PS-PLLA - Www2.che.nthu.edu.tw

PS-PLLA - Www2.che.nthu.edu.tw

PS-PLLA - Www2.che.nthu.edu.tw

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

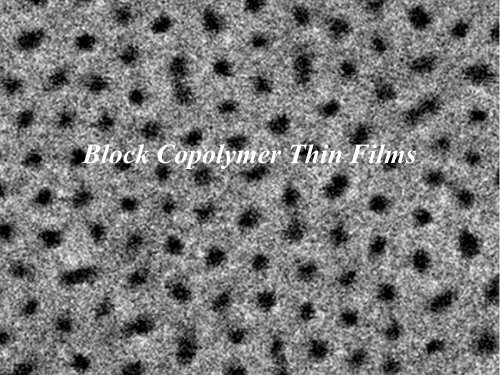

Block Copolymer Thin Films

Thin Film Morphologies of BCPs<br />

Thickness<br />

Air surface<br />

Substrate<br />

Size<br />

Shape<br />

Order<br />

Orientation<br />

@

Thickness Effect<br />

while t is small for a lamellar phase!<br />

FL: symmetric<br />

surface-parallel full<br />

lamella;<br />

AFL: anti-symmetric<br />

surface-parallel<br />

lamella;<br />

AHY: anti-symmetric<br />

hybrid structure;<br />

HL: half-lamella;<br />

HY: symmetric hybrid<br />

structure;<br />

PL: surfaceperpendicular<br />

lamellae.

At equilibrium, symmetric film systems exhibit a series of<br />

stable films when t = nL 0 (n = 1, 2, 3, 4), whereas antisymmetric<br />

films exhibit a similar series of stable films when t =<br />

(n + 1/2)L 0. It is highly possible to form the island-like<br />

textures for t being not equal to nL 0 and (n + 1/2)L 0.<br />

For symmetric surface energy, first, the domain orientation<br />

was film thickness dependent. In particular, PL gained stability<br />

when t = nL 0, and especially for t < L 0. Second, for neutral<br />

surface energetics, PL was stable for all film thicknesses.<br />

@

Phase diagram of thin film morphologies calculated<br />

with the following parameters: N=200, S 1 B = -0.3 kT,<br />

interaction parameter = 0.1, S 1 B /S2 B = R

For a<br />

cylinder<br />

phase

Surface Tension @

Substrate<br />

Effect

Grain boundary problem<br />

for thicker samples<br />

<strong>PS</strong>-PB AFM Morphology<br />

Defect free microdomain!<br />

van Dijk, M. A.; van den Berg, R. Macromolecules 1995, 28, 6773.

Large-scale Orientation of Microdomains<br />

Electric field-Induced Orientation<br />

Russell, U of Massachusetts<br />

Surface-Induced Orientation<br />

Russell, U of Massachusetts<br />

Shear-Induced Orientation<br />

Register, Princeton U<br />

■ Patterned Substrate-induced Orientation<br />

Nealey, U of Wisconsin<br />

■ Graphoepitaxy-induced Orientation<br />

Ross, MIT<br />

■ Photo-induced Orientation<br />

Iyoda, TIT

Electric field-Induced Orientation<br />

ε <strong>PS</strong> = 2.45<br />

ε PMMA = 6<br />

Russell, U of Massachusetts<br />

Russell, T. P. et al. Science, 1996, 273, 931.

Surface-Induced Orientation<br />

Neutral Surface<br />

Russell, T. P. et al. Science 1997, 275, 1458.; Russell, T. P. et al. Nature 1998, 395, 757.<br />

@

Shear-induced Orientation<br />

<strong>PS</strong>-PEP Cylindrical Morphology<br />

<strong>PS</strong><br />

@<br />

Register R. A. et al. Adv. Mater. 2004, 16, 1736.

Patterned Substrate for DSA<br />

(1) Nealey, P. F. et al. Nature, 2003, 424, 411.

Grephoepitaxy-induced Orientation<br />

Confinement effect<br />

Sibener. S. J. et al. Nano Lett. 2002, 4, 273.<br />

@

Photo-induced Orientation<br />

Chromophore molecule<br />

Iyoda, T. et al. J. Am Chem. Soc. 2006, 128, 11010.<br />

@

Evaporation-induced Orientation<br />

Spin Coating-induced Orientation<br />

for <strong>PS</strong>-PEO<br />

Russell, T.P. et al. Adv Mater 2002,<br />

14, 1373.<br />

Tapping-mode<br />

SPM phase images<br />

of the surfaces of<br />

a) solution cast; b)<br />

spin coated<br />

<strong>PS</strong>365-<strong>PLLA</strong>109<br />

(f <strong>PLLA</strong> v =0.24) thin<br />

films on glass<br />

slides.<br />

a)<br />

Solution casting<br />

<br />

spinning<br />

Degradable BCP for mesoporous materials!<br />

Spin-coating for oriented microdomains!<br />

b)<br />

Spin coating

Tapping-mode SPM height images for spin-coated <strong>PS</strong>365-<strong>PLLA</strong>109 (f <strong>PLLA</strong> v =0.24)<br />

thin films on glass slides a) before hydrolysis; b) after hydrolysis.<br />

a) b)<br />

before hydrolysis after hydrolysis<br />

Well-oriented, perpendicular HC nanochannel arrays!

