Tech_Issue 1 2009_0127_Final:TechToday_012709 ... - Raytheon

Tech_Issue 1 2009_0127_Final:TechToday_012709 ... - Raytheon

Tech_Issue 1 2009_0127_Final:TechToday_012709 ... - Raytheon

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

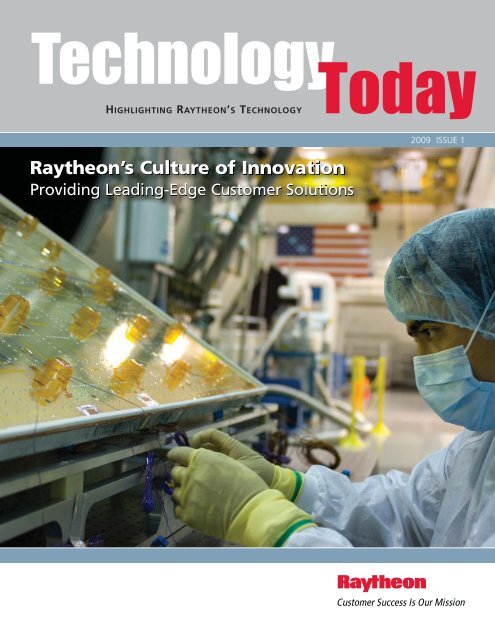

<strong>Tech</strong>nology<br />

Today<br />

HIGHLIGHTING RAYTHEON’S TECHNOLOGY<br />

<strong>Raytheon</strong>’s Culture of Innovation<br />

Providing Leading-Edge Leading Edge Customer Solutions<br />

<strong>2009</strong> ISSUE 1

A Message From Mark E. Russell<br />

Do you have an idea for an article?<br />

We are always looking for ways to connect<br />

with you — our Engineering, <strong>Tech</strong>nology and<br />

Mission Assurance professionals. If you have an<br />

article or an idea for an article regarding<br />

technical achievements, customer solutions,<br />

relationships, Mission Assurance, etc., send it<br />

along. If your topic aligns with a future issue of<br />

<strong>Tech</strong>nology Today or is appropriate for an online<br />

article, we will be happy to consider it and will<br />

contact you for more information.<br />

Send your article ideas to<br />

techtodayeditor@raytheon.com.<br />

On the cover: <strong>Raytheon</strong> technicians<br />

prepare a miniaturized radio frequency<br />

antenna for thermal vacuum testing,<br />

which mimics the extreme conditions<br />

encountered in space, at the company's<br />

Space Manufacturing Center of<br />

Excellence in El Segundo, Calif. It is part<br />

of a <strong>Raytheon</strong>-built radar that will circle<br />

the moon and help scientists search<br />

for ice and water deposits. For more<br />

information, see the story on page 25.<br />

2 <strong>2009</strong> ISSUE 1 RAYTHEON TECHNOLOGY TODAY<br />

Vice President of Engineering, <strong>Tech</strong>nology and Mission Assurance<br />

There are many approaches to technological innovation. At <strong>Raytheon</strong>, our approach<br />

is diverse. It captures both top-down and bottom-up ideas. It is disruptive and<br />

incremental. It is directed at broad areas for use by the entire company, and the<br />

needs of individual <strong>Raytheon</strong> businesses. Our approach is comprehensive because<br />

innovations can come from anywhere.<br />

At the same time, we know that the goal of innovation is not just to come up with<br />

state-of-the-art technologies, but to develop new capabilities that meet our customers’<br />

needs in a timely manner. <strong>Raytheon</strong> has a long history of developing innovative<br />

solutions for our customers, as highlighted in this issue of <strong>Tech</strong>nology Today.<br />

Innovation at <strong>Raytheon</strong> results from a culture that enables individuals to challenge<br />

themselves and the status quo to develop new and better solutions. Innovation<br />

occurs within our programs — as part of our technology planning and independent<br />

research and development programs — and through numerous initiatives<br />

aimed specifically at identifying and nurturing innovation. At <strong>Raytheon</strong>, innovation<br />

is more than coming up with a new idea — it’s making that idea a reality.<br />

That is what makes the difference for our customers.<br />

This philosophy comes directly from our Chairman and CEO William H. Swanson,<br />

who leads <strong>Raytheon</strong> with a consistent focus on the customer. In fact, <strong>Raytheon</strong>’s<br />

goal is to be regarded as a customer focused company known for its technology and<br />

innovation, enabling our customers’ success.<br />

In the following pages, you will learn about the many ways <strong>Raytheon</strong> innovates,<br />

including articles about our culture of innovation, the processes we use to innovate,<br />

and of course, the innovations our culture and processes have produced.<br />

In this issue’s Leaders Corner column, we hear from John Zolper, <strong>Raytheon</strong><br />

vice president of Research and Development. John talks about the importance of<br />

mining fresh ideas and the programs that the company has implemented to<br />

nurture innovation.<br />

In <strong>2009</strong>, innovation is taking on added significance. Engineering, <strong>Tech</strong>nology and<br />

Mission Assurance is holding the <strong>Raytheon</strong> <strong>Tech</strong>nology Forum, March 25–26, in<br />

Washington, D.C. Organized under a theme of “Innovating the Future,” the event<br />

will be an opportunity for our engineers and customers to discuss innovative ways<br />

to meet tomorrow’s evolving mission needs.<br />

Best regards,<br />

Mark E. Russell

View <strong>Tech</strong>nology Today online at:<br />

www.raytheon.com/technology_today/current<br />

<strong>Tech</strong>nology Today is published<br />

quarterly by the Office of Engineering,<br />

<strong>Tech</strong>nology and Mission Assurance.<br />

Vice President<br />

Mark E. Russell<br />

Managing Editor<br />

Lee Ann Sousa<br />

Senior Editors<br />

Donna Acott<br />

Tom Georgon<br />

Kevin J. Wynn<br />

Art Director<br />

Debra Graham<br />

Photography<br />

Jon Black<br />

John Barela<br />

Douglas Bobilya<br />

Brad Hines<br />

Matt Kuhlen<br />

Dan Plumpton<br />

Charlie Riniker<br />

Jeff Thompson<br />

Website Design<br />

Joe Walch IV<br />

Publication Coordinator<br />

Dolores Priest<br />

Contributors<br />

Carrie Brown<br />

John Cacciatore<br />

Christel Kittredge<br />

Marcilene Pribonic<br />

Sharon Stein<br />

INSIDE THIS ISSUE<br />

Feature: <strong>Raytheon</strong>’s Culture of Innovation<br />

An Integrated Approach to Innovation at <strong>Raytheon</strong> 4<br />

<strong>Raytheon</strong>’s Innovations in Sensor Systems 7<br />

Mission Innovation: Fueling the Engine 10<br />

Swarm Intelligence for Automatic Knowledge Extraction 12<br />

The Bike Shop: Engaging the Innovator 14<br />

The Rapid Initiatives Group 17<br />

Office of Innovation 19<br />

Connecting the Quantum Dots 21<br />

<strong>Raytheon</strong>’s Innovation Partnerships 23<br />

<strong>Raytheon</strong> Innovations Making Headlines 25<br />

Leaders Corner: Q&A With John Zopler 27<br />

Legacy of Innovation: Seven Early Innovations<br />

Eye on <strong>Tech</strong>nology<br />

28<br />

RF Systems 31<br />

Architecture & Systems Integration 32<br />

Materials & Structures 34<br />

Information Systems 35<br />

EO/Lasers<br />

Special Interest<br />

36<br />

National Data Exchange System 38<br />

The Science of Sports<br />

Events<br />

39<br />

2008 Summer Symposia<br />

People<br />

40<br />

<strong>Raytheon</strong> Certified Architects 42<br />

U.S. and International Patents 43<br />

EDITOR’S NOTE<br />

At <strong>Raytheon</strong>, we have some of the most talented and innovative people in the world, all<br />

focused on one thing — providing the best possible solutions to our customers around<br />

the world. Whether it’s developing state-of-the-art technologies or redesigning existing<br />

products and technologies in new and creative ways to meet a customer need, innovation<br />

is truly part of our culture — it’s in our DNA.<br />

This issue of <strong>Tech</strong>nology Today explores our innovative culture and initiatives, such as<br />

the <strong>Raytheon</strong> IDEA program, the annual <strong>Raytheon</strong> Innovation Challenge, and university<br />

partnerships, to name a few. It also highlights some of the technologies and programs<br />

that make <strong>Raytheon</strong> an innovative leader, like swarm intelligence, oil extraction from<br />

shale technology and SilenTrack for surveillance in dense urban environments.<br />

