INNOVATIVE RAIL FASTENING SYSTEMS :::::::::::::::::::::::::: - Schwihag

INNOVATIVE RAIL FASTENING SYSTEMS :::::::::::::::::::::::::: - Schwihag

INNOVATIVE RAIL FASTENING SYSTEMS :::::::::::::::::::::::::: - Schwihag

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

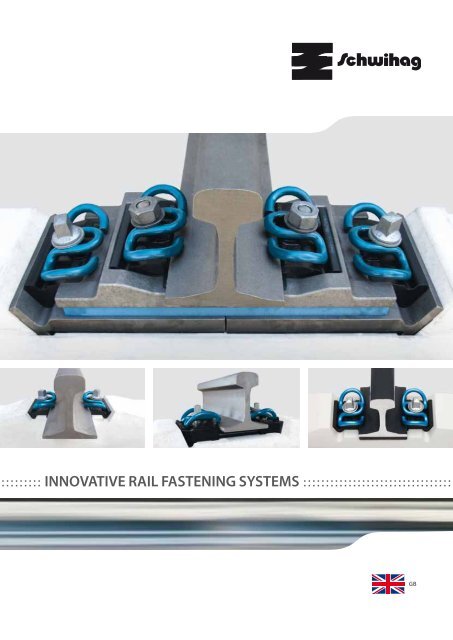

::::::::: <strong>INNOVATIVE</strong> <strong>RAIL</strong> <strong>FASTENING</strong> <strong>SYSTEMS</strong> ::::::::::::::::::::::::::::::::::<br />

GB

:::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::<br />

2<br />

SCHWIHAG‘S<br />

<strong>INNOVATIVE</strong> <strong>RAIL</strong><br />

<strong>FASTENING</strong><br />

<strong>SYSTEMS</strong><br />

SCHWIHAG <strong>RAIL</strong> <strong>FASTENING</strong> <strong>SYSTEMS</strong><br />

PRODUCTS 4<br />

DEVELOPMENT 8<br />

PRODUCTION 10<br />

QUALITY ASSURANCE 12<br />

TECHNICAL INNOVATIONS 13<br />

3

:::::::::::::::::: PRODUCTS ::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::<br />

