Download - Royal BAM Group

Download - Royal BAM Group

Download - Royal BAM Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

In the presence of<br />

Princess Máxima and<br />

leading employers,<br />

Joop van Oosten<br />

signed ‘Talent to the<br />

Top’, a document<br />

designed to help<br />

further the promotion<br />

of women to higher<br />

and senior positions.<br />

Successful test rides<br />

Although Nuttall is still busy building a special bus<br />

lane near Cambridge, the initial test rides have<br />

already been successfully completed. Secretary<br />

of State for Transport, Ruth Kelly, visited the site<br />

this summer and had a ride in the bus and said<br />

what a wonderful project it is!<br />

I<br />

n a joint venture with<br />

client Cambridgeshire<br />

County Council, the<br />

bus companies that will run the<br />

services on the 26-kilometre<br />

lane trialled various types of<br />

bus, including a double-decker.<br />

The buses were driven along the<br />

four-kilometre section between<br />

Longstanton and Oakington at<br />

speeds of up to a hundred<br />

kilometres an hour. A guide<br />

wheel keeps the buses ‘on<br />

track’. ‘The trials have exceeded<br />

our expectations’, says<br />

Cambridgeshire County Council’s<br />

project manager Bob Menzies.<br />

‘Even at such high<br />

speeds it’s a<br />

comfortable ride.<br />

It shows that we’ve<br />

opted for the right<br />

building method.’<br />

Cambridge<br />

commuters are due<br />

to step aboard for<br />

the first time in the<br />

spring of 2009.<br />

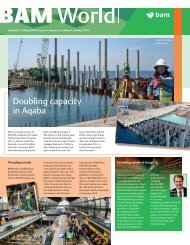

<strong>BAM</strong>World<br />

Internal publication for the employees of <strong>Royal</strong> <strong>BAM</strong> <strong>Group</strong> nv Volume 5, number 3, Autumn 2008<br />

