AUTOMATION UltraCut - Victor Technologies

AUTOMATION UltraCut - Victor Technologies

AUTOMATION UltraCut - Victor Technologies

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

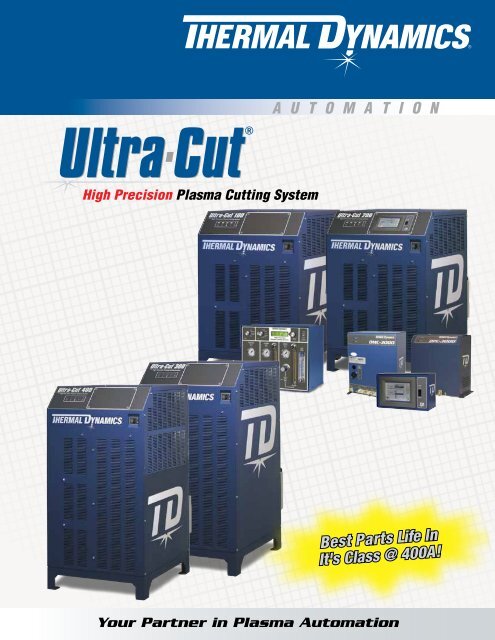

Ultra Cut®<br />

A U T O M A T I O N<br />

Best Parts Life In<br />

It's Class @ 400A!<br />

Your Partner in Plasma Automation

Automated Plasma Cutting<br />

High Precision Plasma Cutting<br />

The Ultra-Cut ® delivers premium precision plasma cutting on mild steel and<br />

non-ferrous alloys. For non-ferrous material, select our unique Water Mist<br />

Secondary process for best in class cut quality. In addition, the Ultra-Cut<br />

systems can also be used for clean, efficient, plasma marking without having<br />

to change consumables.<br />

Quality<br />

• Excellent dross-free cuts using oxygen (O2)<br />

plasma on mild steel<br />

• Unmatched cut quality on non-ferrous materials<br />

by using Thermal Dynamics unique Water Mist<br />

Secondary (WMS ® ) process<br />

Ease of Use<br />

• Fast and easy installation<br />

• Simple set-up and user-friendly gas console<br />

• Quick-change consumable design, SpeedLok<br />

• Easy to identify and troubleshoot problems<br />

• The automated Digital Flow Control increases<br />

ease of use and provides improved cut<br />

consistency<br />

Productivity<br />

• Highest cut speed in its class on stainless steel.<br />

The cut speed can be up to 3 times faster than<br />

with similar cutting systems<br />

• Highest kW output in its class<br />

• Outstanding parts life<br />

• Reduced downtime during parts changes due<br />

to the SpeedLok cartridge design of the<br />

XT-Torch<br />

• Fastest switching times between<br />

marking and cutting processes<br />

GCM-2010 Digitally Controlled<br />

Manual Gas Console<br />

RAS-1000 Remote Arc Starter<br />

Ultra-Cut Power Supply<br />

Automated Digital Flow Control (DFC-3000)<br />

Technology<br />

• Microprocessor controlled to produce the best<br />

cut quality<br />

• Fiber optic communication decreases HF<br />

interference<br />

• Precision torch design offers the best cut quality<br />

in its class<br />

• Higher cut speed than H35 with the use of<br />

N2/H20 on non-ferrous<br />

Reliability<br />

• Exhaustive lab testing and field trials ensure<br />

on-going performance and reliability

XT -Torch Technology<br />

Unique ‘Keyless’ Consumables Cartridge<br />

A U T O M A T I O N<br />

The unique, SpeedLok Consumables Cartridge houses consumable parts only, no built-in head/torch body to drive replacement costs up. Changing<br />

cartridges is fast and easy – a couple of twists and the unique ‘rapid engagement’ retaining collar threads release the cartridge. Down-time is<br />

reduced to seconds and you can change from one process to another or from one application to another quickly and easily.<br />

XT-Torch Head<br />

No Tools Required<br />

Unlike other torches, no tools are required to change either the<br />

torch consumables or major components in the Torch Head.<br />

‘Leakless’ Torch Head Design<br />

Coolant doesn’t drip from the torch head when the consumables<br />

cartridge is removed from the torch head.<br />

Prevents air from entering the system and becoming trapped in<br />

the leads.<br />

Self-centering Components<br />

Cartridge<br />

Consumable parts and torch body are precisely engineered to lock<br />

into place for absolute alignment and remain positioned cut after<br />

cut. Independently-aligned tip and electrode assures accurate<br />

re-centering of the consumable cartridge after each parts change.<br />

This guarantees best cut quality again and again.<br />

Electrode<br />

Superior Warranty<br />

Thermal Dynamics’ XT-Torch warranty covers components and service for<br />

a full 1-year period.<br />

Precision Cuts on all Metals<br />

The XT-Torch dual gas technology provides the highest arc density<br />

plasma stream in the industry for precision cuts on mild steel, stainless<br />

steel, aluminum and other non-ferrous materials. Choices for plasma gas<br />

include Air, N2, O2 or Ar-H2, shield gas choices include Air, N2, O2, H2O, or<br />