4<br />

MODERN<br />

TECHNOLOGY<br />

FOR THE TRACK<br />

The rail fastenings supplied by SCHWIHAG are<br />

based on systems which have been put to the test<br />

in practice for decades. SCHWIHAG has technically<br />

and economically optimised these systems.<br />

SCHWIHAG provides consulting, development,<br />

design, production, delivery and service for rail<br />

fastenings and the following applications:<br />

:: Standard railway lines<br />

:: High-speed lines<br />

:: Heavy freight transport<br />

:: Underground railways<br />

:: Commuter railways<br />

:: Tramways<br />

:: Industrial railways<br />

and in the following types of track construction:<br />

:: Ballast track with concrete sleepers<br />

:: Ballast track with wooden sleepers<br />

:: Ballast track with steel sleepers<br />

:: Slab track<br />

:: Bridge beams (beams on steel bridges)<br />

:: Transition areas<br />

with regard to:<br />

:: Rail profile and cant<br />

:: Sleeper geometry<br />

:: Line layout<br />

(e.g. tight radii, large gradients)<br />

SCHWIHAG rail fastening systems are:<br />

:: Proven standard systems<br />

(standard KS-track or W-track)<br />

:: New developments to customer requirements<br />

:: Adaptations with optimised components, e.g. new<br />

tension clamps for existing sleepers for retrofitting<br />

or conversion<br />

:: Special designs for difficult installation situations<br />

:: Systems with special surface protection for the<br />

RFS components to customer requirements for<br />

critical environmental conditions<br />

:: Systems with highly effective sound insulation<br />

(structure-borne sound/vibrations)<br />

:: Systems for transition areas, e.g. at tunnel/bridge<br />

with large relative movements between the rail<br />

and support<br />

SCHWIHAG rail fastening systems offer many<br />

advantages for assembly and installation:<br />

:: Can be completely preassembled in the<br />

sleeper factory<br />

:: Due to sorted delivery, completely automated<br />

preassembly is also possible in the sleeper factory<br />

:: Quick, automated, mechanical final assembly on the<br />

construction site possible with assembly speed<br />

of > 400 m/h track<br />

Tension clamp Skl 14 in preassembly position<br />

Tension clamp 14 tensioned<br />

Other advantages:<br />

:: Tension clamps are produced free of surface decarburisation<br />

(see page 13 of the brochure) > maximum<br />

dynamic fatigue strength<br />

:: High-quality long-term corrosion protection available<br />

(see page 14 of the brochure) > The dynamic<br />

properties are maintained for the complete life<br />

:: High elasticity > Results in improved load distribution<br />

(deflection curve) along the rail, therefore, associated<br />

significant reduction in point loading on all track<br />

components such as the rail, rail fastening system,<br />

sleeper and ballast<br />

:: Integral anti-tilt protection > prevents overloading of<br />

the tension clamp in extreme load situations<br />

:: Integral electrical insulation > is achieved by using<br />

the insulating plastic fastening components: angle<br />

guide plate, rail pad and dowels<br />

:: Modularity > enables universal usability for all railway<br />

applications from the tramway, underground railway,<br />

and heavy load through to high speed traffic<br />

:: Precise batch marking > Lettering is made using laser<br />

technology and enables exact dating of the production<br />

date of each batch (see page 14 of the brochure)<br />

:: Heavy-duty dowels > Special design of the dowel<br />

geometry in conjunction with optimised material<br />

selection enables high pull-out forces and safety<br />

against excessive torques (see page 14/15 of the<br />

brochure)<br />

SCHWIHAG <strong>RAIL</strong> <strong>FASTENING</strong> <strong>SYSTEMS</strong><br />

5

6<br />

<strong>RAIL</strong> <strong>FASTENING</strong>S FOR CONCRETE SLEEPERS<br />

AND SLAB TRACK<br />

Tension clamp Skl 14 on concrete sleeper (W-fastening)<br />

Tension clamp Skl 15 for System 300-1 for slab track<br />

Tension clamp Skl 12 on elastically supported baseplate<br />

as single support point for slab track<br />

Tension clamp Skl SL 1 for heavy-haul systems on concrete sleeper<br />

<strong>RAIL</strong> <strong>FASTENING</strong>S FOR<br />

WOODEN SLEEPERS<br />

Tension clamp Skl 12 on wooden sleeper (KS-fastening)<br />

<strong>RAIL</strong> <strong>FASTENING</strong>S FOR<br />

TRANSITION AREAS<br />

System BSP-FF-B1 with Skl SL1, concrete<br />

System BSP-FF-B2 with Skl SL1, steel<br />

<strong>RAIL</strong> <strong>FASTENING</strong>S FOR SWITCHES<br />

Tension clamp Skl 14 and Skl 12<br />

as well as spring clip SSb2 for<br />

slide baseplate URg 57 on<br />

W switch bearer<br />

SCHWIHAG <strong>RAIL</strong> <strong>FASTENING</strong> <strong>SYSTEMS</strong><br />

:::::::::::::::::: PRODUCTS ::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::<br />

7

:::::::::::::::::: DEVELOPMENT ::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::<br />