This issue introduces a new section called Legacy of Innovation, which highlights some<br />

of <strong>Raytheon</strong>’s early innovations. You’ll also read about a new MathMovesU initiative,<br />

called Science of Sports, as well as our summer technology symposia.<br />

Enjoy!<br />

Lee Ann Sousa<br />

RAYTHEON TECHNOLOGY TODAY <strong>2009</strong> ISSUE 1 3

Feature<br />

Enterprisewide Innovation Initiatives<br />

<strong>Raytheon</strong> Certified Architects Program<br />

Innovation Challenge<br />

IDEA Program<br />

<strong>Tech</strong>nology Networks<br />

External Collaboration<br />

Independent Research and Development<br />

Collaborating<br />

to Ensure<br />

Customer<br />

Success<br />

An inclusive approach to<br />

Innovation at <strong>Raytheon</strong><br />

Innovation, as embodied in a novel product,<br />

method, or service providing a result<br />

with a valued quantifiable gain, is receiving<br />

significant attention in industry and<br />

government. The mantra, “innovate or<br />

die,” is now being applied to corporations<br />

and industries. At <strong>Raytheon</strong>, we have<br />

always prided ourselves on our culture of<br />

innovation — it’s not a passing trend, it’s<br />

how we do business. This culture of innovation<br />

enables us to provide leading-edge<br />

solutions to our customers, as we have<br />

continuously done for more than 85 years.<br />

But we are not resting on our laurels.<br />

Our innovative culture is rooted in our<br />

diversity of people, products and thoughts,<br />

and we continue to look for new ways to<br />

drive innovation to address our customers’<br />

needs. We nurture numerous specific internal<br />

initiatives and strengthen our external<br />

partnerships to ensure we constantly challenge<br />

ourselves to invigorate the company<br />

with new ideas to maintain our edge in<br />

the marketplace.<br />

4 <strong>2009</strong> ISSUE 1 RAYTHEON TECHNOLOGY TODAY<br />

Experience has convinced us that there is not<br />

just a single approach that leads to successful<br />

innovation in all aspects of the company.<br />

We benefit from multiple complementary<br />

approaches to encourage innovation across<br />

<strong>Raytheon</strong>. Today, we are opening the aperture<br />

by developing and applying internal<br />

and external technologies to core and<br />

growth markets. Our innovative culture<br />

is at the center of these initiatives.<br />

This set of approaches to innovation is<br />

rooted in a set of principles outlined below:<br />

<strong>Raytheon</strong> Principles for Innovation<br />

Ideas can come from anyone, anywhere<br />

in the organization<br />

Robust ideas come from nurturing collaborative<br />

environments<br />

Innovation occurs at the intersection of<br />

needs and ideas<br />

Ideas may exist for sometime before value<br />

or need is determined<br />

Trust is crucial for people to collaborate<br />

and share ideas<br />

Radical/disruptive ideas are more likely to<br />

come from diversity of thought created by<br />

intersections of people with differences<br />

Organizational Innovation Initiatives<br />

Programs and Systems<br />

Office of Innovation<br />

The Bike Shop<br />

Innovation Day<br />

Rapid Initiatives Group<br />

The Mission Innovation Group<br />

Truly radical/disruptive ideas will often be<br />

viewed as not feasible, impractical, or of<br />

no value<br />

Ideas are initially fragile; they need to be<br />

nurtured<br />

Different people have different styles of<br />

creating ideas<br />

Innovation cannot be scheduled, it occurs<br />

when it does (but it can be facilitated and<br />

encouraged)<br />

Like innovation itself, <strong>Raytheon</strong>’s approaches<br />

to innovation are dynamic and varied.<br />

Together, they form a tapestry from which<br />

internal and external inventions are<br />

spawned, nurtured and matured into truly<br />

innovative solutions. Some of the<br />

approaches are summarized below and<br />

described in further detail throughout this<br />

edition of <strong>Tech</strong>nology Today.<br />

Certified Architects – Through the<br />

<strong>Raytheon</strong> Certified Architect Program<br />

(RCAP), <strong>Raytheon</strong>’s top architects receive<br />

advanced training to hone their skills and<br />

enable them to define world-class architectures<br />

that will integrate internal technologies

and products from across industry to form<br />

innovative solutions. More than 100 architects<br />

across the company are RCAP-certified.<br />

Independent Research and<br />

Development – <strong>Raytheon</strong> has a long<br />

history of funding Independent Research and<br />

Development (IRAD) to develop the next<br />

generation of technology ahead of customer<br />

requirements. This has enabled us to maintain<br />

our technical excellence and challenge<br />

our technologists to always consider innovative<br />

approaches to hard problems.<br />

Advanced <strong>Tech</strong>nology Organizations –<br />

Chartered to work with our customers and<br />

programs to develop and mature revolutionary<br />

new technologies and products, our<br />

Advanced <strong>Tech</strong>nology organizations execute<br />

research and development programs under<br />

contract to our customers. We look to team<br />

with small businesses, universities and<br />

commercial partners to leverage external<br />

technologies; we understand that innovation<br />

can come from anywhere.<br />

<strong>Raytheon</strong> Innovation Challenge –<br />

The enterprisewide <strong>Raytheon</strong> Innovation<br />

Challenge (RIC) exposes employees to customer<br />

problems with the belief that they<br />

already have, or could readily conceive of,<br />

new solutions to these difficult problems<br />

when given the opportunity.<br />

For the past two years, <strong>Raytheon</strong> has sponsored<br />

the RIC. Last year’s targeted five key<br />

challenges of one of <strong>Raytheon</strong>’s customers:<br />

the U.S. Department of Homeland Security.<br />

Reviewers received 230 white papers from<br />

engineers in all six <strong>Raytheon</strong> businesses.<br />

Authors of the most compelling white papers<br />

attended a workshop to foster dialogue on<br />

new ideas and stretch their concepts to further<br />

enhance their approach. From the workshop,<br />

eight ideas were selected for further<br />

refinement, analysis and troubleshooting to<br />

move them from an idea to a product concept.<br />

Future plans for the RIC include formulating<br />

additional challenge topics, increasing the<br />

emphasis on constructive feedback and<br />

encouragement, and broadening the pool of<br />

innovators beyond the engineering community.<br />

The challenge format focuses innovators’ attention<br />

on known problems — if these problems<br />

are solved, it immediately benefits our customers<br />

and new product or service offerings.<br />

Identify-Develop-Expose-Action:<br />

<strong>Raytheon</strong>’s IDEA program – The intent<br />

of the corporate IDEA program is to identify<br />

novel ideas of value to the business, develop<br />

them to a point where other funding is<br />

appropriate, expose the idea to appropriate<br />

business leaders, and quickly take action on<br />

the most promising ideas. Here again the key<br />

concept is that innovation can come from<br />

anywhere, and this program enables the<br />

employee with the idea to have time to<br />

refine his or her concept.<br />

This program is administered by Corporate<br />

<strong>Tech</strong>nology and Research with the expressed<br />

intent of making rapid decisions on funding<br />

early-stage ideas for an investigator to perform<br />

initial analysis, simulation or experiments<br />

to refine an idea. The evaluation criteria<br />

address technical originality and business<br />

relevance. This “grass roots” system to gather<br />

ideas allows anyone with a bright idea to<br />

come forward.<br />

<strong>Tech</strong>nology Networks – <strong>Raytheon</strong> has<br />

established five technology networks which<br />

also drive innovation: Mission Systems<br />

Integration, Multifunction RF Systems, Multifunction<br />

EO Systems, Information Systems<br />

and Computing, and Mechanical Materials<br />

and Structures. Within each technology<br />

network are <strong>Tech</strong>nology Interest Groups,<br />

each of which focuses on a specific technology,<br />

and connects experts, peer-to-peer, across<br />

<strong>Raytheon</strong>. For the past decade, <strong>Tech</strong>nology<br />

