TTC Timmler Technology TTC Silent Gravitiy Cooling – Modultherm ...

TTC Timmler Technology TTC Silent Gravitiy Cooling – Modultherm ...

TTC Timmler Technology TTC Silent Gravitiy Cooling – Modultherm ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

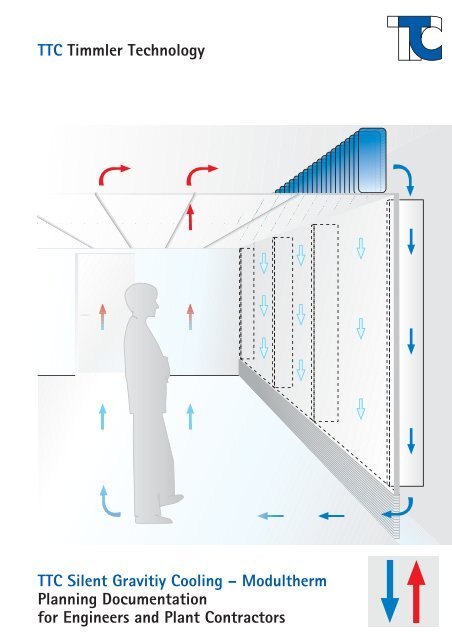

<strong>TTC</strong> <strong>Timmler</strong> <strong>Technology</strong><br />

<strong>TTC</strong> <strong>Silent</strong> <strong>Gravitiy</strong> <strong>Cooling</strong> <strong>–</strong> <strong>Modultherm</strong><br />

Planning Documentation<br />

for Engineers and Plant Contractors

<strong>TTC</strong> Order Key for <strong>Cooling</strong> Units<br />

2<br />

Order Key for <strong>TTC</strong> <strong>Cooling</strong> Units<br />

AASS 30 33 2 L 1<br />

Performance category<br />

1 = for construction height 33 (effective duct height H 1,5<strong>–</strong>6 m)<br />

eff.<br />

2 = for construction height 51 (effective duct height H 1,5<strong>–</strong>7 m)<br />

eff.<br />

Water connection<br />

L = Left<br />

R = Right<br />

Function<br />

2 = 2 pipe system<br />

Construction height [cm]<br />

33 > for series: AASS; ASVI; AISI; AVSI<br />

51 > for series: AASS; ASVI; AISI; AVSI<br />

Width [dm]<br />

08 - 10 - 12 - 14 - 16 - 18 - 20 - 22 - 24 dm<br />

Series<br />

AASS<br />

AISI<br />

AAVS<br />

AASI<br />

© 2004 <strong>TTC</strong> <strong>Timmler</strong> <strong>Technology</strong> GmbH.<br />

This document or any part thereof may not be reprinted, copied, or translated and figures and<br />

diagrams may not be used without prior written agreement from <strong>TTC</strong> <strong>Timmler</strong> <strong>Technology</strong> GmbH.<br />

Issued 02/2005. We reserve the right to make technical changes.

<strong>TTC</strong> Contents<br />

<strong>TTC</strong> <strong>Timmler</strong><br />

<strong>Technology</strong> GmbH<br />

Zum Wetterschacht 1<br />

D-45659 Recklinghausen<br />

Tel +49(0)23 61-9 15 96 80<br />

Fax +49(0) 23 61-9 15 96 89<br />

Email: info@ttc-technology.de<br />

http://www.ttc-technology.de<br />

General Information 4 <strong>–</strong> 5<br />

• Air-conditioning in general<br />

• <strong>TTC</strong> cooling units, function, advantages and applications<br />

Installation Examples 6 <strong>–</strong> 9<br />

• Installation options<br />

• Air inlets and outlets for <strong>TTC</strong> cooling units<br />

• <strong>TTC</strong> cooling units in primary air mode<br />

Technical Data and Information 10 <strong>–</strong> 11<br />

• Dimensions<br />

• Series<br />

• Weights<br />

Performance Diagrams 12 <strong>–</strong> 13<br />

• <strong>Cooling</strong> capacity for categories 1 and 2<br />

• Pressure drop on the water side<br />

• Formulae to calculate capacity<br />

Design Example 14 <strong>–</strong> 15<br />

• Water and air cooling<br />

• Pressure drop on the water side<br />

Accessories 16<br />

• Capacity reducing factors for <strong>TTC</strong> air inlet and outlet grating<br />

• Part no. for <strong>TTC</strong> air inlet and outlet grating<br />

Installation Instructions 17 <strong>–</strong> 18<br />

• Pipe installation for <strong>TTC</strong> cooling units<br />

• Reduced capacity through infiltrated air<br />

Order and Calculation Sheet 19<br />

for <strong>TTC</strong> <strong>Modultherm</strong> cooling units and accessories<br />

3

4<br />

<strong>TTC</strong> Information About Air Conditioning<br />

Advantages of <strong>TTC</strong> <strong>Modultherm</strong> cooling units<br />

