Tech_Issue 1 2009_0127_Final:TechToday_012709 ... - Raytheon

Tech_Issue 1 2009_0127_Final:TechToday_012709 ... - Raytheon

Tech_Issue 1 2009_0127_Final:TechToday_012709 ... - Raytheon

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

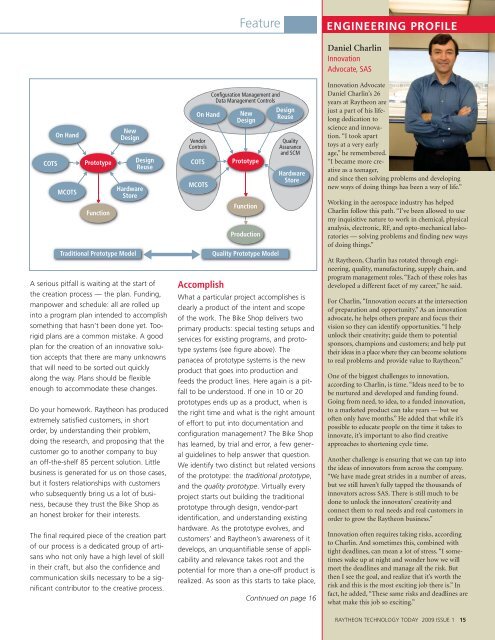

COTS<br />

On Hand<br />

MCOTS<br />

Prototype<br />

Function<br />

New<br />

Design<br />

Hardware<br />

Store<br />

Design<br />

Reuse<br />

A serious pitfall is waiting at the start of<br />

the creation process — the plan. Funding,<br />

manpower and schedule: all are rolled up<br />

into a program plan intended to accomplish<br />

something that hasn’t been done yet. Toorigid<br />

plans are a common mistake. A good<br />

plan for the creation of an innovative solution<br />

accepts that there are many unknowns<br />

that will need to be sorted out quickly<br />

along the way. Plans should be flexible<br />

enough to accommodate these changes.<br />

Do your homework. <strong>Raytheon</strong> has produced<br />

extremely satisfied customers, in short<br />

order, by understanding their problem,<br />

doing the research, and proposing that the<br />

customer go to another company to buy<br />

an off-the-shelf 85 percent solution. Little<br />

business is generated for us on those cases,<br />

but it fosters relationships with customers<br />

who subsequently bring us a lot of business,<br />

because they trust the Bike Shop as<br />

an honest broker for their interests.<br />

The final required piece of the creation part<br />

of our process is a dedicated group of artisans<br />

who not only have a high level of skill<br />

in their craft, but also the confidence and<br />

communication skills necessary to be a significant<br />

contributor to the creative process.<br />

On Hand<br />

Vendor<br />

Controls<br />

COTS<br />

MCOTS<br />

Accomplish<br />

Feature<br />

Configuration Management and<br />

Data Management Controls<br />

New<br />

Design<br />

Prototype<br />

Function<br />

Production<br />

Traditional Prototype Model Quality Prototype Model<br />

Design<br />

Reuse<br />

Quality<br />

Assurance<br />

and SCM<br />

Hardware<br />

Store<br />

What a particular project accomplishes is<br />

clearly a product of the intent and scope<br />

of the work. The Bike Shop delivers two<br />

primary products: special testing setups and<br />

services for existing programs, and prototype<br />

systems (see figure above). The<br />

panacea of prototype systems is the new<br />

product that goes into production and<br />

feeds the product lines. Here again is a pitfall<br />

to be understood. If one in 10 or 20<br />

prototypes ends up as a product, when is<br />

the right time and what is the right amount<br />

of effort to put into documentation and<br />

configuration management? The Bike Shop<br />

has learned, by trial and error, a few general<br />

guidelines to help answer that question.<br />

We identify two distinct but related versions<br />

of the prototype: the traditional prototype,<br />

and the quality prototype. Virtually every<br />

project starts out building the traditional<br />

prototype through design, vendor-part<br />

identification, and understanding existing<br />

hardware. As the prototype evolves, and<br />

customers’ and <strong>Raytheon</strong>’s awareness of it<br />

develops, an unquantifiable sense of applicability<br />

and relevance takes root and the<br />

potential for more than a one-off product is<br />

realized. As soon as this starts to take place,<br />

Continued on page 16<br />

ENGINEERING PROFILE<br />

Daniel Charlin<br />

Innovation<br />

Advocate, SAS<br />

Innovation Advocate<br />

Daniel Charlin’s 26<br />

years at <strong>Raytheon</strong> are<br />

just a part of his lifelong<br />

dedication to<br />

science and innovation.<br />

“I took apart<br />

toys at a very early<br />

age,” he remembered.<br />

“I became more creative<br />

as a teenager,<br />

and since then solving problems and developing<br />

new ways of doing things has been a way of life.”<br />

Working in the aerospace industry has helped<br />

Charlin follow this path. “I’ve been allowed to use<br />

my inquisitive nature to work in chemical, physical<br />

analysis, electronic, RF, and opto-mechanical laboratories<br />

— solving problems and finding new ways<br />

of doing things.”<br />

At <strong>Raytheon</strong>, Charlin has rotated through engineering,<br />

quality, manufacturing, supply chain, and<br />

program management roles. “Each of these roles has<br />

developed a different facet of my career,” he said.<br />

For Charlin, “Innovation occurs at the intersection<br />

of preparation and opportunity.” As an innovation<br />

advocate, he helps others prepare and focus their<br />

vision so they can identify opportunities. “I help<br />

unlock their creativity; guide them to potential<br />

sponsors, champions and customers; and help put<br />

their ideas in a place where they can become solutions<br />

to real problems and provide value to <strong>Raytheon</strong>.”<br />

One of the biggest challenges to innovation,<br />

according to Charlin, is time. “Ideas need to be to<br />

be nurtured and developed and funding found.<br />

Going from need, to idea, to a funded innovation,<br />

to a marketed product can take years — but we<br />

often only have months.” He added that while it’s<br />

possible to educate people on the time it takes to<br />

innovate, it’s important to also find creative<br />

approaches to shortening cycle time.<br />

Another challenge is ensuring that we can tap into<br />

the ideas of innovators from across the company.<br />

“We have made great strides in a number of areas,<br />

but we still haven’t fully tapped the thousands of<br />

innovators across SAS. There is still much to be<br />

done to unlock the innovators’ creativity and<br />

connect them to real needs and real customers in<br />

order to grow the <strong>Raytheon</strong> business.”<br />

Innovation often requires taking risks, according<br />

to Charlin. And sometimes this, combined with<br />

tight deadlines, can mean a lot of stress. “I sometimes<br />

wake up at night and wonder how we will<br />

meet the deadlines and manage all the risk. But<br />

then I see the goal, and realize that it’s worth the<br />

risk and this is the most exciting job there is.” In<br />

fact, he added, “These same risks and deadlines are<br />

what make this job so exciting.”<br />

RAYTHEON TECHNOLOGY TODAY <strong>2009</strong> ISSUE 1 15