Mechanical Drawings - City of London

Mechanical Drawings - City of London

Mechanical Drawings - City of London

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

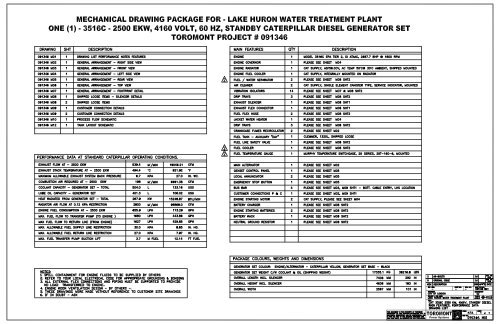

INFORMATION DRAWING SET<br />

LAKE HURON WTP<br />

GRAND BEND, ONTARIO, CANADA<br />

4.16kV UTILITY / GENERATOR<br />

PARALLELING SWITCHGEAR<br />

TOROMONT POWER SYSTEMS<br />

ISO PROJECT No. 36234<br />

TABLE OF CONTENTS<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

TITLE SHEET<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

DRAWN BY MODIFIED BY<br />

HC<br />

BCA<br />

0.4<br />

04-17-10<br />

DATE CREATED DATE MODIFIED<br />

11-24-09<br />

SHEET NUMBER<br />

N.T.S.<br />

TS<br />

REV.<br />

SCALE<br />

J. Richard<br />

APPROVED BY<br />

DATE APPROVED<br />

05-04-10<br />

22<br />

<strong>of</strong><br />

36234-TS<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

ABBREVIATION LEGEND<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

DRAWING LEGEND<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

N.T.S. 0.4 BCA<br />

DATE CREATED DATE MODIFIED<br />

11-23-09 03-02-10<br />

SHEET NUMBER G01 1 <strong>of</strong> 22<br />

DRAWN BY MODIFIED BY<br />

REV.<br />

SCALE<br />

J. Richard<br />

APPROVED BY<br />

DATE APPROVED<br />

05-04-10<br />

36234-G01<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

DEVICE<br />

DEVICE<br />

LOCATION<br />

LOCATION<br />

MANUFACTURE<br />

TYPE<br />

MANUFACTURE<br />

TYPE<br />

FRAME (A)<br />

FRAME (A)<br />

INTERRUPT<br />

CAP. (kA)<br />

INTERRUPT<br />

CAP. (kA)<br />

MV CIRCUIT BREAKER, LUGGING AND CONDUIT ENTRY SCHEDULE - (GS1-A)<br />

TRIP<br />

FUNCTIONS<br />

OPERATION<br />

MOUNTING<br />

CHARGE<br />

SHUNT CLOSE<br />

SHUNT TRIP<br />

AUXILLIARY<br />

MOC<br />

KIRK KEY<br />

TOC<br />

ACCESSORIES<br />

LUGS<br />

PER<br />

PHASE<br />

MV CIRCUIT BREAKER, LUGGING AND CONDUIT ENTRY SCHEDULE - (GS1-B)<br />

TRIP<br />

FUNCTIONS<br />

OPERATION<br />

MOUNTING<br />

CHARGE<br />

SHUNT CLOSE<br />

SHUNT TRIP<br />

AUXILLIARY<br />

MOC<br />

KIRK KEY<br />

TOC<br />

ACCESSORIES<br />

LUGS<br />

PER<br />

PHASE<br />

COMPRESSION LUGS<br />

NEUTRAL<br />

LUGS<br />

GROUND<br />

LUGS<br />

COMPRESSION LUGS<br />

NEUTRAL<br />

LUGS<br />

GROUND<br />

LUGS<br />

NAMEPLATE<br />

DESCRIPTION<br />

NAMEPLATE<br />

DESCRIPTION<br />

TOP<br />

TOP<br />

CONDUIT<br />

ENTRY<br />

BOTTOM<br />

CONDUIT<br />

ENTRY<br />

BOTTOM<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

CIRCUIT BREAKER SCHEDULE<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

BCA<br />

DRAWN BY MODIFIED BY<br />

05-03-10<br />

DATE CREATED DATE MODIFIED<br />

N.T.S. 0.4 BCA<br />

11-24-09<br />

SHEET NUMBER G02 2<br />

REV.<br />

SCALE<br />

J. Richard<br />

APPROVED BY<br />

DATE APPROVED<br />

05-04-10<br />

22<br />

<strong>of</strong><br />

36234-G02<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

R<br />

VT-UTILTY<br />

UTILITY<br />

METERING<br />

UML1<br />

CLOSE LOCKOUT<br />

SWITCH<br />

LOCKOUT AUTO<br />

G R<br />

52L1<br />

VTL1<br />

VTB1<br />

VTB1<br />

52F11<br />

G R<br />

G R<br />

52F11<br />

52F12<br />

52F13<br />

52F13<br />

52F14<br />

ONE LINE<br />

52L1 VTL1 52F12<br />

52F14<br />

52D2<br />

52T1<br />

(PROV)<br />

G R<br />

G R<br />

52D1<br />

(PROV)<br />

G R<br />

G R<br />

FRONT ELEVATION - GS1-A<br />

52D1<br />

52D2<br />

G R<br />

52T1<br />

VTB2<br />

VTB2<br />

VTG1<br />

52G1<br />

VTG1<br />

52G1<br />

VTG2<br />

G R G R<br />

52G2<br />

VTG2<br />

52G2<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

FRONT ELEVATION AND ONE - LINE - (GS1-A)<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

BCA<br />

DRAWN BY MODIFIED BY<br />

03-17-10<br />

DATE CREATED DATE MODIFIED<br />

N.T.S. 0.4 BCA<br />

11-23-09<br />

SHEET NUMBER G03 3<br />

REV.<br />

SCALE<br />

J. Richard<br />

APPROVED BY<br />

DATE APPROVED<br />

05-04-10<br />

22<br />

<strong>of</strong><br />

36234-G03<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

R<br />

VTG3<br />

52G3<br />

VTG3<br />

52G3<br />

VTG4<br />

G R G R<br />

52G4<br />

VTG4<br />

52G4<br />

G R<br />

52T2<br />

52T2<br />

52D3<br />

(PROV)<br />

G R<br />

G R<br />

52D4<br />

(PROV)<br />

VTB3<br />

52D3 52F21<br />

52F23<br />

UML2<br />

52D4<br />

ONE LINE<br />

52F21<br />

G R<br />

G R<br />

52F22<br />

FRONT ELEVATION -GS1-B<br />

52F22<br />

52F23<br />

G R<br />

G R<br />

52F24<br />

52F24<br />

VTL2<br />

VTB3<br />

VTL2<br />

CLOSE LOCKOUT<br />

SWITCH<br />

LOCKOUT AUTO<br />

G R<br />

52L2<br />

52L2<br />

VT-UTILTY<br />

UTILITY<br />

METERING<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

FRONT ELEVATION AND ONE - LINE - (GS1-B)<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