Another stretch of Irish M6 completed<br />

Minister for Transport Noel Dempsey,<br />

T.D. (left) and Councillor Barry Cowen<br />

Chairman of Offaly County Council at<br />

the official opening ceremony.<br />

Another stretch of the M6<br />

Dublin to Galway interurban<br />

National Primary Route, the<br />

Kilbeggan to Athlone dual<br />

carriageway project, has<br />

recently been completed by<br />

Ascon and was officially opened<br />

by Minister for Transport<br />

Noel Dempsey, T.D.<br />

Ascon completed the<br />

29 kilometres of new dual<br />

carriageway on time and within<br />

budget. In addition, the project<br />

comprised eighteen principal<br />

structures, seven kilometres<br />

of national, secondary and<br />

regional roadway and three<br />

grade separated junctions.<br />

Noel Dempsey, T.D. said<br />

at the opening ceremony:<br />

‘The new road will improve the<br />

quality of life for those living<br />

in the local areas while cutting<br />

driving times on the Dublin<br />

to Galway route.’<br />

Tunnel contract<br />

in Luxembourg<br />

Wayss & Freytag Ingenieurbau and<br />

Galère have been awarded a jointventure<br />

contract for the construction<br />

of the Stafelter road tunnel in<br />

Luxembourg. The project value<br />

amounts to 88 million euros, of which<br />

75 percent will be earned by <strong>BAM</strong>. The<br />

client is the ministry of Public Works. The<br />

construction period will be 48 months.<br />

The Stafelter Tunnel has two tubes of<br />

nearly two kilometres length. The<br />

project is part of the Route du Nord<br />

(A7) between Luxembourg City and<br />

Mersch. Both operating companies<br />

have been also involved since 2004 in<br />

the construction of the Grouft Tunnel<br />

for the A7. The Grouft Tunnel will be<br />

completed in 2009.<br />

End in sight<br />

In western Ghana, the end of<br />

Interbeton’s major road<br />

improvement project is in sight.<br />

The company has re-laid and<br />

widened over 44 kilometres of<br />

two-lane road near Sefwi Wiawso.<br />

‘This summer we laid new<br />

pavement on the final sections.<br />

All that remains is to lay a wearing<br />

course, followed by road marking<br />

and the installation of traffic signs.<br />

We’re due to finish any time now’,<br />

says Joost Keessen. Interbeton’s<br />

project manager and his team<br />

landed in the Ghanaian bush in the<br />

autumn of 2005. Their first task<br />

was to build an entire base camp.<br />

The actual road works started in<br />

February 2006. Keessen: ‘What<br />

they had was an unsealed clay<br />

road, which was almost<br />

impassable in the rainy season.<br />

The new road will significantly<br />

improve living standards in the<br />

region.’

Lights on in the Hubertus Tunnel<br />

In the Hubertus Tunnel in The Hague, some of the tunnel<br />

lighting is now on, the ventilation fans have been installed,<br />

and the aid station cabinets are already in place. VTN Verkeers-<br />

& Besturingstechniek, part of <strong>BAM</strong> Infratechniek, is currently<br />

installing all the tunnel’s M&E works.<br />

Marco Beeloo.<br />

The tunnel was built by <strong>BAM</strong><br />

Civiel in a joint venture with<br />

Wayss & Freytag Ingenieurbau.<br />

‘We follow hot on the heels<br />

of the construction team and<br />

consult closely with them about<br />

the work we’re doing’, says<br />

VTN’s site agent Marco Beeloo.<br />

All the electrical installations in<br />

the southern tube, which was<br />

bored first, are in position.<br />

‘We’re now connecting them up.<br />

We won’t have so many teething<br />

troubles to contend with in the<br />

northern tube, so we’ll be able to<br />

make up time there on our M&E<br />

works’, says Beeloo.<br />

Installation involves attaching<br />

thousands of anchors to the<br />

tunnel walls. ‘Here we’re<br />

dealing with wall elements<br />

made of B70 concrete, which is<br />

much harder than the kind used<br />

in normal tunnels. The anchors<br />

Eco version of successful Xbloc<br />

<strong>BAM</strong> Infraconsult is enjoying worldwide success with its Xbloc. At the same time in<br />

IJmuiden (near Amsterdam) researchers are testing an eco version of the breakwater<br />

unit they have developed in-house. ‘2008 is the year of the big breakthrough’, says<br />

Bas Reedijk, coastal engineering team manager and spiritual father of the Xbloc.<br />

