000</strong>,<strong>000</strong> <strong>fatality</strong>-<strong>free</strong> shifts 13<br />

sizing screen facility commissioned 13<br />

Going the extra mile 14<br />

600 incident-<strong>free</strong> weeks 14<br />

Boschmanspoort Lamproom Achievement 14<br />

TRAININg 15<br />

<strong>Optimum</strong> <strong>Coal</strong> CEO inspires future mining engineers at Wits 15<br />

KWAggA NORTH PROJECT 16<br />

Kwagga North Project begins to take shape 16<br />

MOVERS AND SHAKERS 17<br />

The newly appointed Chief Project Development Officer 17<br />

Vincent Molekoa: Learning is a never-ending process 18<br />

New sACAFMA President 18<br />

<strong>Optimum</strong> <strong>Coal</strong> graduates shine 18<br />

EMPLOyEE CORNER 19<br />

Promotions, new employees and obituaries 19<br />

Invention improves reception 19<br />

Best plate welder recognised 20<br />

storing waste responsibly 20<br />

HEALTH 21<br />

Zero tolerance for drug and alcohol use 21<br />

Employee wellness – Careways Group 21<br />

Empower yourself: know your status! 22

Focusing on improved<br />

I<br />

began writing this message in early June and<br />

as you all know, that is the last month of our<br />

financial year. We have not delivered on all our<br />

commitments and this makes our work difficult<br />

as we reflect on the financial year and prepare to<br />

face the new one. <strong>Optimum</strong> Collieries still faces the<br />

challenge of not achieving its targets where <strong>Koornfontein</strong><br />

<strong>Mines</strong> is performing greatly. However, this<br />

should in no way be viewed as a comparison of the<br />

two operations.<br />

One is inclined to enquire as to what needs to<br />

be done to improve or turn around the performance<br />

of <strong>Optimum</strong> Collieries.<br />

The executive team attended a leadership<br />

session on 13 and 14 June in Johannesburg and<br />

the focus was to align leadership and develop a plan<br />

of action to improve the performance of our business.<br />

Reality is that our performance is not what it<br />

should be at <strong>Optimum</strong> Collieries and several areas<br />

of improvement are being looked at to start the new<br />

financial year with the key focus being on improved<br />

performance. Fact is, we have not delivered on our<br />

LEADERsHIP sPEAKs<br />

performance this financial year<br />

safety, Tons and Cost Management, and we cannot<br />

continue with this trend.<br />

We must all realise that we will only build a<br />

great future at <strong>Optimum</strong> <strong>Coal</strong> Holdings by working<br />

together as a team and I am depending on all of<br />

you to be part of this turnaround. several areas of<br />

our business will need focused attention and these<br />

include:<br />

• Productivity efficiencies (open cast and underground);<br />

• <strong>Coal</strong> processing and logistics (Eskom and TFR)<br />

• Cost containment<br />

• Delivery on our approved budget targets.<br />

Beyond the performance improvements at <strong>Optimum</strong><br />

Collieries, you will notice that we continue to proactively<br />

manage our projects and so far we have<br />

made some progress and acquired TNC, which is<br />

an important resource close to <strong>Koornfontein</strong> <strong>Mines</strong>.<br />

This resource will assist us in extending the high<br />

value product life at <strong>Koornfontein</strong> <strong>Mines</strong>, which will<br />

come to an end around 2015.<br />

I request that you all support our new Chief<br />

Operating Officer, Rian du Plooy, who will join our<br />

three General Managers on 1 July this year, namely<br />

Percival Khoza (Mining), Fanie De Waal (Processing<br />

Logistics and Engineering), and Vik Cogho (services).<br />

<strong>Koornfontein</strong> <strong>Mines</strong> is still led by Piet steyn.<br />

Who are we?<br />

• An empowered team capable of harnessing<br />

each other’s talents;<br />

• A diverse team driven by respect and the ability<br />

to harness quality relationships;<br />

• A purpose driven team that thrives on the<br />

achievements of its people and business goals;<br />

• A team that embraces a simple and clean<br />

business approach.<br />

To reiterate, I depend on your support to fulfill the<br />

above as the experienced team that you are.<br />

Mike teke<br />

Chief Executive Officer

4<br />

LEADERsHIP sPEAKs<br />

Mining flexibility and optimisation<br />

Percival Khoza takes leaders and their teams on a roadshow<br />

Percival Khoza, newly appointed <strong>Optimum</strong><br />

Collieries’ General Manager of Mining, took<br />

the mining leaders and their teams from<br />

across <strong>Optimum</strong> Collieries sites on a roadshow,<br />

presenting slides on <strong>Optimum</strong> Collieries mining<br />

status quo. The presentation focused on sigificant<br />

incidents, dragline prime per area, ROM per area,<br />

saleable tonnes per employee, exceeding budget<br />

exposure and extraction within the cost allocation.<br />

The road shows gave the mining teams an<br />

opportunity to share their concerns, comments,<br />

Optimizer Autumn 2011<br />

learnings and contributions, as well as an opportunity<br />

to interact with the General Manager and receive<br />

management recognition for their efforts.<br />

“It doesn’t matter how tough economic times<br />

are,” said Percival. “One thing we will always<br />

stand firm on is that we will increase production<br />

and exceed our production targets at <strong>Optimum</strong><br />

Collieries. There are some difficult times ahead, but<br />

through hard work and team work, I know that we<br />

can emerge from a dark tunnel not only intact, but<br />

also stronger and faster.”<br />

Percival ended the road show presentations by<br />

thanking the mining teams for the upfront support<br />

on the implementation of Productivity Improvement<br />

Teams, which will assist to safely deliver the expit<br />

coal to the belts and tip stockpiles at minimal operating<br />

unit costs in a sustainable manner.<br />

He also believes that visible field leadership,<br />

employee consultation, engagement and empowerment<br />

are key to ensuring the sustainable success of<br />

<strong>Optimum</strong> Collieries.<br />

Percival Khoza handing over an award to<br />

Johannes Mtsweni, RD Operator at Kwagga<br />

section as a token of appreciation for applying<br />

the principle of effective utilisation as an<br />

operator.