Ar-H2.<br />

Plasma Gas<br />

Distributor<br />

Shield Gas<br />

Distributor<br />

Tip Shield Cap<br />

Relaxed Cutting Parameters<br />

Shield Cup<br />

Shield Cap<br />

Retainer<br />

With the XT-Torch the operating window permits wide travel speed<br />

variance which means you'll get great cuts more often and less wasted<br />

material and time.<br />

• Less critical standoff height<br />

• Wider ‘Operating Window’ for dross-free cutting

Automated Plasma Cutting<br />

Automated Digital Flow Control (DFC-3000)<br />

Designed specifically for use with the high-precision Ultra-Cut systems,<br />

the automated DFC-3000 (Digital Flow Control) consists of three separate<br />

modules.<br />

• The TSC-3000 (Touch Screen Controller) offers the only touch screen<br />

in the plasma industry today. The interface allows operators to quickly<br />

choose one of potentially 1000’s of stored programs and start cutting<br />

by touching the green “Go” button. Future software upgrades can be<br />

made through the standard USB port.<br />

• With the TSC-3000 older CNC's can also be used with an automatic gas<br />

console. No new CNC has to be purchased.<br />

• The DMC-3000 (Digital Manifold Control) functions as the central<br />

manifold for all incoming gases. Having (7) inputs and (5) outputs, this<br />

unit enables the gas to be used according to the program selected.<br />

• The DPC-3000 (Digital Pressure Control) controls/maintains gas<br />

flows and pressures needed to optimize the cutting process. The unit<br />

is normally mounted within 4' (1.2 m) of the cutting torch to minimize<br />

time to switch between processes.<br />

• This automated Digital Flow Control system reduces set up time,<br />

minimizes set up errors, provides consistent performance, and offers<br />

the industry’s only touch screen controller for easy set up and operation.

Why choose the automated<br />

Digital Flow Control?<br />

• Easier to use<br />

• No setup errors<br />

• No need for CNC to control the DFC<br />

• Uses the same parts for cutting and marking<br />

• Reduced set up times<br />

• Consistent cut quality<br />

• Improved parts life and cut quality<br />

• Easily switch between marking and cutting<br />

• Integrates easily to most CNC’s<br />

Marking Samples<br />

When To Choose The Automated Digital Flow Control<br />

Consider the automated DFC for:<br />

• Easy setup<br />

• More consistent cut quality<br />

• Plasma marking<br />

• When applications call for frequent changes in<br />

material types or thicknesses<br />

• Optimizing cut quality<br />

• Controlling the Ultra-Cut ® system automatically<br />

A U T O M A T I O N<br />

TSC-3000 with Material Screen Shot<br />

Three Easy Setup Steps<br />

1. Select the material<br />

2. Select the thickness<br />

3. Select the cut type<br />

- Best<br />

- Fastest<br />

- Robotic Bevel<br />

You're Done!