BCA<br />

DRAWN BY MODIFIED BY<br />

05-03-10<br />

DATE CREATED DATE MODIFIED<br />

N.T.S. 0.4 BCA<br />

11-23-09<br />

SHEET NUMBER G04 4<br />

REV.<br />

SCALE<br />

J. Richard<br />

APPROVED BY<br />

DATE APPROVED<br />

05-04-10<br />

22<br />

<strong>of</strong><br />

36234-G04<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

UML1<br />

VTG3<br />

52G3<br />

52L1<br />

VTG4<br />

52G4<br />

VTL1<br />

VTB1<br />

52F11<br />

52F12<br />

52T2<br />

52F13<br />

52F14<br />

GS1-A<br />

GS1-B<br />

VTB3<br />

52D3 52F21<br />

52F23<br />

UML2<br />

52D4<br />

52D1<br />

52D2<br />

52F22<br />

52T1<br />

52F24<br />

VTL2<br />

VTB2<br />

VTG1<br />

52G1<br />

52L2<br />

VTG2<br />

52G2<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

SYSTEM ONE - LINE<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

BCA<br />

DRAWN BY MODIFIED BY<br />

05-03-10<br />

DATE CREATED DATE MODIFIED<br />

N.T.S. 0.4 BCA<br />

12-01-09<br />

SHEET NUMBER G05 5<br />

REV.<br />

SCALE<br />

J. Richard<br />

APPROVED BY<br />

DATE APPROVED<br />

05-04-10<br />

22<br />

<strong>of</strong><br />

36234-G05<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

TOP CONDUIT ENTRY<br />

BOTTOM CONDUIT ENTRY<br />

BOTTOM CONDUIT ENTRY<br />

BOTTOM CONDUIT ENTRY<br />

TOP CONDUIT ENTRY<br />

TOP CONDUIT ENTRY<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

PLAN AND SIDE VIEW<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

DRAWN BY MODIFIED BY<br />

DATE CREATED DATE MODIFIED<br />

N.T.S. 0.4 BCA<br />

11-24-09<br />

SHEET NUMBER G06 6<br />

REV.<br />

SCALE<br />

J. Richard<br />

APPROVED BY<br />

DATE APPROVED<br />

05-04-10<br />

22<br />

<strong>of</strong><br />

36234-G06<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

FLOOR PLAN VIEW<br />

TOP CONDUIT ENTRY<br />

FLOOR PLAN VIEW<br />

BOTTOM CONDUIT ENTRY<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

FLOOR PLAN - (GS1-A)<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

DRAWN BY MODIFIED BY<br />

DATE CREATED DATE MODIFIED<br />

N.T.S. 0.4 BCA<br />

11-24-09<br />

SHEET NUMBER G07 7<br />

REV.<br />

SCALE<br />

J. Richard<br />

APPROVED BY<br />

DATE APPROVED<br />

05-04-10<br />

22<br />

<strong>of</strong><br />

36234-G07<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

FLOOR PLAN VIEW<br />

TOP CONDUIT ENTRY<br />

FLOOR PLAN VIEW<br />

BOTTOM CONDUIT ENTRY<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

FLOOR PLAN - (GS1-B)<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

DRAWN BY MODIFIED BY<br />

DATE CREATED DATE MODIFIED<br />

N.T.S. 0.4 BCA<br />

11-24-09<br />

SHEET NUMBER G08 8<br />

REV.<br />

SCALE<br />

J. Richard<br />

APPROVED BY<br />

DATE APPROVED<br />

05-04-10<br />

22<br />

<strong>of</strong><br />

36234-G08<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

L.A.<br />

CT-A<br />

CT-B<br />

CT-C<br />

CTSB<br />

UML1<br />

CT-A<br />

CT-A<br />

CT-B<br />

CT-B<br />

CT-C<br />

CT-C<br />

52L1<br />

CTSB<br />

VTL1<br />

CTSB<br />

CTSB<br />

CTSB<br />

L1-SR745<br />

N<br />

N<br />

25L1<br />

L1A-3S L1B-3S L1-SR750<br />

L1-TB1<br />

N<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

THREE - LINE DIAGRAM<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

DSA<br />

DRAWN BY MODIFIED BY<br />

03-27-10<br />

DATE CREATED DATE MODIFIED<br />

N.T.S. 0.4 BCA<br />

12-01-09<br />

SHEET NUMBER G09 9<br />

REV.<br />

SCALE<br />

J. Richard<br />

APPROVED BY<br />

DATE APPROVED<br />

05-04-10<br />

22<br />

<strong>of</strong><br />

36234-G09<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

VTB1<br />

CT Z.S.<br />

CT-A<br />

CT-A<br />

CT Z.S.<br />

CT-B<br />

CT-B<br />

CT-C<br />

CT-C<br />

52F11<br />

52F12<br />

CTSB<br />

CTSB<br />

CTSB<br />

CTSB<br />

F35<br />

CT Z.S.<br />

CT-A<br />

CT-A<br />

CT Z.S.<br />

CT-B<br />

CT-B<br />

CT-C<br />

CT-C<br />

52F13<br />

52F14<br />

CTSB<br />

CTSB<br />

CTSB<br />

CTSB<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

THREE - LINE DIAGRAM<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

DRAWN BY MODIFIED BY<br />

DATE CREATED DATE MODIFIED<br />

N.T.S. 0.4 BCA<br />

12-01-09<br />

SHEET NUMBER G10 10<br />

REV.<br />

SCALE<br />

J. Richard<br />

APPROVED BY<br />

DATE APPROVED<br />

05-04-10<br />

22<br />

<strong>of</strong><br />

36234-G10<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

52D1<br />

52D2<br />

CT-A<br />

CT-B<br />

CT-C<br />

52T1<br />

CTSB<br />

L1A-3S L1B-3S<br />

T1-TB1<br />

T1-MIF II<br />

N<br />

VTB2<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

THREE - LINE DIAGRAM<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

DRAWN BY MODIFIED BY<br />

DATE CREATED DATE MODIFIED<br />

N.T.S. 0.4 BCA<br />

12-01-09<br />

SHEET NUMBER G11 11<br />

REV.<br />

SCALE<br />

J. Richard<br />

APPROVED BY<br />

DATE APPROVED<br />

05-04-10<br />

22<br />

<strong>of</strong><br />

36234-G11<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

GENERATOR<br />

STANDBY<br />

RATINGS<br />

CT-A<br />

CT-A<br />

CT Z.S.<br />

CT-B<br />

CT-C<br />

GEN 1<br />

CT-B<br />

CT-C<br />

52G1<br />

NGR<br />

CT-N<br />