We can work harder this<br />

LEADERsHIP sPEAKs<br />

year to deliver on our targets<br />

Dr Vik Cogho, newly appointed <strong>Optimum</strong> Collieries’ General Manager services<br />

once again a challenging financial year has drawn to a close.<br />

Although production improved this year compared to FY10, very<br />

few of the mine’s KPi’s were met, which is very disappointing.<br />

this means that we will have to work harder to achieve our best.<br />

Of serious concern is FY11’s safety performance: 63 of our employees<br />

were hurt performing operational activities. To date, 13 lost time,<br />

16 needed medical treatment and 34 suffered first-aid injuries,<br />

something we cannot be proud of.<br />

Caring and providing a safe work environment for the <strong>Optimum</strong> Collieries<br />

employees and surrounding communities is of paramount importance to the<br />

business and is core to its values. <strong>Optimum</strong> Collieries will continue to strive to<br />

eradicate all work-related injuries to ensure the well-being of all its employees<br />

and the surrounding communities.<br />

The development of the Asiphephe III programme is complete and the<br />

process of appointing and training the necessary course facilitators has begun.<br />

It is anticipated that the Asiphephe III programme will effectively kick off in the<br />

new financial year. I trust that this programme will assist all our employees,<br />

including contractors, to improve on the FY11 situation.<br />

The main sources of occupational exposures are associated with coal dust,<br />

silica and noise. In addition to these are significant employee and communityrelated<br />

risks such as HIV/AIDs, hypertension and diabetes, and are managed<br />

pro-actively on a continuous basis.<br />

<strong>Coal</strong> dust levels at the Boschmanspoort underground mine have improved<br />

during the reporting period as a result of continual focus and the completion<br />

of the second main fan to improve ventilation in the mining area.<br />

Noise is monitored on an ongoing basis. Of note in this regard is the<br />

full compliance with respect to the 105 dB threshold. Noise-induced hearing<br />

loss and tuberculosis account for the majority of occupational illnesses. The<br />

company will continue to strive to significantly reduce occupational illnesses<br />

among its employees.<br />

Monitoring of non-occupational illnesses is also ongoing and focuses<br />

primarily on hypertension and diabetes. Medicine management systems are in<br />

place to ensure that employees use their medications as prescribed. The mine’s<br />

clinic is also in the process of assisting with TB awareness programmes.<br />

striving towards ‘Zero Harm’ remains core to the company’s business ethic<br />

and will continue to do so. It is imperative that leadership and all employees<br />

Striving towards ‘Zero Harm’ remains core to<br />

the company’s business ethic and will continue<br />

to do so. It is imperative that leadership and all<br />

employees drive this on an ongoing basis through<br />

active participation on the floor level.<br />

drive this on an ongoing basis through active participation on the floor level. With<br />

this in mind, I urge all employees and contractors to hold on to the company’s<br />

guiding principles of safety, Tons and Cost. In doing so, we as a collective, will<br />

ensure that <strong>Optimum</strong> Collieries goes from strength to strength.<br />

Optimizer Autumn 2011 5

optimum <strong>Coal</strong> delivers last set of<br />

houses to community members<br />

6<br />

EMPOWERMENT<br />

optimum <strong>Coal</strong> CEo Mike teke, in partnership<br />

with the steve tshwete Local Municipality,<br />

handed over houses to the last rockdale<br />

Farm beneficiaries on 13 May 2011.<br />

In 2005, a portion of the Rockdale farm was<br />

purchased by the Nkangala District Municipality<br />

from Kanhym Estates. The steve Tshwete Local<br />

Municipality established a township on the land,<br />

earmarking 3 <strong>000</strong> stands for an integrated housing<br />

development. In september 2009, the steve Tshwete<br />

Local Municipality and <strong>Optimum</strong> <strong>Coal</strong> came to an<br />

agreement, and construction began in May 2010.<br />

The colourful two and three bedroom units<br />

include an open plan lounge and kitchen area with<br />

hot-water geysers and showers. The units for disabled<br />

citizens have been fitted with wider door frames,<br />

lowered light switches, wheelchair ramps and balustrades.<br />

The houses are also fully electrified. In the<br />

long-term, the stands will be greened in conjunction<br />

with the municipality’s horticultural department. The<br />

land is located in close proximity to an industrial<br />

area, making job opportunities for residents more<br />

accessible.<br />

At completion, the area will be a fully-fledged<br />

township with all the necessary amenities. The municipality<br />

is installing bulk services for water and sanitation<br />

infrastructure with assistance from the Nkangala<br />

District Municipality.<br />

The housing beneficiaries represent senior and<br />

disabled citizens – 82 residents are pensioners and<br />

18 are living with disabilities. Ninety-one year-old<br />

Letta skosana is one of these beneficiaries who<br />

has been living at the settlement since February<br />

2011. Letta has 13 children, including her disabled<br />

daughter Elinah skosana, who owns a separate<br />

house in the township. The project has made<br />

a significant improvement to her and her children’s<br />

living conditions and dignity.<br />

Optimizer Autumn 2011<br />

Councillor Mantlhakeng Mahlangu, Executive Mayor of Steve Tshwethe Local Municipality with one<br />

of the fortunate beneficiaries, Letta Skosana, and <strong>Optimum</strong> <strong>Coal</strong> CEO Mike Teke.<br />

Councillor Mantlhakeng Mahlangu, Executive Mayor of Steve Tswethe Local Municipality and Mike<br />

Teke, <strong>Optimum</strong> <strong>Coal</strong> CEO, cut the ribbon to open the last set of houses that were delivered to the<br />

beneficiaries.