Why do we air condition rooms? Is ventilation required?<br />

Advantages of <strong>TTC</strong> <strong>Modultherm</strong><br />

Working people spend the majority of<br />

their working life indoors. A maximum of<br />

physical and intellectual work is to be<br />

performed in this artificial environment.<br />

Studies with volunteers have shown that a<br />

persons productivity can be directly<br />

related to the thermal and air hygienical<br />

comfort of the room. In this context the<br />

air velocity, the relative humidity, the<br />

temperature gradient and the supply of<br />

primary air are of particular interest.<br />

Fig. 4.1-4.3 show mainly the results of<br />

studies by Prof. Ole Fanger and D. Wyon<br />

with a select number of volun-teers to<br />

determine peoples dissatisfaction with<br />

and acceptance of air-conditioning<br />

systems.<br />

Preferred cooling systems<br />

Either water or air is generally the carrier<br />

for the cooling energy. The following<br />

solutions are commonly used to cool down<br />

commercial premises:<br />

• Centrally treated and cooled primary air<br />

• <strong>Cooling</strong> of structural elements<br />

• Chilled ceiling systems<br />

• Wall and ceiling systems with cooling<br />

units or chilled beams<br />

• <strong>Cooling</strong> units or convectors combined<br />

with cooled primary air<br />

Intellectual Performance [%]<br />

95<br />

90<br />

85<br />

80<br />

75<br />

70<br />

65<br />

60<br />

22 23 24 25 26 27 28 29 30<br />

Room Temperature [°C]<br />

4.1 Intellectual performance at different<br />

room temperatures<br />

Issued 02/2005. We reserve the right to make technical changes.<br />

Relevant laws* and regulations* provide<br />

that commercially used spaces must have<br />

a primary airflow rate of approx. 6-9 m 3 /<br />

(h · m 2 ) or a change of air at 2-3 times the<br />

room volume to comply with air hygiene<br />

requirements. These minimal primary air<br />

streams can thus significantly reduce<br />

ventilation systems and save running and<br />

investment costs.<br />

*(Arbeitsstättenrichtlinie /German Work Place Directive, DIN<br />

1946 / Part 2 / Paragraph 3.2)<br />

4.2 Unhappiness at different temperatures<br />

Unhappy people [%]<br />

60<br />

40<br />

20<br />

10<br />

5<br />

1<br />

0,1<br />

Present in the room for 90 minutes<br />

Present in the room for 180 minutes<br />

0 1 2 3 4 5 6<br />

Temperature curve [K]<br />

Percentage of people who are unhappy with the<br />

rooms air conditioning, dependent on the:<br />

• floor level (ankle height) 0.1 m and<br />

head height (person is seated) 1.1m<br />

• No draughts, air speed 0.1-0.2 m/s<br />

• Condensation tray as standard, to<br />

prevent damage to furnishings and the<br />

building if condensation occurs<br />

• High fall ducts for the cooling air to<br />

provide high cooling capacity with<br />

a small space requirement<br />

• <strong>Silent</strong> operation without ventilation<br />

• Low running and investment costs for<br />

high comfort levels<br />

• Easy to upgrade if alterations are required<br />

• A wealth of design options for the<br />

room, for planners and architects<br />

• High thermal and hygienic comfort if<br />

combined with a primary air system<br />

• Additional to let area<br />

• Room temperatures can be individually<br />

controlled<br />

4.3 Acceptance with different airconditioning<br />

systems<br />

Unhappy People (%)<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

with RLT system<br />

without RLT system<br />

5<br />

0<br />

cooling ceiling* and<br />

distributed ventilation<br />

22 23 24 25 26 27 28<br />

Room temperature [°C]<br />

Acceptance with different air-conditioning systems<br />

and room temperatures. (A study by P. O.<br />

Fanger and D. Wyon)<br />

* Note! Instead of cooling ceilings, cooling units or<br />

cooling convectors could be used as an alternative.

<strong>TTC</strong> <strong>Modultherm</strong> <strong>Cooling</strong> System<br />

The functional principle of <strong>TTC</strong> <strong>Modultherm</strong><br />

Functional principle<br />

The functional principle of the <strong>TTC</strong> cooling units is based on the<br />

natural fact that warm and cold air have a different air density<br />

ρ [kg/m 3 ].<br />

At ceiling level warm air enters through the inlet grating (4) and<br />

is cooled down in the air cooler (1) through which cold water<br />

flows (see Fig. 5.1). If operated at high humidity, e.g. in a hotel<br />

room, special production rooms or when operated with-out preconditioned<br />

primary air a conden-sation tray is supplied as<br />

standard under-neath the air cooler. Through the fall duct (2)<br />

and an attractive air outlet (3) the cooled air is returned to the<br />

room.<br />

This cooled air is then warmed up again by heat sources in the<br />

room, e.g. people, lighting, computers and other electrical and<br />

electronic equipment, sunrays through the windows, the warmth<br />

of the walls and rises to the ceiling.<br />

The air velocity generated in the room through thermal<br />

conditions is very low and can only be measured with special<br />

equipment. This minute air circulation results in high thermal<br />

comfort levels and minimum temperature gradients in the<br />

occupied zone. The characteristic curves shown in the capacity<br />

diagrams on pages 12-14 are based on test rig measurements<br />

and were carried out under defined installation and operating<br />

conditions.<br />

Differing constructional conditions will need to be taken into<br />

account when determining the cooling performance of cooling<br />

units. <strong>TTC</strong> will be happy to help you with your calculations.<br />

H wirks.<br />

12<br />

11<br />

2<br />

1<br />

T erf.<br />

4<br />

3<br />

Performance factors<br />

The performance of the <strong>TTC</strong> cooling units depends on many<br />

factors, for example:<br />

• The effective fall duct height, H eff.<br />

• The fall duct depth D req. (for unit height 330 = 100 mm and<br />

for unit height 510 = 150 mm)<br />

• Spacing between sealing off walls (desired 600-800 mm,<br />

see page 17)<br />

• Smooth surface of the fall ducts and sealing off walls<br />

• Prevention of infiltrated air<br />

• Duct insulation on front and rear walls<br />

• The free cross-section of the inlet and outlet gratings (at<br />

least 70% of the visible surface of the finned cooling unit).<br />

For other cross-sections see the chapter Reduced<br />

Performance on page 16<br />

• Median temperature difference ∆ϑ m [K] between air intake<br />

and median temperature of the cooling medium<br />

• Water viscosity and quality (VDI 2025)<br />

• Flow path restriction caused by the pipe work or structural<br />

obstacles<br />

• Redirection of the cool air flow<br />

Area of application<br />

<strong>TTC</strong> <strong>Modultherm</strong> cooling units are ideally suited for all areas of<br />

application, where silent and efficient control of temperature is<br />

required:<br />

Small and open plan offices, Conference rooms, Computer<br />

rooms, Recording and TV studios, Hotel rooms, Public access<br />

areas, Reception areas, Department stores, Printing and paper<br />

works, Assembly and production facilities, to remove heat from<br />

electronic or electrical control cabinets, etc.<br />

10<br />

5.1 Room airflow in cooling<br />

mode using <strong>TTC</strong> cooling units<br />

(1) Air cooler incl. condensation<br />

tray<br />

(2) Fall duct for cold air<br />

(3) Air opening (min. 70 % free<br />

cross-section of the air cooler<br />

visible area)<br />

(4) Air inlet grating (min. 70 %<br />

free cross-section of the air<br />

cooler visible area)<br />

(10) False floor convector for<br />

heating mode<br />

(11) Required fall duct depth Dreq. (12) Effective fall duct height Heff. Issued 02/2005. We reserve the right to make technical changes.<br />

5

<strong>TTC</strong> Installation Examples<br />

Fig. 6.1 shows the installation of an AASS unit in a TV studio or a<br />

test centre on a wall (dry construction wall installed in post-andbeam<br />

construction).<br />

Key to 6.1<br />

14<br />

1<br />

4<br />

(1) <strong>Cooling</strong> unit incl. condensation tray to collect condensate in<br />

2<br />

dehumidification mode<br />

(2) Fall duct with sealing off walls (5) (spacing 600-800 mm)<br />

The minimum depth D is 100mm for unit height 33 and<br />

req.<br />

5<br />

150mm for unit height 51<br />

(6) Floor outlet grating with a free cross-section of 70 % of the<br />

visible area of the finned air cooler<br />

(4) Air inlet grating with a free cross-section of 70% of the<br />

visible area of the finned air cooler<br />

9<br />

(5) Sealing off walls to stabilize the cold air flow<br />

(9) Mixing desk or test console in studios or test centres<br />

Note!<br />

The minimum requirements under 2, 3 and 4.1 must be complied<br />

with to ensure the quoted capacities.<br />

6<br />

For other free cross-sections see page 16 or contact <strong>TTC</strong>. 6.1 Room air flow with <strong>TTC</strong> cooling units in cooling mode<br />