C<br />

ompared to the<br />

concrete cubes that<br />

cover many seaport<br />

jetties, the Xbloc is not only<br />

cheaper, but provides better<br />

protection. The Xbloc also scores<br />

very favourably in comparative<br />

tests with other types of<br />

breakwater unit. The ‘secret’ lies<br />

in its smart design, which not<br />

only saves on concrete, but<br />

allows the units to interlock<br />

much more effectively. Reedijk:<br />

‘Even though the concrete<br />

cubes currently used on the<br />

embankments in IJmuiden weigh<br />

forty tonnes, they’re easily<br />

<strong>BAM</strong> Civiel technicians get the<br />

formwork ready for the pour.<br />

Bas Reedijk (left) with <strong>BAM</strong> Civiel<br />

site agent Arie Bootsma.<br />

shifted around by the waves.<br />

The more complex shape of<br />

the Xblocs makes them much<br />

less susceptible to wave action.<br />

They’re also quick and easy to<br />

put into position. What all this<br />

amounts to is a<br />

considerable saving on<br />

building costs and more<br />

economical use of raw<br />

materials, which in turn<br />

reduces CO2 emissions.’<br />

The unit was first used<br />

three years ago in a<br />

harbour on the east coast of<br />

Ireland. ‘Two winters on and the<br />

blocks have withstood everything<br />

the Irish Sea has been able to<br />

throw at them. The blocks have<br />

since been used in Indonesia and<br />

Nigeria. We currently have<br />

projects on the go in Georgia,<br />

Guatemala and again in Ireland.<br />

The largest project to date is<br />

being carried out in Panama, with<br />

30,000 Xblocs being placed over<br />

a three kilometre stretch for bank<br />

protection.’<br />

are usually put into pre-drilled<br />

holes rather than shot in, but,<br />

after carrying out various tests,<br />

we decided for the sake of speed<br />

to shoot them in.’<br />

www.hubertustunnel.nl<br />

Eco version<br />

The new development is the eco<br />

version of the Xbloc, designed<br />

to enhance the ecological value<br />

of hard protective structures.<br />

The inner side walls of the steel<br />

formwork manufactured by<br />

<strong>BAM</strong> Materieel are lined with<br />

rubber mats featuring various<br />

profiles. This produces rough<br />

surfaces that make it easier for<br />

shellfish and seaweed to attach<br />

to the concrete. In early June,<br />

<strong>BAM</strong> Civiel placed ten of these<br />

blocks on IJmuiden’s southern<br />

jetty breakwater.<br />

www.xbloc.com<br />

IJmuiden<br />

Amsterdam<br />

U<br />

The Hague<br />

Rotterdam<br />

Brussels<br />

Xbloc placement in IJmuiden.

Groningen<br />

Lelystad<br />

trecht<br />

Maastricht<br />

‘Giving direction to sustainability policy’<br />

‘The formulation of the <strong>BAM</strong> Business Principles has given<br />

direction to the further development of the <strong>Group</strong>’s policy<br />

on sustainability’, says Tom van Beek.<br />

T<br />

he corporate staff<br />

department’s director<br />

of Human Resources<br />

was also appointed director of<br />

Corporate Social Responsibility<br />

(CSR) by the Executive Board<br />

from the beginning of this year.<br />

In his new position, Van Beek was<br />

closely involved in the development<br />

of the <strong>BAM</strong> Business Principles,<br />

as published in <strong>BAM</strong>’s first<br />

sustainability report.<br />

‘Sustainability has been very<br />

much in the spotlight for some<br />

years now and <strong>BAM</strong> hasn’t been<br />

sitting on its hands in this area<br />

either. Our operations occupy a<br />

central position in the community<br />

and we need to be open to all the<br />

signals the community sends us.<br />

A wide range of initiatives have<br />

already been put in place. The<br />

<strong>BAM</strong> Business Principles provide<br />

a cohesive framework for all<br />

these initiatives.’<br />

‘We decided on a realistic,<br />

pragmatic approach. We don’t<br />

commit ourselves to things we<br />

can’t deliver. There are the<br />

familiar themes of People, Planet<br />

and Profit, but with a certain<br />

degree of ambition too. We want<br />

to show our shareholders, our<br />

clients and our building partners<br />

as well as our current and future<br />

employees that we are serious<br />

about making significant inroads<br />

in sustainable development and<br />

sustainable construction.’<br />

Emphasis<br />

Now that the Business Principles<br />

are there in black and white, it is<br />

essential to take the next steps.<br />

The director of CSR: ‘Firstly, we<br />

aim to document the initiatives<br />

we’ve been developing within<br />

the <strong>Group</strong>. A good deal of<br />

In Brussels’ European district<br />

Building around an inner court<br />

Interbuild is part of a consortium building a 75,000 m2 office complex in the<br />

heart of the European district in Brussels. But this strategic location has its<br />

drawbacks. During EU summits, which are held four times a year, the district<br />

is closed off. Interbuild can continue with construction, but the movement of<br />

materials in and out is prohibited. Work is due to be completed in June 2009.<br />