optimum <strong>Coal</strong> recently kept Hendrina<br />

and KwaZamokuhle communities from<br />

prolonged water restrictions and a cap<br />

on further development by supplying the<br />

Hendrina Water reservoir with potable<br />

water from the Water reclamation Plant.<br />

<strong>Optimum</strong> <strong>Coal</strong> built and commissioned the<br />

<strong>Optimum</strong> <strong>Coal</strong> Water Reclamation Plant at a<br />

cost of R600 million with an average flow of<br />

15 million kilolitres a day. The plant will assist with<br />

the sustainable management of surplus affected water<br />

needs for the next 22 years and beyond mine closure.<br />

<strong>Optimum</strong> <strong>Coal</strong> was recently delegated as a water<br />

service provider for the Hendrina and KwaZamokuhle<br />

communities and will supply three million kilolitres<br />

of potable water a day to these communities via the<br />

municipal water reservoir.<br />

To celebrate this momentous occasion, a ribbon<br />

cutting ceremony was held at the Hendrina water reservoir<br />

by Councillor Mantlhakeng Mahlangu, Percival<br />

Khoza (General Manager of Mining at <strong>Optimum</strong><br />

Collieries), sibongile shongwe (Group Transformation<br />

Manager at <strong>Optimum</strong> <strong>Coal</strong>) and Xolani Lwandle<br />

(General Manager designate of <strong>Koornfontein</strong> <strong>Mines</strong>).<br />

speaking at the event Councillor<br />

Mahlangu said: “We would like<br />

to thank optimum <strong>Coal</strong> for going<br />

beyond the extra mile in their<br />

social responsibilities. today we<br />

officially hand over the plant to the<br />

community of Hendrina, which will<br />

ensure the community of highly<br />

purified drinking water”.<br />

The residents from Hendrina and KwaZamokuhle,<br />

were the first beneficiaries to receive potable water<br />

from the <strong>Optimum</strong> <strong>Coal</strong> Water Reclamation Plant.<br />

EMPOWERMENT<br />

<strong>Optimum</strong> <strong>Coal</strong> ends 18-month long water restrictions<br />

Percival Khoza, General Manager of Mining at <strong>Optimum</strong> Collieries, Executive Mayor of the Steve<br />

Tshwete Local Municipality, Mantlhakeng Mahlangu, and Xolani Lwandle, General Manager designate<br />

of <strong>Koornfontein</strong> <strong>Mines</strong> celebrate the commencement of water supply from the <strong>Optimum</strong> <strong>Coal</strong><br />

Water Reclamation Plant to the Hendrina and KwaZamokuhle communities.<br />

Hendrina Water Reservoir.<br />

Optimizer Autumn 2011 7

8<br />

EMPOWERMENT<br />

tree planting at Cosmos Community Hall<br />

A tree planting ceremony held at the Hendrina Cosmos Community Hall was attended by the<br />

General Manager of Mining at optimum Collieries Percival Khoza, and the General Manager<br />

designate of <strong>Koornfontein</strong> <strong>Mines</strong> Xolani Lwandle, accompanied by the Executive Mayor<br />

of steve tshwete Local Municipality, Mantlhakeng Mahlangu.<br />

<strong>Optimum</strong> <strong>Coal</strong> recently donated R5 million<br />

to restore and renovate Hendrina Cosmos<br />

Community Hall as part of its social and<br />

Labour Plan (sLP) commitment to improve social<br />

infrastructure in the communities in which it operates.<br />

<strong>Optimum</strong> <strong>Coal</strong> CEO Mike Teke offered university<br />

study bursaries on behalf of <strong>Optimum</strong> <strong>Coal</strong> to<br />

12 hard-working learners from the steve Tshwete<br />

Local Municipality, and recently hosted them for<br />

breakfast. The top achievers in the group were:<br />

• Bongani sibanyoni: 100% in Mathematics and<br />

99% in Physical science. He will study Mechanical<br />

Engineering at the University of Witwatersrand.<br />

• sthembiso Hlatshwayo: 97% in Mathematics<br />

and 94% in Physical science. He will study<br />

Metallurgical Engineering at the University of<br />

Pretoria.<br />

• thulani Mahlangu: 93% in Mathematics<br />

and 83% in Physical science. He will study<br />

Mechanical Engineering at the University of<br />

Witwatersrand.<br />

• nomusa Mnguni: 91% in Mathematics and<br />

82% in Physical science, studying Electrical<br />

Engineering at the University of Cape Town.<br />

Optimizer Autumn 2011<br />

Councillor Mahlangu expressed her sincere<br />

gratitude for the outstanding contribution <strong>Optimum</strong><br />

<strong>Coal</strong> is making towards the local communities and<br />

the company’s sustainable way of doing business<br />

within its areas of operation.<br />

Left: The structure of Cosmos Community Hall.<br />

Xolani Lwandle rolled up his sleeves to plant the<br />

first tree.<br />

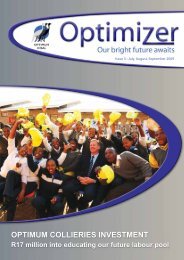

optimum <strong>Coal</strong> hosts bursars for breakfast<br />

• richmond nurthy: 90% in Mathematics and<br />

90% in Physical science, studying Mining Engineering<br />

at the University of Pretoria.<br />

The rest of the bursars boast a combination of<br />

achievements of B plus in English, Mathematics, and<br />

Physical science. Their fields of studies include Business<br />

and Management studies, Engineering, Medical<br />

sciences and Engineering sciences.<br />

What makes these learners’ achievement exceptional<br />

is that they beat all odds and succeeded<br />

despite their historically disadvantaged schools<br />

and backgrounds. The bursars were sourced from<br />

Mphanama, sofunda and Eastdene schools.<br />

some learners came through <strong>Optimum</strong> <strong>Coal</strong>’s<br />

flagship Maths and science Programme sponsored<br />

through the Corporate, social and Investment section.<br />

This programme has yielded notable improvements<br />

in the results of the broader community of learners<br />

within the steve Tshwete Local Municipality.<br />

<strong>Optimum</strong> <strong>Coal</strong> CEO Mike Teke and the bursars<br />

after the breakfast session.<br />

The beneficiary schools saw improvements in<br />

both subject average and pass rates, which were<br />

better than the Mpumalanga provincial pass rate and<br />

national average. <strong>Optimum</strong> <strong>Coal</strong> is proud to be associated<br />

with these learners and their bright future.