Fig. 6.2-6.4 show three options for the air intake. Other options<br />

are available, please contact <strong>TTC</strong>.<br />

Fig. 6.2 shows the air flow to the cooling unit (1) via an air inlet<br />

grating (4) which has been integrated into a false ceiling.<br />

In Fig. 6.3 the air inlet grating has been replaced by an air gap<br />

(7) in the false ceiling.<br />

Fig. 6.4 shows ceiling panels with slits for the air intake.<br />

Optionally slots may also be placed at the ceiling edges.<br />

Key to 6.2-6.4<br />

(1) <strong>Cooling</strong> unit incl. condensation tray to collect condensate in<br />

dehumidification mode<br />

(2) Fall duct with sealing off walls (5) (spacing 600-800 mm)<br />

The minimum depth D req. is 100mm for unit height 33 and<br />

150mm for unit height 51<br />

(4) Air inlet grating with a free cross-section of 70% of the<br />

visible area of the finned air cooler<br />

(7) Air gap in the false ceiling (70% free cross-section)<br />

(8) Ceiling panels with air slits (free cross-section, 70% or the<br />

visible area of the finned air cooler)<br />

Gaps between wall and ceiling (not shown)<br />

Note!<br />

The minimum requirements under 2, 4, 7 and 8 must be complied<br />

with to ensure the quoted capacities.<br />

For other free cross-sections see page 16 or contact <strong>TTC</strong>.<br />

6<br />

Example 1: <strong>Cooling</strong> unit on a wall<br />

Example 2: Air intake for cooling units<br />

Issued 02/2005. We reserve the right to make technical changes.<br />

2<br />

1<br />

6.2 Air intake through air inlet gratings in a false ceiling<br />

1<br />

2 7<br />

6.3 Air intake through an air gap in the false ceiling<br />

2<br />

1<br />

6.4 Air intake through ceiling panels<br />

4<br />

8

<strong>TTC</strong> Installation Examples<br />

2<br />

1<br />

5<br />

4<br />

3<br />

4<br />

7.1 Room air flow with <strong>TTC</strong> cooling units in cooling mode<br />

2<br />

1<br />

5<br />

3<br />

4<br />

7.2 Air being released into the room through wall and floor<br />

gratings<br />

Example 3: <strong>Cooling</strong> unit behind a screen<br />

This example (Fig. 7.1) illustrates the installation of an AASS<br />

cooling unit above a cupboard or shelves.<br />

Key to 7.1<br />

(1) <strong>Cooling</strong> unit AASS incl. condensation tray to collect<br />

condensate in dehumidification mode<br />

(2) Fall duct with sealing off walls (5) (spacing 600-800 mm)<br />

The minimum depth, D req. is 100mm for unit height 33 and<br />

150mm for unit height 51<br />

(3) Air outlet grating with a free cross-section of 70% of the<br />

visible area of the finned air cooler<br />

(4) Screened air inlet grating (the free air intake should be 70%<br />

of the visible area of the finned air cooler)<br />

(5) Sealing off walls to stabilize the cold air flow<br />

Note!<br />

The minimum requirements under 2, 3 and 4 must be complied<br />

with to ensure the quoted performances.<br />

For other free cross-sections see page 16 or contact <strong>TTC</strong>.<br />

Example 4: Air outlet grating into the room<br />

Fig. 7.2 illustrates the option for air to be dispersed into the<br />

room through an air outlet grating (3). This type of air flow into<br />

the room ensures a good, even temperature distribution.<br />

To dimension the floor air outlets consultation with a ventilation<br />

engineer is recommended.<br />

Key to 7.2<br />

(1) <strong>Cooling</strong> unit AASS incl. condensation tray to collect<br />

condensate in dehumidification mode<br />

(2) Fall duct with sealing off walls (5) (spacing 600-800 mm)<br />

The minimum depth D req. is 100mm for unit height 33 and<br />

150mm for unit height 51<br />

(3) Air outlet grating with a free cross-section of 70% of the<br />

visible area of the finned air cooler<br />

(4) Air inlet grating with a free cross-section of 70% of the<br />

visible area of the finned air cooler<br />

Note!<br />

The minimum requirements under 3 and 4 must be complied<br />

with to ensure the quoted performance.<br />

For other free cross-sections see page 16 or contact <strong>TTC</strong>.<br />

Issued 02/2005. We reserve the right to make technical changes.<br />

7

<strong>TTC</strong> Installation Examples<br />

8<br />

Example 5: <strong>Cooling</strong> unit integrated into the duct<br />

Fig. 8.1 shows the AISI cooling unit (1) integrated into a fall<br />

duct (2). On the room side the cooling unit is screened by an<br />

architecturally appealing air inlet grating which should have a<br />

free cross-section of 70%. For this type of installation a<br />

mounting frame is supplied as standard. The top joint to the<br />

bare ceiling is formed, for example, by a waffle-type ceiling at<br />

the discretion of the architect and client.<br />

Key to 8.1<br />

(1) <strong>Cooling</strong> unit AISI incl. condensation tray to collect<br />

condensate in dehumidification mode<br />

(2) Fall duct with sealing off walls 5 (spacing 600<strong>–</strong>800 mm)<br />

The minimum depth D req. is 100mm for unit height 33 and<br />

150mm for unit height 51<br />

(3) Air outlet grating with a free cross-section of 70% of the<br />

visible area of the finned air cooler<br />

(4) Air inlet grating with a free cross-section of 70% of the<br />

visible area of the finned air cooler<br />

(5) Sealing off walls to stabilize the cold air flow<br />

Note!<br />

The minimum requirements under 2, 3 and 4 must be complied<br />

with to ensure the quoted performance.<br />

For other free cross-sections see page 16 or contact <strong>TTC</strong>.<br />

2<br />

1<br />

5<br />

3<br />

5<br />

4<br />

2<br />

1<br />

5<br />

3<br />

8.1 <strong>TTC</strong> cooling unit integrated in the duct<br />

Example 6: <strong>Cooling</strong> unit on a wall with dispersed air outlet at the window<br />

Fig. 8.2 shows the cooling unit AASS (1)<br />

above a fall duct (2). On the room side the<br />

cooling unit is screened by an<br />

architecturally appealing air inlet grating<br />

(4) which should have a free cross-section<br />

of 70%.<br />

The air is returned to the room through a<br />

floor grating at the window. This type of<br />

installation always requires a false floor.<br />

Key to 8.2<br />

Items (1), (2), (4) are (5) equivalent to<br />

Fig. 8.1.<br />

(6) Floor grating integrated into the false<br />

floor as a dispersed air outlet.<br />

Note!<br />

The minimum requirements under 2, 3 and<br />

4 must be complied with to ensure the<br />

quoted performance.<br />

For other free cross-sections see page 16<br />

or contact <strong>TTC</strong>.<br />

Issued 02/2005. We reserve the right to make technical changes.<br />

8.2 Air distribution via air dispersal outlet in the floor<br />

4<br />

6

<strong>TTC</strong> Installation Examples<br />

Example 7: <strong>Cooling</strong> unit in a false ceiling with additional primary air mode Function<br />

Function<br />

Example 7 (Fig. 9.1) shows how <strong>TTC</strong> units may be combined with a primary air system.<br />

Via the primary channel (8) conditioned outdoor air is blown at low speed into the fall<br />

ducts via channels or pipes. If suitable silencers are used the sound pressure level can<br />

be kept below 30 (dBA).<br />

Installation<br />

The cooling unit (1) can be installed on a wall between the bare and the false ceiling,<br />

on a cupboard or shelves. Design options showing how the cooling units could be<br />

covered on the room side are shown on page 6 (Fig. 6.2-6.4).<br />

For the primary air intake the following variants would be suitable:<br />

• Air outlet gratings (3) in walls, cupboards or shelves<br />

• Air outlet gratings in the false floor, see Fig. 8.1 on page 8<br />

• Dispersed air outlets<br />

Outdoor air flow<br />

In rooms to be occupied by people the outdoor air flow needs to be sized dependent on<br />

how many people are present in the room at the same time and what the room is used<br />

for (see the table on the right).<br />

The outdoor air flow is frequently provided at 2.5-3 times the change of room air.<br />

At the maximum outdoor temperature values (see DIN 4701 / parts 1 and 2 as well as<br />