8<br />

SCHWIHAG<br />

DEVELOPS, TESTS<br />

AND PRODUCES <strong>RAIL</strong><br />

<strong>FASTENING</strong> <strong>SYSTEMS</strong><br />

Targeted research and product development play an<br />

important role in SCHWIHAG. The requirements for<br />

forward-looking track components are determined<br />

through continuous dialogue with the railway engineers<br />

of the railway companies.<br />

The 3D CAD system Pro Engineer is used to develop<br />

new products and to adapt or optimise products that<br />

have already proven their worth. The necessary FEM<br />

analyses are then performed on the basis of this CAD<br />

data. Prototypes are examined in our own test laboratory<br />

to determine their general technical properties<br />

and their suitability for use in railway operations.<br />

Continuous load (endurance) tests can be performed<br />

according to the test conditions of international<br />

standards and/or the specifications of the railway<br />

companies.<br />

In addition to the static and dynamic load tests, the<br />

following material tests can also be performed:<br />

:: Hardness test<br />

:: Tensile/compressive strength test<br />

:: Grinding preparation and microstructural analyses<br />

(optical microscopy)<br />

:: Polymer tests (melting point, heat of fusion, glass<br />

transition point)<br />

:: Optical 3D measurement of components<br />

SCHWIHAG AG‘s jig construction department enables<br />

the production of customer-specific adapters and test<br />

apparatus, which ensures optimum position adjustment<br />

and clamping of the components to be tested<br />

during the tests.<br />

SCHWIHAG AG in Tägerwilen (CH) with research and<br />

development facilities<br />

Selected variants or fail fastening tension clamps produced by SCHWIHAG<br />

Development and design laboratory of SCHWIHAG AG in Tägerwilen<br />

SCHWIHAG GmbH, Radefeld near Leipzig<br />

SCHWIHAG GMBH MANUFACTURES<br />

SCHWIHAG AG INHOUSE DEVELOPED<br />

PRODUCTS. SCHWIHAG GMBH HAS<br />

STATE OF THE ART PROCESS<br />

TECHNOLOGY FOR TENSION<br />

CLAMP PRODUCTION.<br />

Biaxial, static and dynamic tests can be performed<br />

in the test laboratory. The max. vertical test force is<br />

400 kN and the max. horizontal test force is 100 kN.<br />

The components can be tested, among other things,<br />

in a horizontal position (biaxial) or in an inclined test<br />

(mono-axial).<br />

Based on this development concept, our customers‘<br />

specific requirements can be implemented in new<br />

products or new product variants.<br />

Following successful testing in the SCHWIHAG laboratory,<br />

the components and systems are subjected to<br />

further testing by an independent test institute as part<br />

of the approval procedure. Here SCHWIHAG works<br />

closely with renowned test and research facilities, e.g.<br />

the University of Technology of Munich or Dresden.<br />

Test machine for strength tests<br />

(tensile test) on material samples<br />

Test laboratory with test equipment for continuous load (endurance) tests<br />

Test machine for recording spring characteristic curves<br />

SCHWIHAG <strong>RAIL</strong> <strong>FASTENING</strong> <strong>SYSTEMS</strong><br />

9

10<br />

1<br />

FROM THE WIRE TO THE<br />

FINISHED TENSION CLAMP:<br />

SCHWIHAG PRODUCES IN A FULLY<br />

AUTOMATED PRODUCTION PROCESS<br />

WIRE ROLL MADE OF<br />

SPRING STEEL<br />

5<br />

SORTED PACKAGING OF<br />

THE FINISHED PRODUCT<br />

2<br />

BENDING LINE 3 SORTED TRANSPORT TO<br />

QUENCHING AND HARDENING<br />

6<br />

AUTOMATIC TRANSPORT<br />

INTO THE WAREHOUSE<br />

7<br />

INDOOR STORES - WAREHOUSE 8 OUTDOOR STORES<br />

PRODUCTS ARE READY FOR DISPATCH<br />

4<br />

SCHWIHAG <strong>RAIL</strong> <strong>FASTENING</strong> <strong>SYSTEMS</strong><br />

:::::::::::::::::: PRODUCTION :::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::<br />