Networks have provided an exceptional tool<br />

for engaging leading-edge technology and<br />

explaining customer needs. Each <strong>Tech</strong>nology<br />

Network also hosts an annual symposium<br />

and periodic workshops on special topics to<br />

promote the exchange of technology and<br />

knowledge sharing.<br />

University Collaboration – The<br />

<strong>Raytheon</strong> University Program sponsors university<br />

memberships and research in areas that<br />

align with our business needs, ensure our<br />

awareness of important current innovations,<br />

and enable our growth strategy. Colleges and<br />

Continued on page 6<br />

Feature<br />

William H. Swanson on<br />

<strong>Tech</strong>nology and Innovation<br />

“<strong>Raytheon</strong> is a technology<br />

company. We believe that<br />

developing the best solutions<br />

for our customers is<br />

all about fostering an<br />

open culture that supports<br />

rich dialog to generate<br />

the best ideas. In<br />

other words, it comes<br />

down to inclusion: creating<br />

a welcoming environment,<br />

drawing on the<br />

largest pool of the best<br />

talent, and encouraging<br />

diversity of thought and<br />

opinion with customer<br />

success in mind.”<br />

William H. Swanson<br />

Chairman and CEO<br />

<strong>Raytheon</strong> Company<br />

RAYTHEON TECHNOLOGY TODAY <strong>2009</strong> ISSUE 1 5

Feature Innovation at <strong>Raytheon</strong><br />

Continued from page 5<br />

universities are the vanguard of basic and<br />

applied research in the United States and<br />

abroad. The objectives of this program are<br />

to strategically align <strong>Raytheon</strong> technology<br />

road maps and university research, sponsor<br />

targeted advancements in core and adjacent<br />

markets, and implement a disciplined<br />

process for leveraging investments to<br />

enable growth. The University Program also<br />

operates in conjunction with other<br />

<strong>Raytheon</strong> university activities to build relationships<br />

and provide assistance to our college<br />

recruiting program.<br />

Small Business Collaboration<br />

Programs – <strong>Raytheon</strong> is working to find,<br />

nurture and leverage technologies being<br />

developed by small businesses. Two programs<br />

that foster this collaboration are the<br />

Small Business Innovation Research (SBIR)<br />

and pilot Mentor-Protégé Program. The<br />

SBIR program is a federal program that<br />

funds small businesses to conduct research<br />

and development of new and emerging<br />

technology. These programs enable<br />

<strong>Raytheon</strong> to utilize small-business capability<br />

to develop key technologies while establishing<br />

long-term relationships with small businesses<br />

and strengthening relationships with<br />

our customers. The U.S. Dept. of Defense<br />

pilot Mentor-Protégé Program is designed<br />

to provide small disadvantaged businesses<br />

with technical and developmental assistance<br />

from large businesses.<br />

Innovation Organizations –<br />

Organizations have been chartered across<br />

<strong>Raytheon</strong> with identifying and developing<br />

innovative products and business models.<br />

Five such organizations are currently executing<br />

in <strong>Raytheon</strong>, and each has demonstrated<br />

results with a slightly different approach<br />

to innovation.<br />

Mission Innovation<br />

<strong>Raytheon</strong> Integrated Defense Systems’<br />

Mission Innovation (MI) group provides an<br />

excellent example of far forward-looking<br />

innovation applied to compelling issues<br />

threatening our world: global warming,<br />

renewable energy, biological diversity<br />

protection, world health, education, and<br />

civil defense. Using a dedicated group of<br />

innovators, MI applies the company’s<br />

6 <strong>2009</strong> ISSUE 1 RAYTHEON TECHNOLOGY TODAY<br />

technologies and capabilities beyond the<br />

core businesses. Not constrained to our current<br />

products or technologies, MI broadly<br />

partners with universities or other businesses<br />

to create valuable solutions.<br />

The Bike Shop<br />

The Bike Shop at <strong>Raytheon</strong> Missile Systems<br />

houses a world-class capability to rapidly<br />

develop solutions and prototypes, drawing<br />

on a skilled, passionate small team of people<br />

who ignore the time clock and do<br />

whatever it takes to fulfill the customer’s<br />

needs — and fulfill them now.<br />

The Bike Shop starts all projects with a<br />

brainstorming session — its Envision<br />

phase — to understand the real problem.<br />

Once a workable solution to a problem is<br />

envisioned, The Bike Shop assembles the<br />

smallest possible team to execute the<br />

effort: This is the Create phase of<br />

their process.<br />

The result of the final phase — Accomplish<br />

— is a product of the intent and scope of<br />

the work. The Bike Shop delivers two<br />

primary products: special testing setups<br />

and services for existing programs, and<br />

prototype systems.<br />

Rapid Initiatives Group<br />

Within <strong>Raytheon</strong> Network Centric Systems,<br />

the Rapid Initiatives Group provides the<br />

mechanisms to tap into the broad, distributed<br />

capabilities of the business. Established<br />

to quickly address customer needs, it maintains<br />

an experienced staff of program leaders<br />

and a network of connections to the<br />

engineering and functional units.<br />

Using proven processes, the RIG can rapidly<br />

marshal resources to meet a customer need.<br />

All functions — business development,<br />

contracts, finance, operations and<br />

engineering — rapidly converge on a<br />

viable approach to offer a solution to<br />

the customer.<br />

The ability to convert concepts and ideas to<br />

contracted solutions provides strong benefits<br />

to customers.<br />

Office of Innovation<br />

<strong>Raytheon</strong> Space and Airborne Systems<br />

established an Office of Innovation to foster<br />

a culture of innovation across all employees<br />

and leverage ideas into new business. The<br />

dedicated staff provides focus, creating a<br />

connect point for anyone with an idea or a<br />

problem needing a solution. Four systems<br />

gather and develop ideas into business<br />

value: Originator Assisted, Innovation<br />

Centers, Innovation Challenge, and<br />

Distributed Think Tank.<br />

Innovation Day<br />

In November 2008, <strong>Raytheon</strong> Intelligence<br />

and Information Systems (IIS) held its first<br />

“Innovation Day.” The event took place at<br />

nine sites and showcased the best of the<br />

business’s technology and innovation.<br />

Innovation Day also included the first IIS<br />

Innovator of the Year Award.<br />

Five IIS projects received funding during<br />

2008 under <strong>Raytheon</strong>’s IDEA program:<br />

Helibuoy Prototype<br />

Capture HPC for Malware Analysis<br />

Stealth Modulation<br />

Fast, Unsupervised Hyperspectral Imagery<br />

Exploitation<br />

Swarm Intelligence for Knowledge<br />

Extraction<br />

In <strong>2009</strong>, IIS will begin implementing its own<br />

IDEA program, using the tools from the corporate<br />

program to help uncover more innovative<br />

ideas from within the business.<br />

Summary<br />

<strong>Raytheon</strong>’s world-class innovation systems<br />

continue to pump technology, products,<br />

and customer solutions, creating value for<br />

our stakeholders. The breadth and richness<br />

of the systems that allow each business<br />

and each individual to find novel, valued<br />

solutions are unique.<br />

Innovation is important to individuals as<br />

well as to the company’s business growth.<br />

Innovation kindles a special engineering<br />

spirit: With a can-do attitude, nothing is<br />

really impossible.<br />

This edition of <strong>Tech</strong>nology Today describes<br />

some of our innovations and the systems<br />

used to produced them. We hope that the<br />

examples provided will give you a glimpse<br />

into the types of exciting work we do.<br />

Bill Kiczuk<br />

kiczuk@raytheon.com

<strong>Raytheon</strong>’s<br />

Innovations in Sensor Systems<br />

<strong>Raytheon</strong> has a long history of applying<br />

and integrating innovations to produce<br />

world-class sensor solutions for<br />

our customers. One area where this is<br />

readily apparent is in our state-of-the-art<br />

systems. Today’s sensor systems have<br />

become more capable, affordable and<br />

reliable through an evolution fueled by constant<br />

and consistent innovation. For example,<br />

systems such as the Cobra Dane and<br />

Pave Paws radar systems were leading-edge<br />

radar sensors when developed 30 years<br />

ago, and with 21st-century enhancements,<br />

these early-warning systems continue to<br />

play a key role in missile defense.<br />

Numerous innovations are required to realize<br />

each of these systems. During World<br />

War II, radar systems were enabled by innovations<br />

such as mass production of the<br />

magnetron, which <strong>Raytheon</strong> pioneered in<br />

the 1940s. Future sensor systems will benefit<br />

from some innovative new technologies:<br />

Gallium nitride (GaN), which will provide<br />

radio frequency (RF) sensors with<br />

increased power and advanced capabilities,<br />

where needed<br />

Compound Semiconductor Materials on<br />

Silicon (COSMOS) to achieve revolutionary<br />

semiconductor performance<br />

Advanced electro-optical (EO)/infrared (IR)<br />

detection and imaging devices for applications<br />

in the x-ray, visible, infrared, terahertz<br />

and millimeter-wave regions of the<br />

electromagnetic spectrum<br />

Advanced materials and mechanical<br />

structures that not only provide support<br />

and environmental protection, but also<br />

remove heat, all while maintaining the<br />

critical tolerances necessary for optimal<br />

performance<br />

Supercomputing technologies that execute<br />

advanced signal processing algorithms<br />

Systems that maintain the nanosecond<br />

timing tolerances required for success<br />

This wealth of experience and portfolio of<br />

technologies enable <strong>Raytheon</strong> to provide<br />

solutions that are scalable, affordable,<br />

reliable and highly capable in response to<br />

our customers’ operational needs.<br />

Four of <strong>Raytheon</strong>’s state-of-the-art complex<br />

sensor systems are described below:<br />