The Black Management Forum<br />

Mpumalanga recently hosted<br />

a corporate social investment<br />

dinner and award ceremony at<br />

Emalahleni/Witbank.<br />

During the event, <strong>Optimum</strong> <strong>Coal</strong><br />

was recognised for achieving the Most<br />

Improved Corporate social Investment<br />

Projects in 2010.<br />

Congratulations to all involved<br />

in making CsI decisions and<br />

availing resources to this socioeconomic<br />

development imperative.<br />

EMPOWERMENT<br />

Award for Outstanding Contribution<br />

Towards Community Empowerment<br />

<strong>Optimum</strong> <strong>Coal</strong> was given a special award<br />

for its outstanding contribution towards<br />

community empowerment during the<br />

Mayoral Awards ceremony on 14 April 2011.<br />

This is a clear indication that <strong>Optimum</strong> <strong>Coal</strong><br />

places a high priority on assisting the communities<br />

it operates in.<br />

The special award certificate (above) and the award trophy (left).<br />

Most improved Csi Projects<br />

The BMF trophy.<br />

Optimizer Autumn 2011 9

The residents of the Hlalanikahle community have expressed their need for a multipurpose community centre for over ten years. In partnership with the<br />

Emalahleni Municipality, <strong>Optimum</strong> <strong>Coal</strong> responded to build a centre that will serve as a central meeting place for all Hlalanikahle residents in the future.<br />

optimum <strong>Coal</strong> hands over multi-purpose centre<br />

optimum <strong>Coal</strong> CEo Mike teke handed over<br />

the r4.2 million Hlalanikahle Multi-purpose<br />

Community Centre to the Emalahleni Executive<br />

Mayor, Lesley nhlapo.<br />

Hlalanikahle Community Centre is<br />

a visible example of <strong>Optimum</strong> <strong>Coal</strong>’s<br />

“The<br />

commitment to operate mindfully<br />

within the communities where we conduct business,”<br />

said Mike.<br />

Hlalanikahle, a proclaimed township and a<br />

subset of Kwa-Guga Township in Emalahleni, 15 km<br />

west of the town centre, has an estimated population<br />

of 45 <strong>000</strong>.<br />

The centre was designed following a detailed<br />

beneficiary needs assessment. The centre can seat<br />

approximately 500 people in a table setting format<br />

for banquets or wedding receptions and comprises<br />

separate female and male ablution facilities, a ticket<br />

booth or pay-point facility, a kitchen, a change room<br />

and indoor sporting facility. The centre has been<br />

designed to optimise the use of natural light, and<br />

make provision for the disabled.<br />

“It was also decided to add a separate car wash<br />

facility to the project to increase the sustainability<br />

of the centre, and the quality of life of community<br />

members. The washing bay will act as a job<br />

creation stimulus with women and adolescents<br />

10<br />

Optimizer Autumn 2011<br />

From L-R: <strong>Optimum</strong> <strong>Coal</strong> CEO Mike Teke, unveils the plaque of the R4.2 million Hlalanikahle Multipurpose<br />

Community Centre. From left to right is Willem Heyneke, Ndumi Khoza, Rowan Karstel,<br />

Clr Lindiwe Ntshalintshali, Executive Mayor of Emalahleni Local Municipality Lesley Nhlapo and<br />

<strong>Optimum</strong> <strong>Coal</strong> CEO Mike Teke.<br />

being the main beneficiaries,” stated Human<br />

Resources Manager at <strong>Optimum</strong> Colliery, Johnny<br />

Makhale.<br />

This infrastructure investment will add value to<br />

the Hlalanikahle community in a long-term and practical<br />

manner.

Preparing for optimum<br />

Collieries’ Management<br />

system External Audit<br />

Employees at <strong>Optimum</strong> Collieries are busy preparing for the<br />

forthcoming <strong>Optimum</strong> Management system external audit<br />

which is scheduled for 27 to 30 June this year.<br />

During the audit, 1sO 1400 (environment), IsO 9001 (quality)<br />

and OHsAs 18001 (safety) will be measured and rated for IsO<br />

certification.<br />

The HsECQ initiatives are measured annually in order to verify<br />

that there is progress towards meeting set targets.<br />

<strong>Optimum</strong> <strong>Coal</strong>’s HsECQ policy sets the foundation for our<br />

actions and guides us in what we do and how we do it.<br />

Barnstone outsourcing services visits <strong>Optimum</strong> <strong>Coal</strong><br />

On 9 February 2011 consultants from <strong>Optimum</strong> sAP support provider,<br />

Barnstone Outsourcing services, paid <strong>Optimum</strong> <strong>Coal</strong> a visit. This gave<br />

them a much needed insight into the <strong>Optimum</strong> <strong>Coal</strong> operation and its business<br />

processes. The day was spent going through the current support processes and<br />

procedures with the <strong>Optimum</strong> <strong>Coal</strong> sAP process owners and super users, in<br />

order to ensure that the best possible service is rendered when it comes to sAP<br />

and its daily operation.<br />

The day was closed off with a visit to the dragline which was<br />

definitely a highlight, thanks to the arrangements of Anton Victor and his crew,<br />

as well as Kate and Alma for the logistical arrangements.<br />

The Barnstone team thanked <strong>Optimum</strong> <strong>Coal</strong> for the opportunity to see how<br />

the company operates behind the scenes, and to enrich their knowledge of the<br />

daily operations at <strong>Optimum</strong> <strong>Coal</strong>.<br />

Michael Calitz, Group IT Manager <strong>Optimum</strong> <strong>Coal</strong> with the Barnstone team.<br />