From left: Martijn Berckmans, site<br />

agent, Jos Jonkers and Manu Leysen,<br />

project manager.<br />

The project, with a<br />

contract value of<br />

81 million euros, is being<br />

built for Axa Real Estate<br />

Belgium. The building<br />

has two underground<br />

floors, and at some<br />

Tom van Beek will explain the<br />

<strong>BAM</strong> Business Principles at<br />

Young <strong>BAM</strong>’s Ultrasustainability<br />

workshop.<br />

information about them is<br />

already to be found in our<br />

recently published Sustainability<br />

Report for 2007. We will also be<br />

putting an emphasis on certain<br />

areas.<br />

A start was<br />

made with<br />

the June<br />

symposium on reducing CO2 emissions. Furthermore, we<br />

want to report on various<br />

subjects in more detail. There<br />

is also a concern that we should<br />

focus on the management of<br />

locations even three. It has<br />

seven above-ground floors of<br />

offices and one level devoted to<br />

technical installations. ‘All the<br />

parties involved, including the<br />

client and architect – Atelier de<br />

Genval/ELD Partnership – use<br />

Procos, an internet platform for<br />

data exchange and approving<br />

drawings. As a tool, it’s virtually<br />

indispensable to controlling the<br />

construction process. It would<br />

be nigh on impossible to see a<br />

large project like this through<br />

without this kind of internet<br />

platform’, says senior site agent<br />

Jos Jonkers.<br />

‘<strong>BAM</strong> employees are very<br />

involved in sustainability’<br />

waste flows. Thirteen per cent<br />

of all the materials we take<br />

onto building sites is returned<br />

unused. So thirteen out of every<br />

one hundred roof tiles go back<br />

into storage.<br />

We should be<br />

able to make<br />

this issue the<br />

subject of a sustainability drive<br />

in collaboration with our<br />

building partners.’<br />

Batavia Stad<br />

extension<br />

<strong>BAM</strong> subsidiary Heilijgers is to<br />

work on Batavia Stad again.<br />

The company that helped to<br />

complete the first phase of<br />

this factory outlet centre near<br />

Lelystad (central Netherlands)<br />

in 2001 is now part of a<br />

construction team building<br />

a new 25-shop extension. The<br />

shops will be ready to shell<br />

stage by the end of this year.<br />

www.bataviastad.nl

Ashmolean in Oxford<br />

Latest techniques for oldest museum<br />

Opened in 1683, the Ashmolean Museum of Art & Archaeology<br />

at Oxford is on record as the oldest museum in the world. As<br />

part of the renowned Oxford University, it has always played an<br />

important role in education. The museum’s new home will enable<br />

it to continue to perform the full extent of this role in the future.<br />

H<br />

BG Construction<br />

is building a new<br />

exposition centre<br />

directly behind the six-metre<br />

deep main Ashmolean building<br />

with its monumental facade<br />

dating from 1875. The contract<br />

value totals 42 million euros,<br />

including the amount required<br />

to finish room interiors. The<br />

project will be completed in<br />

August 2009.<br />

Logistic puzzle<br />

Construction manager Anthony<br />

Nagle: ‘The existing structure<br />

on the site was built in the fifties<br />

and had a very inefficient floor<br />

plan. The new building will double<br />

the floor space and enable<br />

visitors to circulate more easily.’<br />

The construction site is fully<br />

enclosed by other buildings.<br />

Both sides border on university<br />

buildings, to which the new<br />

structure will be as close as<br />

25 millimetres. Only at the back<br />

is there a little more room, and<br />

that is where the only possible<br />

access to the site will run,<br />

making use of a nearly fourmetre-wide<br />

lane to the public<br />

street. ‘The problem is that we<br />

will have to cross a busy<br />

walkway along which many<br />

hundreds of pedestrians pass<br />

every day. Material deliveries<br />

will be completely impossible<br />

when the annual St. Giles fair is<br />

being held. During these four<br />

Anthony Nagle.<br />

days, we will only be able to<br />

access the construction site on<br />

foot. All in all, it is a big logistic<br />

puzzle.’<br />

Eye-catcher<br />

Because the building is fully<br />

enclosed, only the back wall<br />