AN/APG-79 AESA, which makes the U.S.<br />

Navy’s F/A-18 E/F Super Hornet more<br />

lethal and less vulnerable<br />

X-Band Radar, the largest, most sophisticated<br />

phased array, electro-mechanically<br />

steered X-band radar in the world<br />

SPY-3, the U.S. Navy’s first shipboard<br />

active phased array multifunction radar<br />

ARTEMIS, a sophisticated hyperspectral<br />

imaging sensor that was designed and<br />

built in less than 15 months<br />

AN/APG-79 AESA Radar System<br />

The AN/APG-79 AESA radar system is a significant<br />

advance in airborne radar technology.<br />

Entirely new — from front-end array to<br />

back-end processor and operational software<br />

— the system substantially increases<br />

the power of the U.S. Navy’s F/A-18 E/F<br />

Super Hornet, making it more lethal and<br />

less vulnerable than ever before.<br />

With its active electronic beam scanning,<br />

which allows the radar beam to be rapidly<br />

steered as it searches the surrounding airspace,<br />

the APG-79 optimizes situational<br />

awareness and provides superior air-to-air<br />

and air-to-ground capability. The agile beam<br />

enables the radar’s air-to-air and air-toground<br />

modes to interleave in near-real<br />

time, so that pilot and crew can use both<br />

modes simultaneously, an unprecedented<br />

technological leap.<br />

Now in flight test with the Navy, the APG-79<br />

demonstrates reliability, image resolution,<br />

and targeting-and-tracking range signifi-<br />

Feature<br />

cantly greater than that of the current<br />

F/A-18 radar. With its open systems architecture<br />

and compact, commercial-off-theshelf<br />

(COTS) parts, it delivers dramatically<br />

increased capability in a smaller, lighter<br />

package. The array is composed of numerous<br />

solid-state transmit and receive modules<br />

to virtually eliminate mechanical breakdown.<br />

Other system components include<br />

an advanced receiver/exciter, ruggedized<br />

COTS processor, and power supplies.<br />

X-Band Radar<br />

The nine-story-high XBR is the world’s<br />

largest X-band radar, weighing four million<br />

pounds. The sea-based X-band (SBX) platform<br />

that it sits on stands more than 250<br />

feet and displaces more than 50,000 tons.<br />

It consists of a semi-submersible oil production<br />

platform, topped with the XBR. XBR is<br />

the primary payload on the semi-submersible<br />

platform supporting the Ground-<br />

Based Midcourse Defense phase of the<br />

Missile Defense Agency Ballistic Missile<br />

Defense System. SBX’s floating platform, a<br />

modified oil-drilling vessel, was designed<br />

for exceptional stability in high winds and<br />

storms. Measuring 240 feet wide and 390<br />

feet long, the vessel includes a power plant,<br />

bridge and control rooms, living quarters,<br />

storage areas, and enough floor space and<br />

infrastructure to support the X-band radar.<br />

The X-band radar itself, which sits on top of<br />

the floating platform, is the largest, most<br />

sophisticated phased array, electro-mechanically<br />

steered X-band radar in the world. It<br />

consists of thousands of elements driven by<br />

transmit/receive (T/R) modules. In the Xband<br />

radar, they provide the full fire control<br />

sensor functions for the Ground-Based<br />

Midcourse Defense system, including<br />

search, acquisition, tracking, discrimination<br />

and kill assessment.<br />

Continued on page 8<br />

RAYTHEON TECHNOLOGY TODAY <strong>2009</strong> ISSUE 1 7

Feature<br />

Continued from page 7<br />

SPY-3<br />

The AN/SPY-3 Multi-Function Radar (MFR) is<br />

the U.S. Navy’s first shipboard active phased<br />

array multifunction radar. It is an X-band<br />

active phased array radar designed to meet<br />

all horizon search and fire control requirements<br />

for the Navy in the 21st century. MFR<br />

is designed to detect the most advanced<br />

low-observable anti-ship cruise missile<br />

(ASCM) threats and support fire-control illumination<br />

requirements for the Evolved Sea<br />

Sparrow Missile, Standard Missiles, and<br />

future missiles that will be required to support<br />

engagement of the most stressing<br />

ASCMs. MFR combines the functions provided<br />

by more than five separate radars<br />

currently aboard Navy combatant ships and<br />

also supports new ship-design requirements<br />

for reduced radar cross-section, significantly<br />

reduced manning (no operators), and total<br />

ownership cost reduction.<br />

The radar performs such functions as horizon<br />

search, limited above-the-horizon search,<br />

and fire control track and illumination. One<br />

of the most significant design features of the<br />

radar is to provide automatic detection,<br />

tracking and illumination of low-altitude<br />

threat missiles in the adverse environmental<br />

conditions routinely found in coastal waters.<br />

ENGINEERING PROFILE<br />

Katherine<br />

Herrick<br />

Deputy to the<br />

<strong>Tech</strong>nology<br />

Director, RMS<br />

A fresh face at<br />

<strong>Raytheon</strong> Missile<br />

Systems (RMS),<br />

Dr. Katherine<br />

Herrick arrived<br />

in Tucson, Ariz., in April 2008 from<br />

<strong>Raytheon</strong> Integrated Defense<br />

Systems’ Advanced <strong>Tech</strong>nology<br />

Directorate. She brought her extensive<br />

experience in cutting-edge RF<br />

semiconductor technology, but<br />

Herrick sees her current work as<br />

deputy to RMS’ technical director as<br />

drawing less upon her background<br />

in solid state III-V devices, and<br />

more upon her experience as a yoga<br />

instructor and cellist.<br />

8 <strong>2009</strong> ISSUE 1 RAYTHEON TECHNOLOGY TODAY<br />

SPY-3 uses three fixed-face arrays, each<br />

containing around 5,000 T/R elements.<br />

These elements are connected to T/R integrated<br />

multi-channel modules, each of<br />

which drives eight elements. Individual<br />

modules are designed to slide into the array<br />

structure and provide a high-conductivity<br />

thermal path to the cooling-array manifold<br />

without having any connection to the T/R<br />

module itself.<br />

ARTEMIS<br />

ARTEMIS is a sophisticated hyperspectral<br />

imaging sensor for the Operationally<br />

Responsive Space Office’s flagship Tactical<br />

Satellite (TacSat) program. The U.S. Air<br />

Force selected <strong>Raytheon</strong> to research and<br />

develop the primary surveillance sensor for<br />

the TacSat-3 mission. This groundbreaking<br />

space sensor was designed and built in<br />

less than 15 months as a rapid development<br />

project.<br />

ARTEMIS makes extensive use of COTS<br />

components and industry-standard interfaces<br />

to create an affordable, high-performance<br />

space-based surveillance option. It also realizes<br />

the operationally responsive space vision<br />

of fast, flexible launch and use capability.<br />

As defined by the joint Operationally<br />

Responsive Space Office at Kirtland Air<br />

“RMS is a bit like the human body,<br />

or an orchestra,” Herrick said. “It’s<br />

an extraordinarily complex system<br />

of systems that’s capable of amazing<br />

performance, but you can’t get the<br />

best out of it unless you view it<br />

holistically and determine the optimal<br />

way for its elements to work<br />

together in a dynamic environment.<br />

“We work across RMS, and enterprisewide,<br />

to develop strategic technology<br />

road maps at multiple levels,<br />

from basic technological innovation<br />

to Supply Chain to Business<br />

Development.” she explained. “We<br />

evaluate capability gaps against<br />

internal technology investment<br />

efforts aimed at an array of technology<br />

solutions. What we bring into<br />

the equation is an integrative<br />

approach that treats RMS as a<br />

whole, preparing it for agility and<br />

success in a complex environment of<br />

developing customer needs and<br />

technological possibilities.”<br />

After receiving her Ph.D. in 2000<br />

and conducting post-doctoral work<br />

at the University of Michigan,<br />

Herrick joined the Advanced<br />

<strong>Tech</strong>nology Department at<br />

<strong>Raytheon</strong> RF Components with a<br />

focus on high-frequency semiconductor<br />

circuits and integrated<br />

arrays. After transferring to<br />

<strong>Raytheon</strong> IDS’ Advanced <strong>Tech</strong>nology<br />

Directorate, Herrick led the capture<br />

of, and served as <strong>Raytheon</strong>’s principal<br />

investigator for, the DARPA<br />

COSMOS (Compound<br />

Semiconductor Materials On<br />

Silicon) program. That effort, she<br />

recalled, was one of the most exciting<br />

and rewarding experiences of<br />

her professional career. “COSMOS<br />

truly enables a new paradigm in circuit<br />

design through the innovative<br />

ARTEMIS baffle mirror assembly<br />

Force Base, N.M., the responsive space<br />

approach seeks to “assure space power<br />

focused on timely satisfaction of Joint Force<br />

Commanders’ needs.” Under one envisioned<br />

scenario, warehoused satellite components<br />

would be rapidly assembled, configured,<br />

and transported to nearby sites for<br />

quick launch into low Earth orbit — some<br />

200 miles overhead. The TacSat-3 program<br />

will test the feasibility of launching a payload<br />

such as ARTEMIS within as few as<br />

seven days after receiving the request.<br />

Once in orbit, ARTEMIS’s quick-reaction<br />

optics will enable it to see otherwise hidden<br />

targets, such as disturbed earth.<br />

When operated by a military commander<br />

in the field, ARTEMIS is able to provide data<br />

heterogeneous integration of semiconductors<br />

via direct epitaxial<br />

growth. It’s easy to be passionate<br />

about your work when it’s this<br />

transformational.”<br />

Herrick received the 2007 IDS<br />

President’s Award as the driving<br />

force behind <strong>Raytheon</strong>’s path-breaking<br />

COSMOS effort. Her other<br />

recent awards include: the 2008<br />

Outstanding Young Engineer Award<br />

from the IEEE Microware Theory<br />

and <strong>Tech</strong>niques Society, 2008 RMS<br />

<strong>Tech</strong>nical Honors Award, and<br />

selection to the 2008 National<br />

Academy of Engineers Frontiers’<br />

of Engineering Symposium.<br />

Herrick has published more than<br />

40 technical papers, and holds<br />

several patents in the areas of<br />

antennas, RF MEMS packaging,<br />

and microwave circuits.