VTG1<br />

CTSB<br />

CTSB<br />

CTSB<br />

CTSB<br />

G1-TB<br />

G1-3S<br />

G1-SR489<br />

N<br />

GENERATOR<br />

STANDBY<br />

RATINGS<br />

CT-A<br />

CT-A<br />

CT Z.S.<br />

CT-B<br />

CT-C<br />

GEN 2<br />

CT-B<br />

CT-C<br />

52G2<br />

NGR<br />

CT-N<br />

VTG2<br />

CTSB<br />

CTSB<br />

CTSB<br />

CTSB<br />

G2-TB<br />

G2-3S<br />

G2-SR489<br />

N<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

THREE - LINE DIAGRAM<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

PTS<br />

DRAWN BY MODIFIED BY<br />

02-16-10<br />

DATE CREATED DATE MODIFIED<br />

N.T.S. 0.4 BCA<br />

12-01-09<br />

SHEET NUMBER G12 12<br />

REV.<br />

SCALE<br />

J. Richard<br />

APPROVED BY<br />

DATE APPROVED<br />

05-04-10<br />

22<br />

<strong>of</strong><br />

36234-G12<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

GENERATOR<br />

STANDBY<br />

RATINGS<br />

CT-A<br />

CT-A<br />

CT Z.S.<br />

CT-B<br />

CT-C<br />

GEN 3<br />

CT-B<br />

CT-C<br />

52G3<br />

NGR<br />

CT-N<br />

VTG3<br />

CTSB<br />

CTSB<br />

CTSB<br />

CTSB<br />

G3-TB<br />

G3-3S<br />

G3-SR489<br />

N<br />

GENERATOR<br />

STANDBY<br />

RATINGS<br />

CT-A<br />

CT-A<br />

CT Z.S.<br />

CT-B<br />

CT-C<br />

GEN 4<br />

CT-B<br />

CT-C<br />

52G4<br />

NGR<br />

CT-N<br />

VTG4<br />

CTSB<br />

CTSB<br />

CTSB<br />

CTSB<br />

G4-TB<br />

G4-3S<br />

G4-SR489<br />

N<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

THREE - LINE DIAGRAM<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

PTS<br />

DRAWN BY MODIFIED BY<br />

02-16-10<br />

DATE CREATED DATE MODIFIED<br />

N.T.S. 0.4 BCA<br />

12-01-09<br />

SHEET NUMBER G13 13<br />

REV.<br />

SCALE<br />

J. Richard<br />

APPROVED BY<br />

DATE APPROVED<br />

05-04-10<br />

22<br />

<strong>of</strong><br />

36234-G13<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

CT-A<br />

CT-B<br />

CT-C<br />

52T2<br />

CTSB<br />

L2A-3S L2B-3S<br />

T2-TB1<br />

T2-MIF II<br />

N<br />

52D3<br />

52D4<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

THREE - LINE DIAGRAM<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

DRAWN BY MODIFIED BY<br />

DATE CREATED DATE MODIFIED<br />

N.T.S. 0.4 BCA<br />

12-01-09<br />

SHEET NUMBER G14 14<br />

REV.<br />

SCALE<br />

J. Richard<br />

APPROVED BY<br />

DATE APPROVED<br />

05-04-10<br />

22<br />

<strong>of</strong><br />

36234-G14<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

CT Z.S.<br />

CT-A<br />

CT-A<br />

CT Z.S.<br />

CT-B<br />

CT-B<br />

CT-C<br />

CT-C<br />

52F21<br />

52F22<br />

CTSB<br />

CTSB<br />

CTSB<br />

CTSB<br />

F35<br />

CT Z.S.<br />

CT-A<br />

CT-A<br />

CT Z.S.<br />

CT-B<br />

CT-B<br />

CT-C<br />

CT-C<br />

52F23<br />

52F24<br />

CTSB<br />

CTSB<br />

CTSB<br />

CTSB<br />

VTB3<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

THREE - LINE DIAGRAM<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

DRAWN BY MODIFIED BY<br />

DATE CREATED DATE MODIFIED<br />

N.T.S. 0.4 BCA<br />

12-01-09<br />

SHEET NUMBER G15 15<br />

REV.<br />

SCALE<br />

J. Richard<br />

APPROVED BY<br />

DATE APPROVED<br />

05-04-10<br />

22<br />

<strong>of</strong><br />

36234-G15<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

CT-A<br />

CT-A<br />

CT-B<br />

CT-B<br />

CT-C<br />

CT-C<br />

52L2<br />

CTSB<br />

VTL2<br />

CTSB<br />

CTSB<br />

CTSB<br />

L2-SR745<br />

N<br />

N<br />

25L2<br />

L2A-3S L2B-3S L2-SR750<br />

L2-TB1<br />

N<br />

CT-A<br />

CT-B<br />

CT-C<br />

L.A.<br />

CTSB<br />

UML1<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

THREE - LINE DIAGRAM<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

DSA<br />

DRAWN BY MODIFIED BY<br />

03-27-10<br />

DATE CREATED DATE MODIFIED<br />

N.T.S. 0.4 BCA<br />

12-01-09<br />

SHEET NUMBER G16 16<br />

REV.<br />

SCALE<br />

J. Richard<br />

APPROVED BY<br />

DATE APPROVED<br />

05-04-10<br />

22<br />

<strong>of</strong><br />

36234-G16<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

CBOP<br />

CBCL<br />

86<br />

CBOP<br />

CBCL<br />

86<br />

CBCS<br />

CBCS<br />

CBOP<br />

SR750<br />

SCHEMATIC DIAGRAM - GEN (TYPICAL)<br />

CBOP<br />

SCHEMATIC DIAGRAM - UTILITY (TYPICAL)<br />

86<br />

CP<br />

86<br />

SR489<br />

86<br />

SR745<br />

CR5 CR5<br />

86<br />

CR5<br />

CBCS<br />

CR4<br />

25<br />

CBCL<br />

CBCS<br />

CR4<br />

SR750-R6<br />

UCLOS<br />

CBCL<br />

CR4<br />

CR2A TMR<br />

CR1<br />

3.S OK<br />

LA-3S-OK<br />

LB-3S-OK<br />

CBOP<br />

3.S OK<br />

TMR<br />

CR2A CR2A<br />

CBOP<br />

3.S OK<br />

PL<br />

PL PL<br />

PL<br />

CBOP<br />

CBCL<br />

86<br />

CBCS<br />

SCHEMATIC DIAGRAM - DIST (TYPICAL)<br />

CBOP<br />

CBCL<br />

86<br />

SCHEMATIC DIAGRAM - TIE (TYPICAL)<br />

CBOP<br />

CBCS<br />

CR10 CR10<br />

MIF-II<br />

86<br />

CBOP<br />

F35<br />

86<br />

86<br />

CBCS<br />

CR9<br />

CBCL<br />

86<br />

CR9<br />

CBCS<br />

CBCL<br />

T-HBR1<br />

T-HBR2<br />

CBOP<br />

CR8A CR8A<br />

CBOP<br />

PL<br />

PL<br />

PL<br />

PL<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

SCHEMATIC DIAGRAM<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

