vinavil 5406

vinavil 5406

vinavil 5406

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

VINAVIL ®<br />

APPLICATIONS<br />

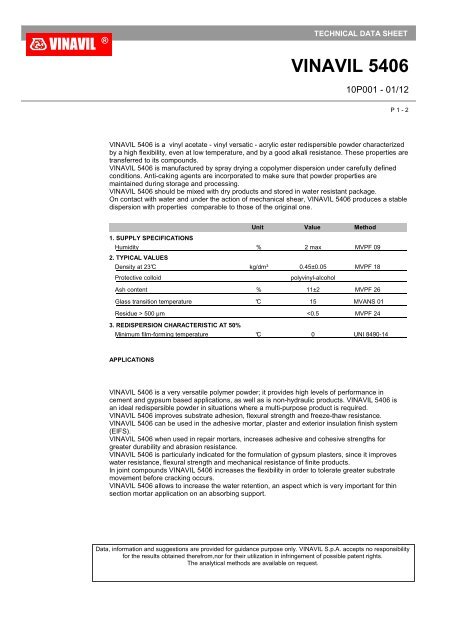

TECHNICAL DATA SHEET<br />

VINAVIL <strong>5406</strong><br />

10P001 - 01/12<br />

VINAVIL <strong>5406</strong> is a very versatile polymer powder; it provides high levels of performance in<br />

cement and gypsum based applications, as well as is non-hydraulic products. VINAVIL <strong>5406</strong> is<br />

an ideal redispersible powder in situations where a multi-purpose product is required.<br />

VINAVIL <strong>5406</strong> improves substrate adhesion, flexural strength and freeze-thaw resistance.<br />

VINAVIL <strong>5406</strong> can be used in the adhesive mortar, plaster and exterior insulation finish system<br />

(EIFS).<br />

VINAVIL <strong>5406</strong> when used in repair mortars, increases adhesive and cohesive strengths for<br />

greater durability and abrasion resistance.<br />

VINAVIL <strong>5406</strong> is particularly indicated for the formulation of gypsum plasters, since it improves<br />

water resistance, flexural strength and mechanical resistance of finite products.<br />

In joint compounds VINAVIL <strong>5406</strong> increases the flexibility in order to tolerate greater substrate<br />

movement before cracking occurs.<br />

VINAVIL <strong>5406</strong> allows to increase the water retention, an aspect which is very important for thin<br />

section mortar application on an absorbing support.<br />

P 1 - 2<br />

VINAVIL <strong>5406</strong> is a vinyl acetate - vinyl versatic - acrylic ester redispersible powder characterized<br />

by a high flexibility, even at low temperature, and by a good alkali resistance. These properties are<br />

transferred to its compounds.<br />

VINAVIL <strong>5406</strong> is manufactured by spray drying a copolymer dispersion under carefully defined<br />

conditions. Anti-caking agents are incorporated to make sure that powder properties are<br />

maintained during storage and processing.<br />

VINAVIL <strong>5406</strong> should be mixed with dry products and stored in water resistant package.<br />

On contact with water and under the action of mechanical shear, VINAVIL <strong>5406</strong> produces a stable<br />

dispersion with properties comparable to those of the original one.<br />

1. SUPPLY SPECIFICATIONS<br />

Unit Value<br />

Method<br />

Humidity % 2 max<br />

MVPF 09<br />

2. TYPICAL VALUES<br />

Density at 23°C kg/dm³ 0.45±0.05 MVPF 18<br />

Protective colloid polyvinyl-alcohol<br />

Ash content % 11±2<br />

MVPF 26<br />

Glass transition temperature °C 15<br />

MVANS 01<br />

Residue > 500 µm

VINAVIL ®<br />

PACKAGING<br />

TECHNICAL DATA SHEET<br />

VINAVIL <strong>5406</strong><br />

10P001 - 01/12<br />

VINAVIL <strong>5406</strong> is available in 25 Kg paper bags with polyethylene liners and big bag of 600 and<br />

1000 Kg.<br />

STORAGE<br />

VINAVIL <strong>5406</strong> should be stored in its original packaging in a cool dry place with temperature<br />

below 30°C.<br />

Excessive pressure can cause VINAVIL <strong>5406</strong> to cake under prolonged storage.<br />

It is recommended to use VINAVIL <strong>5406</strong> within six months of delivery.<br />

P 2 - 2<br />

Data, information and suggestions are provided for guidance purpose only. VINAVIL S.p.A. accepts no responsibility<br />

for the results obtained therefrom,nor for their utilization in infringement of possible patent rights.<br />

The analytical methods are available on request.