in a user-friendly format, greatly reducing<br />

critical response times and enhancing battle<br />

assessment capabilities.<br />

The Future of Sensor Systems<br />

<strong>Raytheon</strong> continues technological advances<br />

that improve sensing capabilities at different<br />

wavelengths. As these sensors improve<br />

in performance with reductions in size and<br />

cost, wideband/multispectral/multiband sensors<br />

are becoming powerful, practical solutions<br />

for many applications. These sensors<br />

integrate multiple phenomenologies to<br />

exploit the unique characteristics of the target<br />

and environment, for improved performance<br />

against the most challenging targets<br />

in the most challenging environments.<br />

Polarization: A natural discriminant.<br />

Electromagnetic waves may be resolved into<br />

orthogonal oscillating electric fields. If there<br />

is a significant difference in the amplitude<br />

of one of the fields compared to the other,<br />

the light is said to be polarized. Polarization<br />

is of interest because manmade objects that<br />

contain sharp edges and flat surfaces tend<br />

to polarize light, while naturally occurring<br />

objects do not.<br />

Multiband: Detection can be optimized by<br />

employing many segments of the spectrum.<br />

Targets appear different across the spectrum<br />

because of their composition. Components<br />

are designed to operate across a limited range<br />

of the spectrum, driven by system requirements<br />

and physical parameters. By using sensors<br />

that employ multiple portions of the spectrum,<br />

selected for the best sensor performance<br />

in that range, sensing can be optimized.<br />

Multispectral: A color-based discriminant.<br />

Objects are not typically blackbodies —<br />

they emit or reflect some wavelengths preferentially<br />

to others. This is obvious in the<br />

visible, when we see the rich diversity of<br />

color in the world. We can far more easily<br />

separate objects from their surroundings in<br />

a color image than a black-and-white one.<br />

Yet we only sense three primary colors. All<br />

other sensed colors are mixtures of these.<br />

This is the idea of multispectral systems that<br />

are two or three infrared colors.<br />

Hyperspectral: Exploring color as a multidimensional<br />

discriminant. Hyperspectral<br />

systems use tens to hundreds of colors at<br />

each pixel. Using this technology, we can<br />

identify individual chemicals through their<br />

line emissions. Thus, we can discriminate<br />

painted vehicles from foliage, and even<br />

identify gas emission from factories or gas<br />

clouds. <strong>Raytheon</strong> has been a pioneer in this<br />

technology for space applications.<br />

Wideband: System range resolution is driven<br />

by its operating bandwidth. Wideband is<br />

a relative term used to describe a broader<br />

range of operating frequencies enabled by<br />

the use of improved component designs.<br />

Ultra-Wideband: Ultra-wideband yields<br />

higher range resolution. This is also a relative<br />

term used to describe a significantly<br />

broader frequency range; octaves or even<br />

decades wider in operating frequencies.<br />

Under DARPA’s COSMOS program,<br />

<strong>Raytheon</strong> offers the designer the “best<br />

junction for the function” without compromising<br />

the yield and scale of complementary<br />

metal oxide semiconductor (CMOS) or<br />

the speed and breakdown of compound<br />

semiconductors (CS). COSMOS’s unique<br />

technology enables the micron-scale placement<br />

of CS (GaAs, InP, and eventually GaN)<br />

in arbitrary locations on a CMOS wafer,<br />

while maintaining co-planarity with the<br />

CMOS for simple, high yield, monolithic<br />

integration. This monolithic integration<br />

approach is akin to the move from hybrids<br />

to MMICs, which enabled compound semiconductor<br />

insertions into systems over the<br />

last decade. The figure below shows InP<br />

heterojunction bi-polar transistors (HBT)<br />

integrated onto a silicon-on-lattice engineered<br />

substrate to enable InP performance<br />

while maintaining CMOS affordability.<br />

HBT<br />

CMOS<br />

Today’s multifunction systems integrate<br />

sensing functions with communications and<br />

electronic warfare functions by sharing the<br />

aperture, processing and power to minimize<br />

weight, volume and total lifecycle costs.<br />

Two additional constraints are also driving<br />

innovations in future sensor systems. First,<br />

the available surface area or volume on a<br />

platform may not accommodate multiple<br />

unique sensors, each optimized for a specific<br />

Feature<br />

application. Second, if platforms operate<br />

independently, this results in larger and<br />

more expensive sensor systems. Thus, the<br />

next generation of sensor systems will use<br />

the techniques described, to enable multiple<br />

simultaneous functions out of a<br />

common aperture and to operate as nodes<br />

in a network, sharing information with<br />

other sensors.<br />

Sensor netting is a powerful capability that<br />

provides an interoperable plug-and-fight<br />

architecture with networked multimission<br />

sensors that are tasked by “mission managers.”<br />

Acting as a network, the sensors<br />

can provide persistent surveillance while<br />

supporting multiple simultaneous missions.<br />

Additionally, network performance exceeds<br />

what is achievable by any individual sensor<br />

because multiple sensors are viewing<br />

objects from multiple angles and potentially<br />

with greater spectral diversity (RF, millimeter<br />

wave, terahertz, IR, visible regions, ultraviolet,<br />

etc.) to dramatically improve our ability<br />

to detect, track and identify objects.<br />

<strong>Raytheon</strong> is a world leader in sensor<br />

networking with products such as the<br />

Cooperative Engagement Capability (CEC),<br />

deployed by the U.S. Navy, and the<br />

Tactical Component Network (TCN) which<br />

provides a bandwidth-efficient composite<br />

tracking capability.<br />

Summary<br />

The four systems described in this article are<br />

examples of how <strong>Raytheon</strong>’s culture of<br />

innovation has resulted in providing<br />

unmatched capabilities for our customers<br />

and warfighters. As we address next-generation<br />

systems, we continue to extend the<br />

performance envelope while reducing cost<br />

and increasing reliability. <strong>Raytheon</strong> is<br />

extending its technological expertise and<br />

integration skills to provide key sensor<br />

technologies in a joint environment: joint<br />

in the sense of the services working together,<br />

joint in the sense of space, air, surface<br />

and subsurface, and joint in the sense of<br />

allies working together. We are developing<br />

the architecture, the connectivity, the<br />

software, the sensors and the electronics<br />

to help choreograph how today’s joint task<br />

force commanders integrate and employ<br />

their assets.<br />

Bill Kiczuk<br />

kiczuk@raytheon.com<br />

Contributor: Tony Marinilli<br />

RAYTHEON TECHNOLOGY TODAY <strong>2009</strong> ISSUE 1 9

Feature<br />

Mission<br />

Innovation: Fueling The Engine. A Dual V Model Approach<br />

<strong>Raytheon</strong>’s formal innovation organizations<br />

are the “sparks” that ignite the<br />

engine into creative action for solving<br />

a wide variety of pressing global issues. One<br />

such organization — Integrated Defense<br />

Systems’ (IDS) Mission Innovation (MI) —<br />

has been generating sparks for four years.<br />

A Model for Innovation<br />

The Mission Innovation team uses a Dual V<br />

Model to look at society and technology<br />

trends to anticipate where the next needs<br />

and solutions may be — extending well<br />

beyond just developing the next product<br />

and into imagining how existing world challenges<br />

potentially intersect with existing<br />

<strong>Raytheon</strong> technologies and capabilities.<br />

Following the top-down path, the MI team<br />

examines near- and long-term global issues<br />

across a multitude of focus areas; matching<br />

those broad areas with external technologies,<br />

solutions and partners in an open<br />

innovation model. The bottom-up path<br />

continuously draws from <strong>Raytheon</strong>’s<br />

portfolio of technologies, capabilities and<br />

expertise, using them to resolve world<br />

problems. The intersection of these paths<br />

10 <strong>2009</strong> ISSUE 1 RAYTHEON TECHNOLOGY TODAY<br />

is where appropriate business models,<br />

technologies, partners, and supporting<br />

functions meet to create a solution.<br />

<strong>Raytheon</strong> IDS Mission Innovation applies<br />

the Dual V model to several focus areas,<br />

including energy and environment, global<br />

health, and civil defenses.<br />

Oil Extraction From Shale Reserves<br />

According to the latest studies, the United<br />

States has an oil reserve of at least three<br />

times that of Saudi Arabia locked in a<br />

16,000-square-mile formation of oil shale<br />

deposits beneath federal land in Colorado,<br />

Utah and Wyoming. If successfully harvested,<br />

it’s estimated that this resource could<br />

yield anywhere from 500 billion to more<br />

than two trillion barrels of oil — enough<br />

to meet U.S. demand at current levels for<br />

more than 250 years.<br />

<strong>Raytheon</strong>’s solution combined its established<br />

expertise in radio frequency (RF)<br />

technology — more commonly used for<br />

radar and guidance systems — with critical<br />

fluids (CF) processes of small-business<br />

partner CF <strong>Tech</strong>nologies.<br />

Under this extraction scenario, oil wells are<br />

drilled into the shale strata using standard<br />

oil industry equipment. RF antennae, or<br />

transmitters, are lowered into the shale.<br />

The antennae then transmit RF energy to<br />

heat the buried shale. Super-critical carbondioxide<br />

is pumped into the shale formations<br />

to extract the oil from the rock and carry<br />

the oil to an extraction well. At the surface,<br />

the carbon-dioxide fluid is separated and<br />

pumped back into injection wells, while the<br />

oil and gas are refined into gasoline, heating<br />

oil and other products. These same<br />

process could also be used to extract oil<br />

from tar sands.