Automated Plasma Cutting<br />

XTremeLife Consumables For Mild Steel<br />

The XTremeLife technology delivers the parts life and cut quality on mild<br />

steel with O 2 plasma that the high-end customer expects. Unrivaled cut<br />

quality from gauge (0.5 mm) to 2" (50 mm) material with the<br />

widest range of consumables in the market.<br />

• Bevel angles range three or better according to ISO 9013<br />

• Square cut face with minimal top edge rounding<br />

• Smooth cut edge surface<br />

• Virtually dross-free parameter window up to 2" (50 mm)<br />

• Consistent cut quality over entire parts life<br />

in/min.<br />

IPM<br />

200<br />

150<br />

100<br />

50<br />

0<br />

1/2"<br />

(12 mm)<br />

Relative Cutting Speed<br />

400 Amp<br />

Oxyfuel<br />

3/4"<br />

(20 mm)<br />

1"<br />

(25 mm)<br />

Material Thickness<br />

Ultra-Cut 400<br />

1¼"<br />

(35 mm)<br />

mm/min.<br />

5080<br />

3810<br />

2540<br />

1270<br />

1½"<br />

(40 mm)<br />

Number of Starts<br />

Longer Parts Life with XTremeLife<br />

Consumables<br />

5000<br />

4000<br />

3000<br />

2000<br />

1000<br />

10 20 30 40 50<br />

Cut Duration (seconds)<br />

100 Amp<br />

200 Amp<br />

400 Amp<br />

Combined Utlra-Cut 100, 200 & 400 Data

Ultra-Cut ® 400 vs Oxyfuel<br />

• Averages 3 times faster cut speeds<br />

• Pierces 1¼" (35 mm) in 1.5 seconds<br />

• One Ultra-Cut 400 can replace up to 4 oxy-fuel torches -<br />

each requiring their own height controls.<br />

• Ultra-Cut 400 provides superior stainless steel and<br />

aluminum cut quality<br />

• Higher arc density equals faster speeds without<br />

sacrificing cut quality<br />

• Smaller tip orifices create a narrow kerf for tighter angles<br />

and radiuses at higher speeds - less material waste<br />

• Patented consumable technology<br />

XTR Robotic Torch<br />

1/2" (12 mm) Cut Sample (detail)<br />

• Specifically designed for the Ultra-Cut ®<br />

precision cutting systems<br />

• One of the shortest Robotic torches on<br />

the market for ease of articulation and<br />

improved access. Only 9.3 (236 mm)<br />

in length<br />

• Profile/Bevel consumables for improved<br />

access and bevel cutting<br />

Easy Access<br />

Consumables<br />

A U T O M A T I O N<br />

• Ultra-light, ultra-flexible, robust torch leads<br />

• Torch mounting indicators for positive torch<br />

positioning<br />

• Position teach tool for point to point<br />

programming<br />

New 15A and 30A<br />

O2 consumables<br />

9.3 (236mm)<br />

(not to scale)

Automated Plasma Cutting<br />

Water Mist Secondary (WMS ® ) For Non-Ferrous Materials<br />

WMS delivers excellent non-ferrous cut quality and low cost of<br />

operation by using N2 as plasma gas and ordinary tap water as<br />

the secondary. A reducing atmosphere is produced in the cut by<br />

the release of hydrogen from the secondary water. The reducing<br />

atmosphere decreases oxidation on the cut face surface. WMS<br />

is recommended for materials up to 1½" (25 mm) thick.<br />

WMS Benefits<br />

• Lowest operating cost<br />

• Up to 3 times faster cutting speeds than H35<br />

• Dross-free cutting<br />

• Oxide-free cut surface<br />

• Wide parameter window<br />

• Easy to use<br />

• Laser-like cut quality on Aluminum<br />

• Small heat effected zone<br />

• Less distortion<br />

• Same weldability as H35<br />

Cutting Aluminum with the Ultra-Cut ® 200<br />

Example for 3/4" (20 mm) with WMS<br />

Example for 1/4" (6 mm)<br />

Aluminum cut with WMS<br />

The WMS process uses nitrogen as the plasma gas while<br />

water is used as the secondary gas (shield gas). The water in<br />

the torch is divided into its principal components (hydrogen<br />

and oxygen) during the cutting process. The majority of the<br />

water used during the process (from 4 to 8 GPH (0.25 to 0.5 l/<br />

min)) is converted to principal components (gas) and thereby<br />

does not require disposal.<br />

Speed<br />

(in/min)<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

80A<br />

Stainless Steel -<br />

Cutting Speed Comparison<br />

100A<br />

1/4"<br />

(6 mm)<br />

260A<br />

300A<br />

3/8"<br />

(10 mm)<br />

260A<br />

Ultra-Cut<br />

Competitor H35/N2<br />

® N2/H20<br />

300A<br />

5/8"<br />

(15 mm)<br />

Material Thickness<br />

400A<br />

400A<br />

1"<br />

(25 mm)<br />

Speed<br />

(mm/min)<br />

4000<br />

3500<br />

3000<br />

2500<br />

2000<br />

1500<br />

1000<br />

500<br />

0

How To Select The Right System<br />

Ultra-Cut ® 100 Ultra-Cut 200<br />

Production Pierce 1/2" (12 mm) 1" (25 mm)<br />

1/4" (6 mm) 150 ipm (3.21m/min) 200 ipm (5.08 m/min)<br />

1/2" (12 mm) 64 ipm (1.63 m/min) 115 ipm (2.92 m/min)<br />

3/4" (20 mm) 25 ipm (0.64 m/min) 65 ipm (1.65 m/min)<br />

1" (25 mm) 48 ipm (1.22m/min)<br />

A U T O M A T I O N<br />

Ultra-Cut 300 Ultra-Cut 400<br />

Production Pierce 1½" (40 mm) 2" (50 mm)<br />

1/4" (6 mm)<br />

1/2" (12 mm) 140 ipm (3.55 m/min) 150 ipm (3.21 m/min)<br />

3/4" (20 mm) 100 ipm (2.54 m/min) 115 ipm (2.92 m/min)<br />

1" (25 mm) 70 ipm (1.78 m/min) 80 ipm (2.10 m/min)<br />

1½" (40 mm) 35 ipm (0.9 m/min) 45 ipm (1.10 m/min)<br />

2" (50 mm) 30 ipm (0.7 m/min)<br />

*Cut speeds using O 2/Air on Mild Steel at max output current.