has received any attention from<br />

architect Rick Mather, insofar<br />

as it is visible with a little effort<br />

from the public street. He put<br />

most of his energy into the<br />

building. Nagle: ‘The six-storey<br />

high atrium will be an eyecatcher.<br />

Since the floors on the<br />

upper storeys are spread further<br />

apart, the atrium widens out at<br />

the top. The various spaces<br />

around this atrium are accessed<br />

by means of narrow bridges<br />

supported on glass beams. A<br />

glass skylight in the roof allows<br />

daylight into the building.’<br />

The building will accommodate<br />

39 exhibition rooms, each<br />

equipped with so-called ‘fat<br />

walls’. ‘These consist of concrete<br />

structural walls with a facing<br />

wall built<br />

from<br />

steelwork<br />

covered with<br />

two layers of<br />

plywood and<br />

two layers of<br />

drywall. This<br />

creates a<br />

strong wall<br />

for attaching<br />

display cases. All the building<br />

services, including air<br />

conditioning, can be hidden<br />

in these walls.’<br />

Drawing contest<br />

The museum welcomes<br />

schoolchildren and students<br />

almost every day. To better<br />

facilitate their visits, there will<br />

be a separate entrance at the<br />

back with a reception area<br />

and a classroom. The strong<br />

association with schoolchildren<br />

was also expressed in a drawing<br />

contest. Many children were<br />

inspired during the construction<br />

activities, and HBG Construction<br />

awarded a laptop computer to<br />

each of the three prize winners.<br />

www.ashmolean.org<br />

Boring simultaneously<br />

German transport minister Wolfgang Tiefensee recently set two<br />

tunnel boring machines in motion at the same time to start work on<br />

building the Finne Tunnel. Wayss & Freytag Ingenieurbau is a joint<br />

venture partner in the construction of the seven-kilometre rail<br />

tunnel, which will form part of a new rail link between Erfurt and<br />

Leipzig in eastern Germany. The two single-track tunnels, each<br />

eleven metres in diameter, are being bored simultaneously.<br />

Meanwhile, the tunnel tubes are being excavated from the other end<br />

using traditional methods. The project will be completed in 2011.

Best score for<br />

considerate construction<br />

Independent CCS inspectors visited over seven hundred construction<br />

sites in the United Kingdom during July. HBG’s site for the new<br />

facilities at Newcastle-under-Lyme College scored a massive 39<br />

out of 40 points including six maximum scores of five out of five.<br />

The average score for all sites by all contractors was under 32;<br />

fewer than one in two hundred sites achieve a score of 39.<br />

T<br />

he measures taken<br />

at the new College<br />

include industryleading<br />

occupational health<br />

arrangements available to<br />

staff and visitors, including a<br />

fortnightly visit by a registered<br />

nurse to give toolbox talks on<br />

healthy eating and BMI, skin<br />

cancer, prostate cancer and<br />

other topics about men’s health.<br />

Appointments and drop-in<br />

sessions provide one to one<br />

confidential consultations and<br />

testing of blood pressure and<br />

blood sugar monitoring for<br />

diabetes.<br />

Further initiatives have included<br />

raising awareness of giving<br />

John Van Vooren (middle),<br />

project manager, together<br />

with Jean-Pierre Vansweevelt<br />

(right), site agent and Koen<br />

Nollet, project engineer.<br />

blood; the local NHS Stop<br />

Smoking Service will run a sevenweek<br />

support programme for<br />

operatives, staff and visitors,<br />

and the site has purchased a<br />

defibrillator and trained several<br />

staff to provide immediate<br />

emergency first aid on and<br />

off site.<br />

Community involvement and<br />

environmental initiatives include<br />

inviting local businesses to<br />

advertise on site free of charge<br />

and proving a monthly window<br />

cleaning service for neighbours.<br />

Environmental initiatives are<br />

reviewed through an Eco-<br />

Committee which has<br />

introduced carbon footprint<br />

Sliding bridge over the Albert Canal<br />

To make the Albert Canal suitable for four-barge push-tow units, the<br />

Belgian <strong>BAM</strong> subsidiary CEI-De Meyer is building a new bridge near<br />