This method is more economical and environmentally<br />

responsible than older oil shale<br />

extraction techniques, as it uses far less<br />

power, does not severely disrupt the landscape<br />

or leave behind residue that can<br />

enter groundwater supplies.<br />

<strong>Raytheon</strong> sold its technology to extract oil<br />

from shale and tar sands to Schlumberger Ltd.,<br />

a leading oilfield services company, in 2008.<br />

Global Public Health Surveillance System<br />

Disease surveillance at the national and<br />

international levels can provide critical information<br />

for early detection and containment<br />

of emerging health threats. However, disease<br />

surveillance systems have evolved<br />

without international standards or collaborative<br />

protocols for specific data types,<br />

resulting in a wide variety of unique databases<br />

containing valuable information.<br />

Information-sharing across the various<br />

reporting systems (human, veterinary and<br />

wildlife) happens via human-intensive, timeconsuming<br />

activities such as the exchange<br />

of e-mails or faxes.<br />

The Global Public Health Surveillance<br />

(GPHS) system would connect all existing<br />

healthcare networks and add additional<br />

virological disease-monitoring capabilities<br />

to provide real-time global situational<br />

awareness. The system leverages technologies<br />

developed for the U.S. Department of<br />

Defense with the existing public health<br />

communications infrastructure to provide<br />

data exchange.<br />

Applications automatically process the<br />

metadata in real time, and software agents<br />

continuously search the metadata for virological<br />

disease anomalies and trends using<br />

numerical, temporal and geographic criteria<br />

for alerting human operators when and<br />

where appropriate. A metadata catalog provides<br />

a substantial information resource for<br />

human exploration using visualization tools<br />

and data mining applications.<br />

Feature<br />

Detection of Threats Using Honeybees<br />

For more than 100 years, it has been<br />

known that honeybees can be conditioned<br />

to detect chemical substances. In fact, the<br />

bees can detect chemicals in parts per<br />

quadrillion — orders of magnitude more<br />

sensitive than the best man-made sensors.<br />

Training insects to detect threats is not a<br />

new concept. Using associate conditioning,<br />

bees are exposed to a scent and then fed.<br />

Within a couple of hours, bees associate<br />

the scent with food. When they detect<br />

the scent, they swarm to the source to<br />

find the food.<br />

<strong>Raytheon</strong> has built on this established<br />

research and leveraged its expertise in RF<br />

technology to improve upon previous<br />

methods. <strong>Raytheon</strong> has developed a technique<br />

of attaching RF identification tags to<br />

honeybees. When bees that have been<br />

trained to detect chemicals swarm to a<br />

location, that location becomes a point of<br />

interest for security officials.<br />

Previous methods to track insects have<br />

relied on “line of sight” methods, which<br />

are difficult to maintain. Using RF<br />

technology, the swarm can be monitored<br />

electronically, out of sight of the handler.<br />

In the short term, applications of the<br />

technology could include locating landmines<br />

and buried devices. Future uses could<br />

involve homeland security applications such<br />

as sensing explosives and illegal drugs.<br />

Innovation for Global Stewardship<br />

<strong>Raytheon</strong> is a leader in defense, homeland<br />

security, and other government markets,<br />

but the company now applies its<br />

technologies and capabilities beyond<br />

our core businesses, emphasizing our<br />

responsibility of “global stewardship” to<br />

solve issues threatening our world: global<br />

warming, renewable energy, biological<br />

diversity protection, world health,<br />

education, and civil defense.<br />

ENGINEERING PROFILE<br />

Colin Whelan<br />

Engineering Fellow<br />

IDS<br />

Whether developing<br />

the next generation<br />

of radar technology<br />

or modifying sports<br />

cars, Colin Whelan’s<br />

passion for innovation<br />

is unmistakable.<br />

“I always wanted to<br />

understand how<br />

things worked, so I could try to improve<br />

their performance and use them in new ways,”<br />

said Whelan.<br />

After joining <strong>Raytheon</strong> in 1998, Whelan led the<br />

development of the Metamorphic High Electron<br />

Mobility Transistor technology used in low-noise<br />

microwave receivers. InP had long been the ultimate<br />

low-noise transistor, but was cost prohibitive.<br />

“Our diverse team of skilled engineers and technicians<br />

took an innovative approach to the problem.<br />

By discovering how to grow InP transistor layers<br />

on low-cost gallium arsenide (GaAs) substrates, we<br />

realized the performance and manufacturing<br />

advantages, without the associated costs,” noted<br />

Whelan. Following the successful transition of the<br />

technology to <strong>Raytheon</strong>’s production GaAs<br />

foundry, the team was recognized with <strong>Raytheon</strong>’s<br />

Excellence in <strong>Tech</strong>nology Award.<br />

With such projects, Whelan became fascinated<br />

with “driving innovation through the right technology<br />

investments, leadership and organizational<br />

and team structures.” He graduated from<br />

<strong>Raytheon</strong>’s Engineering Leadership Development<br />

Program and <strong>Raytheon</strong> Integrated Defense<br />

Systems’ Program Management College. He also<br />

earned executive education certificates in strategy<br />

and innovation and management and leadership<br />

from the MIT Sloan School of Management.<br />

In his present role as technology director for IDS’<br />

Advanced <strong>Tech</strong>nology group, he fosters the innovation<br />

of state-of-the-art materials, software and<br />

sensors to meet our warfighters’ needs by partnering<br />

with our customers, universities and small<br />

businesses. Specializing in radar module technology,<br />

Whelan leads the development of gallium<br />

nitride (GaN), a semiconductor circuit technology<br />

that offers disruptive capabilities in efficient<br />

microwave power generation. “We needed numerous<br />

innovations to bring this technology from<br />

initial concept to its current robust state. Led by a<br />

core group of dedicated <strong>Raytheon</strong> engineers, our<br />

diverse team of government customers, universities<br />

and business partners were able to significantly<br />

accelerate the development,” he said. As GaN<br />

now transitions into <strong>Raytheon</strong>’s systems, it will<br />

enable a new generation of smaller, more affordable<br />

RF sensors that produce even higher power.<br />

“<strong>Raytheon</strong> has honed its development activities<br />

to produce not just inventions, but innovations,<br />

where cost-effective technology solutions for our<br />

customers’ needs are created and quickly moved<br />

to production.”<br />

RAYTHEON TECHNOLOGY TODAY <strong>2009</strong> ISSUE 1 11

Feature<br />

<strong>Raytheon</strong> internal research in ant<br />

colony systems (ACS) and artificial<br />

immune systems (AIS) was recognized<br />

with <strong>Raytheon</strong>’s 2007 IDEA Program<br />

Innovator of the Year award. (For more<br />

about the IDEA program, see “Innovation<br />

at <strong>Raytheon</strong>.”) The IDEA Program seed<br />

funding led to the award of a highly competitive<br />

contract research and development<br />

project from the National Reconnaissance<br />

Office’s Director’s Innovation Initiative<br />

Program. It also led to another recently<br />

awarded highly competitive contract with<br />

the Air Force Research Laboratory on<br />

dynamic defensive counter-space indications<br />

and warning.<br />

Most complex problems in mission management<br />

and sensor data exploitation are related<br />

to optimization, search, learning or control.<br />

Traditional mathematical techniques in<br />

operations research require rigorous problem<br />

formulation, and an optimal solution is<br />

not always achievable. Furthermore, a realtime<br />

solution is frequently needed by the<br />

decision-maker in the battlefield and often<br />

must be drawn from a set of incomplete<br />

and uncertain observations.<br />

12 <strong>2009</strong> ISSUE 1 RAYTHEON TECHNOLOGY TODAY<br />

Swarm Intelligence<br />

for Automatic Knowledge<br />

Extraction<br />

<strong>Raytheon</strong>’s 2007 IDEA program of the year enables competitive awards<br />