Automated Plasma Cutting<br />

Ultra Cut<br />

®<br />

100<br />

• Production cut: 1/2" (12 mm)<br />

• Maximum cut: 3/4" (20 mm)<br />

• Ideal for robotic applications<br />

Specifications (subject to change without notice)<br />

Rated Output 100 Amps<br />

Output Range (A) 10 - 100 Amps<br />

Output (V) 80 - 180V<br />

Input Volts 208-230/460V, 3ph, 50-60 Hz,<br />

400V, 3ph, 50-60 Hz,<br />

600V, 3ph, 50-60 Hz<br />

Input Amps @<br />

Rated Output<br />

Duty Cycle<br />

(@104˚F / 40˚C)<br />

MAX OCV 380 VDC<br />

60A @ 208V, 50A @ 230V, 35A @ 400V,<br />

33A @ 460V, 26A @ 600V<br />

100% @ 100A @ 180V (18kW)<br />

Pre-Flow Gas Air @ 120 psi (8.3bar)<br />

Plasma Gas O 2 , H35, N 2 , Air @ 120 psi (8.3bar)<br />

Shield Gas O 2 , N 2 , Air @ 120 psi (8.3bar)<br />

H 2 0 @ 10 GPH (0.6 l /min)<br />

Weight Power Supply - 343 lbs. (156kg)<br />

Dimensions H 41.5" (1054 mm) x W 27.5" (700 mm) x<br />

D 38.5" (978 mm)<br />

(Fully Assembled Power Supply)<br />

Warranty Two Years Power Supply & One Year Torch<br />

Certifications CE, CCC, CSA<br />

4000<br />

3000<br />

2000<br />

Number of Starts 5000<br />

1000<br />

Longer Parts Life with<br />

XTremeLife Consumables<br />

10 20 30 40 50<br />

Cut Duration (seconds)<br />

Data obtained by cutting 3/8" (10 mm) with O2 @ 100 Amps<br />

Cutting Speed Chart<br />

Torch Model XT-Torch<br />

Production Piercing & Cutting Capacity (Mild Steel) 1/2" (12 mm)<br />

Maximum Piercing & Cutting Capacity (Mild Steel) 5/8" (15 mm)<br />

Maximum Edge Start (Mild Steel) 3/4" (20 mm)<br />

Material<br />

Mild Steel<br />

Stainless Steel<br />

Aluminum<br />

Thickness<br />

Inch<br />

Speed<br />

IPM<br />

Amps<br />

Plasma/<br />

Shield<br />

Thickness<br />

mm<br />

Speed<br />

mm/min.<br />

20 ga. 130 30 O2/O2 1 3050<br />

10 ga. 30 3 910<br />

10 ga. 210 70 O2/Air 3 6620<br />

1/4 120 6 3100<br />

3/16 190 100 O2/Air 5 4670<br />

1/4 150 6 4030<br />

3/8 95 10 2300<br />

1/2 64 12 1800<br />

5/8 50 15 1370<br />

26 ga. 350 30 Air/Air 0.6 8300<br />

20 ga. 300 1 7190<br />

16 ga. 110 1.5 3100<br />

14 ga. 170 50 N2/H20 2 4310<br />

12 ga. 150 3 3660<br />

3/16 70 5 1523<br />

10 ga. 120 70 N2/H20 3 3040<br />

3/16 90 5 2140<br />

1/4 50 6 1495<br />

1/4 72 100 N2/H20 6 1880<br />

3/8 55 10 1350<br />

1/2 42 12 1140<br />

1/4 70 100 H35/N2 6 1810<br />

16 ga. 140 50 N2/H20 2 2990<br />

11 ga. 60 3 1520<br />

3/16 40 5 950<br />

3/8 70 100 N2/H20 10 1665<br />

1/2 40 12 1190<br />

5/8 35 15 925<br />

1/2 50 100 H35/N2 12 1330<br />

Note: This cutting speed chart includes preliminary data and is subject to change<br />

without notice. Take care in comparison. The speeds noted above are best cut<br />

speeds. Often, competitors show maximum cutting speeds. Although much higher<br />

speeds can be achieved, edge quality and bevel angle may be compromised. The<br />

capabilities shown in this table were obtained by using new consumables, correct gas<br />

and current settings, accurate torch height control and with the torch perpendicular<br />

to the workpiece. The operating chart does not list all processes available for the<br />

Ultra-Cut 100. Please contact Thermal Dynamics® for more information.

