Cavitation and Hydraulic Flip in the Outward-Opening GDi ... - Delphi

Cavitation and Hydraulic Flip in the Outward-Opening GDi ... - Delphi

Cavitation and Hydraulic Flip in the Outward-Opening GDi ... - Delphi

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>in</strong> Gill<strong>in</strong>gham. The experimental methodologies applied<br />

are photographic imag<strong>in</strong>g, <strong>in</strong> conjunction with<br />

measurements of <strong>the</strong> pressure <strong>and</strong> flow rate. The focus<br />

of <strong>the</strong> study is to obta<strong>in</strong> basic flow <strong>in</strong>formation regard<strong>in</strong>g<br />

<strong>the</strong> condition of flow with<strong>in</strong> <strong>the</strong> <strong>in</strong>jector – with <strong>the</strong> aid of<br />

imag<strong>in</strong>g <strong>and</strong> pressure measurement at several locations<br />

- <strong>and</strong> <strong>the</strong> spray. This <strong>in</strong>formation is <strong>in</strong>tended to assist<br />

development of <strong>the</strong> valve-group design <strong>and</strong> support<br />

validation of a current state-of-<strong>the</strong>-art CFD multi-phase<br />

simulation method.<br />

The large-scale modell<strong>in</strong>g uses <strong>the</strong> pr<strong>in</strong>ciples of<br />

geometric <strong>and</strong> dynamic similarity for steady state flow<br />

conditions. In this respect, <strong>the</strong> two most relevant nondimensional<br />

groups are <strong>the</strong> Reynolds number <strong>and</strong><br />

cavitation number, to match <strong>the</strong> model operation<br />

condition with that of <strong>the</strong> actual-size counterpart. The<br />

Reynolds number similarity takes account of <strong>the</strong> different<br />

properties of <strong>the</strong> actual-size fluid (i.e. n-Heptane) <strong>and</strong> <strong>the</strong><br />

large-scale work<strong>in</strong>g fluid (i.e. ISO4113 calibration fluid).<br />

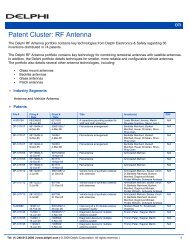

Table 1 presents <strong>the</strong> correspondence between <strong>the</strong> largescale<br />

model tests <strong>and</strong> <strong>the</strong> actual-size <strong>in</strong>jector operation.<br />

Actual size Model (x35)<br />

Liquid Properties<br />

Work<strong>in</strong>g Fluid n - Heptane<br />

ISO 4113<br />

calibration<br />

fluid<br />

Viscosity [mm2/s] 0.575 2.75<br />

Density [kg/m3] 680 817<br />

Vapour Pressure [bar] 0.0413 0.002<br />

System Pressure [MPa]<br />

5 0.112<br />

10 0.224<br />

15 0.337<br />

20 0.449<br />

Ambient Pressure [MPa]<br />

0.4 0.009<br />

Table 1. Correspondence of <strong>the</strong> Large-scale model<br />

tests <strong>and</strong> actual-size <strong>in</strong>jector operation<br />

EXPERIMENTAL FLOW RIG - Figure 1 shows <strong>the</strong> flow<br />

rig <strong>and</strong> <strong>the</strong> large-scale model <strong>in</strong> situ. The static<br />

pressures at <strong>the</strong> tapp<strong>in</strong>gs are measured with a<br />

Scanivalve unit us<strong>in</strong>g a calibrated transducer, <strong>and</strong><br />

processed / stored via a personal computer. The flow<br />

rate is cont<strong>in</strong>uously monitored with a vane-type flow<br />

meter. In order to create <strong>the</strong> correct flow cavitation<br />

number, <strong>the</strong> <strong>GDi</strong> valve -group model discharges <strong>in</strong>to a<br />

vacuum chamber.<br />

LARGE-SCALE VALVE-GROUP MODEL - The model is<br />

shown <strong>in</strong> Figure 2. It is modular <strong>in</strong> construction to allow<br />

design changes to be easily implemented. The ma<strong>in</strong><br />

hous<strong>in</strong>g <strong>and</strong> <strong>the</strong> swirler are manufactured from acrylic<br />

material to allow view<strong>in</strong>g of <strong>the</strong> cavitations regions <strong>in</strong> <strong>the</strong><br />

fluid flow. The p<strong>in</strong>tle can be adjusted to be concentric or<br />

eccentric <strong>in</strong> <strong>the</strong> guide bore. A leakage path orifice is<br />

fitted <strong>in</strong>to <strong>the</strong> swirler plate to model leakage flow through<br />

<strong>the</strong> p<strong>in</strong>tle - guide clearance annulus.<br />

Figure 1. The <strong>in</strong>-situ assembled model <strong>and</strong> <strong>the</strong> test<br />

apparatus<br />

Figure 2 : construction of <strong>the</strong> large-scale model <strong>and</strong><br />

arrangement of <strong>the</strong> pressure tapp<strong>in</strong>gs (<strong>the</strong> p<strong>in</strong>tle is<br />

shown seated)