QUENCHING AND HARDE-<br />

NING LINE<br />

11

12<br />

HIGH TECH<br />

IN THE TEST LAB<br />

We guarantee our customers that SCHWIHAG products<br />

are produced according to the following criteria:<br />

:: Careful selection of suitable heavy-duty materials<br />

:: Selection of the optimum production method under<br />

the aspects of product quality, flexibility and use of<br />

resources (manpower, material, energy consumption)<br />

:: Continuous monitoring of the production processes<br />

and the product data through material and dimensional<br />

checks according to national, international<br />

standards or those specified by our customers.<br />

SCHWIHAG has a quality management system certified<br />

to ISO 9001-2008 and for many years has been a Q1<br />

supplier of Deutsche Bahn AG and a certified supplier<br />

of numerous other railway companies (including SNCF,<br />

Network Rail, RFI).<br />

The SCHWIHAG production concept in conjunction<br />

with the SCHWIHAG logistics concept enables us to<br />

respond to customers‘ special wishes at short notice<br />

and to deliver standard products or special designs<br />

worldwide and on-schedule.<br />

Measuring the tension clamp geometry by means<br />

of 3 dimensional digitising<br />

NO SURFACE<br />

DECARBURISATION<br />

SCHWIHAG tension clamps can be produced free of<br />

surface decarburisation thanks to a special heat treatment<br />

method in closed chambers.<br />

Following the heat treatment of the spring steel the<br />

fine acicular, martensitic microstructure forms. If<br />

classical heat treatment methods are used with open<br />

processes, surface decarburisation forms all around<br />

the perimeter of a wire with circular cross-section:<br />

these are the starting points for cracking. In the area<br />

No surface decarburisation, free of incipient cracks<br />

Example of the microstructural change in metals caused by the<br />

heat treatment process: acicular martensitic microstructure<br />

of this surface decarburisation the material is brittle<br />

and tends to form cracks, especially under dynamic<br />

loading. These cracks or incipient cracks produce a<br />

notch effect and propagate in the quenched and hardened<br />

material and can cause a component to break.<br />

This process is also accelerated by increased formation<br />

of rust, which can occur especially in the area of the<br />

surface decarburisation.<br />

The tension clamps produced using the SCHWIHAG<br />

method do not have any surface decarburisation<br />

zones and therefore achieve high dynamic fatigue<br />

strength.<br />

All-round surface decarburisation with formation of incipient cracks<br />

SCHWIHAG <strong>RAIL</strong> <strong>FASTENING</strong> <strong>SYSTEMS</strong><br />

:::::::::::::::::: QUALITY ASSURANCE :::::::::::::::::::::::::::::::::::::::::::::::::::::::: TECHNICAL INNOVATIONS ::::::::::::::::::::::::::::::::::::::::::::::::::::<br />

13

:::::::::::::::::: TECHNICAL technISche INNOVATIONS InnovatIonen ::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::<br />

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::<br />

14<br />

LONG-TERM<br />

langzeit-<br />

CORROSION korroSionSSchutz PROTECTION<br />

schwihag SCHWIHAG bietet offers new, für spannklemmen high-quality long-term aus Federstahl corro-<br />

einen sion protection neuen hochwertigen for tension clamps langzeit-korrosionsschutz<br />

made from spring<br />

an. steel. Mit With diesem this new neuartigen type of korrosionsschutz corrosion protection, kann<br />

die rusting rostbildung can be verifiably nachweislich and significantly über die gesamte reduced over<br />

lebensdauer the entire life unter under operativen operative conditions. Bedingungen In this deutlich way<br />

reduziert the fatigue werden. strength damit properties bleiben of die the dauerfestigkeits-<br />

tension clamps<br />

eigenschaften remain virtually der constant spannklemmen over very nahezu long use konstant cycles.<br />

über sehr lange einsatzzyklen.<br />

PRECISE chargengenaue<br />

BATCH<br />

LABELLING<br />

kennzeichnung<br />

schwihag In future, each spannklemmen batch of SCHWIHAG werden tension zukünfig clamps chargen- will<br />

genau be marked markiert. precisely. die Beschriftung The labelling erfolgt is carried mittels out using hochmoderner<br />

highly modern lasertechnik laser technology und ermöglicht and enables die exakte exact<br />

datierbarkeit dating of the production des Produktionsdatums date of each jeder batch. charge.<br />