FESEM micrographs of hydrolyzed <strong>PS</strong>-<strong>PLLA</strong> samples by viewing<br />

parallel to the cylindrical axes<br />

Top-view<br />

Fracture of substrate<br />

Cross-section view<br />

Spin-coated <strong>PS</strong>365-<strong>PLLA</strong>109 (f <strong>PLLA</strong> v =0.26) thin films on<br />

glass slides after hydrolysis. (50nm thickness)

Thin-film Thickness Control<br />

The plot of film thickness versus spin rate for spin-coated <strong>PS</strong>365-<br />

<strong>PLLA</strong>109 (f v<br />

<strong>PLLA</strong> =0.24) thin films on glass slides. Open circle<br />

indicates the sample thickness measured by SPM whereas open<br />

triangle indicates the thickness measured by depth profile.<br />

Thickness [nm]<br />

180<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

Surface Prfiler<br />

0 1000 2000 3000 4000 5000 6000 7000 8000<br />

Spin Rate [rpm]<br />

SPM

Tunable dimensions of nanostructures<br />

Varieties of synthesized <strong>PS</strong>-<strong>PLLA</strong> block copolymers having HC microstructures.<br />

Entry<br />

<strong>PS</strong>83-<strong>PLLA</strong>41<br />

<strong>PS</strong>198-<strong>PLLA</strong>71<br />

<strong>PS</strong>280-<strong>PLLA</strong>122<br />

<strong>PS</strong>365-<strong>PLLA</strong>109<br />

Mn, <strong>PS</strong><br />

[g/mol]<br />

[a]<br />

8900<br />

20700<br />

29400<br />

38200<br />

Mn, <strong>PLLA</strong><br />

[g/mol]<br />

[b]<br />

5900<br />

10200<br />

17500<br />

15700<br />

PDI<br />

1.15<br />

1.17<br />

1.21<br />

1.21<br />

0.66<br />

0.73<br />

0.69<br />

0.76<br />

[c]<br />

12.7<br />

25.8<br />

31.4<br />

34.1<br />

d-spacing [nm]<br />

[d]<br />

16.8<br />

28.4<br />

37.2<br />

39.7<br />

[e]<br />

20.8<br />

32.9<br />

35.5<br />

44.2<br />

[c]<br />

7.2<br />

10.7<br />

13.3<br />

17.0<br />

Diameter [nm]<br />

[a] measured from GPC analysis. [b] obtained from integration of 1 H NMR measurement. [c] obtained from<br />

calculation of TEM micrographs. [d] determined from first scattering peak of SAXS. [e] obtained from surface<br />

analysis of SPM.<br />

f <strong>PS</strong> v<br />

[d]<br />

12.0<br />

19.8<br />

25.6<br />

26.4<br />

[e]<br />

9.1<br />

19.7<br />

23.0<br />

20.9

Topographic <strong>PS</strong> Nanopattern<br />

Schematic illustration of <strong>PS</strong>-<strong>PLLA</strong> and <strong>PS</strong>-PLA nanopattern<br />

prepared by spin coating.<br />

Continuity and Uniformity of Thin Films<br />

Silicon wafer; Silicon oxide; glass; carbon; ITO glass;<br />

Light emitted diode; Aluminum ----<br />

Coated on various substrates

Spin-coated <strong>PS</strong>-<strong>PLLA</strong> thin films<br />

Perpendicular morphology<br />

SPM phase image TEM image<br />

100 nm<br />

40

Proposed Mechanism<br />

Solvent evaporation<br />

d<br />

funnel effect<br />

Step 1: well-ordered microphase separation<br />

Step 2: solvent permeate through specific microdomain<br />

fs<br />

41

Definition of Solvent<br />

Solvent Molar volume χ <strong>PS</strong>-solvent <strong>PLLA</strong>-solvent δ solvent<br />