Ultra Cut<br />

®<br />

200<br />

• Production cut: 1" (25 mm)<br />

• Maximum cut: 1½" (40 mm)<br />

• Handles 85% of applications<br />

• Highest cut speeds in the 200A range<br />

Specifications (subject to change without notice)<br />

Rated Output 200 Amps<br />

Output Range (A) 10 - 200 Amps<br />

Output (V) 80 - 180V<br />

Input Volts 208-230/460V, 3ph, 50-60 Hz,<br />

400V, 3ph, 50-60 Hz,<br />

600V, 3ph, 50-60 Hz<br />

Input Amps @<br />

Rated Output<br />

Duty Cycle<br />

(@104˚F / 40˚C)<br />

MAX OCV 380 VDC<br />

130A @ 208V, 125A @ 230V, 77A @ 400V,<br />

75A @ 460V, 78A @ 600V<br />

100% @ 200A @ 180V (36kW)<br />

Pre-Flow Gas Air @ 120 psi (8.3bar)<br />

Plasma Gas O 2 , H35, N 2 , Air @ 120 psi (8.3bar)<br />

Shield Gas O 2 , N 2 , Air @ 120 psi (8.3bar)<br />

H 2 0 @ 10 GPH (0.6 l /min)<br />

Weight Power Supply - 433 lbs. (197kg)<br />

Dimensions H 41.5" (1054 mm) x W 27.5" (700 mm) x<br />

D 38.5" (978 mm)<br />

(Fully Assembled Power Supply)<br />

Warranty Two Years Power Supply & One Year Torch<br />

Certifications CE, CCC, CSA<br />

Number of Starts<br />

3000<br />

2500<br />

2000<br />

1500<br />

1000<br />

500<br />

Longer Parts Life with<br />

XTremeLife Consumables<br />

10 20 30 40<br />

Cut Duration (seconds)<br />

Data obtained by cutting 5/8" (15 mm) with O2 @ 200 Amps<br />

A U T O M A T I O N<br />

Cutting Speed Chart<br />

Torch Model XT-Torch<br />

Production Piercing & Cutting Capacity (Mild Steel) 1" (25 mm)<br />

Maximum Piercing & Cutting Capacity (Mild Steel) 1½" (40 mm)<br />

Maximum Edge Start (Mild Steel) 2½" (65 mm)<br />

Material<br />

Mild Steel<br />

Stainless Steel<br />

Aluminum<br />

Thickness<br />

Inch<br />

Speed<br />

IPM<br />

Amps<br />

Plasma/<br />

Shield<br />

Thickness<br />

mm<br />

Speed<br />

mm/min.<br />

20 ga. 130 30 O2/O2 1 3050<br />

10 ga. 30 3 910<br />

10 ga. 210 70 O2/Air 3 6620<br />

1/4 120 6 3100<br />

1/4 150 100 O2/Air 6 4030<br />

3/8 95 10 2300<br />

1/2 64 12 1800<br />

5/8 50 15 1370<br />

1/2 100 150 O2/Air 12 2650<br />

3/4 50 20 1120<br />

1 25 25 650<br />

3/4 65 200 O2/Air 20 1590<br />

1 48 25 1250<br />

20 ga. 300 30 N2/H20 1 7190<br />

16 ga. 110 1.5 3100<br />

14 ga. 170 50 N2/H20 2 4310<br />

12 ga. 150 3 3660<br />

3/16 70 5 1523<br />

3/16 90 70 N2/H20 5 2140<br />

1/4 50 6 1495<br />

1/4 72 100 H35/N2 6 1880<br />

3/8 55 10 1350<br />

1/2 42 12 1140<br />

1/4 70 100 N2/H20 6 1810<br />

3/8 70 150 N2/H20 10 1740<br />

1/2 60 12 1580<br />

5/8 50 15 1250<br />

3/4 45 20 1140<br />

3/4 50 200 N2/H20 20 1100<br />

1 35 25 900<br />

3/4 40 200 H35/N2 20 950<br />

1 30 25 770<br />

11 ga. 60 50 Air/Air 3 1520<br />

3/16 40 5 950<br />

1/4 100 100 N2/H20 6 2760<br />

1/2 75 150 H35/N2 12 2100<br />

5/8 40 15 1260<br />

3/4 40 150 N2/H20 20 960<br />

3/4 90 200 N2/H20 20 2200<br />

1 50 25 1300<br />

3/4 70 200 H35/N2 20 1600<br />

1 40 25 1050<br />

Note: This cutting speed chart includes preliminary data and is subject to change without<br />

notice. Take care in comparison. The speeds noted above are best cut speeds. Often,<br />

competitors show maximum cutting speeds. Although much higher speeds can be achieved,<br />

edge quality and bevel angle may be compromised. The capabilities shown in this table were<br />

obtained by using new consumables, correct gas and current settings, accurate torch height<br />

control and with the torch perpendicular to the workpiece. The operating chart does not list<br />

all processes available for the Ultra-Cut 200. Please contact Thermal Dynamics® for more<br />

information.