Maastricht. The two hundred metre bridge is being fabricated in<br />

sections on the eastern bank, and the sections are slid into place across<br />

temporary piers using jacks. The interim bridge will be open to traffic<br />

at the end of this year. CEI-De Meyer will then demolish the old bridge<br />

and build new abutments and piers in its place. At the end of 2009<br />

the whole bridge will be moved sideways into its final position.<br />

A range of facilities will be integrated into the western abutment,<br />

including a bunker, a war museum with a cafeteria and an open air<br />

theatre.<br />

monitoring, promoting car<br />

sharing, and a range of recycling<br />

measures for glass, stone,<br />

aluminium and tyres. The College<br />

joins the Eco-Committee on a<br />

monthly basis.<br />

Following a visit from the<br />

Environment<br />

Agency, the site<br />

has been recommended for the<br />

Queen’s Award for Excellence.<br />

HBG’s project manager Ivan<br />

Gethin said: ‘I’m delighted we<br />

achieved maximum score for six<br />

of the eight categories assessed<br />

for the new College. It is<br />

‘39 out of 40 points’<br />

Ivan Gethin with two schoolchildren<br />

at HBG’s Newcastle-under-Lyme<br />

College site.<br />

important to us that the College’s<br />

neighbours can see we are doing<br />

our best to minimise the impact<br />

of construction and that we reach<br />

out to the community we work<br />

in to be good neighbours. I’m<br />

particularly looking forward to<br />

showing children<br />

from local schools<br />

what we do on and around<br />

the site.’<br />

Gethin is overseeing the sixtymillion-euro<br />

project, which<br />

started on site in June, and<br />

is expected to complete in<br />

September 2009.<br />

New office in Poland<br />

Tebodin SAP-Projekt, the Polish<br />

branch of the Tebodin family,<br />

has moved into a new office in<br />

Warsaw. The growth of the<br />

branch made it necessary to look<br />

for a more modern and efficient<br />

accommodation. This has been<br />

found in the Marynarska Business<br />

Park, close to the centre of the<br />

capital city. About 250 employees<br />

are working on various projects at<br />

the new location.<br />

In the photo, the Lafarge project<br />

team is meeting to discuss the<br />

recently awarded contract for<br />

the design, procurement, safety<br />

control, construction<br />

management and supervision<br />

of the extension of two cement<br />

plants for Lafarge. Both the<br />

projects in Malogoszcz and<br />

Piechcin includes the<br />

construction of storage facilities,<br />

cement mills, truck offloading<br />

installations, internal transport<br />

equipment, etcetera. The project<br />

in Malogoszcz, some two<br />

hundred kilometres south of<br />

Warsaw, will be finished in<br />

April 2009. The completion of<br />

the new facilities in Piechcin,<br />

250 kilometres northwest<br />

of the capital, is scheduled<br />

for November 2010.<br />

~<br />

~

<strong>BAM</strong> Rail shares in<br />

‘tartan’ tram deal<br />

<strong>BAM</strong> Rail has been granted a<br />

contract from Siemens as a<br />

subcontractor for the<br />

construction of a tram line in<br />

Edinburgh. The contract includes<br />

the construction of nine<br />

kilometres of double-track tram<br />

line in the centre of Edinburgh<br />

as well as ten kilometres in the<br />

direction of the suburbs and the<br />

airport to the west of the Scottish<br />

capital. The total building costs<br />

amount to approximately forty<br />

million euros. <strong>BAM</strong> Rail is<br />

responsible for the construction<br />

of nineteen kilometres of<br />

embedded rail in the centre of<br />

Edinburgh, twelve kilometres of<br />

Building restoration in<br />

Brussels’ Grote Markt<br />

The Grote Markt in Brussels has a series of magnificent historic<br />

facades that are on UNESCO’s World Heritage List. The Belgian<br />

