Airase™ SSDL™ defoamers - Air Products and Chemicals, Inc.

Airase™ SSDL™ defoamers - Air Products and Chemicals, Inc.

Airase™ SSDL™ defoamers - Air Products and Chemicals, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

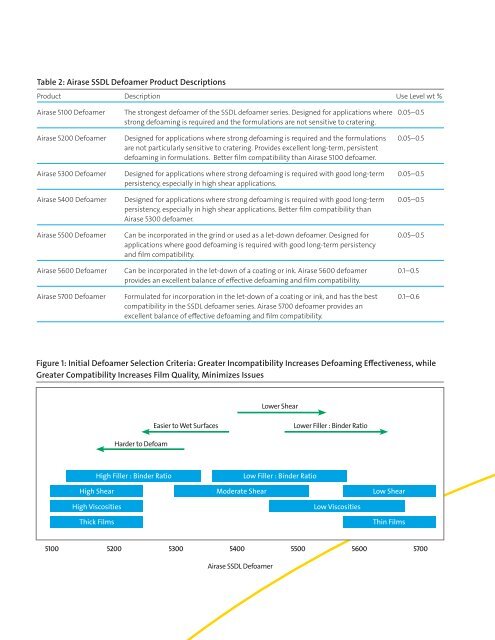

Table 2: <strong>Air</strong>ase SSDL Defoamer Product Descriptions<br />

Product Description Use Level wt %<br />

<strong>Air</strong>ase 5100 Defoamer The strongest defoamer of the SSDL defoamer series. Designed for applications where 0.05–0.5<br />

strong defoaming is required <strong>and</strong> the formulations are not sensitive to cratering.<br />

<strong>Air</strong>ase 5200 Defoamer Designed for applications where strong defoaming is required <strong>and</strong> the formulations 0.05–0.5<br />

are not particularly sensitive to cratering. Provides excellent long-term, persistent<br />

defoaming in formulations. Better film compatibility than <strong>Air</strong>ase 5100 defoamer.<br />

<strong>Air</strong>ase 5300 Defoamer Designed for applications where strong defoaming is required with good long-term 0.05–0.5<br />

persistency, especially in high shear applications.<br />

<strong>Air</strong>ase 5400 Defoamer Designed for applications where strong defoaming is required with good long-term 0.05–0.5<br />

persistency, especially in high shear applications. Better film compatibility than<br />

<strong>Air</strong>ase 5300 defoamer.<br />

<strong>Air</strong>ase 5500 Defoamer Can be incorporated in the grind or used as a let-down defoamer. Designed for 0.05–0.5<br />

applications where good defoaming is required with good long-term persistency<br />

<strong>and</strong> film compatibility.<br />

<strong>Air</strong>ase 5600 Defoamer Can be incorporated in the let-down of a coating or ink. <strong>Air</strong>ase 5600 defoamer 0.1–0.5<br />

provides an excellent balance of effective defoaming <strong>and</strong> film compatibility.<br />

<strong>Air</strong>ase 5700 Defoamer Formulated for incorporation in the let-down of a coating or ink, <strong>and</strong> has the best 0.1–0.6<br />

compatibility in the SSDL defoamer series. <strong>Air</strong>ase 5700 defoamer provides an<br />

excellent balance of effective defoaming <strong>and</strong> film compatibility.<br />

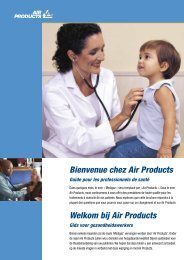

Figure 1: Initial Defoamer Selection Criteria: Greater <strong>Inc</strong>ompatibility <strong>Inc</strong>reases Defoaming Effectiveness, while<br />

Greater Compatibility <strong>Inc</strong>reases Film Quality, Minimizes Issues<br />

High Shear Moderate Shear Low Shear<br />

High Viscosities Low Viscosities<br />

Thick Films<br />

Harder to Defoam<br />

High Filler : Binder Ratio Low Filler : Binder Ratio<br />

5100 5200 5300 5400<br />

Easier to Wet Surfaces Lower Filler : Binder Ratio<br />

<strong>Air</strong>ase SSDL Defoamer<br />

Lower Shear<br />

Thin Films<br />

5500 5600 5700