VDI 2078) the outdoor air flow can be reduced by 50% of the minimum outdoor air<br />

flow per person. For rooms with additional pollution through smells (e.g. tobacco<br />

smoke) the minimum outdoor air flow is increased by 20 m3 /h per person.<br />

4<br />

3<br />

5<br />

1<br />

2<br />

13<br />

Minimum primary air flow per person<br />

and hour*<br />

Room type m3 /h<br />

Small office 30<br />

Open plan office 50<br />

Theatre/concert hall 20<br />

Canteen 30<br />

Conference room 30<br />

Cinema 20<br />

Banqueting hall 20<br />

Rest room 30<br />

Break room 30<br />

Class room 30<br />

Reading room 20<br />

Lecture theatre 30<br />

Show room 20<br />

Shop 20<br />

Museum 20<br />

Hotel room 30<br />

Public house/restaurant<br />

Gymnastic and sport hall<br />

40<br />

with seating for spectators 20<br />

*) in accordance with DIN 1946 / Part 2 /Paragraph<br />

3.2<br />

9.1 <strong>TTC</strong> <strong>Modultherm</strong> cooling unit with<br />

primary air mode<br />

(1) Air cooler incl. condensation tray<br />

(2) Fall duct for cold air<br />

(3) Air outlet grating (min. 70% free<br />

cross-section of the visible area of<br />

the air cooler)<br />

(4) Air inlet grating (min. 70% free crosssection<br />

of the visible area of the air<br />

cooler)<br />

(5) Sealing off walls to stabilize the cold<br />

air flow<br />

(13) Primary air channel<br />

Issued 02/2005. We reserve the right to make technical changes.<br />

9

<strong>TTC</strong> Dimensions and Information<br />

AASS 33 (51)** series<br />

Design<br />

(1) Air cooler made of copper pipes with<br />

aluminium fins, max. operating<br />

temperature 90 0C, max. operating<br />

pressure 10 bar<br />

(2) Housing completely made of<br />

galvanized steel plate<br />

(3) Water connection with R 3/4“, torsion<br />

protection<br />

(4) Condensation tray to collect<br />

condensate in dehumidification mode<br />

(5) Condensate drain, ø12 mm, mounted<br />

on the condensate tray and supplied as<br />

standard<br />

Installation<br />

The cooling unit can be installed above<br />

shafts, cupboards or shelves. For examples<br />

see pages 6-9.<br />

Important: To ensure optimum operation<br />

sealing off walls spaced at 600 to 800 mm<br />

need to be installed in the fall ducts.<br />

10<br />

AAVS 33/51** series<br />

Design<br />

(1) Air cooler made of copper pipes with<br />

aluminium fins, max. operating<br />

temperature 90 0 C, max. operating<br />

pressure 10 bar<br />

(2) Housing completely made of<br />

galvanized steel plate incl. mounting<br />

frame (6)<br />

(3) Water connection with R 3/4“, torsion<br />

protection<br />

(4) Condensation tray to collect<br />

condensate in dehumidification mode<br />

(5) Condensate drain, ø12 mm, mounted<br />

on the condensate tray and supplied as<br />

standard<br />

(6) Mounting frame made of galvanized<br />

steel sheet, supplied as standard<br />

Installation<br />

The mounting frame is used to install the<br />

cooling unit in front of the fall duct wall.<br />

Important: To ensure optimum operation<br />

sealing off walls spaced at 600 to 800 mm<br />

need to be installed in the fall ducts.<br />

Issued 02/2005. We reserve the right to make technical changes.<br />

10.1<br />

Part no: AASS .. ..**) 08 10 12 14 16 18 20 22 24<br />

Finned length L finned [mm] 720 920 1120 1320 1520 1720 1920 2120 2320<br />

Total unit length L tot. [mm] 800 1000 1200 1400 1600 1800 2000 2200 2400<br />

Total weight (33) ≈ [kg] 26 32 39 46 52 59 65 72 79<br />

Total weight (51) ≈ [kg] 39 49 59 69 80 90 100 110 120<br />

**) see order key on page 2<br />

10.2<br />

3<br />

40<br />

40<br />

*) Dimensions in brackets are for construction height 51<br />

Part no: AAVS .. ..**) 08 10 12 14 16 18 20 22 24<br />

Finned length L finned [mm] 720 920 1120 1320 1520 1720 1920 2120 2320<br />

Total unit length L tot. [mm] 800 1000 1200 1400 1600 1800 2000 2200 2400<br />

Total weight (33) ≈ [kg] 24 30 37 44 50 57 63 70 77<br />

Total weight (51) ≈ [kg] 37 47 57 67 78 88 98 108 118<br />

**) see order key on page 2<br />

2<br />

1<br />

1<br />

2<br />

Finned length Lfinned<br />

Frame length FL<br />

Finned length Lfinned<br />

Frame length FL<br />

4<br />

330 (510)*<br />

300 (510)*<br />

*) Dimensions in brackets are for construction height 51<br />

5<br />

25<br />

105<br />

5<br />

50<br />

30<br />

Ø12 mm<br />

200<br />

1<br />

5<br />

150<br />

5<br />

80<br />

3<br />

300<br />

4<br />

30<br />

100<br />

(150)*<br />

6<br />

100<br />

(150)*

<strong>TTC</strong> Dimensions and Information<br />

11.1<br />

Part no: AISI .. ..**) 08 10 12 14 16 18 20 22 24<br />

Finned length L finned [mm] 720 920 1120 1320 1520 1720 1920 2120 2320<br />

Total unit length L tot. [mm] 800 1000 1200 1400 1600 1800 2000 2200 2400<br />

Total weight (33) ≈ [kg] 23 29 36 43 49 56 62 69 76<br />

Total weight (51) ≈ [kg] 36 46 56 66 77 87 97 107 117<br />

**) see order key on page 2<br />

11.2<br />

3<br />

40<br />

3<br />

40<br />

Part no: AASI .. ..**) 08 10 12 14 16 18 20 22 24<br />

Finned length L finned [mm] 720 920 1120 1320 1520 1720 1920 2270 2320<br />

Total unit length L tot. [mm] 800 1000 1200 1400 1600 1800 2000 2200 2400<br />

Total weight (33) ≈ [kg] 23 29 36 43 49 56 62 69 76<br />

Total weight (51) ≈ [kg] 36 46 56 66 77 87 97 107 117<br />

**) see order key on page 2<br />

5<br />

345 (525)*<br />

*) Dimensions in brackets are for construction height 51<br />

2<br />

5<br />

2<br />

Finned length Lfinned<br />

Frame length FL<br />

50<br />

Finned length Lfinned<br />

Frame length FL<br />

50<br />

25<br />

Ø 12 mm<br />

225<br />

(405)*<br />

145<br />

(325)*<br />

45<br />

25<br />

Ø 12 mm<br />

145<br />

(325)*<br />

*) Dimensions in brackets are for construction height 51<br />

6<br />

30<br />

70<br />

70<br />

153<br />

1<br />

4<br />

1<br />

4<br />

153<br />

30<br />

6<br />

345 (525)*<br />

225<br />

(405)*<br />

AISI 33 (51)** series<br />

Design<br />

(1) Air cooler made of copper pipes with<br />

aluminium fins, max. operating<br />

temperature 90 0C (2) Housing completely made of<br />

galvanized steel plate incl. mounting<br />

frame (6)<br />

(3) Water connection R 3/4“ torsion<br />

protection<br />

(4) Condensation tray to collect<br />

condensate in dehumidification mode<br />

(5) Condensate drain, ø12 mm,<br />

mounted on the condensate tray and<br />