(MPa) 0.5<br />

Vapor Pressure<br />

(mmHg)<br />

Chlorobenzene 102.1 0.36 0.62 19.6 12<br />

benzene 89.4 0.34 0.81 18.6 70<br />

THF 81.7 0.35 0.6 19.4 176<br />

1,1,2-trichloroethane 100.4 0.36 < 0.5 19.6 17.1<br />

1,2-dichloroethane 79.2 0.42 0.44 20.4 61<br />

chloroform 80.7 0.34 < 0.5 19 159.6<br />

χ = χ H + χ S = V i (δ i –δ j ) 2 /RT + 0.34<br />

χ <strong>PS</strong>-solvent < 0.5 and χ <strong>PLLA</strong>-solvent >0.5 <strong>PS</strong> selective solvent<br />

χ <strong>PS</strong>-solvent < 0.5 and χ <strong>PLLA</strong>-solvent

<strong>PS</strong>-<strong>PLLA</strong> with Cylinder Morphology<br />

Table 1. Varieties of synthesized <strong>PS</strong>-<strong>PLLA</strong> block copolymers having HC microstructures.<br />

Entry<br />

Mn, <strong>PS</strong><br />

[g/mol]<br />

[a]<br />

Mn, <strong>PLLA</strong><br />

[g/mol]<br />

[b]<br />

PDI f <strong>PS</strong> v<br />

d-spacing [nm] Diameter[nm]<br />

[c] [d] [e] [c] [d] [e]<br />

<strong>PS</strong>83-<strong>PLLA</strong>41 8900 5900 1.15 0.65 12.7 16.8 20.8 7.2 12.2 10.1<br />

<strong>PS</strong>198-<strong>PLLA</strong>71 20700 10200 1.17 0.71 25.8 28.4 32.9 13.8 18.9 19.7<br />

<strong>PS</strong>280-<strong>PLLA</strong>97 29400 14000 1.21 0.72 31.4 37.2 35.5 16.7 23.5 20.0<br />

Control<br />

Molecular weight<br />

Control<br />

Size<br />

<strong>PS</strong>365-<strong>PLLA</strong>109 38200 15700 1.21 0.75 34.1 39.7 44.2 17.0 24.6<br />

.<br />

20.9<br />

[a] measured from GPC analysis.<br />

[c] obtained from calculation of TEM micrographs. [e] obtained from surface analysis of SPM.<br />

[b] obtained from integration of 1H NMR measurement. [d] determined from first scattering peak of SAXS.<br />

43

Evaporation Rate Effect<br />

Selective solvent<br />

131.5 mmHg 70 mmHg 12 mmHg<br />

Solvent Evaporation<br />

Vapor Pressure<br />

Evaporation Rate<br />

Time scale of microphase separation<br />

44

Selectivity Effect<br />

Neutral solvent<br />

160 mmHg 61mmHg 17.1 mmHg<br />

Solvent Evaporation<br />

Neutral solvent<br />

Segregation strength ~ χN<br />

45

Solution Casting<br />

Neutral solvent<br />

Crystalline <strong>PS</strong>-<strong>PLLA</strong> Amorphous <strong>PS</strong>-PLA<br />

46

Solution Casting<br />

Selective solvent<br />

Crystalline <strong>PS</strong>-<strong>PLLA</strong> Amorphous <strong>PS</strong>-PLA<br />

47

Molecular Weight Effect<br />

Selective Solvent with Low Evaporation Rate<br />

S83L41<br />

S198L71<br />

S280L97 S365L109<br />

Solvent evaporation<br />

Molecular weight<br />

Segregation strength ~ χN<br />

48

Bottom Morphology<br />

Before hydrolysis<br />

<strong>PS</strong> <strong>PLLA</strong><br />

Hydrophilic substrate<br />

After hydrolysis<br />

Interfacial energy of <strong>PS</strong>-hydrophilic substrate > Interfacial energy of <strong>PLLA</strong>-hydrophilic substrate<br />

49

Tg Effect<br />

Side view image of FESEM<br />

100 nm<br />

Phase image<br />

Spin-coated <strong>PS</strong>-<strong>PLLA</strong> thin films at the temperature above T g<strong>PLLA</strong><br />

but below T g<strong>PLLA</strong> (ca. 50 o C)<br />

50

<strong>PS</strong> <strong>PLLA</strong><br />

Hydrophilic substrate<br />

Spin coating at room temperature<br />

D <strong>PS</strong> (glass state) = D <strong>PLLA</strong> (glass state)<br />

S <strong>PS</strong>-<strong>PS</strong> selective solvnet > S <strong>PLLA</strong>-<strong>PS</strong>-selective solvent<br />

Permeation<br />

Diffusivity & Solubility<br />

Kinetic control & Dynamic control<br />

<strong>PS</strong> <strong>PLLA</strong><br />

Hydrophilic substrate<br />

Spin coating at 50 O C<br />

D <strong>PS</strong> (glass state) S <strong>PLLA</strong>-<strong>PS</strong>-selective solvent<br />