New techniques that are more robust, fast<br />

and effective in solving these problems are<br />

required. <strong>Raytheon</strong> has been exploring<br />

bio-inspired techniques, in particular swarm<br />

intelligence, for automatic knowledge<br />

extraction, target recognition and tracking,<br />

and anomalous event detection. Two<br />

specific techniques under investigation<br />

within <strong>Raytheon</strong> include ACS and AIS,<br />

due to their robustness, great flexibility,<br />

and efficiency in automatic complex<br />

optimization problem-solving.<br />

ACS and AIS provide better tools for solving<br />

complex problems in mission management<br />

and data exploitation. They are particularly<br />

suitable for designing multi-agent systems<br />

for solving difficult combinatorial optimization<br />

problems. There is currently a lot of<br />

ongoing activity in the scientific community<br />

to extend/apply these algorithms to many<br />

different problems like task scheduling,<br />

vehicle routing, sequential ordering, graph<br />

coloring, routing in communications<br />

networks, etc.<br />

Recognizing the utility of swarm intelligence,<br />

a team of European researchers is<br />

currently developing tiny autonomous<br />

robots that can cooperate to perform<br />

different tasks — much like termites, ants<br />

or bees forage collaboratively for food,<br />

build nests and work together for the<br />

greater good of the colony. Under the<br />

European Union-funded I-SWARM<br />

project, a team created a 100-strong<br />

centimeter-scale robots to be used for<br />

future exploration of the planet Mars.<br />

Applying Swarm Intelligence<br />

Swarm intelligence, when combined<br />

with knowledge representation techniques<br />

such as cognitive graphs, will become a<br />

very powerful means for solving many<br />

complex problems in data exploitation;<br />

system analysis; intent identification; and<br />

intelligence, surveillance and reconnaissance<br />

mission management.<br />

Current research and development efforts<br />

are in the use of swarm intelligence for<br />

automatic knowledge extraction for

situational awareness, robust intrusion<br />

detection, mobile target detection and<br />

tracking, abnormal behavior recognition,<br />

cancer detection and screening, etc. The<br />

use of ACS and AIS as a new and better<br />

way of solving old problems in <strong>Raytheon</strong><br />

traditional markets will support our effort<br />

to maintain our customer base and provide<br />

a means to expand our business into<br />

adjacent markets.<br />

Ant Colony Systems<br />

Ant algorithms were inspired by the observation<br />

of real ant colonies. Ants are social<br />

insects; insects that live in colonies are<br />

directed more to the survival of the<br />

colony as a whole than to that of a single<br />

individual component of the colony. An<br />

important and interesting behavior of ant<br />

colonies is their foraging behavior, in<br />

particular how they can find the shortest<br />

paths between food sources and their nest.<br />

While walking from food sources to<br />

the nest and vice versa, ants deposit<br />

pheromones, forming a pheromone trail.<br />

Ants can smell the pheromones, and when<br />

choosing their way, they tend to choose, in<br />

probability, paths marked by strong<br />

pheromone concentrations. It has been<br />

shown experimentally that this pheromone<br />

trail-following behavior can give rise, once<br />

employed by a colony of ants, to the emergence<br />

of the shortest paths.<br />

Artificial ants (e.g., robotic ants or software<br />

agents) have a double nature. On one<br />

hand, they are an abstraction of those<br />

behavioral traits of real ants that seem to<br />

be at the heart of the shortest-path-finding<br />

behavior observed in real ant colonies. On<br />

the other hand, they have been enriched<br />

with some capabilities that do not have a<br />

natural counterpart, making them more<br />

effective and efficient.<br />

Artificial Immune Systems<br />

Parallels have been drawn between the<br />

human immune system (HIS) and anomaly<br />

detection problem domains, particularly<br />

with regard to intrusion detection systems.<br />

The HIS, for the most part, successfully pro-<br />

Feature<br />

tects the body from harmful pathogens<br />

that come in many forms. Each type of<br />

pathogen has a different cellular structure,<br />

method of replication and mechanism for<br />

entering the body. The immune system<br />

has evolved complex structures and<br />

methods for identifying these pathogens<br />

and removing or responding to the threat<br />

that they possess.<br />

The widely held view in immunology is that<br />

the main function of the immune<br />

system is to distinguish between “self”<br />

(cells belonging to the individual) and “nonself”<br />

(pathogens). However, immunologists<br />

are increasingly finding fault with traditional<br />

“self–nonself” thinking and a new “danger<br />

theory” is emerging. This new theory suggests<br />

that the immune system reacts to<br />

threats based on the correlation of various<br />

(danger) signals, and it provides a method<br />

of “grounding” the immune response, i.e.,<br />

linking it directly to the attacker.<br />

In AIS, a variety of contextual clues may be<br />

essential for a meaningful danger signal,<br />

and immunological studies provide a framework<br />

of ideas as to how danger is assessed<br />

in the HIS. Once the danger signal has been<br />

transmitted, the AIS can react to those artificial<br />

antigens (e.g., anomalous events/targets<br />

in the input data set) that are “near”<br />

the emitter of the danger signal. This allows<br />

the AIS to pay special attention to dangerous<br />

components and would have the<br />

advantage of detecting rapidly spreading<br />

viruses or scanning intrusions at an<br />

early stage, preventing serious damage.<br />

Swarm intelligence belongs to the<br />

relatively new wave of stochastic metaheuristics<br />

like evolutionary computation,<br />

simulated annealing, tabu search and<br />

neural computation, which are built<br />

around some basic principles taken by<br />

the observation of a particular natural<br />

phenomenon. Within the artificial-life<br />

field, ACS and AIS represent the two<br />

most successful applications of<br />

swarm intelligence.<br />

Duong Nguyen<br />

dnguyen1@raytheon.com<br />

ENGINEERING PROFILE<br />

Duong<br />

Nguyen<br />

Senior Principal<br />