supplied as standard<br />

(6) Mounting frame made of galvanized<br />

steel sheet, supplied as standard<br />

Installation<br />

The cooling unit is installed in the fall<br />

duct for the cold air (see page 8).<br />

Important: To ensure optimum operation<br />

sealing off walls spaced at 600 to 800 mm<br />

need to be installed in the fall ducts.<br />

AASI 33 (51)** series<br />

Design<br />

(1) Air cooler made of copper pipes with<br />

aluminium fins, max. operating<br />

temperature 90 0C, max. operating<br />

pressure 10 bar<br />

(2) Housing completely made of<br />

galvanized steel plate incl. mounting<br />

frame (6)<br />

(3) Water connection R 3/4“ torsion<br />

protection<br />

(4) Condensation tray to collect<br />

condensate in dehumidification mode<br />

(5) Condensate drain, ø12 mm,<br />

mounted on the condensate tray and<br />

supplied as standard<br />

(6) Mounting frame made of galvanized<br />

steel sheet, supplied as standard<br />

Installation<br />

The mounting frame is used to install the<br />

cooling unit in front of the fall duct wall.<br />

Important: To ensure optimum operation<br />

sealing off walls spaced at 600 to 800 mm<br />

need to be installed in the fall ducts.<br />

Issued 02/2005. We reserve the right to make technical changes.<br />

11

<strong>TTC</strong> Capacity Diagrams<br />

Category 1<br />

Specific cooling capacity: category 1 Specific pressure drop heat exchanger: category 1<br />

1700<br />

1600<br />

1500<br />

1400<br />

1300<br />

1200<br />

1100<br />

1000<br />

900<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

280<br />

200<br />

100<br />

12.1<br />

12<br />

Category 1 (cooling)<br />

2,2 m<br />

6 7 8 9 10 11 12 13<br />

Median temperature difference ∆ϑ [K] m<br />

6,0 m<br />

5,0 m<br />

4,0 m<br />

3,5 m<br />

3,0 m<br />

2,5 m<br />

2,0 m<br />

1,5 m<br />

Formula to calculate the median temperature difference ∆ϑ m<br />

1<br />

<<br />

Specific cooling capacity q spec. [W/m]<br />

.<br />

<<br />

<<br />

t [°C] + t [°C]<br />

W1 W2 ∆ϑ [K] = t <strong>–</strong> for cooling mode<br />

m R<br />

2<br />

∆ϑ m [K] = median temperature difference between cooling<br />

medium and room temperature<br />

t W1 [°C] = cold water inlet<br />

t W2 [°C] = cold water outlet<br />

t R [°C] = room temperature<br />

Issued 02/2005. We reserve the right to make technical changes.<br />

<<br />

15<br />

10<br />

8<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1,0<br />

0,8<br />

0,6<br />

0,5<br />

0,4<br />

0,3<br />

0,2<br />

0,1<br />

0,08<br />

0,06<br />

kg/h 10<br />

kg/s<br />

12.3<br />

.<br />

< ><br />

Specific pressure drop ∆p w specif. [kPa/m] finned<br />

0,003<br />

15<br />

20<br />

25 30 40 50 60 80 100 150 200 300 400 500 700<br />

0,005 0,007 0,01 0,015 0,02 0,03 0,04 0,06 0,08 0,1 0,15 0,20<br />

.<br />

< Water mass flow mw ><br />

Formula to calculate the overall sensitive cooling capacity of<br />

the <strong>TTC</strong> <strong>Modultherm</strong> cooling unit<br />

3<br />

. .<br />

Q [W] = q [W/m] · L [m]<br />

K(tot.) K(spec.) finned<br />

·<br />

QK.(tot.) .<br />

qspecif. [W]<br />

[W/m]<br />

= total cooling capacity of a cooling unit<br />

= specific cooling capacity of a cooling unit<br />

Lfinned [m] = finned length of the cooling unit<br />

.<br />

Formula to calculate the specific water mass flow mw · q [kW] · L [m]<br />

·<br />

(specif.) finned<br />

4 m<br />

·<br />

[kg/h] = 860 ·<br />

W t - t [K]<br />

W2 W1<br />

Formula to calculate the overall pressure drop ∆p of the<br />

w(tot.)<br />

cooling unit on the water side<br />

.<br />

.<br />

·<br />

5 ∆p [kPa] = ∆p [kPa/m] • L [m]<br />

w(tot.) w(spec.) finned<br />

∆p. [kPa/m] = see figure 12.3<br />

w(specif.)

<strong>TTC</strong> Performance Diagrams<br />

Category 2<br />

Specific cooling capacity: category 2 Specific pressure drop heat exchanger: category 2<br />

2600<br />

2500<br />

2400<br />

2300<br />

2200<br />

2100<br />

2000<br />

1900<br />

1800<br />

1700<br />

1600<br />

1500<br />

1400<br />

1300<br />

1200<br />

1100<br />

1000<br />

900<br />

800<br />

700<br />

600<br />

500<br />

435<br />

400<br />

300<br />

200<br />

13.1<br />

Specific cooling capacity q spec. [W/m]<br />

.<br />

<<br />

<<br />

Category 2 (cooling)<br />

<<br />

2,2 m<br />

6 7 8 9 10 11 12 13 14 15 16<br />

7,0 m<br />

6,0 m<br />

Median temperature difference ∆ϑ m [K]<br />

5,0 m<br />

4,0 m<br />

3,5 m<br />

3,0 m<br />

2,5 m<br />

2,0 m<br />

1,5 m<br />

Formula to calculate the overall pressure drop ∆p of the<br />

w(tot.)<br />

cooling unit on the water<br />

.<br />

.<br />

5 ∆p [kPa] = ∆p [kPa/m] • L [m]<br />

w(tot.) w(spec.) finned<br />

.<br />

∆p [kPa/m] = see Fig. 12.3<br />

w(spec.)<br />

<<br />

15,0<br />

10,0<br />

8,0<br />

6,0<br />

5,0<br />

4,0<br />

3,0<br />

2,0<br />

1,5<br />

1,0<br />

0,8<br />

0,6<br />

0,5<br />

0,4<br />

0,3<br />

0,2<br />

0,1<br />

0,09<br />

0,08<br />

0,06<br />

0,05<br />

0,04<br />

0,03<br />

0,02<br />

kg/h<br />

217 kg/h<br />

50 60 80 100 150 200 300 400 500 700 1000 1500 2000 3000 4000<br />

kg/s<br />

13.3<br />

0,015 0,02 0,03 0,04 0,06 0,08 0,1 0,15 0,20 0,30 0,40 0,6 0,8 01,0 1,4<br />

Formula to calculate the medium temperature difference ∆ϑ m<br />

1<br />

.<br />

< ><br />

Specific pressure drop ∆p w specif. [kPa/m]<br />

t [°C] + t [°C]<br />

W1 W2<br />

∆ϑ [K] = t <strong>–</strong> for cooling mode<br />

m R 2<br />

∆ϑ m [K] = median temperature difference between cooling<br />

medium and room temperature<br />

t W1 [°C] = cold water inlet<br />

t W2 [°C] = cold water outlet<br />

t R [°C] = room temperature<br />

Formula to calculate the overall sensitive cooling capacity of<br />

the <strong>TTC</strong> <strong>Modultherm</strong> cooling unit<br />

3<br />

. .<br />

Q [W] = q [W/m] · L [m]<br />

K(tot.) K(spec.) finned<br />

·<br />

Q [W] K.(tot.)<br />

.<br />

q [W/m] spec.<br />

= total cooling capacity of a cooling unit<br />

= specific capacity of a cooling unit<br />

L [m] finned = finned length of a cooling unit<br />

Formula to calculate the specific water mass flow mw 4 m· [kg/h] = 860 ·<br />

W<br />

·<br />

·<br />

q [kW] · L [m]<br />

(spec.) finned<br />

t - t [K]<br />

W2 W1<br />

<<br />

.<br />

Water mass flow mw Issued 02/2005. We reserve the right to make technical changes.<br />