Skl skl 14 without ohne (links) (left) und and (rechts) with (right) mit neuem new long-term langzeit-korrosionsschutz<br />

corrosion protection<br />

Labelling kennzeichnung of tension von clamps spannklemmen by means mittels of laser lasertechnik<br />

technology<br />

schwihag SCHWIHAG kunststoffschraubdübel plastic anchor dowel Sdü sdü-s3 S3<br />

hochbelaStbarer<br />

dübel<br />

HEAVY-DUTY DOWELS<br />

der dübel ist eine wesentliche komponente für<br />

schienenbefestigungssysteme The dowel is an essential component auf Betonschwellen.<br />

for rail fastening<br />

damit systems kommt on concrete dem dübel sleepers. als im The Beton dowel, eingegossenes<br />

as a compo-<br />

Bauteil nent cast hohe in the Bedeutung concrete, für is therefore die Funktionalität very important der for<br />

schienenbefestigung the function of the rail zu. fastening. die Belastbarkeit The loading von capacity dübelkonstruktionen<br />

of dowel constructions kann hauptsächlich can mainly be anhand determined ihres kon- by its<br />

struktiven design failure. versagens This can festgemacht not only be werden. loss of the dieses connec- kann<br />

sowohl tion or keying ein verlust of the der dowel verbindung with the bzw. sleeper verzahnung body, e.g.<br />

des pulling dübels out of mit the dem dowel schwellenkörper, from the sleeper z.B. or herausreißen<br />

damage to<br />

des the surrounding dübels aus der concrete, schwelle but bzw. also Beschädigung failure of the internal des<br />

umgebenden plug construction, Betons, e.g. als pulling auch out ein versagen of the screw der or inneren bolt<br />

dübelkonstruktion, from the plug. z.B. auszug der schraube aus dem<br />

dübel, sein.<br />

The objective of the development of the new<br />

Ziel SCHWIHAG der entwicklung plastic anchor des neuen dowel schwihag Sdü S3 was kunst- to reduce<br />

stoffschraubdübels the tensile stresses in sdü the s3 concrete war, die body aus der resulting schraube- from<br />

the dübel-kombination screw-dowel combination. resultierenden In critical Zugspannungen loading situa- im<br />

tions, Betonkörper which occur zu reduzieren. especially dadurch during laying soll in of kritischen the track<br />

and Belastungssituationen, the tightening of the die rail insbesondere fastening, this bei should der Monensuretage a des reserve gleises against und der failure verspannung of the dowel der construction<br />

schienen-<br />

and befestigung the bonding auftreten, with the eine sleeper reserve concrete. gegen versagen<br />

The development objective was achieved in design<br />

terms by the geometrical formation of the dowel‘s<br />

external (male) thread and the allocation of the<br />

corresponding dowel internal (female) thread. In<br />

addition, different wall thicknesses were implemented<br />

in the design of the dowel‘s thread area. This material<br />

distribution causes any stress peaks occurring due to<br />

elastic and plastic deformation of the dowel material<br />

to be absorbed and therefore prevents damage to the<br />

surrounding concrete contour.<br />

The newly developed plastic anchor dowel Sdü S3 can<br />

be used not only with the sleeper screw Ss 25 but also<br />

with the sleeper screw Ss 35. Damage to the internal<br />

thread of the dowel caused by incorrect positioning of<br />

the sleeper screw Ss 25 with pointed thread is prevented<br />

by special design of the internal thread runout.<br />

Within the scope of qualification tests it was established<br />

that the new SCHWIHAG plastic anchor dowel<br />

Sdü S3 has a factor of safety of up to 4 for the pull-out<br />

force. The SCHWIHAG design also has a 3-fold factor of<br />

safety for the tightening torque, which is introduced<br />

into the dowel when tightening the sleeper screw.<br />

Apart from laboratory tests, this was also verified by<br />

practical tests on the track panel. When the sleeper<br />

screw was tightened and undone 10 times, no movement<br />

in the dowel crown was found and the bonding<br />

between the sleeper concrete and the dowel was<br />

completely intact.<br />

Test sample after screwing in ten times using<br />

a power assembly tool in the screw in tests<br />

under practical conditions.<br />

15

:::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::<br />

SCHWIHAG AG<br />

Track and Switch Technology<br />

Lebernstrasse 3, CH-8274 Tägerwilen<br />

Tel +41(0)71 666 88 00 Fax +41(0)71 666 88 01<br />

info@schwihag.com www.schwihag.com