Permeation (P=DXS)<br />

Diffusivity (D) ~ T g<br />

Solubility (S)<br />

51

Substrate Effect<br />

Glass slide Carbon film<br />

ITO Silicon wafer<br />

52

Thickness Effect<br />

160 nm 80 nm 50 nm<br />

53

Proposed Mechanism<br />

Segregation strength and time scale Permeation (P=DXS)<br />

Selectivity (selective and neutral solvent) Diffusivity (Tg effect)<br />

Evaporation rate Solubility<br />

Molecular weight<br />

Solvent evaporation<br />

Step 1: well-ordered microphase separation<br />

Step 2: solvent permeate through specific microdomain<br />

d<br />

fs<br />

@

Solvent-induced Orientation<br />

SPM phase images<br />

Spin-coated thin film Solvent-annealed thin film<br />

<strong>PS</strong>-PEO with cylindrical microdomain<br />

Russell, T. P. et al. Adv. Mater. 2004, 16, 226.<br />

39

Nanopatterning for Lamellar Nanostructures<br />

Composition profile<br />

Chemical nanopattern<br />

Height profile<br />

Topographic nanopattern

What is Epitaxy-induced Orientation?<br />

Crystallizable solvent<br />

T max =150 o C<br />

80 o C<br />

T m, BA ≒ 123 o C<br />

Cooling<br />

Benzoic acid (BA)<br />

PLM image<br />

b BA

Large-Scale Orientation for <strong>PS</strong>-<strong>PLLA</strong> Lamellae<br />

Spin-coated lamellar thin film<br />

O<br />

C<br />

Induced by<br />

Crystallizable solvent<br />

O [ CH2 C H ] n<br />

O<br />

Oriented lamellar thin film<br />

H C<br />

3<br />

H C<br />

3<br />

CH 3<br />

CH 3<br />

Hydrolysis of <strong>PLLA</strong><br />

O<br />

Trench-like<br />

topographic nanopattern<br />

N [ C C ] m<br />

Semicrystalline copolymer: <strong>PS</strong>-<strong>PLLA</strong><br />

O<br />

H<br />

CH<br />

3<br />

<strong>PS</strong> <strong>PLLA</strong><br />

O H<br />

Amorphous and non-degradable Crystalline and degradable

Strongly Segregated <strong>PS</strong>-<strong>PLLA</strong><br />

Quench from melt<br />

S14-L15<br />

Lamellar morphology<br />

250nm<br />

Strongly Segregated <strong>PS</strong>-<strong>PLLA</strong><br />

RuO 4 staining (dark: <strong>PS</strong> and bright: <strong>PLLA</strong>)

Directional eutectic solidification<br />

Strongly Segregated <strong>PS</strong>-<strong>PLLA</strong><br />

500 nm<br />

Homogeneous mixture of substrate and polymer<br />

Quenching<br />

Directional eutectic solidification<br />

for strongly segregated <strong>PS</strong>-<strong>PLLA</strong><br />

Glass slide<br />

<strong>PS</strong><br />

<strong>PLLA</strong> Eutectic liquid<br />

Crystalline substrate<br />

Glass slide

Crystallization-Induced Orientation<br />

Strongly Segregated <strong>PS</strong>-<strong>PLLA</strong><br />

200 nm<br />

Homogeneous mixture of substrate and polymer<br />

Crystalline <strong>PLLA</strong><br />

Directional eutectic solidification<br />

for strongly segregated <strong>PS</strong>-<strong>PLLA</strong><br />

Non-lattice matching substrate (HMB)<br />

<strong>PS</strong><br />

Glass slide<br />

<strong>PS</strong><br />

<strong>PLLA</strong> Eutectic liquid<br />

Crystalline substrate<br />

Glass slide<br />

Isothermal<br />

crystallization<br />

Crystalline substrate

Lattice Matching Effect<br />

Strongly Segregated <strong>PS</strong>-<strong>PLLA</strong><br />

100 nm<br />

500 m<br />

Homogeneous mixture of substrate and polymer<br />

Crystalline <strong>PLLA</strong><br />

Directional eutectic solidification<br />

for strongly segregated <strong>PS</strong>-<strong>PLLA</strong><br />

<strong>PS</strong><br />

Glass slide<br />

<strong>PS</strong><br />

<strong>PLLA</strong> Eutectic liquid<br />

Crystalline substrate<br />

Glass slide<br />

Isothermal<br />

crystallization<br />

Crystalline substrate<br />

Lattice matching substrate (BA)<br />

Lattice matching improve nanostructure orientation !!