><br />

13

<strong>TTC</strong> Design Example<br />

Example 1: Dimensioning a cooling unit for cooling mode<br />

Calculation assumptions ><br />

Calculate ∆ϑ m<br />

Determine q· K(spec.)<br />

Required ribbed width, L finned ><br />

Required <strong>TTC</strong> cooling units ><br />

<strong>Cooling</strong> performance on the<br />

water side ><br />

Result ><br />

14<br />

><br />

><br />

Task:<br />

An office (see page 15, Fig. 15.1) with a sensitive cooling load Q = 2.000 W is to be cooled<br />

K(sen.)<br />

with AASS or AVSI series cooling units and also to be ventilated with additional, pre-conditioned<br />

primary air. The unit is to be installed above a range of cupboards or a set of shelves at a height of<br />

2.5m (see Fig. 15.1). The room volume is approx. 80 m3 . The pre-conditioned primary air is blown<br />

into the room at 180 ·<br />

C through flexible pipes in the fall ducts.<br />

• Cold water temperatures: t = 16 W1 0C and t = 20 W2 0C • Room temperature: t = 26 ºC<br />

R<br />

• Primary air temperature: t = 18 ºC<br />

L(ZU)<br />

• Max. possible installation length L for the cooling unit(s) = 5.50 m<br />

max.<br />

• The primary air rate, V is 240 m A(prim) 3 ·<br />

/h at 3 times room air change<br />

• The sound pressure level shall not exceed 30 dB(A)<br />

• The effective fall duct hight H ≈ 2.2 m<br />

eff.<br />

Step-by-step illustration of the solution:<br />

1. Calculate the median temperature difference ∆ϑ with the following formula<br />

m<br />

∆ϑ = t - [(t + t ) : 2] (see pages 12/13, equation 1)<br />

m R W1 W2<br />

∆ϑ = 26 - [(16 + 20) : 2] = 8 K<br />

m<br />

2. For ∆ϑ = 8 K take the specific cooling values q<br />

·<br />

from the diagrams for capacity<br />

m Conv.(spec.)<br />

categories „1“ and „2“ (see page 12/13):<br />

• Category „1“ = 280 W/m<br />

• Category „2“ = 435 W/m<br />

this results in:<br />

a) required finned length, L for category 1 = 2000 W : 280 W/m ≈ 7.15 m<br />

finned<br />

b) required finned length, L for category 2 = 2000 W : 435 W/m ≈ 4.60 m<br />

finned<br />

Conclusion:<br />

• Due to structural restrictions (max. 5.5m) the length required under a), L = 7m, cannot be<br />

finned<br />

used<br />

• The length calculated under b), L = 4.6 m meets the requirement<br />

finned<br />

3. Select the required <strong>TTC</strong> cooling units<br />

• Max. available <strong>TTC</strong> cooling unit length, L total = 2.4 m with L finned = 2.32 m<br />

• To fulfil the requirement you will need 2 <strong>TTC</strong> performance category 2 cooling units<br />

2 off: AASS.24.51.2._.2 (see order key on page 2)<br />

4. Calculation to check the actual cooling capacity on the water side<br />

·<br />

Q [W] = q [W/m] · W [m] · n [units]<br />

K(total) spec. finned<br />

·<br />

= 435 · W/m · 2.32 m · 2 ≈ 2020 W = 2.02 kW (required 2.000 kW)<br />

Q K(total.)<br />

<strong>Cooling</strong> power of the primary air > 5. Calculate the additional cooling capacity from the primary air<br />

·<br />

V [m A(tot.)<br />

Q (kW) = K(air) = 0.64 kW<br />

3 /h] · r [kg/m . L 3 ]· cp[kJ/kg·K] · ∆t [K]<br />

L L<br />

3600<br />

240 (m3 /h) · 1,2 (kg/m . 3 ·<br />

Q [kW] =<br />

K(air)<br />

·<br />

) · 1 (kJ/kg·K) · 8 (K)<br />

3600<br />

Overall cooling power > 6. In total the cooling capacity on the water and air side:<br />

.<br />

Q = 2.02 kW (step4 4) + 0,64 kW (step 5) = 2.66 kW<br />

K(water,air)<br />

Please note ><br />

Issued 02/2005. We reserve the right to make technical changes.<br />

• If <strong>TTC</strong> Gratings are used as air inlets and outlets (see page 16) the cooling power calculated<br />

under point 4 must be multiplied by the correction factors in tables 16.1-16.7.

<strong>TTC</strong> Design Example<br />

Example 2: How to calculate the pressure drop on the water side<br />

Calculation assumptions ><br />

Result water mass flow ><br />

Specific pressure drop ><br />

Result ∆p w(tot.)<br />

><br />

Task<br />

To calculate the pressure drop on the water side, ∆p of the cooling unit with part no:<br />

W(total)<br />

AASS.24.51.2._.2 in example 1 (page 14)<br />

Parameters required for the calculation:<br />

• Cold water temperatures: t = 16 ºC; t = 20 ºC<br />

W1 W2<br />

• Finned length of the cooling unit, L = 2.32 m<br />

finned<br />

·<br />

• Specific cooling capacity q = 435 W/m (see page 14, calculation step 2)<br />

K(spec.)<br />

Solution<br />

.<br />

The water pressure drop is approximated via the water mass flow m using equation 4 (see page<br />

W<br />

13)<br />

·<br />

m W [kg/h] = 860 ·<br />

·<br />

q [kW/m] · L [m]<br />

(spezif.) finned<br />

t - t [K]<br />

W2 W1<br />

0,435 kW/m · 2,32 m<br />

20 0C - 16 0 m<br />

·<br />

= 860 · ≈ 217 kg/h<br />

W<br />

C<br />

From diagram 13.3 (page 13) take the<br />

specific hydraulic pressure drop ∆p w(spec.) ≈ 0,09 kPa/m<br />

The total water pressure drop ∆p W(total) for the cooling unit (L finned = 2.32 m) is:<br />

∆p w(ges.) [kPa] = ∆p w(spezif.) [kPA/m] · L finned [m]<br />

∆p w(total) = 0.09 kPa/m · 2.32 m ≈ 0.21 kPa<br />

3. Illustration of the system calculated in examples 1 and 2<br />

15.1<br />

(1) Air cooler with condensation tray<br />

(2) Fall duct for cold air<br />

(3) Air outlet grating<br />

(4) Air inlet grating<br />

(8) Primary air channel<br />

(AL) Sealing batten against infiltrated air<br />

Note!<br />

For other free cross-sections of the air inlet<br />

and air outlet gratings please refer to page<br />

16 or contact <strong>TTC</strong>.<br />

Issued 02/2005. We reserve the right to make technical changes.<br />

15

<strong>TTC</strong> Air Inlet and Outlet Gratings<br />

Order no.<br />

Reduced performance of the <strong>TTC</strong> air outlets in conjunction with <strong>TTC</strong> cooling units<br />

