You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

VINAVIL ®<br />

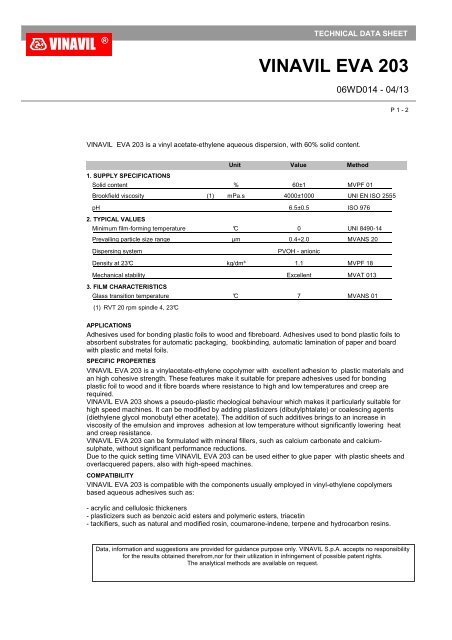

TECHNICAL DATA SHEET<br />

VINAVIL EVA <strong>203</strong><br />

VINAVIL EVA <strong>203</strong> is a vinyl acetate-ethylene aqueous dispersion, with 60% solid content.<br />

1. SUPPLY SPECIFICATIONS<br />

06WD014 - 04/13<br />

APPLICATIONS<br />

Adhesives used for bonding plastic foils to wood and fibreboard. Adhesives used to bond plastic foils to<br />

absorbent substrates for automatic packaging, bookbinding, automatic lamination of paper and board<br />

with plastic and metal foils.<br />

SPECIFIC PROPERTIES<br />

Unit Value<br />

Method<br />

Solid content % 60±1<br />

MVPF 01<br />

Brookfield viscosity (1) mPa.s 4000±1000<br />

UNI EN ISO 2555<br />

pH 6.5±0.5 ISO 976<br />

2. TYPICAL VALUES<br />

Minimum film-forming temperature °C 0<br />

UNI 8490-14<br />

Pr<strong>eva</strong>iling particle size range µm 0.4÷2.0<br />

MVANS 20<br />

Dispersing system PVOH - anionic<br />

Density at 23°C kg/dm³ 1.1<br />

MVPF 18<br />

Mechanical stability Excellent MVAT 013<br />

3. FILM CHARACTERISTICS<br />

Glass transition temperature °C 7<br />

MVANS 01<br />

(1) RVT 20 rpm spindle 4, 23°C<br />

VINAVIL EVA <strong>203</strong> is a vinylacetate-ethylene copolymer with excellent adhesion to plastic materials and<br />

an high cohesive strength. These features make it suitable for prepare adhesives used for bonding<br />

plastic foil to wood and it fibre boards where resistance to high and low temperatures and creep are<br />

required.<br />

VINAVIL EVA <strong>203</strong> shows a pseudo-plastic rheological behaviour which makes it particularly suitable for<br />

high speed machines. It can be modified by adding plasticizers (dibutylphtalate) or coalescing agents<br />

(diethylene glycol monobutyl ether acetate). The addition of such additives brings to an increase in<br />

viscosity of the emulsion and improves adhesion at low temperature without significantly lowering heat<br />

and creep resistance.<br />

VINAVIL EVA <strong>203</strong> can be formulated with mineral fillers, such as calcium carbonate and calciumsulphate,<br />

without significant performance reductions.<br />

Due to the quick setting time VINAVIL EVA <strong>203</strong> can be used either to glue paper with plastic sheets and<br />

overlacquered papers, also with high-speed machines.<br />

COMPATIBILITY<br />

VINAVIL EVA <strong>203</strong> is compatible with the components usually employed in vinyl-ethylene copolymers<br />

based aqueous adhesives such as:<br />

- acrylic and cellulosic thickeners<br />

- plasticizers such as benzoic acid esters and polymeric esters, triacetin<br />

- tackifiers, such as natural and modified rosin, coumarone-indene, terpene and hydrocarbon resins.<br />

P 1 - 2<br />

Data, information and suggestions are provided for guidance purpose only. VINAVIL S.p.A. accepts no responsibility<br />

for the results obtained therefrom,nor for their utilization in infringement of possible patent rights.<br />

The analytical methods are available on request.

VINAVIL ®<br />

TECHNICAL DATA SHEET<br />

VINAVIL EVA <strong>203</strong><br />

06WD014 - 04/13<br />

- natural rubber latex, after addition of ammonia (to approx. 9 pH), to the VINAVIL EVA <strong>203</strong>.<br />

VINAVIL EVA <strong>203</strong> is also compatible with most VINAVIL dispersions; however it is advisable to check<br />

VINAVIL EVA <strong>203</strong> compatibility with the other component to be used.<br />

PACKAGING<br />

VINAVIL EVA <strong>203</strong> is available in bulk, 1000 l minibulks and drums of 125 kg.<br />

STORAGE<br />

VINAVIL EVA <strong>203</strong> is stable for at least 6 months when stored between +5 and +40°C.<br />

P 2 - 2<br />

Data, information and suggestions are provided for guidance purpose only. VINAVIL S.p.A. accepts no responsibility<br />

for the results obtained therefrom,nor for their utilization in infringement of possible patent rights.<br />

The analytical methods are available on request.