Lattice Matching<br />

<strong>PLLA</strong> -PCL<br />

0.514 nm<br />

1.07 nm<br />

Crystalline <strong>PLLA</strong> lamellae<br />

b<br />

a<br />

<strong>PLLA</strong><br />

a<br />

BA<br />

2b<br />

Amorphous <strong>PLLA</strong> and PCL domain<br />

axis mismatch<br />

b <strong>PLLA</strong> - a BA<br />

a BA<br />

a <strong>PLLA</strong> - 2b BA<br />

2b BA<br />

= 7%<br />

= 4%<br />

Ho, R.M. et al., Macromolecules 2003, 36, 9085.<br />

2D Lattice Matching

<strong>PS</strong>128LLA106 diblock copolymer: Lamellar morphology<br />

Epitaxy-induced Morphology<br />

Phase-separated Morphology<br />

500nm<br />

Area > 150μm 2 !<br />

<strong>PLLA</strong>(200)<br />

<strong>PLLA</strong>(110)<br />

500nm

Mechanisms<br />

1.Homogeneous mixture<br />

of solvent and polymer<br />

<strong>PS</strong> <strong>PLLA</strong><br />

Polymer-crystallizable solvent solution<br />

Crystalline substrate<br />

Glass-slide<br />

2.Directional crystallization<br />

of crystallizable solvent<br />

T m, solvent<br />

1<br />

2<br />

L+<br />

5<br />

6<br />

Liquid<br />

+<br />

L+<br />

0 0.5 1<br />

Weight fraction of block copolymer<br />

3.Directional eutectic solidification<br />

for strongly segregated <strong>PS</strong>-<strong>PLLA</strong><br />

T m, <strong>PLLA</strong> block<br />

T e<br />

T C, <strong>PLLA</strong> block<br />

T ODT<br />

: Crystalline substrate<br />

: <strong>PS</strong>-<strong>PLLA</strong><br />

4.Isothermal crystallization<br />

Ho, R.-M. et al. Macromolecules 2006, 39, 7071.

Nanopatterning<br />

Nanopattern: pattern with nanoscale features (1~100 nm)<br />

Height profile<br />

Topographic nanopattern<br />

Composition profile<br />

Substrate<br />

Chemical nanopattern

Methods for Nanopatterning<br />

Photolithography?<br />

Excimer Laser Micro-processing?<br />

Soft Lithography?<br />

Scanning Probe Lithography<br />

Electronlithography<br />

Self-assembly of Living Cells, Surfactant,<br />

Dendrimer and Polymer<br />

Bottom-up methods<br />

@Top-down methods<br />

External forces!

Electronlithography<br />

Write with electron beam<br />

Martin, J.I.; Velez, M.; Morales, R. J. Magn. Mater. 2002, 249, 156.

Soft Lithography<br />

Whitesides, G. M. et. al.<br />

J. Mater. Chem. 1997, 7, 1069<br />

Stupp, S. I. et. al.<br />

Nano Lett. 2007, 7, 1165

Nanoimprint Lithography<br />

PMMA film<br />

PMMA film<br />

Au dots<br />

Au lines<br />

Chou, S. Y. et. al. Science 1996, 272, 85

Scanning Probe Lithography<br />

Atomic force microscope tip as a “pen”<br />

A solid-state substrate as “paper”<br />

Molecules with a chemical affinity for<br />

the solid-state substrate as “ink”<br />

Transport of the molecules from the<br />

AFM tip to the solid substrate<br />

Mirkin, C. A. et. al. Science, 1999, 283, 661

Why Degradable Block Copolymers ?<br />

Polyesters: degradable<br />

characteristics for<br />

mesoporous materials<br />

Substrate<br />

Bio-degradation<br />

Chemical degradation<br />

Zalusky, A. S.; Olayo-Valles, R.; Taylor, C.; Hillmyer, M. A.<br />

J. Am. Chem. Soc. 2001, 123, 1519.<br />

Degradable blocks<br />

Non-degradable blocks<br />

Height profile<br />

Substrate<br />

Topographic nanopattern<br />

Nanopatterned template

Advantages and Disadvantages<br />

Electronlithography<br />

PMMA<br />

van Blaaderen, A. et al. Nature 1997, 385, 323.<br />

Require precise manufacturing<br />

(expensive!)<br />

Topographic pattern only<br />

Limitation in pattern area<br />

Creative features<br />

Block copolymer<br />

<strong>PS</strong>-<strong>PLLA</strong><br />

Ho, R.-M. et al. US24265548A1<br />

Large-scale orientation<br />

Easy to prepare (cheap!)<br />

Quick!<br />

Available for topographic and<br />

chemical nanopatterns<br />

Flexibility

Degradation of Block Copolymer<br />

Dry Pyrolysis<br />

<strong>PS</strong>-PB <strong>PS</strong>-PMMA <strong>PS</strong>-PDMS<br />

O3 ; RIE<br />

UV O3 ; RIE<br />

Russell T. P. et al. Adv. Mater.<br />

2000, 12, 787.<br />

Park M, Harrison C, Chaikin P. M., Register R. A.,<br />

Adamson D. H. Science 1997, 276, 1401.<br />

Ross, C.A. et al. Nano. Lett.<br />

2007, 7, 2046.