BCA<br />

DRAWN BY MODIFIED BY<br />

03-04-10<br />

DATE CREATED DATE MODIFIED<br />

N.T.S. 0.4 BCA<br />

12-01-09<br />

SHEET NUMBER G17 17<br />

REV.<br />

SCALE<br />

J. Richard<br />

APPROVED BY<br />

DATE APPROVED<br />

05-04-10<br />

22<br />

<strong>of</strong><br />

36234-G17<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

SW-A<br />

SW-B<br />

GEN 3<br />

L1A<br />

L1B<br />

3.S 3.S<br />

G3<br />

3.S<br />

GEN 4<br />

G4<br />

3.S<br />

DIST. I/O #1<br />

DIST. I/O #2<br />

WIRE LEGEND<br />

DIST. I/O #3<br />

DIST. I/O #4<br />

REMOTE<br />

PC<br />

SW-A<br />

DATA TABLE<br />

INTERFACE<br />

SW-B<br />

TSP<br />

DATA<br />

3.S<br />

BUILDING<br />

MANAGEMENT<br />

SYSTEM<br />

MASTER I/O #1<br />

MASTER I/O #2<br />

DATA<br />

GEN 1<br />

G1<br />

3.S<br />

L2A<br />

L2B<br />

3.S 3.S<br />

GEN 2<br />

DEVICE LEGEND<br />

G2<br />

3.S<br />

3.S<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

AUTOMATION COMMUNICATIONS PLAN<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

N.T.S. 0.4 BCA<br />

DATE CREATED DATE MODIFIED<br />

12-01-09 05-03-10<br />

SHEET NUMBER G18 18 <strong>of</strong> 22<br />

DRAWN BY MODIFIED BY<br />

REV.<br />

SCALE<br />

J. Richard<br />

APPROVED BY<br />

DATE APPROVED<br />

05-04-10<br />

36234-G18<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

NO. FROM<br />

NOTES:<br />

CONDUIT<br />

TO QTY-SIZE<br />

CONTROL CIRCUIT CONDUIT SCHEDULE (SEE NOTE 1)<br />

CONDUCTOR<br />

FUNCTION<br />

CONDUIT<br />

SIZE<br />

CONDUIT<br />

TABLE<br />

CONDUIT TABLE<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

CONTROL CONDUIT SCHEDULE<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

SCALE<br />

REV.<br />

DRAWN BY MODIFIED BY<br />

N.T.S. 0.4 BCA HC<br />

DATE CREATED DATE MODIFIED<br />

05-04-10<br />

12-01-09 04-17-10<br />

SHEET NUMBER<br />

36234-G19 G19 19 <strong>of</strong> 22<br />

J. Richard<br />

APPROVED BY<br />

DATE APPROVED<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

NOTES:<br />

R<br />

VTG3<br />

52G3<br />

VTG4<br />

G R G R<br />

52G4<br />

GEN 3 GEN 4<br />

R<br />

VT-UTILTY<br />

UTILITY<br />

METERING<br />

G R<br />

52T2<br />

CLOSE LOCKOUT<br />

SWITCH<br />

LOCKOUT AUTO<br />

52D3<br />

(PROV)<br />

G R<br />

G R<br />

G R<br />

52D4<br />

(PROV)<br />

52F21<br />

52F22<br />

VTB1<br />

G R<br />

G R<br />

52F23<br />

52F24<br />

52F11<br />

G R<br />

G R<br />

G R<br />

G R<br />

52F13<br />

52L1 VTL1 52F12<br />

52F14<br />

52D2<br />

52T1<br />

(PROV)<br />

G R<br />

G R<br />

VTB3<br />

VTL2<br />

CLOSE LOCKOUT<br />

SWITCH<br />

LOCKOUT AUTO<br />

52D1<br />

(PROV)<br />

G R<br />

G R<br />

G R<br />

52L2<br />

G R<br />

VT-UTILTY<br />

UTILITY<br />

METERING<br />

VTB2<br />

VTG1<br />

52G1<br />

VTG2<br />

G R G R<br />

52G2<br />

GEN 1 GEN 2<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

CONTROL CONDUIT SCHEDULE - ELEVATION<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

SCALE<br />

REV.<br />

DRAWN BY MODIFIED BY<br />

N.T.S. 0.4 BCA HC<br />

DATE CREATED DATE MODIFIED<br />

05-04-10<br />

12-01-09 04-17-10<br />

SHEET NUMBER<br />

36234-G20 G20 20 <strong>of</strong> 22<br />

J. Richard<br />

APPROVED BY<br />

DATE APPROVED<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

Functional Sequence <strong>of</strong> Operation for each Mode<br />

NORMAL (AUTOMATIC/STAND-BY) Mode<br />

1. The utility main breakers (L1&L2) are closed serving utility power to each load bus.<br />

2. The emergency tie breakers (T1&T2) are open.<br />

3. The generator main breakers (G1-G4) are open.<br />

4. The plant is being fed from the two power transformers.<br />

5. The automation is standing by to act in response to a utility failure.<br />

EMERGENCY Mode<br />

Dual Utility Failure<br />

1. Utility protective relaying senses utility voltage or frequency out <strong>of</strong> tolerance at both utility sources.<br />

2. Both utility main breakers (L1 & L2) are opened.<br />

3. A run request is sent to the generator plant from the SCADA system. A request is defined as the operator pushing the generator start<br />

from the plant SCADA system or the power has been <strong>of</strong>f for more than the preset time limit (set at 30 minutes - adjustable by<br />

operator)<br />

4. The first generator up to voltage and frequency is closed (G1, 2, 3 or 4) to the generator bus.<br />

5. Both emergency tie breakers (T1 & T2) are closed.<br />

6. The remaining generators are synchronized and paralleled to the bus as they come up to voltage and frequency.<br />

7. The system is now in Emergency Mode.<br />

Dual Utility Restoration and Exit from Emergency Mode<br />

1. Utility protective relaying senses utility voltage and frequency within tolerance at both utility sources. The operator turns <strong>of</strong>f the run<br />

request from the SCADA system<br />

2. Following an adjustable time delay (which can be abbreviated by the operator) to assure that the utility power sources are stable, the<br />

generator plant is passively synchronized and paralleled to utility #1 source by closing the utility #1 main breaker (L1).<br />