Optimizer Autumn 2011 11

12<br />

sAFETY<br />

Well done to the Kwagga section<br />

for achieving 600 safety weeks!<br />

Congratulations to the Kwagga section team for achieving 600 safety<br />

weeks! Andre Van Wyk, Mine Manager at the Kwagga section and his<br />

team are very proud and believe that everybody is not only responsible<br />

for their own safety, but also for the safety of their colleagues. Always apply<br />

Optimizer Autumn 2011<br />

four steps to safety to work safely not only at work, but also at home. The<br />

team have safety and production meetings on a weekly basis to makesure<br />

they demonstrate commitment and support the leadership of <strong>Optimum</strong> <strong>Coal</strong><br />

in growing the business.<br />

Andre Van Wyk and his proud team (top is B shift, above is C shift).

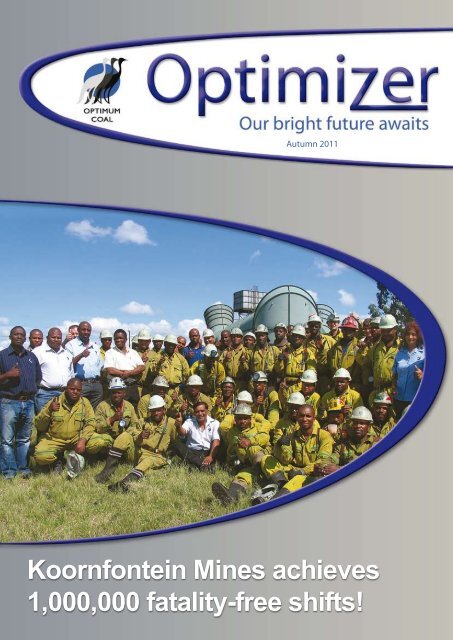

The <strong>Koornfontein</strong> <strong>Mines</strong>’ team achieved 1,<strong>000</strong>,<strong>000</strong> <strong>fatality</strong> <strong>free</strong> shifts during the month of January 2011.<br />

1,<strong>000</strong>,<strong>000</strong> <strong>fatality</strong>-<strong>free</strong> shifts<br />

<strong>Koornfontein</strong> <strong>Mines</strong>’ team was recognised for<br />

their 1,<strong>000</strong>,<strong>000</strong> <strong>fatality</strong>-<strong>free</strong> production shifts<br />

at the <strong>Coal</strong>safe in March 2011. <strong>Koornfontein</strong> <strong>Mines</strong><br />

employees take their commitment seriously and<br />

strive to improve safety through numerous initiatives,<br />

with the primary focus being changing behaviour.<br />

This is an indication that Zero Harm is not a<br />

dream – it is a reality and it is achievable. It is a great<br />

achievement; your efforts are much appreciated.<br />

Congratulations and well done.<br />

Sizing screen facility commissioned<br />

sAFETY<br />

Zero Harm is not a dream –<br />

it is a reality and it is<br />

achievable.<br />

sizing screen facility was successfully commissioned at <strong>Koornfontein</strong> plant<br />

A at the beginning of January 2011. The 300 tonne per hour plant, which was<br />

designed and constructed over a period of four months, was built in order to take<br />

advantage of the inland demand for export grade sized coal.<br />

The screening facility contains a large number of components,<br />

most notably the Dabmar screen obtained from the recently demolished<br />

Eikeboom washing and screening plant, in order to minimise costs. Close<br />

co-operation took place between the project teams of <strong>Optimum</strong> Collieries and<br />

<strong>Koornfontein</strong> <strong>Mines</strong> and the plant is currently supplying enough pea coal to<br />

satisfy its inland customers.<br />

Optimizer Autumn 2011<br />

13

14<br />

sAFETY<br />

Optimizer Autumn 2011<br />

Kwagga section Overland Engineering supervisor<br />

Martin Coetzee (right) and RD Operator at<br />

Pullenshope simon Mashabela (left), were recently<br />

honoured for going beyond their job descriptions.<br />

The awards were presented by Fanie de Waal, GM<br />

Engineering Process and Projects <strong>Optimum</strong> Collieries<br />

during the Leadership Forum meetings recently.<br />

Martin<br />

During the latter part of December when many of his<br />

co-workers were on leave, Martin persevered under challenging<br />

circumstances and managed the conveyor belt<br />

infrastructure superbly.<br />

On many occasions, Martin placed the interest of the<br />

company above his own. Martin ensured belt availabilities<br />

were excellent, and never complained when faced with<br />

adversity.<br />

simon<br />

Simon Mashabela.<br />

simon saved a colleague and an RD machine from burning by<br />

using a fire extinguisher to put out the fire.<br />

Martin Coetzee.<br />

600<br />

incident-<strong>free</strong><br />

weeks<br />

Well done to the Bypass Plant team for<br />

achieving 600 weeks without incidents.<br />

Going the extra mile<br />

Boschmanspoort Lamproom Achievement!<br />

floating trophy for the best lamproom in the<br />

A Witbank/Emalahleni area was awarded to<br />

<strong>Optimum</strong> Collieries’ Boschmanspoort section.<br />

The lamproom team attributed the<br />

excellent perfomance to good teamwork and<br />

excellent support from management.<br />

From L-R: Maxwell Nksosi, Mduduzi Ngwenya,<br />

Millicent Mahlangu and Thokozani Skhosana.