Nanopatterning from Degradable BCPs<br />

(a)<br />

staining with OsO4 (b) (c)<br />

Spin-coated film<br />

<strong>PS</strong>-PB m n<br />

O 3<br />

Spin-coated film<br />

with annealing<br />

unstained<br />

Spin-coated film with<br />

annealing<br />

exposure to ozone<br />

@<br />

Register, R. A. et. al. Science, 1997, 276, 1401<br />

Register, R. A. et. al. Appl. Phys. Lett. 2000, 12, 787

Nanopatterning from Degradable BCPs<br />

<strong>PS</strong>-PMMA<br />

UV<br />

O O<br />

Height image Phase image<br />

m<br />

n<br />

Top-view FESEM<br />

Cross-section-view FESEM<br />

Russell, T. P. et. al. Adv. Mater. 2000, 12, 787<br />

@

Nanopatterning from Degradable BCPs<br />

Methanol 40 V<br />

NaOH+H2O (0.5M) 60 V<br />

<strong>PS</strong>-PLA bulk Nanoporous bulk<br />

Degradation solution<br />

Hillmyer, M. A. et. al. J. Am. Chem. Soc. 2001, 123, 1519<br />

@

<strong>PS</strong>-<strong>PLLA</strong>, Degradable Diblock Copolymers<br />

O<br />

C<br />

<strong>PS</strong><br />

O [ CH2 C H ] n<br />

O<br />

H C<br />

3<br />

H C<br />

3<br />

Non-degradable block<br />

CH 3<br />

CH 3<br />

O<br />

<strong>PLLA</strong><br />

chiral center<br />

N [ C C ] m<br />

O<br />

*<br />

H<br />

CH<br />

3<br />

O H<br />

Degradable block

Synthetic routes of <strong>PS</strong>-<strong>PLLA</strong> block copolymers<br />

O<br />

Ph O<br />

Ph<br />

O N<br />

m<br />

<strong>PS</strong>-TEMPO-OH<br />

Living free radical polymerization<br />

Living ring-opening polymerization<br />

OH<br />

Toluene<br />

O O<br />

Li TEMPO-<strong>PS</strong><br />

O<br />

Li<br />

Li<br />

Li<br />

Li<br />

O<br />

Li TEMPO-<strong>PS</strong><br />

O O<br />

Lithium Alkoxide Macroinitiator<br />

OEt 2<br />

O C<br />

Li<br />

O<br />

Li<br />

Li<br />

Li<br />

Li<br />

C<br />

Li<br />

O O<br />

OO<br />

<strong>PS</strong> H OO<br />

O<br />

3<br />

C<br />

O N O<br />

O<br />

H<br />

O N O<br />

O<br />

H<br />

Ph O<br />

O<br />

P h O<br />

O<br />

C O [ C H C ]<br />

2<br />

H<br />

n<br />

O<br />

Ph<br />

O<br />

P h m<br />

O<br />

*<br />

m n n<br />

Non-biodegradable H Biodegradable<br />

<strong>PS</strong>-<strong>PLLA</strong>3<br />

C CH 3<br />

P S - P L L A<br />

CH 3<br />

O<br />

N O [ C C H O ]<br />

m<br />

H<br />

CH 3<br />

+<br />

Lin, C.-C. et al. J. Am. Chem. Soc. 2001, 123, 7973-7977.<br />

n L-LA/ CH 2Cl 2, 0 o C<br />

<strong>PLLA</strong><br />

Poly(styrene)-block-Poly(L-lactide) (<strong>PS</strong>-<strong>PLLA</strong>)<br />

O -<br />

O -<br />

t-Bu<br />

=<br />

t-Bu<br />

t-Bu<br />

O- O- t-Bu

Log(I)<br />

Various nanostructures of <strong>PS</strong>-<strong>PLLA</strong> block copolymers<br />

<strong>PS</strong>198-<strong>PLLA</strong>28 (f <strong>PLLA</strong> v =0.14)<br />

*<br />

q<br />

*<br />

2q<br />

*<br />

3q<br />

*<br />

4q<br />

*<br />

5q<br />

*<br />

6q<br />

*<br />

7q<br />

BCC<br />

*<br />

9q<br />

0.3 0.4 0.5 0.6 0.7 0.8<br />

q(nm -1 )<br />

Similar to <strong>PS</strong>-PLA!<br />

Log(I)<br />

<strong>PS</strong>280-<strong>PLLA</strong>97 (f <strong>PLLA</strong> v =0.29)<br />