operating company Galère is tackling five of these monumental<br />

buildings with kid gloves.<br />

Robert Giunta, Galère’s site<br />

agent: ‘We’re cleaning the<br />

facades, restoring the stone<br />

and ornaments, and are<br />

working on the windows too.<br />

A lot of the decorative elements<br />

ballasted sections and seven<br />

kilometres of tracks on a<br />

concrete surface, as well as sixty<br />

switches within the turnkey<br />

project. The embedded Rheda<br />

rail system was used for the<br />

first time by <strong>BAM</strong> Rail when<br />

constructing high-speed line<br />

‘HSL-Zuid’ in the Netherlands.<br />

<strong>BAM</strong> Rail will be using the<br />

Rheda City system, a simplified<br />

version of the ballastless track<br />

system, in Edinburgh where the<br />

rails and sleepers are concreted<br />

into place using concrete slabs.<br />

It is expected that the tram line<br />

will be delivered at the end of<br />

2010.<br />

are being given a new layer of<br />

gold leaf.’<br />

The facades are sandblasted at<br />

low pressure. Giunta: ‘The<br />

pressure is so low that only the<br />

dirt and grime are removed.<br />

Foam concrete:<br />

light and airy<br />

A work floor here, a filler layer there, and now and then even a load<br />

pumped in to fill an old sewer ... <strong>BAM</strong> Betontechnieken somehow<br />

always knows how to successfully bring the advantages of foam<br />

concrete into the limelight.<br />

‘It’s a versatile product that is<br />

quick and easy to use’, says Jan<br />

Bergsma, project manager at<br />

<strong>BAM</strong> Betontechnieken, while<br />

behind him foam concrete flows<br />

like thin yoghurt from a hose.<br />

A thirty centimetre filler layer is<br />

being poured on the top floor of an<br />

office building under construction<br />

on the flower auction site. ‘We mix<br />

the materials in situ, which avoids<br />

the inconvenience of concrete<br />

mixers coming and going’, says<br />

site agent Co van Moorselaar.<br />

Bergsma: ‘We can pour around<br />

four hundred cubic<br />

metres a day. Once it’s<br />

cured, you have a strong<br />

filler layer that can take<br />

loads of up to seventy<br />

tonnes a square metre<br />

depending on the type<br />

of foam concrete used.<br />

It’s easy to process and<br />

lightens the workload<br />

considerably.’<br />

The stone is unaffected. The<br />

machine is turned on at five<br />

o’clock in the morning. At ten<br />

we have to stop and remove all<br />

the sealing materials we’ve put<br />

around windows and doors. The<br />

protective tarpaulin around the<br />

scaffolding is rolled up so that<br />

Like thin yoghurt ...<br />

Weak peat soil<br />

Foam concrete also seems to be<br />

a hot item in the civil engineering<br />

sector as well as in residential and<br />

non-residential construction.<br />

<strong>BAM</strong> Betontechnieken recently<br />

used it for the foundations of<br />

a road built over weak peat soil.<br />

Bergsma: ‘To prevent subsidence<br />

and to avoid giving vermin a place<br />

to nest, we also fill in old sewers.<br />

In Amsterdam this year, we’ll be<br />

using close to a thousand cubic<br />

metres of foam concrete to do<br />

just that.’<br />

Jan Bergsma (left)<br />

and Co van Moorselaar.<br />

visitors can see the shop<br />

windows and the entrances<br />

to the brewery museum and<br />

the restaurant. We are allowed<br />

to work above them on the<br />

scaffolding as long as we<br />

keep the noise down.’<br />

Design Boulogne Jonkers, Zoetermeer<br />

Photography De Beeldredaktie, René van den Burg, Dries Vandenbrande<br />

Printing Thieme Media Services, Delft<br />

<strong>BAM</strong> World is compiled by Monica van Soldt, <strong>Royal</strong> <strong>BAM</strong> <strong>Group</strong> nv,<br />

Public Relations Department: +31 (0)30 659 86 22, m.van.soldt@bamgroep.nl