3. The generator plant is s<strong>of</strong>t ramp unloaded until the utility #1 source is nominally serving load bus #1.<br />

4. The emergency tie #1 breaker (T1) is opened.<br />

5. The generator plant is passively synchronized and paralleled to utility #2 source by closing the utility #2 main breaker (L2).<br />

6. The generator plant is s<strong>of</strong>t ramp unloaded until the utility #2 source is nominally serving load bus #2.<br />

7. The emergency tie #2 breaker (T2) is opened.<br />

8. The generator breakers (G1-G4) are opened.<br />

9. The generators are allowed to run for their programmed cool down period.<br />

10. The system is now back in Automatic/Standby Mode.<br />

Single Utility Failure<br />

1. The system performs as described in the Dual Utility Failure section. The only difference is plant power is now being fed from one (1)<br />

transformer. If L1 is open, T1 can close or L2 is open, T2 can close.<br />

Single Utility Restoration<br />

1. No action is taken until the system senses both utilities are restored.<br />

2. The system performs as described in the Dual Utility Restoration section.<br />

MAINTENANCE Mode (Password Protected)<br />

Feeding the facility from a single transformer (TX1 or TX2)<br />

1. The operator places the Utility Selector Switch for Transfer to Maintenance Mode into the “MAINTENANCE” position.<br />

2. The operator places the Master Mode Selector Switch into the Transfer “TX1” or “TX2” position.<br />

3. If TX1 is selected, utility #2 main breaker (L2) is opened<br />

4. Emergency tie #1 (T1) and #2 breaker (T2) will close.<br />

5. This will allow TX1 to feed the facility<br />

6. If TX2 is selected, utility #1 main breaker (L1) is opened<br />

7. Emergency tie #1 (T1) and #2 breaker (T2) will close.<br />

8. This will allow TX2 to feed the facility<br />

Exiting the facility from a single transformer (TX1 or TX2)<br />

1. The operator places the Utility Selector Switch for Transfer to either AUTOMATIC/STAND-BY or Emergency.<br />

2. By selecting Transfer to AUTOMATIC/STAND-BY Mode, Emergency tie #1 (T1) and #2 (T2) breakers will open, utility #1 or #2 (L1<br />

or L2) (depending on which was open) will close and the systems is now back in Automatic/Standby Mode with each transformer<br />

feeding its respective load side.<br />

3. By selecting Transfer to Emergency Mode, the sequence for Emergency Mode will be entered which the exception that only one<br />

utility breaker needs to be paralleled with the generators as the other utility breaker is already open.<br />

Manual Transfer to Emergency Mode (Password Protected)<br />

Entry into Emergency Mode on Load Bus #1 & #2<br />

1. The operator places the Utility Selector Switch for Transfer to Emergency Mode into the “Both” position.<br />

2. The operator places the Master Mode Selector Switch into the Transfer to Emergency position.<br />

3. A run request is sent to the generator plant.<br />

4. The first generator up to voltage and frequency is closed (G1-G4) to the generator bus.<br />

5. The remaining generators are synchronized and paralleled to the bus as they come up to voltage and frequency.<br />

6. The generators are allowed to run for a five-minute warm-up time (which can be abbreviated by the operator).<br />

7. After completion <strong>of</strong> the warm-up time, the generator plant is passively synchronized and paralleled to the utility #1 source by closing<br />

the emergency tie #1 breaker (T1).<br />

8. The generator plant is s<strong>of</strong>t ramp loaded until the generator plant is nominally serving load bus #1.<br />

9. The utility #1 main breaker (L1) is opened.<br />

10. The generator plant is passively synchronized and paralleled to the utility #2 source by closing the emergency tie #2 breaker (T2).<br />

11. The generator plant is s<strong>of</strong>t ramp loaded until the generator plant is nominally serving load bus #2.<br />

12. The utility #2 main breaker (L2) is opened.<br />

13. The entire system is now in Emergency Mode.<br />

Exit from Emergency Mode on Load Bus #1 & #2<br />

1. The operator removes the Master Mode Selector Switch from Transfer to Emergency position and returns it to the Auto position.<br />

2. Following an adjustable time delay (which can be abbreviated by the operator), the generator plant is passively synchronized and<br />

paralleled to the utility #1 source by closing the utility #1 main breaker (L1).<br />

3. The generator plant is s<strong>of</strong>t ramp unloaded until the utility #1 source is nominally serving load bus #1.<br />

4. The emergency tie #1 breaker (T1) is opened.<br />

5. The generator plant is passively synchronized and paralleled to the utility #2 source by closing the utility #2 main breaker (L2).<br />

6. The generator plant is s<strong>of</strong>t ramp unloaded until the utility #2 source is nominally serving load bus #2.<br />

7. The emergency tie #2 breaker (T2) is opened.<br />

8. The generator breakers (G1-G4) are opened.<br />

9. The generators are allowed to run for their programmed cool down period.<br />

10. The system is now back in Automatic/Standby Mode.<br />

No Load Test Mode (Password Protected)<br />

Entry<br />

1. The No Load Test Switch is placed in the ON position.<br />

2. All available generators are started.<br />

3. The first generator up to voltage and frequency is closed to the bus.<br />

4. The remaining generators are synchronized and paralleled to the bus as they come up to<br />

voltage and frequency.<br />

5. The system is now in No Load Test Mode.<br />

Exit<br />

1. The No Load Test Switch is placed in the OFF position.<br />

2. All generator breakers are opened.<br />

3. The generators are allowed to run for their programmed cool down period.<br />

4. The system is now back in Automatic/Standby Mode.<br />

Utility Fail Test Mode (Password Protected)<br />

Entrance into Utility #1 Fail Test Mode<br />

1. The Utility #1 Fail Test Switch is placed in the ON position.<br />

2. Voltage sensing at the utility #1 protective relay is opened, which simulates a loss <strong>of</strong> utility #1.<br />

3. The system enters into a Single Utility Failure as described in the “Emergency Mode” sequence above.<br />

Exit from Utility #1 Fail Test Mode<br />

1. The Utility #1 Fail Test Switch is placed in the OFF position.<br />

2. Voltage sensing at the utility #1 protective relay is restored, which simulates the return <strong>of</strong> utility power.<br />