*<br />

q<br />

*<br />

3q<br />

*<br />

4q<br />

*<br />

7q *<br />

9q<br />

HC<br />

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8<br />

q(nm -1 )<br />

Log(I)<br />

<strong>PS</strong>125-<strong>PLLA</strong>167 (f <strong>PLLA</strong> v =0.57)<br />

*<br />

q<br />

*<br />

2q<br />

*<br />

3q<br />

*<br />

4q<br />

Lamellae<br />

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8<br />

q(nm -1 )<br />

Ho, R.-M. et al. J. Am. Chem. Soc. 2004, 126, 2704.<br />

100nm<br />

Hillmyer, M. A. et al. J. Am. Chem. Soc. 2002, 124, 12761.

Nanotemplate (i.e., Nanoreactor)<br />

A convenient way to generate organic or inorganic nanostructure!<br />

Substrate<br />

Substrate<br />

(1) Spin-coating<br />

Substrate<br />

(2) Self-assembly<br />

Self-ordering<br />

Substrate<br />

Substrate<br />

Substrate<br />

(3) Hydrolysis<br />

(4) Sol-gel reaction; Porefilling;<br />

Electroplating;<br />

CVD etc.<br />

(5) Remove template<br />

regularly sized and spaced features

Sol-gel Process for NanoTemplates<br />

One example: Nanoreactor for nanoarrays<br />

High-efficiency photocatalysis!<br />

TiO 2 nanoarrays<br />

FESEM Images<br />

Particle array Diameter:20~30nm(sol particle size

Pore-filling for Nanotemplates<br />

Capillary force driven from the<br />

tunable wetting property of<br />

solution for the templates<br />

H 2S vapor<br />

tubular-like<br />

cylinder-like<br />

Ho, R.-M. et al. Macromolecules, 2007, 40, 2621.

air-block releasing<br />

directed capillary force (method 1)<br />

directed capillary force (method 2)

TEM : Air-block releasing<br />

Nanoporous template<br />

Vacuum<br />

Injection<br />

Cd(Ac) 2/methanol<br />

Pump<br />

Vacuum<br />

R<strong>edu</strong>ction by H 2S (g)<br />

inefficient filling<br />

CdS nanocrystals

TEM : directed capillary force (method 1)<br />

Nanoporous template<br />

from hydrolysis by<br />

<strong>PS</strong>-<strong>PLLA</strong> thin film<br />

(b)<br />

H 2O solution<br />

Water<br />

lack of wetting capability for<br />

driving of capillary force<br />

grid<br />

Small area !!<br />

grid<br />

Cd(Ac) 2/ X solution<br />

Methanol solution<br />

R<strong>edu</strong>ction by H 2S (g)<br />

partial filling of<br />

going-through solution

TEM : directed capillary force (method 2)<br />

Nanoporous template<br />

Large area !!<br />

Cd(Ac) 2/methanol/water<br />

Cd(Ac) 2/methanol/water<br />

R<strong>edu</strong>ction by H 2S (g)

PL and UV spectra<br />

Exciting length is at 450 nm<br />

a greater density of<br />

CdS nanocrystals<br />

residing in the<br />

template!<br />

No QDE: CdS<br />

nanoparticles > 6<br />

nm).

Confocal Microscopy Observation<br />

CdS solid state<br />

exciting at 454nm and detected from 480nm~600nm<br />

200 μm 200 μm 200 μm<br />

air-block releasing<br />

directed capillary force<br />

The emission intensity of the CdS nanoarray can be<br />

modulated by pore-filling process.

Electroplating of Metallic Materials<br />

Nanoarrays of Catalytic Materials<br />

Ni nanoarrays embedded<br />

in the template of <strong>PS</strong><br />

matrix<br />

Eletroplating for the growth of Ni<br />

The exploitation of carbon<br />

nanotubes (CNTs) for display and<br />

lighting purposes require<br />

controlled size, special spacing,<br />

and layout of patterns.<br />

Ni nanoarrays<br />

thermal CVD at<br />

500 o C for CNT<br />

growth<br />

CNT nanoarrarys<br />

Ho, R.-M. et al. Adv. Mater.,<br />

2007, 19, 3584-3588.