optimum <strong>Coal</strong> CEo inspires<br />

future mining engineers at Wits<br />

CEo of optimum <strong>Coal</strong> Mike teke shared<br />

optimum <strong>Coal</strong>’s views on the future of<br />

mining in south Africa with Wits mining<br />

engineering students at a university event<br />

in May.<br />

<strong>Optimum</strong> <strong>Coal</strong> began, it<br />

was never the intention to be<br />

“When<br />

an impersonal coal-producing<br />

mining company,” said Mike. “<strong>Optimum</strong> <strong>Coal</strong> is a<br />

people business, with the well-being of its people<br />

and the integrity of its leadership at the heart. We<br />

are starting to deliver the vision of prosperity that<br />

we created two years ago. We will continue to create<br />

wealth, not only for our shareholders but also for<br />

our employees and communities and south Africa<br />

as a whole”.<br />

<strong>Optimum</strong> <strong>Coal</strong> brought about true broad-based<br />

black economic empowerment through the establishment<br />

of its two trusts. Mike went on to elaborate<br />

on the benefit <strong>Optimum</strong> <strong>Coal</strong> is spreading beyond<br />

its own bottom-line: sustainable development<br />

programmes continue to weave its business footprint<br />

into the communities of the steve Tshwete<br />

Local Muncipality in an integrated manner.<br />

Mike explained that the key strategic focus areas<br />

for sustainable initiatives are education, health,<br />

social infrastructure development and enterprise<br />

development.<br />

“<strong>Optimum</strong> <strong>Coal</strong> does not operate in isolation<br />

from its communities and the environment and<br />

in the past year, the sustainability of its affected<br />

communities remained a key business imperative<br />

for the group. This will continue to be the case for<br />

the future”, he stated.<br />

“<strong>Optimum</strong> <strong>Coal</strong> is driven by its vision to become<br />

south Africa’s leading empowerment company in<br />

the mining sector”.<br />

TRAINING<br />

From L-R: Dr Cuthbert Musingwini from the Wits School of Mining Engineering, together with<br />

<strong>Optimum</strong> <strong>Coal</strong> CEO Mike Teke and Makete Thema, Chairman of the Student Mining Engineering<br />

Society (SMES). Mike addressed more than 100 enthusiastic mining engineering students from the<br />

Wits School of Mining Engineering on Mine Managers Day.<br />

Mike’s inspirational presentation focused on the importance of one’s attitude in business. The<br />

students were literally sitting at the edge of their seats as Mike gave them five important tips to<br />

consider when entering the mining world one day.<br />

Optimizer Autumn 2011 15

16<br />

KWAGGA NORTH PROJECT<br />

Kwagga North Project taking shape<br />

the main conveyor system, which will<br />

cost r741 million, should be completed<br />

by december 2012 and the surge capacity<br />

bunkers by April 2012.<br />

530 m 3 transfer bin to control coal flow to the<br />

bunkers and overland.<br />

Concrete works are complete for the rotary<br />

breaker, and it should be installed by mid July<br />

2011. It will ensure that the maximum size of<br />

ROM on the conveyor system is 140 mm and it<br />

will separate rock from the coal ROM product.<br />

Material will move from Kwagga North mining<br />

area to the new ROM tip, and will be used for<br />

filling. A total of 360 <strong>000</strong> cubes are required.<br />

Optimizer Autumn 2011<br />

Manufacturing of panels for ROM tip: total 917.<br />

Bosmanspruit Crossing.<br />

Kwagga North – Bosmanspruit Crossing.<br />

Preparation on servitude – six kilometres to link<br />

up with Kwagga Central conveyor.<br />

Areas on the servitude are wet and need<br />

special treatment.<br />

Steel pipes are used to build a bridge. It was<br />

designed by professional civil engineers. The<br />

installation process is time consuming and very<br />

challenging as it is in a river bed.

the newly appointed<br />

rowan was recently appointed Chief<br />

Project development officer for optimum<br />

<strong>Coal</strong> Holdings where he is responsible for<br />

the development and execution of the oCH<br />

project pipeline. He also assists in business<br />

development opportunities and strategic<br />

life of mine planning for the company.<br />

He has traversed the full mining business<br />

circle from operations, technical, projects<br />

to business development. He worked for<br />

17 years for BHP Billiton, three years for Xstrata<br />

<strong>Coal</strong> and the last two at Mmakau Mining.<br />

Rowan is a highly motivated individual with a<br />

Bachelor of science degree in Mining and Civil Engineering<br />

from the University of Pretoria, a Masters<br />

degree in Mineral Economics from the University of<br />

the Witwatersrand, and an MBA from the University<br />

of stellenbosch.<br />

He is very excited about his new job and talks<br />

with passion about the opportunities for <strong>Optimum</strong><br />

<strong>Coal</strong>. He feels that <strong>Optimum</strong> is ideally positioned to<br />

consolidate the burgeoning coal sector and become a<br />

leading coal player in sub-sahara Africa. He believes<br />

that <strong>Optimum</strong> <strong>Coal</strong> has a strong project pipeline<br />

which is critical to future expansions.<br />

<strong>Optimum</strong> has always been considered a benchmark<br />

operation by Rowan and he remembers the time<br />

after the BHP Billiton merger when the Australians<br />

visited the mine regularly to look at the operations.<br />

The challenge now is to focus on talent management<br />

and key strategic initiatives to help make <strong>Optimum</strong> a<br />

world benchmark operation once more.<br />

To Rowan, one of the most important <strong>Optimum</strong><br />

values is integrity, without which a business cannot<br />

be successful and grow in the future.<br />

Rowan began his career in deep level gold<br />

mining in the Free state before moving to coal. His<br />

coal mine experience started at Blinkpan section,<br />

<strong>Koornfontein</strong> <strong>Mines</strong>. During this period, he obtained<br />

his Mine Manager’s Certificate of Competency for<br />

Metalliferous (hard rock) and Fiery <strong>Mines</strong> (coal<br />

mines). He later worked as Operations Manager at<br />

<strong>Optimum</strong> Colliery and Khutala <strong>Coal</strong> Mine.<br />

He spent substantial time as Technical Manager<br />

at <strong>Optimum</strong> Colliery and Middelburg <strong>Mines</strong>. During<br />