<strong>TTC</strong> Air inlet and outlet gratings Rod free Reduced performance factors ”f“<br />

All figures are based on the cooling unit and the air outlet<br />

graving being identical in length. The heights of the cooling<br />

units are for a grating height of 200mm in line with the<br />

spacing<br />

”a“<br />

crosssection<br />

<strong>TTC</strong> <strong>Modultherm</strong> cooling unit series<br />

AASS AASS AAVS AAVS AISI AISI AVSI AVSI<br />

preliminary documentation.<br />

mm % 33 51 33 51 33 51 33 51<br />

Note: The cooling power of the cooling unit in the diagrams (pages 12 and 13) must be corrected by the reduced performance factors<br />

”f“ stated in tables 16.1-16.7 if the above air inlet and outlet gratings are used. The reduced performance factors ”f“ are dependent<br />

on the type and the free cross-section of the gratings. The following formula is to be used:<br />

Q K(reduced) = Q K(1unit) · f min<br />

QK(reduced) QK(1unit) fin = reduced cooling capacity<br />

= calculated cooling capacity p.unit<br />

= for in flowing room air<br />

= for out flowing cooling air<br />

Example<br />

Q = 1.01 kW (see example on page 12)<br />

K(1unit)<br />

f = 0.84 (Table 16.3, Type AASS 51)<br />

in<br />

f = 0.84 (Table 16.3, Type AASS 51)<br />

out<br />

=> f = 0.84<br />

min<br />

f out<br />

Issued 02/2005. We reserve the right to make technical changes.<br />

16<br />

16.1<br />

16.2<br />

a a<br />

a a<br />

16.3<br />

a a<br />

16.4<br />

a a<br />

Longitudinal gratings rigid (full<br />

profile), made of aluminium, for<br />

air inlets and outlets in ceilings,<br />

walls and on the floor<br />

Comb gratings rigid (full<br />

profile), made of aluminium or<br />

V2A, for air inlets and outlets in<br />

ceilings, walls and on the floor<br />

Part no: <strong>TTC</strong>-KSF ❐ Alu ❐ V2A<br />

Comb gratings rigid (T-profile),<br />

(full profile), made of aluminium,<br />

for air inlets and outlets in<br />

ceilings, walls and on the floor<br />

Part no: <strong>TTC</strong>-KST ❐ Alu<br />

Comb gratings rigid (U-profile),<br />

(full profile), made of V2A or aluminium,<br />

for air inlets and outlets<br />

in ceilings, walls and on the floor<br />

20 88 0.94 0.84 0.94 0.84 0.94 0.84 0.94 0.84<br />

15 83 0.93 0.82 0.93 0.82 0.93 0.82 0.93 0.82<br />

10 77 0.92 0.81 0.92 0.81 0.92 0.82 0.92 0.81<br />

20 87 0.94 0.83 0.94 0.83 0.94 0.83 0.94 0.83<br />

15 83 0.93 0.82 0.93 0.82 0.93 0.82 0.93 0.82<br />

10 77 0.92 0.81 0.92 0.81 0.92 0.82 0.92 0.81<br />

20 80 0.92 0.82 0.92 0.82 0.92 0.82 0.92 0.82<br />

15 73 0.91 0.80 0.91 0.80 0.91 0.80 0.91 0.80<br />

10 65 0.88 0.78 0.88 0.78 0.88 0.78 0.88 0.78<br />

15 73 0.91 0.80 0.91 0.80 0.91 0.80 0.91 0.80<br />

10 65 0.88 0.78 0.88 0.78 0.88 0.78 0.88 0.78<br />

16.5<br />

Roll gratings flexible (hollow<br />

17.5 70 0.81 0.71 0.81 0.71 0.81 0.71 0.81 0.71<br />

7<br />

profile), made of V2A or alumi-<br />

16 60 0.79 0.70 0.79 0.70 0.79 0.70 0.79 0.70<br />

a nium, for air outlets on the floor<br />

12.5 62 0.79 0.69 0.79 0.69 0.79 0.69 0.79 0.69<br />

a<br />

Part no: <strong>TTC</strong>-QFH ❐ Alu ❐ V2A<br />

16.6<br />

16.7<br />

a<br />

a<br />

a<br />

a<br />

Part no: <strong>TTC</strong>-LSF ❐ Alu<br />

Part no: <strong>TTC</strong>-KSZ ❐ Alu ❐ V2A<br />

Roll gratings flexible (T-profile),<br />

made of aluminium, for air<br />

outlets on the floor<br />

Part no: <strong>TTC</strong>-QFT ❐ Alu<br />

Roll gratings flexible (Tprofile),<br />

made of aluminium,<br />

for air outlets on the floor<br />

Part no: <strong>TTC</strong>-BST ❐ Alu<br />

20 80 0.83 0.74 0.83 0.74 0.83 0.74 0.83 0.74<br />

15 70 0.81 0.71 0.81 0.71 0.81 0.71 0.81 0.71<br />

10 65 0.89 0.70 0.79 0.70 0.79 0.70 0.79 0.70<br />

8 40 0.71 0.61 0.71 0.61 0.71 0.61 0.71 0.61<br />

Q K(reduced) = 1.01 kW · 0.84 ≈ 0.85 kW<br />

Control of cooling capacity<br />

2 x AASS = 1,36 kW<br />

<strong>Cooling</strong> power of inflowing primary<br />

air = 0,64 kW<br />

Total of cooling capacity 2000 W = 2,0 kW

<strong>TTC</strong> Instructions For Pipe Work Installation<br />

Pipe work installation examples<br />

<strong>Modultherm</strong> AASS cooling unit <strong>Modultherm</strong> AISI cooling unit<br />

17.1<br />

<strong>Modultherm</strong> AAVS cooling unit <strong>Modultherm</strong> AASI cooling unit<br />