Automated Plasma Cutting<br />

Ultra Cut<br />

®<br />

300<br />

• Production cut: 1½" (40 mm)<br />

• Maximum cut: 1¾" (45 mm)<br />

• Ideal for bevel cutting up to 45°<br />

on 1½" (40 mm)<br />

• Up to 3x faster than a single<br />

oxyfuel torch<br />

Specifications (subject to change without notice)<br />

Rated Output 300 Amps<br />

Output Range (A) 10 - 300 Amps<br />

Output (V) 80 - 180VDC<br />

Input Volts 208-230/460V, 3ph, 50-60 Hz,<br />

400V, 3ph, 50-60 Hz,<br />

600V, 3ph, 50-60 Hz<br />

Input Amps @<br />

Rated Output<br />

Duty Cycle<br />

(@104˚F / 40˚C)<br />

MAX OCV 380 VDC<br />

208A @ 208V, 188A @ 230V, 109A @ 400V,<br />

112A @ 460V, 81A @ 600V<br />

100% @ 300A @ 180V (54kW)<br />

Pre-Flow Gas Air @ 120 psi (8.3bar)<br />

Plasma Gas O 2 , H35, N 2 , Air @ 120 psi (8.3bar)<br />

Shield Gas O 2 , N 2 , Air @ 120 psi (8.3bar)<br />

H 2 0 @ 10 GPH (0.6 l /min).<br />

Weight Power Supply - 535 lbs. (243kg)<br />

Dimensions H 53.1" (1298 mm) x W 27.5" (700 mm) x<br />

D 38.5" (978 mm)<br />

(Fully Assembled Power Supply)<br />

Warranty Two Years Power Supply & One Year Torch<br />

Certifications CE, CCC, CSA<br />

Number of Starts<br />

2000<br />

1500<br />

1000<br />

Longer Parts Life with<br />

XTremeLife Consumables<br />

500<br />

10 20 30 40<br />

Cut Duration (seconds)<br />

Data obtained by cutting 3/4" (20 mm) with O2 @ 250 Amps<br />

Cutting Speed Chart<br />

Torch Model XT-Torch<br />

Production Piercing & Cutting Capacity (Mild Steel) 1½" (40 mm)<br />

Maximum Piercing & Cutting Capacity (Mild Steel) 1¾" (45 mm)<br />

Maximum Edge Start (Mild Steel) 3" (75 mm)<br />

Material<br />

Mild Steel Precision<br />

Stainless Steel<br />

Aluminum<br />

Thickness<br />

Inch<br />

Speed<br />

IPM<br />

Amps<br />

Plasma/<br />

Shield<br />

Thickness<br />

mm<br />

Speed<br />

mm/min.<br />

20 ga. 130 30 O2/O2 1 3050<br />

10 ga. 30 3 910<br />

1/4 120 70 O2/Air 6 3100<br />

1/4 150 100 O2/Air 6 4030<br />

3/8 95 10 2300<br />

1 48 200 O2/Air 25 1250<br />

1-1/4 30 35 750<br />

1-1/2 20 40 510<br />

3/4 100 300 O2/Air 20 2540<br />

1 70 25 1780<br />

1-1/4 50 35 900<br />

3 7 70 285<br />

20 ga. 300 30 N2/H20 1 7190<br />

16 ga. 110 1.5 3100<br />

14 ga. 170 50 N2/H20 2 4310<br />

12 ga. 150 3 3660<br />

3/16 70 5 1523<br />

3/16 90 70 N2/H20 5 2140<br />

1/4 50 6 1495<br />

1/4 72 100 H35/N2 6 1880<br />

3/8 55 10 1350<br />

1/4 70 100 N2/H20 6 1810<br />

3/4 50 200 N2/H20 20 1100<br />

1 35 25 900<br />

1 40 300 N2/H20 25 1030<br />

1-1/4 30 35 760<br />

1 35 300 H35/N2 25 920<br />

1-1/4 30 35 760<br />

11 ga. 60 50 Air/Air 3 1520<br />

3/16 40 5 950<br />

1/4 100 100 N2/H20 6 2760<br />

3/8 70 10 1700<br />

3/4 90 200 N2/H20 20 2200<br />

1 50 25 1300<br />

1 60 300 N2/H20 25 1560<br />

1-1/4 40 35 1000<br />

1 85 300 H35/N2 25 2190<br />

Note: This cutting speed chart includes preliminary data and is subject to change<br />

without notice. Take care in comparison. The speeds noted above are best cut<br />

speeds. Often, competitors show maximum cutting speeds. Although much higher<br />

speeds can be achieved, edge quality and bevel angle may be compromised. The<br />

capabilities shown in this table were obtained by using new consumables, correct gas<br />

and current settings, accurate torch height control and with the torch perpendicular<br />

to the workpiece. The operating chart does not list all processes available for the<br />

Ultra-Cut 300. Please contact Thermal Dynamics® for more information.

Ultra Cut<br />

®<br />

400<br />

• Production cut: 2" (50 mm)<br />

• Maximum cut: 2¼" (60 mm)<br />

• Ideal for bevel cutting up to 45°<br />

and up to 2" (50 mm)<br />

Specifications (subject to change without notice)<br />

Rated Output 400 Amps<br />

Output Range (A) 10 - 400 Amps<br />

Output (V) 80 - 200VDC<br />

Input Volts 208-230/460V, 3ph, 50-60 Hz,<br />

400V, 3ph, 50-60 Hz,<br />

460V, 3ph, 50-60 Hz<br />

Input Amps @<br />

Rated Output<br />

Duty Cycle<br />

(@104˚F / 40˚C)<br />

Number of Starts<br />

MAX OCV 380 VDC<br />

336A @ 208V, 304A @ 230V, 174A @ 400V,<br />

148A @ 460V<br />

100% @ 400A @ 200V (80kW)<br />

Pre-Flow Gas Air @ 120 psi (8.3bar)<br />

Plasma Gas O 2 , H35, N 2 , Air @ 120 psi (8.3bar)<br />

Shield Gas O 2 , N 2 , Air, H35 @ 120 psi (8.3bar)<br />

H 2 0 @ 10 GPH (0.6 l /min).<br />

Weight Power Supply - 636 lbs. (289kg)<br />

Dimensions H 53.1" (1298 mm) x W 27.5" (700 mm) x<br />

D 38.5" (978 mm)<br />

(Fully Assembled Power Supply)<br />

Warranty Two Years Power Supply & One Year Torch<br />

Certifications CE, CCC, CSA<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