this period, he presented several papers at international<br />

conferences on mine optimisation and<br />

productivity improvements.<br />

He acquired international project management<br />

experience in Queensland, Australia, where<br />

he was the Project Manager for the Togara south<br />

Project. Locally, he worked as Project Director for<br />

the Klipspruit <strong>Coal</strong> Mine Project near Ogies for BHP<br />

Billiton.<br />

At Xstrata <strong>Coal</strong>, he was responsible for the<br />

group technical services and business development<br />

opportunities in sub-saharan Africa. The technical<br />

service function included life-op mine optimisation,<br />

mining right issues, signing off group reserve and<br />

resource statements and taking projects through<br />

the value chain (concept, pre-feasibility etc.) As<br />

MOVERs AND sHAKERs<br />

Chief Project development officer<br />

Getting to know Rowan Karstel<br />

part of his business development role, various coal<br />

due diligence studies were done on opportunities in<br />

Mozambique, Botswana, Tanzania and Zambia.<br />

As a Director at Mmakau Mining, he was responsible<br />

for business development across a number of<br />

commodities like gold, coal, platinum, uranium and<br />

chrome. Mmakau Mining was the equity partner of<br />

Total <strong>Coal</strong> and Rowan was responsible for business<br />

development opportunities for Total <strong>Coal</strong> in south<br />

Africa. He was Chief Operating Officer of Mmakau<br />

<strong>Coal</strong> as well as director of several companies: shaft<br />

sinkers, Hernic Ferrochrome, Dorstfontein <strong>Coal</strong><br />

Mine, Forzando <strong>Coal</strong> Mine, Madibeng Platinum<br />

(Xstrata) and Marula Platinum (Impala).<br />

Rowan is a supporter of the Lions (rugby) and<br />

Orlando Pirates (soccer). He is married to Trudie<br />

and has two children, John-Rowan (20) and Marike<br />

(16). He dedicates his leisure time to his family but is<br />

also a keen golfer (handicap 14), plays tennis, enjoys<br />

jogging and likes to scuba dive in Mozambique. He<br />

also enjoys reading non-fiction.<br />

Optimizer Autumn 2011 17

MOVERs AND sHAKERs<br />

Learning is a never-ending process<br />

Vincent Molekoa, who was recently appointed Hr Manager for<br />

<strong>Koornfontein</strong> <strong>Mines</strong>, is extremely humbled to be part of optimum<br />

<strong>Coal</strong> and works tirelessly to make a meaningful contribution to<br />

the success of the company.<br />

He joined <strong>Koornfontein</strong> <strong>Mines</strong> as an HR superintendent in January<br />

2008. His role includes, among others, industrial relations, recruitment,<br />

and employee relations in general.<br />

Vincent worked for various industries such as National Brands Limited in<br />

the Fast Moving Consumer Goods, Viro Locks and two multi-nationals AssA<br />

ABLOY and Maxam Dantex in the Metal and Explosives Industries respectively.<br />

He completed both a National Diploma in HR and a BTech degree studying<br />

part-time while employed by the multi-nationals. He was employed as an HR<br />

Practitioner, HRD Officer, HR Training Manager and lastly as an HR Manager.<br />

In 2009 at <strong>Optimum</strong> <strong>Coal</strong>, he became passionate about understanding<br />

general business management principles and in 2010, he completed Management<br />

Advancement Programme (MAP) with Wits Business school.<br />

He is married to Queeneth and has two sons Tokoloho (20) and Talente (15).<br />

new sACAFMA President<br />

Willem Van der Merwe, Group Risk and Audit Manager <strong>Optimum</strong><br />

<strong>Coal</strong>, was elected as President of sACAFMA (south African Colliery<br />

Administration and Financial Managers Association) for the 2011/2012<br />

term on 18 March this year. He has served on the sACAFMA Council for<br />

a couple of years, being the Vice President for the 2010/2011<br />

term.<br />

sACAFMA is the official body looking after the interests of<br />

the south African coal mining industry’s financial disciplines,<br />

and is therefore not only company bound, but industry<br />

bound. sACAFMA is affiliated with MPAs,<br />

the Mine Profession Association, which is<br />

serving the mining industry, inclusive of<br />

Hard Rock.This is the forum where best<br />

practices are shared between mining<br />

houses.<br />

sACAFMA gives inputs to<br />

sACMA (south African Colliery<br />

Managers Association), and is also<br />

represented at sentinel and WCMAs<br />

by trustee or board members.<br />

Vincent Molekoa receiving his Management Advancement Programme<br />

certificate from Wits Business School.<br />

optimum <strong>Coal</strong><br />

graduates shine<br />

From L-R: Vusi Zwane (<strong>Optimum</strong> <strong>Coal</strong>), Wiseman Dladla<br />

(<strong>Optimum</strong> <strong>Coal</strong>), Raymond Tshividzo (survey graduate), Quinton<br />

Kleinhans (mining graduate), Fhumulani Khomola (mining<br />

graduate), Bernard Malapane (finance graduate), Rebecca<br />

Phahlane (mining graduate) and Felicia Zikalala (<strong>Optimum</strong> <strong>Coal</strong>).