Double-length-Scale Patterns<br />

(a)<br />

Conductive Micropatterning<br />

Conductive<br />

Ho, R.-M. et al. Adv. Mater.,<br />

2007, 19, 3584-3588.<br />

P02940028US; P02940028TW<br />

(composite micro- and nano-patterned)<br />

Spin-Coating<br />

<strong>PS</strong>-<strong>PLLA</strong> sol.<br />

Lithography<br />

Growing<br />

CNT<br />

Nanopatterning<br />

(b)<br />

Electroplating Template removal<br />

(c)<br />

Electroplating Ni<br />

Block Copolymer<br />

Templating<br />

Electroplating

Screening Effect<br />

High site density (>109 /cm2 )<br />

leading to small electrical<br />

enhancement at the tips. A site<br />

density of about 107 /cm2 (according to electrostatic<br />

calculation) has been<br />

calculated to be the right<br />

number for optimal electron<br />

emission properties in the<br />

sense of both emission site<br />

and current density.<br />

Appl. Phys. Lett., 76, 2071 (2000); Chem. Mater.,<br />

17, 237 (2005); J. Mater. Res., 16, 3246 (2001);<br />

Thin Solid Film, 405, 243 (2002).<br />

Patterns with both in micro-scale and nano-scale for the CNT<br />

arrays have been expected to reach high-field-emission<br />

capability and uniformity.

FESEM images of CNTs grown from <strong>PS</strong>/Ni composite films<br />

Patterned<br />

cross-section<br />

low magnification high magnification<br />

Non-patterned<br />

FESEM image of CNTs grown from Ni layer

Two-electrode field emission device<br />

Double-length-scale<br />

High current density with<br />

low threshold voltage and<br />

high field emission<br />

efficiency for patterned<br />

CNT arrays!<br />

Single-length-scale<br />

Ho, R.-M. et al. Adv. Mater.,<br />

2007, 19, 3584-3588.

Lighting<br />

DTC<br />

Phosphor (CRT)<br />

Ni on DC-206<br />

Patterning ITO<br />

substrate<br />

<strong>tw</strong>o-electrode field emission device<br />

Spacer 150μm<br />

Spacer<br />

FP-R-054-taping<br />

1000v<br />

二極結構

Drug-Eluting Stent for Atherosclerosis<br />

■ Sirolimus: immunosupressive agent with anti-<br />

inflammation and antiproliferation characteristics<br />

■ Metallic stent: prevent vascular recoil<br />

■ Local delivery for the sustained release of drug<br />

Stent implantation during percutaneous<br />

transluminal coronary angioplasty (PTCA)<br />

Mixture of drug and<br />

polymer coated<br />

on the stent for<br />

drug-eluting control<br />

SIBS

Pore-filling for Sirolimus<br />

Capillary force driven from the<br />

tunable wetting property of<br />

aqueous solution for the templates<br />

Ho, R.-M. et al. Macromolecules<br />

2007, 40, 2621.<br />

nanoscale releasing<br />

Ho, R.-M. et al. ACS Nano, 2009, 3, 2260.<br />

Water → enhance the surface<br />

tension for the deposition of<br />

the <strong>PS</strong> template<br />

Ethanol → wet the <strong>PS</strong> template<br />

for the driven capillary force

Pore-filling of Sirolimus<br />

Before pore filling After pore filling<br />

TEM images of templated sirolimus nanoarrays

Accumulative Accumulative release release (%) (%)<br />

100<br />

80<br />

60<br />

40<br />

20<br />

Drug-releasing profile <strong>PS</strong> AAO Sirolimus<br />

24 hr<br />

42 hr<br />

0<br />

0 50 100 150 200 250<br />

Macrostructure<br />

with burst relesae!!<br />

85 hr<br />

extended drugeluting<br />

duration<br />

Time (hr)<br />

Ho, R.-M. et al. ACS Nano, 2009, 3, 2260.

Pore-filling of hydrophilic Conjugated Polymers<br />

Conjugated Polymer<br />

PEO-PPV<br />

Hydrolysis<br />

Solvent<br />

Annealing<br />

14<br />

O<br />

n<br />

HF<br />

code<br />

Mn<br />

(g/mol)<br />

PVE3 10309 1.12<br />

PVE7 14866 1.10<br />

PEO-PPV<br />

Ho, R.-M. et al. Adv. Funct. Mater. 2011, 21, 2729.<br />

PDI Solvent<br />

Acetic<br />

acid<br />

Acetic<br />

acid

Nanoscale Spatial Effect<br />

PY/CM thin film<br />

templated PY/CM<br />

nanoarrays<br />

PVE3<br />

PVE7<br />

with nanoporous template without nanoporous template

PL result : in-situ solvent annealing<br />

PVE3<br />

solvent annealing<br />

PVE7

Chain Alignment Mechanism<br />

Solventannealing<br />

process<br />

Ho, R.-M. et al. Adv. Funct. Mater. 2011, 21, 2729.