Longer Parts Life with<br />

XTremeLife Consumables<br />

TDC<br />

Competitor<br />

10 20 30 40 50 60<br />

Cut Duration (seconds)<br />

Data obtained by cutting 1" (25 mm) with O2 @ 400 Amps<br />

* Parts life Ultra-Cut 400 with DFC-3000 Automatic Gas Console<br />

A U T O M A T I O N<br />

Cutting Speed Chart<br />

Torch Model XT-Torch<br />

Production Piercing & Cutting Capacity 2" (50 mm)<br />

Maximum Piercing & Cutting Capacity (Aluminum) 2¼" (60 mm)<br />

Maximum Edge Start 4" (100 mm) (SS) 3½" (90 mm) (MS)<br />

Material<br />

Thickness<br />

Inch<br />

Speed<br />

IPM<br />

Amps<br />

Plasma/<br />

Shield<br />

Thickness<br />

mm<br />

Speed<br />

mm/min.<br />

Mild Steel Precision<br />

10 ga. 30 30 O2/O2 3 910<br />

1/4 120 70 O2/Air 6 3100<br />

1/4 150 100 O2/Air 6 4030<br />

3/8 95 10 2300<br />

1 48 200 O2/Air 25 1250<br />

1-1/4 30 35 750<br />

3/4 100 300 O2/Air 20 2540<br />

1 70 25 1780<br />

1-1/4 50 35 900<br />

1 80 400 O2/Air 25 2100<br />

1-1/2 45 40 1330<br />

2 30 50 790<br />

Stainless Steel<br />

16 ga. 110 30 N2/H20 1.5 3100<br />

14 ga. 170 50 N2/H20 2 4310<br />

3/16 70 5 1523<br />

1/4 50 70 N2/H20 6 1495<br />

1/4 72 100 H35/N2 6 1880<br />

3/8 55 10 1350<br />

1/4 70 100 N2/H20 6 1810<br />

3/4 50 200 N2/H20 20 1100<br />

1 35 25 900<br />

1 40 300 N2/H20 25 1030<br />

1-1/4 30 35 760<br />

1 35 300 H35/N2 25 920<br />

1-1/2 30 40 760<br />

3/4 90 400 N2/H20 20 2286<br />

1-1/2 30 40 760<br />

1 45 400 H35/N2 25 1170<br />

2 17 50 440<br />

4 3.5 400 H35/H35 100 90<br />

Aluminum<br />

11 ga. 60 50 Air/Air 3 1520<br />

1/4 100 100 N2/H20 6 2760<br />

3/8 70 10 1700<br />

3/4 90 200 N2/H20 20 2200<br />

1 50 25 1300<br />

1 60 300 N2/H20 25 1560<br />

1-1/4 40 32 1000<br />

1 85 H35/N2 25 2190<br />

3/4 90 400 N2/H20 20 2200<br />

1-1/2 55 40 1350<br />

1 90 400 H35/N2 25 2330<br />

2 30 50 810<br />

Note: This cutting speed chart includes preliminary data and is subject to change<br />

without notice. Take care in comparison. The speeds noted above are best cut<br />

speeds. Often, competitors show maximum cutting speeds. Although much higher<br />

speeds can be achieved, edge quality and bevel angle may be compromised. The<br />

capabilities shown in this table were obtained by using new consumables, correct gas<br />

and current settings, accurate torch height control and with the torch perpendicular<br />

to the workpiece. The operating chart does not list all processes available for the<br />

Ultra-Cut 400. Please contact Thermal Dynamics® for more information.

