Machinery Lubrication May June 2011 - Welcome to ECN Digital ...

Machinery Lubrication May June 2011 - Welcome to ECN Digital ...

Machinery Lubrication May June 2011 - Welcome to ECN Digital ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

HYDRAULICS AT WORK<br />

passing, then by process of elimination, the fan mo<strong>to</strong>r must be<br />

leaking excessively.<br />

Note that the combination of the pressure gauge, needle valve<br />

and pho<strong>to</strong>cell tachometer counting mo<strong>to</strong>r RPM is a crude but<br />

effective flow-meter. And a flow-meter is the ultimate flowchaser’s<br />

<strong>to</strong>ol…<br />

Flow-meter/tester<br />

The reason it’s last on this list is because it’s the most expensive.<br />

And because they’re expensive (a good hydraulic flow-tester<br />

can run <strong>to</strong> several thousand dollars or more) it means, even<br />

though it’s usually the best <strong>to</strong>ol for the job, it’s also the one least<br />

likely <strong>to</strong> be available <strong>to</strong> you.<br />

But if a flow-tester is available it increases the flow-chaser’s<br />

options considerably. The downside is a flow-tester must be<br />

installed in the circuit being tested. This takes time, requires suitable<br />

adap<strong>to</strong>rs, and carries the risks inherent in opening the<br />

system – such as oil spill and the ingression of air and other<br />

contaminants.<br />

For these reasons, a flow-tester is not always the first <strong>to</strong>ol a<br />

savvy flow-chaser will reach for. A good example of this is the<br />

multiple-pump excava<strong>to</strong>r discussed above; individual pump cycle<br />

Contamination Control<br />

Implemented at Holcim<br />

The Midlothian, Texas, Holcim facility recently overhauled a lube system for a critical<br />

piece of equipment, a separa<strong>to</strong>r on a finish mill unit that holds 10 gallons of 220 EP oil.<br />

Often, the lid or fill cap would be taken off for inspections or other checks. The area became<br />

dusty and dirty and at times, allowing mass amounts of contamination.<br />

Jason Frankiewicz, a lubrication technician for Holcim, said the problem was resolved<br />

by encasing the equipment in a steel box which was almost air-tight, except for the doors.<br />

According <strong>to</strong> Frankiewicz, the infamous lid which was known for being left off was<br />

removed, a new one bolted-on and a gasket seal <strong>to</strong>p was installed. A minimess sampling<br />

valve was installed and directional arrows were added.<br />

It not only is visually appealing, but the filtration system can now keep up with the<br />

manufacturing facility, increasing the life of the bearings, oil and availability of the equipment.<br />

Frankiewicz said this type of contamination control is being implemented in other<br />

areas of the plant <strong>to</strong> help maintain best practices.<br />

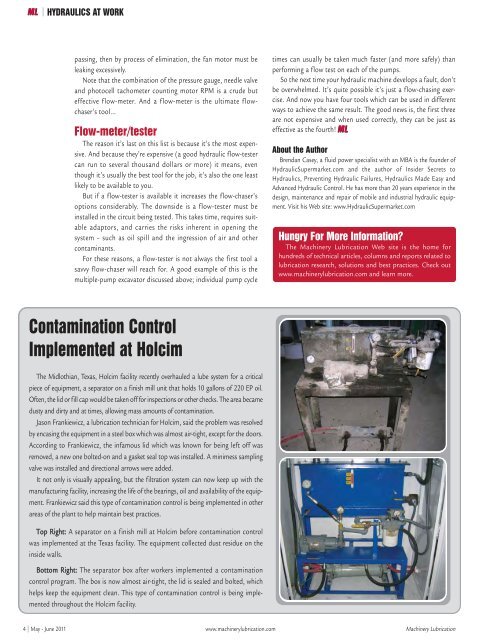

Top Right: A separa<strong>to</strong>r on a finish mill at Holcim before contamination control<br />

was implemented at the Texas facility. The equipment collected dust residue on the<br />

inside walls.<br />

Bot<strong>to</strong>m Right: The separa<strong>to</strong>r box after workers implemented a contamination<br />

control program. The box is now almost air-tight, the lid is sealed and bolted, which<br />

helps keep the equipment clean. This type of contamination control is being implemented<br />

throughout the Holcim facility.<br />

times can usually be taken much faster (and more safely) than<br />

performing a flow test on each of the pumps.<br />

So the next time your hydraulic machine develops a fault, don’t<br />

be overwhelmed. It’s quite possible it’s just a flow-chasing exercise.<br />

And now you have four <strong>to</strong>ols which can be used in different<br />

ways <strong>to</strong> achieve the same result. The good news is, the first three<br />

are not expensive and when used correctly, they can be just as<br />

effective as the fourth!<br />

About the Author<br />

Brendan Casey, a fluid power specialist with an MBA is the founder of<br />

HydraulicSupermarket.com and the author of Insider Secrets <strong>to</strong><br />

Hydraulics, Preventing Hydraulic Failures, Hydraulics Made Easy and<br />

Advanced Hydraulic Control. He has more than 20 years experience in the<br />

design, maintenance and repair of mobile and industrial hydraulic equipment.<br />

Visit his Web site: www.HydraulicSupermarket.com<br />

Hungry For More Information?<br />

The <strong>Machinery</strong> <strong>Lubrication</strong> Web site is the home for<br />

hundreds of technical articles, columns and reports related <strong>to</strong><br />

lubrication research, solutions and best practices. Check out<br />

www.machinerylubrication.com and learn more.<br />

4 <strong>May</strong> - <strong>June</strong> <strong>2011</strong> www.machinerylubrication.com <strong>Machinery</strong> <strong>Lubrication</strong>