3. The system exits from a Single Utility Failure as described in the “Emergency Mode” sequence above.<br />

Entrance into Utility #2 Fail Test Mode<br />

1. The Utility #2 Fail Test Switch is placed in the ON position.<br />

2. Voltage sensing at the utility #2 protective relay is opened, which simulates a loss <strong>of</strong> utility #2.<br />

3. The system enters into a Single Utility Failure as described in the “Emergency Mode” sequence above.<br />

Exit from Utility #2 Fail Test Mode<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

SEQUENCE OF OPERATIONS<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

DRAWN BY MODIFIED BY<br />

HC<br />

04-17-10<br />

DATE CREATED DATE MODIFIED<br />

N.T.S. 0.4 BCA<br />

12-02-09<br />

SHEET NUMBER G21 21<br />

REV.<br />

SCALE<br />

J. Richard<br />

APPROVED BY<br />

DATE APPROVED<br />

05-04-10<br />

22<br />

<strong>of</strong><br />

36234-G21<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

1. The Utility #2 Fail Test Switch is placed in the OFF position.<br />

2. Voltage sensing at the utility #2 protective relay is restored, which simulates the return <strong>of</strong> utility power.<br />

3. The system exits from a Single Utility Failure as described in the “Emergency Mode” sequence above.<br />

Entrance into Dual Utility Fail Test Mode<br />

1. Both Utility Fail Test Switch's are placed in the ON position.<br />

2. Voltage sensing at the utility #1 & #2 protective relays is opened, which simulates a loss <strong>of</strong> utility #1 & #2.<br />

3. The system enters into a Dual Utility Failure as described in the “Emergency Mode” sequence above.<br />

Exit from Dual Utility Fail Test Mode<br />

1. Both Utility Fail Test Switch's are placed in the OFF position.<br />

2. Voltage sensing at the utility #1 & #2 protective relays is restored, which simulates the return <strong>of</strong> utility power.<br />

3. The system exits from a Dual Utility Failure as described in the “Emergency Mode” sequence above.<br />

Load Management Mode (future)<br />

Entry<br />

1. Select one <strong>of</strong> the modes <strong>of</strong> operation:<br />

a. Import Limit - The user places the Import/Export toggle switch in the Import position andplaces the Base Load/Utility Tracking<br />

toggle switch in the Utility Tracking position. The user sets the Utility Import Set point to the desired amount <strong>of</strong> kW that they<br />

want to import through the Utility Circuit Breaker during Load Management Mode.<br />

b. Export Limit - The user places the Import/Export toggle switch in the Export position and places the Base Load/Utility Tracking<br />

toggle switch in the Utility Tracking position. The user sets the Utility Export Set point to the desired amount <strong>of</strong> kW that they<br />

want to export through the Utility Circuit Breaker during Load Management Mode.<br />

c. Base Load Import - The user places the Import/Export toggle switch in the Import position and places the Base Load/Utility<br />

Tracking toggle switch in the Base Load position. The user sets the Base Load Set point to the desired amount <strong>of</strong> kW that they<br />

want the generator plant to assume during Load Management Mode. The controls will not allow the generator plant to export<br />

kW through the Utility Circuit Breaker and will always maintain a nominal amount <strong>of</strong> Utility kW imported through the Utility Circuit<br />

Breaker.<br />

d. Base Load Export - The user places the Import/Export toggle switch in the Export position and places the Base Load/Utility<br />

Tracking toggle switch in the Base Load position. The user sets the Base Load Set point to the desired amount <strong>of</strong> kW that they<br />

want the generator plant to assume during Load Management Mode. The controls will allow the generator plant to export kW<br />

through the Utility Circuit Breaker.<br />

2. The operator places the Utility Selector Switch for Load Management Mode into either the Utility #1 or Utility #2 position depending<br />

on which utility source the operator wants the generator plant to parallel with.<br />

3. The user places the Master Mode Selector Switch in the Load Management position.<br />

4. A run request is sent to the generator plant.<br />

5. The first generator up to voltage and frequency is closed to the generator bus.<br />

6. The remaining generators are synchronized and paralleled to the bus as they come up to voltage and frequency.<br />

7. The generators are allowed to run for a five-minute warm-up time (which can be abbreviated by the operator).<br />

8. After completion <strong>of</strong> the warm-up time, the generator plant is passively synchronized and paralleled to the utility source selected on<br />

the Utility Selector Switch for Load Management Mode by closing the associated emergency tie breaker.<br />

9. The generator plant is s<strong>of</strong>t ramp loaded until it is serving nominally the required amount <strong>of</strong> the load on the bus to meet the mode <strong>of</strong><br />

operation selected.<br />

10. The generator output is dynamically adjusted to maintain the set point to meet the mode <strong>of</strong> operation selected.<br />

11. Should the utility fail at any time during Load Management operation, the utility protective relays shall cause the utility main to open<br />

and be locked out, thus placing the system in Emergency Mode until the Utility is restored (as described in Emergency Mode exit).<br />

Exit<br />

1. The operator removes the Master Mode Selector Switch from Load Management position and returns it to the Auto position.<br />

2. The generator plant is s<strong>of</strong>t ramp unloaded until the utility source is nominally serving the entire system load.<br />

3. The emergency tie breaker is opened.<br />

4. The generator main breakers are opened.<br />

5. The generators are allowed to run for their programmed cool down period.<br />

6. The system is now back in Automatic/Standby Mode.<br />

Load Shed Control<br />

The System Controls shall include a Load Shed Control function to control the loads served by the<br />

generator plant. The Load Shed Control shall have one Essential Load Shed Priority Level for each<br />

generator in the system plus one Non-Essential Load Shed Priority Level (which is always shed in<br />

the Emergency Mode <strong>of</strong> operation).<br />

The Load Shed Control shall control each <strong>of</strong> the distribution circuit breakers within the switchgear.<br />

Each electrically operated distribution circuit breaker shall be field selectable to be assigned to any<br />

<strong>of</strong> the available Load Shed Priority Levels. Additionally, Load Shed Control shall provide a 4 pole,<br />

10A, 120VAC rated, form C set <strong>of</strong> contacts for each Load Shed Priority Level to allow for control <strong>of</strong><br />

loads external to the switchgear.<br />

The following controls shall be provided for each level:<br />

Shed Delay Timer, adjustable from 0 to 1024 seconds<br />

Add Delay Timer, adjustable from 0 to 1024 seconds<br />

Load Shed Override Selector (shed/auto//add)<br />

Status indicators to show whether the Priority Level is Added or Shed<br />

The Load Shed Controls shall have:<br />

Load Shed Control Switch (On/Off)<br />

User-settable Load Shed % (as a function <strong>of</strong> on-line generator capacity)<br />