Automated Plasma Cutting<br />

Height Control: SC-3100 and SC-3200<br />

Features<br />

Torch Height Adjustable in Distance or Voltage<br />

Distance mode:<br />

• Change speed without changing stand-off height<br />

• Automatically adjusts for electrode wear<br />

• Cut continuously at peak performance<br />

Voltage mode:<br />

• Ideal for contoured materials<br />

Built-in Collision Sensor<br />

• No costly sensor to replace<br />

• No air source required at lifter station<br />

• Works in X-Y-Z planes; works in all directions<br />

Arc Voltage Range<br />

• Ready for most applications, from plasma marking<br />

to cutting the thickest materials<br />

Easy to Operate<br />

• High contrast display for maximum visibility<br />

• Operating parameters accessed using two<br />

drop-down menus<br />

Fast Installation<br />

• Easily connects to most CNC and plasma systems on<br />

the market today<br />

Pierce Retract<br />

• Lifts torch after initial piercing to increase pierce capacity<br />

Direct Control<br />

• Lifter can be controlled directly from CNC interface; no<br />

separate terminal necessary<br />

Instant Pierce Height<br />

• Adjustable torch height for better initial pierce height<br />

finding on gauge materials<br />

Specifications<br />

(subject to change without notice)<br />

Lifter Station SC-3100 SC-3200<br />

Height: 18.70" (475 mm) 19.76" (502 mm)<br />

Width: 3.93" (100 mm) 4.92" (125 mm)<br />

Depth: 6.73" (171 mm) 8.97" (228 mm)<br />

Weight: 22 lbs. (10 kg) 26.4 lbs (12 kg)<br />

Position Speed: 283.5 ipm (120 mm/sec.) 190 ipm (80 mm/sec.)<br />

Stroke: 4.72" (120 mm) 8.66" (220 mm)<br />

Lifting Capacity: 15.4 lbs. (7 kg) 26.4 lbs (12 kg)<br />

Remote Terminal SC-3100 SC-3200

Ultra-Cut ® Systems Include<br />

• Power supply<br />

• Supply leads to remote arc starter<br />

• Manual Gas console (GCM-2010) or Automated<br />

Digital Flow Controller (DFC-3000)<br />

• Torch installation starter kit<br />

• Remote arc starter (RAS-1000)<br />

• Torch leads<br />

Options And Accessories<br />

• Spare parts kit<br />

• Wheel kit<br />

Cat. No. 9-9379<br />

• TSC-3000 (Touch Screen Controller)<br />

• Ohmic clip<br />

Cat. No. 9-9414<br />

• Water filter<br />

Cat. No. 9-1068<br />

• Water filter cartridge<br />

Cat. No. 9-1069<br />

• Water pressure regulator<br />

Cat. No. 8-6118<br />

• RAS shelf kit and hardware<br />

Cat. No. 9-9484<br />

DFC-3000 RAS-1000<br />

A U T O M A T I O N<br />

Manual Gas Box<br />

Torch Coolant<br />

Power Supply<br />

Extra Cool Coolant<br />

Cat No. 7-3580<br />

Resists freezing down to +10˚ (-12˚C)<br />

Ultra Cool Coolant<br />

Cat. No. 7-3581<br />

Resists freezing down to -27˚ (-33˚C)<br />

Extreme Cool Coolant<br />

Cat. No. 7-3582<br />

Resists freezing down to -65˚F (-51˚C)<br />

De-I Cool Coolant<br />

Cat. No. 7-3583<br />

De-ionized water mixture for use where freezing<br />

protection is not required<br />

For complete ordering information contact<br />

Thermal Dynamics ® or your local Thermal<br />

Dynamics Automation Distributor.

performance<br />

A U T O M A T I O N<br />

technology<br />

reliability<br />

innovation<br />

service<br />

DISTRIBUTED BY:<br />

U.S. Plasma Automation Customer Care: 866-279-2628 / FAX 800-535-0557 • Canada Customer Care: 905-827-4515 / FAX 800-588-1714<br />

International Customer Care: 940-381-1212 / FAX 940-483-8178 • www.thermal-dynamics.com<br />

Denton, TX USA<br />

U.S. Customer Care<br />

Ph: 1-800-426-1888 (tollfree)<br />

Fax: 1-800-535-0557 (tollfree)<br />

International Customer Care<br />

Ph: 1-940-381-1212<br />

Fax: 1-940-483-8178<br />

A Global Cutting & Welding Market Leader <br />

WORLD HEADQUARTERS: 16052 Swingley Ridge Road, Suite 300 • St. Louis, Missouri 63017 U.S.A.<br />

THE AMERICAS EUROPE ASIA/PACIFIC<br />

Miami, FL USA<br />

Sales Office, Latin America<br />

Ph: 1-954-727-8371<br />

Fax: 1-954-727-8376<br />

Oakville, Ontario, Canada<br />

Canada Customer Care<br />

Ph: 1-905-827-4515<br />

Fax: 1-800-588-1714 (tollfree)<br />

Chorley, United Kingdom<br />

Customer Care<br />

Ph: +44 1257-261755<br />

Fax: +44 1257-224800<br />

Milan, Italy<br />

Customer Care<br />

Ph: +39 0236546801<br />

Fax: +39 0236546840<br />

Cikarang, Indonesia<br />

Customer Care<br />

Ph: 6221-8990-6095<br />

Fax: 6221-8990-6096<br />

Rawang, Malaysia<br />

Customer Care<br />

Ph: +603 6092-2988<br />

Fax: +603 6092-1085<br />

Melbourne, Australia<br />

Australia Customer Care<br />

Ph: 1300-654-674 (tollfree)<br />

Ph: 61-3-9474-7400<br />

Fax: 61-3-9474-7391<br />

International<br />

Ph: 61-3-9474-7508<br />

Fax: 61-3-9474-7488<br />

Shanghai, China<br />

Sales Office<br />

Ph: +86 21-64072626<br />

Fax: +86 21-64483032<br />

Singapore<br />

Sales Office<br />

Ph: +65 6832-8066<br />

Fax: +65 6763-5812<br />

Form No. 63-2905 (07/15/11) © 2011 Thermadyne Industries, Inc. www.thermadyne.com Printed in U.S.A.