Multi-Disciplined<br />

Engineer, IIS<br />

During his seven<br />

years with<br />

<strong>Raytheon</strong>, Duong<br />

Nguyen has been<br />

a member of the<br />

Intelligence and<br />

Information<br />

Systems (IIS)<br />

Rocky Mountain<br />

Engineering/Advanced Planning and <strong>Tech</strong>nology<br />

Development program. He is also responsible<br />

for contract funded research and development<br />

(CRAD) and University Directed Research<br />

Programs at IIS’ Aurora, Colo. site.<br />

Before joining <strong>Raytheon</strong>, Nguyen was in<br />

academia for many years. He also worked in<br />

research and development at Centre National<br />

d’Etudes Spatiales in France, as chief scientist<br />

at Geodynamics, and as a technical advisor<br />

at Northrop Grumman.<br />

According to Nguyen, innovation is creating a<br />

new and useful idea that provides a solution to<br />

a problem of interest to our customer, or helps<br />

improve <strong>Raytheon</strong> in-house capability and<br />

allows it to operate more effectively. He has<br />

applied this definition throughout his career.<br />

He was the first to propose the use of “Real<br />

Options Theory” in the financial investment<br />

domain for dynamic satellite tasking and<br />

secured a highly competitive CRAD project for<br />

the idea. Later, while exploring bio-inspired<br />

techniques for better space mission planning<br />

and management, he proposed the use of<br />

“swarm intelligence” for automatic knowledge<br />

extraction. This innovative idea led him to<br />

receive an in-house IDEA award and another<br />

CRAD project. In all, Nguyen has been awarded<br />

two in-house IDEA projects and three highly<br />

competitive CRAD projects, with two patents<br />

pending, in four years.<br />

One of the biggest challenges that Nguyen<br />

encounters is motivating engineers to come up<br />

with innovative ideas. He believes that it’s<br />

imperative for <strong>Raytheon</strong> engineers to realize<br />

that innovation generates CRAD, and CRAD<br />

sustains and supports business growth.<br />

“It’s relatively easy to motivate young engineers<br />

to realize that innovation and CRAD have a<br />

causal relationship. Without innovation, it’s<br />

hard to get CRAD projects,” he explained.<br />

“Also, without CRAD requirements we don’t<br />

know what innovative ideas customers need.”<br />

RAYTHEON TECHNOLOGY TODAY <strong>2009</strong> ISSUE 1 13

Feature<br />

The Bike Shop: Engaging the Innovator<br />

Understanding the problem; working with the customer; methods to achieve success through<br />

Envision, Create and Accomplish; and pitfalls to avoid<br />

Innovation, rapid product development,<br />

rapid reaction, prototyping, rapid transition<br />

to production. Sound familiar?<br />

These, and many other semantically similar<br />

phrases, have become the ubiquitous<br />

clichés of developmental industries. This<br />

article is about innovation and innovators; it<br />

is also about customers, problem solving<br />

and growing the business.<br />

<strong>Raytheon</strong> Missile Systems’ Bike Shop is often<br />

asked what the formula is for innovation.<br />

Our answer is simple: “You are asking for a<br />

roadmap to a place where nobody has<br />

been before; it doesn’t exist.” We describe<br />

ourselves as a rapid product development<br />

and experimentation lab. Fundamentally,<br />

we are problem solvers. Problems come in<br />

myriad forms but generally share some<br />

basic characteristics: A customer is willing<br />

to pay to satisfy a need. The customer has<br />

a pre-conceived notion of what the solution<br />

looks like. The first is the genesis of business.<br />

The second is the first mistake in the process.<br />

The Bike Shop’s motto is “Envision – Create<br />

– Accomplish.” This consistently proves to be<br />

an effective program plan for innovation.<br />

Envision<br />

The first task of an innovative solution<br />

provider is to understand the problem —<br />

the real problem. Too often engineers make<br />

their first mistake on a project by trying to<br />

understand the solution or accepting the<br />

proffered problem statement at face value.<br />

The Bike Shop starts all projects with a<br />

brainstorming session.<br />

Here is an opportunity for an early mistake.<br />

Assuming you don’t need a theoretical<br />

physicist and a machinist at your brainstorming<br />

session is a sure sign that you<br />

have pre-supposed the expertise required to<br />

achieve an optimum solution. Envision the<br />

problem. Put the problem into your own<br />

14 <strong>2009</strong> ISSUE 1 RAYTHEON TECHNOLOGY TODAY<br />

team’s terms and understand it from the<br />

ultimate user’s perspective.<br />

If your team can’t envision the problem,<br />

and communicate it to each other and<br />

the customer in their own terms, you<br />

have no business trying to solve it.<br />

If a customer comes in and says “I need a<br />

bridge,” don’t start ordering steel and<br />

searching for a civil engineer. Find out what<br />

problem he or she is trying to solve. The<br />

real answer may not be “I need a bridge.”<br />

The problem may be something like, “My<br />

house is on this side of the river and my<br />

fields are on the other side.” There are a lot<br />

of solutions to that problem. Build a new<br />

house, reroute the river, plant new fields,<br />

sell everything and move to a new location.<br />

In the end, you might not build a bridge.<br />

The Box<br />

Think of industry as three nested boxes,<br />

business inside physics inside imagination.<br />

We can imagine all kinds of things we can’t<br />

build. We can build all kinds of things that<br />

the business is not set up to handle. The<br />

business box is the safe box, the box where<br />

there is a process, procedure or precedent<br />

to cover an action or concept. It is also the<br />

box that supplies paychecks, benefits, capital,<br />

facilities, resources and retirement.<br />

Paradoxically, we want everyone to operate<br />

outside the box while simultaneously telling<br />

them on a daily basis that they must follow<br />

the rules. Company policies define the business<br />

box. If you start the process of innovation<br />

inside the business box you will fail, by<br />

definition. As Albert Einstein once stated,<br />

“The definition of insanity is doing the<br />

same thing over and over again and expecting<br />

different results.” Attempting to accomplish<br />

outside of the business box is tricky. If<br />