User-settable Load Add % (as a function <strong>of</strong> on-line generator capacity)<br />

User-settable Bus Under frequency Set point<br />

Bus Under frequency Reset Pushbutton<br />

Bus Under frequency indicator<br />

Conditional Load Shed: Upon entrance into Emergency Mode <strong>of</strong> operation, the Load Shed Control<br />

shall shed all Essential and Non-Essential loads. As generators come to the bus, Essential Priority<br />

Level loads shall be added conditionally based on the number <strong>of</strong> generators on line. When the first<br />

generator comes to the bus, Priority Level 1 loads shall be added; Second generator, priority 2, etc.<br />

After a time delay that allows all operational generators to come to the bus, Load Shed Mode shall<br />

shift to Load Sensitive Mode.<br />

Load Sensitive Load Shed - After all generators have been given sufficient time to come to the bus,<br />

load shed shall shift to “Load Sensitive” mode. The system shall compare current generator on-line<br />

capacity (in kW) to current load requirements. If surplus capacity is greater than the calculated Load<br />

Add setpoint, after the Load Add Time Delay the next Load Shed Priority will be added. This<br />

calculation will continue until all Sheddable Loads are added, or until surplus capacity is less than<br />

the calculated Load Add setpoint. If surplus capacity is less than the calculated Load Shed setpoint,<br />

after the Load Shed Time Delay the next Load Shed Priority will be shed. This calculation will<br />

continue until all Sheddable Loads are shed, or until surplus capacity is greater than the calculated<br />

Load Shed setpoint. The Load Shed Control, in its automatic shedding and adding <strong>of</strong> loads, shall<br />

not override any manual load shed/add operation.<br />

Should the load bus frequency fall below the user selected bus underfrequency setpoint for a period<br />

longer than the bus underfrequency time delay, then all Priority Level loads shall be shed and load<br />

addition shall not resume until the operator has depressed the Bus Underfrequency Reset button.<br />

The bus underfrequency protection shall override any manual load add operation.<br />

Generator Demand Priority Control<br />

The System Controls shall include a Generator Demand Priority Control function to automatically<br />

match the on-line generator capacity to the loads to avoid unnecessary operation <strong>of</strong> all the<br />

generators when the loads are low.<br />

The following controls shall be provided for each generator:<br />

User-settable Generator Priority Selector<br />

Status indicator for the Generator Priority Selected<br />

Status indicator for generator On-line or Off-line<br />

The Generator Demand Priority Control shall have the following controls:<br />

Generator Demand Priority Control Switch (On/Off)<br />

User-settable Generator Remove % (as a function <strong>of</strong> a single generator capacity)<br />

User-settable Generator Remove Delay<br />

User-settable Generator Add % (as a function <strong>of</strong> a single generator capacity)<br />

User-settable Generator Add Delay<br />

Upon entrance into Emergency or Load Management modes, all generators shall be started and<br />

paralleled to the bus. After the Remove Time Delay, generators shall be removed from the bus as a<br />

function <strong>of</strong> the generator percentage loading by the user selected Generator Remove time delay.<br />

Generators shall be removed from the bus in descending priority. Should the generator percentage<br />

loading increase to the user selected Generator Add limits for the user selected Add Delay, the next<br />

generator will be started, synchronized and paralleled to the bus. Generators shall be added to the<br />

bus in ascending priority order. Should the generator plant ever reach 95% loading, the next priority<br />

generator shall be started and added to the bus with no time delay.<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

SEQUENCE OF OPERATIONS<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

BCA<br />

DRAWN BY MODIFIED BY<br />

02-24-10<br />

DATE CREATED DATE MODIFIED<br />

N.T.S. 0.4 BCA<br />

12-02-09<br />

SHEET NUMBER G22 22<br />

REV.<br />

SCALE<br />

J. Richard<br />

APPROVED BY<br />

DATE APPROVED<br />

05-04-10<br />

22<br />

<strong>of</strong><br />

36234-G22<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

1R60<br />

8R60<br />

125VDC BATT CHGR<br />

24VDC BATTERY<br />

125VDC BATTERY<br />

9R60<br />

TB-BC<br />

2R80<br />

TB1<br />

CTSB-N145<br />

DATA<br />

3.S<br />

SWGR GS1-A<br />

REMOTE<br />

PC<br />

CR-M311<br />

CR-M314<br />

CR-M317<br />

CR-M320<br />

CR-M323<br />

CR-M326<br />

CR-M330<br />

CR-M333<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

FIELD INTERCONNECTS - SYSTEM<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

SCALE<br />

REV.<br />

DRAWN BY MODIFIED BY<br />

N.T.S. 0.2 EM<br />

HC<br />

DATE CREATED DATE MODIFIED<br />

05-04-10<br />

01-04-10 04-17-10<br />

SHEET NUMBER<br />

36234-F01 F01 1 <strong>of</strong> 7<br />

J. Richard<br />

APPROVED BY<br />

DATE APPROVED<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

SWGR GS1-B<br />

GEN 3<br />

SW-A<br />

SW-B<br />

SWGR GS1-A<br />

SECT 1 SECT 8<br />

SW-A<br />

SECT 1 SECT 8<br />

SW-B<br />

E-TB E-TB<br />

L2-TB2<br />

24VDC+<br />

24VDC-<br />

TB1<br />

24VDC+<br />

24VDC-<br />

GEN 2<br />

SWGR GS1-A<br />

SWGR GS1-B<br />

VTB2 TB G3-VTB2-TB<br />

CTSB-N141<br />

CTSB-N134<br />

11R80<br />

11R60<br />

15R60<br />

19R60<br />

SWGR GS1-B<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

FIELD INTERCONNECTS - SYSTEM<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

DRAWN BY MODIFIED BY<br />

REV.<br />

SCALE<br />

J. Richard<br />

APPROVED BY<br />

DATE CREATED DATE MODIFIED<br />

DATE APPROVED<br />

05-04-10<br />

7<br />

<strong>of</strong><br />

N.T.S. 0.2 EM<br />

01-04-10<br />

SHEET NUMBER F02 2<br />

36234-F02<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

E-TB<br />

SPEED BRICK<br />

GEN 1<br />

GEN 1<br />

GEN 1<br />

GEN 1<br />

CDVR<br />

E-TB<br />

PB-E343<br />

E-TB<br />

CTSB G1<br />

CTSB-E144<br />

CT-E128<br />

R-E143<br />

CAT MODBUS<br />

CT-E130<br />

CT-E132<br />

CT-E144<br />

SWGR GS1-A<br />

GEN 1<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

FIELD INTERCONNECTS - GEN 1<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