Welcome to<br />

optimum <strong>Coal</strong><br />

new employees<br />

<strong>Optimum</strong> <strong>Coal</strong> welcomes all new employees<br />

(<strong>Koornfontein</strong> <strong>Mines</strong>, Head Office and <strong>Optimum</strong><br />

Collieries).<br />

You are joining a ‘happy family’ and we hope<br />

that you will share in our values:<br />

• Empowerment<br />

• Integrity<br />

• Care<br />

• Respect<br />

• Purpose-driven<br />

• Accountability, and<br />

• simplicity.<br />

Congratulations<br />

Promotions<br />

Congratulations to employees whose hard work<br />

has paid off. We wish them well in their new<br />

roles.<br />

Survey assistant Dennis shabangu recently<br />

invented a solution to faulty satellite signal<br />

reception in certain areas on the mine<br />

property for the GPs equipment used by <strong>Optimum</strong><br />

Collieries surveyors.<br />

He designed a portable mast that can safely be<br />

bolted on to the mine vehicles which elevates the<br />

GPs unit and the repeater unit to a height where the<br />

signals are easier to detect.<br />

EMPLOYEE CORNER<br />

invention improves reception<br />

He then went to the workshops on his own<br />

initiative and asked the boilermakers to assist<br />

him in building the mast.<br />

They then helped him and he tested the<br />

workability of his invention before announcing its<br />

viability to his survey manager, Apie de Klerk.<br />

Well done Dennis! Your invention will go a<br />

long way to improve satellite signal reception at<br />

<strong>Optimum</strong> Collieries.<br />

Optimizer Autumn 2011 19

20<br />

EMPLOYEE CORNER<br />

Apprentice Boilermaker at <strong>Optimum</strong> Collieries Joel Malema received an award for the Best Plate Welder 2010 from Colliery Training<br />

College (CTC). A delighted Joel said: “I am honoured, excited and motivated to complete my studies and become an artisan so that<br />

I can be employed at <strong>Optimum</strong> <strong>Coal</strong>. I enjoy the diversity of the organisation and the constant daily challenges. Working with highly<br />

skilled individuals and the opportunities offered are some of the great benefits of working for the <strong>Optimum</strong> <strong>Coal</strong> group.”<br />

Invention ensures waste is stored responsibly<br />

<strong>Koornfontein</strong> <strong>Mines</strong> Foreman tinus de<br />

Bruyn and his team constructed a waste<br />

management station to be used underground.<br />

The station consists of:<br />

• a black and red bin for hazardous waste;<br />

• a green waste bin for general waste;<br />

• a blue waste bin for scrap metals;<br />

• an oil tank for used oil;<br />

• empty compartment for all the pipes.<br />

This is a commendable initiative because it will<br />

promote waste management as per our colour<br />

coding, thus ensuring good housekeeping in our<br />

sections.<br />

A job well done to Tinus and his team!<br />

Optimizer Autumn 2011<br />

Best plate welder recognised<br />

Waste storage bins at <strong>Koornfontein</strong> <strong>Mines</strong>.

Zero tolerance<br />

HEALTH<br />

for drug and alcohol use<br />

<strong>Optimum</strong> <strong>Coal</strong> has a zero tolerance policy towards the abuse of alcohol<br />

and drugs on site. This means that you are not allowed on site if you<br />

have been taking alcohol or any drugs that can affect your health<br />

or safety. This could include medication, which may have an intoxicating<br />

effect on you and render you unfit to work. (You must declare any medication<br />

and possible side effects to your supervisor as soon as possible, and before<br />

arriving for work).<br />

Please remember that you are responsible for your own health and safety<br />

as well as the safety of others. Please be responsible. If you need help, you<br />

can speak to your supervisor, HR practitioner or contact the Careways Group,<br />

before you put yourself or others at risk.<br />

Whatever the circumstance, you will receive immediate, extensive and<br />

confidential counselling and advice from a highly trained health professional.<br />

Employee wellness<br />

During the course of our everyday lives we all, at one time or another,<br />

experience pressure from our jobs, our family relationships, financial<br />

burdens, ill health, HIV/AIDs related matters, the change and transformation<br />

occuring at <strong>Optimum</strong> <strong>Coal</strong>, and the easy access to alcohol and drugs<br />

etc. It is during these times that we are at risk of possibility developing problems<br />

that may affect work performance.<br />

When we are worried or upset we are often unable to work through our<br />

problems without professional help, and it is for this reason that we take this<br />

opportunity to remind all employees to contact the Careways Group.<br />

to connect your body, mind and soul,<br />

call the Care Centre at the<br />

Careways Group on 0800 004 770<br />

Optimizer Autumn 2010 21

HEALTH<br />

VCCT Campaign<br />

Empower yourself: know your status!<br />

<strong>Optimum</strong> <strong>Coal</strong> recently hosted its third<br />

Voluntary Counselling and Confidential<br />

Testing (VCCT) campaign for all employees<br />

(including contractors) so that each employee would<br />

be empowered by knowing his/her HIV/AIDs status.<br />

The campaign took place at <strong>Optimum</strong> Collieries,<br />

<strong>Koornfontein</strong> <strong>Mines</strong> and Head Office. <strong>Optimum</strong> <strong>Coal</strong><br />

CEO Mike Teke pledged 1% of his annual salary to one<br />

person who participated in the <strong>Optimum</strong> <strong>Coal</strong> VCCT<br />

campaign. Congratulations to Eddie Mkhwanazi, who<br />

had the lucky number.<br />

We are very excited to announce that this year’s<br />

campaign was very successful, with a large percentage<br />

of our employees deciding to test. HIV/AIDs is a<br />

great concern and a reality; one that we need to take<br />

seriously and deal with vigorously!<br />

<strong>Optimum</strong> <strong>Coal</strong> will need the support from every<br />

employee and contractor to take responsibility, share<br />

knowledge about HIV/AIDs and make sure they know<br />

their status!<br />

<strong>Optimum</strong> <strong>Coal</strong> CEO Mike Teke congratulated Eddie Mkhwanazi for being the lucky winner. Mike<br />

pledged 1% of his annual salary to an employee who participated in the <strong>Optimum</strong> <strong>Coal</strong> VCCT<br />

campaign at various sites at <strong>Optimum</strong> <strong>Coal</strong>.

HEALTH

<strong>Optimum</strong> <strong>Coal</strong><br />

DO YOU know of any FOUL PLAY in your workplace?<br />

GIVE US A CALL, NO ONE WILL KNOW<br />

0800 212 138<br />

PRIVATE & CONFIDENTIAL<br />

BLOW THE<br />

WHISTLE!