E<br />

17.2<br />

G<br />

E<br />

F<br />

Fall duct walls<br />

Spacing 600…800 mm<br />

A Cold water supply pipes (do<br />

not install these in front of<br />

the air cooler)<br />

B Stop valves for forward and<br />

return flow<br />

C Electrical control valve<br />

D Sealing off walls in the fall<br />

duct for the cooling air<br />

A<br />

A<br />

D<br />

Fall duct walls<br />

Spacing 600…800 mm<br />

A Cold water supply pipes (do<br />

not install these in front of<br />

the air cooler)<br />

B Stop valves for forward and<br />

return flow<br />

C Electrical control valve<br />

D Sealing off walls in the fall<br />

duct for the cooling air<br />

D<br />

F<br />

G<br />

B<br />

C<br />

≈ 250<br />

H<br />

~<br />

G<br />

H<br />

C<br />

E Siphon to drain<br />

condensation<br />

F Side seals on the cooling<br />

unit against infiltrated air<br />

G Flexible connecting hoses<br />

H Relief valve<br />

E Siphon to drain<br />

condensation<br />

F Side seals on the cooling<br />

unit against infiltrated air<br />

G Flexible connecting hoses<br />

H Relief valve<br />

I<br />

~<br />

B<br />

A<br />

A Cold water supply pipes (do<br />

not install these in front of<br />

the air cooler)<br />

B Stop valves for forward and<br />

return flow<br />

C Electrical control valve<br />

D Sealing off walls in the fall<br />

duct for the cooling air<br />

B<br />

H<br />

G<br />

17.3<br />

17.4<br />

E<br />

A A<br />

F<br />

E<br />

~<br />

Fall duct walls<br />

Spacing 600…800 mm<br />

~~<br />

F<br />

D<br />

Fall duct walls<br />

Spacing 600…800 mm<br />

A Cold water supply pipes (do<br />

not install these in front of<br />

the air cooler)<br />

B Stop valves for forward and<br />

return flow<br />

C Electrical control valve<br />

D Sealing off walls in the fall<br />

duct for the cooling air<br />

D<br />

F<br />

F<br />

I<br />

E Siphon to drain<br />

condensation<br />

F Side seals on the cooling<br />

unit against infiltrated air<br />

G Flexible connecting hoses<br />

H Relief valve<br />

I Mounting frame supplied as<br />

standard<br />

H<br />

I<br />

E Siphon to drain<br />

condensation<br />

F Side seals on the cooling<br />

unit against infiltrated air<br />

G Flexible connecting hoses<br />

H Relief valve<br />

Issued 02/2005. We reserve the right to make technical changes.<br />

C<br />

H<br />

~<br />

A<br />

B<br />

C<br />

17

<strong>TTC</strong> Best Performance By Reducing Infiltrated Air<br />

Design of side sealing off walls and fall ducts<br />

18<br />

1 2 2 Correct 1<br />

Installation<br />

600…800 mm<br />

18.1<br />

The cooling unit has been correctly installed,<br />

no reduction in performance.<br />

(1) Side sealing off walls<br />

(2) Fall duct walls correctly arranged<br />

Infiltrated Air Infiltrated Air<br />

1 2 2<br />

1<br />

600…800 mm<br />

Incorrect<br />

Installation<br />

Correct<br />

Installation<br />

100<br />

(150)*<br />

18.7<br />

The calculated performance will be<br />

achieved with this installation.<br />

Air infiltration will not be possible.<br />

1<br />

Infiltrated Air<br />

600…800 mm<br />

2 2 Incorrect<br />

Installation<br />

1<br />

18.2<br />

The <strong>Cooling</strong> unit is too big. The calculated<br />

performance will not be achieved.<br />

(1) Side sealing off walls<br />

(2) Fall duct walls<br />

Air<br />

Air<br />

Turbulence<br />

turbulence<br />

1 2 2<br />

1<br />

600…800 mm<br />

Incorrect<br />

Installation<br />

18.4 18.5 18.6<br />

The cooling unit is too small. The calculated<br />

performance will not be achieved.<br />

(1) Side sealing off walls<br />

(2) Fall duct walls<br />

Installation in front of ducts<br />

Issued 02/2005. We reserve the right to make technical changes.<br />

The cooling unit is too small. The calculated<br />

performance will not be achieved.<br />

(1) Side sealing off walls<br />

(2) Fall duct walls<br />

Incorrect<br />

Installation<br />

100<br />

(150)*<br />

18.8<br />

The calculated performance will not be<br />

achieved with this installation (air<br />

turbulences).<br />

Infiltrated Air Infiltrated Air<br />

1 2 2 Incorrect 1<br />

600…800 mm Installation<br />

18.3<br />

The cooling unit is too big. The calculated<br />

performance will not be achieved.<br />

(1) Side sealing off walls<br />

(2) Fall duct walls<br />

1 Unstable air flow Incorrect 1<br />

due to lack of fall Installation<br />

duct walls<br />

Fall ducts have not been installed. The<br />

calculated performance will not be<br />

achieved with this installation.<br />

(1) Side sealing off walls<br />

Incorrect<br />

Installation<br />

100<br />

(150)*<br />

18.9<br />

The calculated performance will not be<br />

achieved with this installation (problems<br />

with infiltrated air).

<strong>TTC</strong> Calculation and Order Sheet<br />

Company Name<br />

Address<br />

Tel<br />

Fax<br />

Project Room<br />

Item<br />

Calculation Parameters Parameters Notes, Calculation Formulae<br />

1 Req. sensible cooling performance QK(sens.) W<br />

2 Clear room height hclear m<br />

3 Clear room width wclear m<br />

4 Clear room length lclear m<br />

5 Room volume<br />

m<br />

6 Effective fall duct height Heff. 7 To be installed above:<br />

8 Max. length for cooling unit(s) L (total)<br />

9 Max. height for cooling unit(s) H (total)<br />

3 /h<br />

m<br />

❏ Cupboard, shelves ❏ in front of ❏ above ❏ in the fall duct<br />

m<br />

m<br />

10 Cold water inlet t w1<br />

11 Cold water outlet t w2<br />

12 Room temperature t R<br />

13 Primary air temperature tL(in) 14 Primary air volume flow VL(in) m<br />

15 Max. sound pressure level for primary air<br />

Calculate which cooling unit is required<br />

16 Median temperature difference ∆ϑm 17 Specific cooling capacity qKspec. 18 Total ribbed length required Lfinned 19 Specific cooling capacity qKspec. 20 Total finned length required Lfinned 21 Select the no. of cooling units required<br />

22 Required length, Lfinned for one cooling unit<br />

23 <strong>Cooling</strong> capacity Q (one cooling unit)<br />

K(1 unit)<br />

24 Corrected cooling capacity QK(1 unit)<br />

25 <strong>Cooling</strong> capacity Q from V K air L(in)<br />

26 Water mass flow mW 27 Specific pressure drop water side ∆pWspec. 28 Total pressure drop ∆pWtotal 3 /h<br />

dB(A)<br />

.<br />

> for category 1:<br />

K<br />

W/m<br />

.<br />

> for category 1:<br />

> for category 2:<br />

m<br />

W/m<br />

> for category 2: m<br />

n<br />

.<br />

.<br />

.<br />

m<br />

W<br />

W<br />

kW<br />

Calculate the pressure difference on the water side<br />

.<br />

.<br />

.<br />

kg/h<br />

kPa/m<br />

kPa<br />

Vital for your order<br />

<strong>Cooling</strong> unit part no. (see page 2):<br />

Type<br />

Air inlet grating part no:<br />

Type<br />

Make: <strong>TTC</strong> <strong>Timmler</strong> <strong>Technology</strong> GmbH Make: Make:<br />

Zum Wetterschacht 1, D-45659 Recklinghausen<br />

0C 0C 0C 0C With regard to the whole of the room<br />

h • w • l clear clear clear<br />

See Page 5, 5.1<br />

Please tick as appropriate<br />

With reference to the installation space<br />

With reference to the installation space<br />

See Page15, 15.1<br />

Item 12 <strong>–</strong> [Item 10 + Item 11 : 2]<br />

From Fig. 12.1 (s. page 12)<br />

(Item 1) : (Item 17)<br />

From Fig. 13.1 (s. page 13)<br />

(Item 1) : (Item 19)<br />

See tables on pages 10 and 11<br />

(Item 18) or (Item 20) : (Item 22)<br />

(Item 22) · (Item 17) or (Item 19)<br />

See table on page 16<br />

(Item 14) · 0.0003 · (Item 12 - Zif. 13)<br />

860 · [Item 23 (in kW) : Item 11-Item 10]<br />

See Fig. on page 12 or 13<br />

Item 22 · Item 26<br />

Air outlet grating part no:<br />

Type<br />

Issued 02/2005. We reserve the right to make technical changes.<br />

19