DRAWN BY MODIFIED BY<br />

REV.<br />

SCALE<br />

J. Richard<br />

APPROVED BY<br />

DATE CREATED DATE MODIFIED<br />

DATE APPROVED<br />

05-04-10<br />

7<br />

<strong>of</strong><br />

N.T.S. 0.2 EM<br />

10-27-09<br />

SHEET NUMBER F03 3<br />

36234-F03<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

E-TB<br />

SPEED BRICK<br />

GEN 2<br />

GEN 2<br />

GEN 2<br />

GEN 2<br />

CDVR<br />

E-TB<br />

PB-E843<br />

E-TB<br />

CTSB G2<br />

CTSB-E644<br />

CT-E628<br />

R-E643<br />

CAT MODBUS<br />

CT-E630<br />

CT-E632<br />

CT-E644<br />

SWGR GS1-A<br />

GEN 2<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

FIELD INTERCONNECTS - GEN 2<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

DRAWN BY MODIFIED BY<br />

REV.<br />

SCALE<br />

J. Richard<br />

APPROVED BY<br />

DATE CREATED DATE MODIFIED<br />

DATE APPROVED<br />

05-04-10<br />

7<br />

<strong>of</strong><br />

N.T.S. 0.2 EM<br />

10-27-09<br />

SHEET NUMBER F04 4<br />

36234-F04<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

E-TB<br />

SPEED BRICK<br />

GEN 3<br />

GEN 3<br />

GEN 3<br />

GEN 3<br />

CDVR<br />

E-TB<br />

PB-E343<br />

E-TB<br />

CTSB G3<br />

CTSB-E144<br />

CT-E128<br />

R-E143<br />

CAT MODBUS<br />

CT-E130<br />

CT-E132<br />

CT-E144<br />

SWGR GS1-B<br />

GEN 3<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

FIELD INTERCONNECTS - GEN 3<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

DRAWN BY MODIFIED BY<br />

REV.<br />

SCALE<br />

J. Richard<br />

APPROVED BY<br />

DATE CREATED DATE MODIFIED<br />

DATE APPROVED<br />

05-04-10<br />

7<br />

<strong>of</strong><br />

N.T.S. 0.2 EM<br />

10-27-09<br />

SHEET NUMBER F05 5<br />

36234-F05<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

E-TB<br />

SPEED BRICK<br />

GEN 4<br />

GEN 4<br />

GEN 4<br />

GEN 4<br />

CDVR<br />

E-TB<br />

PB-E843<br />

E-TB<br />

CTSB G4<br />

CTSB-E644<br />

CT-E628<br />

R-E643<br />

CAT MODBUS<br />

CT-E630<br />

CT-E632<br />

CT-E644<br />

SWGR GS1-B<br />

GEN 4<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

FIELD INTERCONNECTS - GEN 4<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

DRAWN BY MODIFIED BY<br />

REV.<br />

SCALE<br />

J. Richard<br />

APPROVED BY<br />

DATE CREATED DATE MODIFIED<br />

DATE APPROVED<br />

05-04-10<br />

7<br />

<strong>of</strong><br />

N.T.S. 0.2 EM<br />

10-27-09<br />

SHEET NUMBER F06 6<br />

36234-F06<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

L1-TB-FLD<br />

L2-TB-FLD<br />

L1-TB-FLD L2-TB-FLD<br />

LAKE HURON WTP<br />

TITLE:<br />

DATE<br />

REVISION<br />

NO.<br />

FIELD INTERCONNECTS - L1 & L2<br />

SUBMITTAL<br />

RELEASE<br />

4.16kV UTILITY / GENERATOR PARALLELING SWITCHGEAR<br />

SCALE<br />

REV.<br />

DRAWN BY MODIFIED BY<br />

N.T.S. 0.2 HC<br />

HC<br />

DATE CREATED DATE MODIFIED<br />

05-04-10<br />

04-17-10 04-27-10<br />

SHEET NUMBER<br />

36234-F07 F07 7 <strong>of</strong> 7<br />

J. Richard<br />

APPROVED BY<br />

DATE APPROVED<br />

FILE NAME<br />

THIS DOCUMENT AND THE DETAILS EMBODIED THEREIN CONSTITUTE CONFIDENTIAL AND PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF INTELLIGENT SWITCHGEAR ORGANIZATION LLC, 4955 MARCONI DRIVE, ALPHARETTA, GA., 30005, U.S.A., AND IS NOT TO BE USED OR REPRODUCED BY ANY PART EXCEPT AND TO THE EXTENT IN THE MANNER AUTHORIZED BY INTELLIGENT SWITCHGEAR ORGANIZATION LLC, INC.

iMACS<br />

PROJECT BILL OF MATERIALS<br />

Project: Lake Huron Water Treatment Plant By: Engineering<br />

Stock #: P091346A Print Date: 29-Jan-10<br />

No Qty Part # Description Supplier Manufacturer Tag # Comp<br />

Location<br />

1 1 0P1793 ***GEN SET TEST CHG @ 0.8 PF** Toromont CAT Engine<br />

2 1 0P7607 SHRINK WRAP PROTECTION - 3516 Toromont CAT Engine<br />

3 1 0V1065 END USE: GENERAL EPG Toromont CAT Engine<br />

4 1 2523944 GENERATOR AR - POWER Toromont CAT Engine<br />

5 1 2523944 GENERATOR AR - POWER Toromont CAT Engine<br />

6 1 2523972 GENERATOR AR - POWER Toromont CAT Engine<br />

7 1 2666136 ENGINE AR - 3516C HD Toromont CAT Engine<br />

8 1 2787089 CONNECTION GP Toromont CAT Engine<br />

9 1 3223173 HEATER GP-GEN Toromont CAT Engine<br />

10 1 516DE5Q CONFIGURATION Toromont CAT Engine<br />

11 1 5N9599 VOLTAGE INDICATOR 4160V, 60HZ Toromont CAT Engine<br />

12 1 60H4160 VOLTAGE Toromont CAT Engine<br />

13 2 93192A Nelson Ecovent Recirculator - crankcase fumes filter with<br />

replaceable element<br />

Page 1 <strong>of</strong> 4<br />

Nelson/Fleetguard Engine<br />

14 1 9Y8156 NOTE - STAMP FOR STANDBY POWER Toromont CAT Engine<br />

15 1 ANNNFPA ANNUNCIATOR MODULES Toromont CAT Engine<br />

16 1 AUXPNLL EMCP3 CONTROL PANEL OPTIONS Toromont CAT Engine<br />

17 1 BUSBM6L CIRCUIT BREAKER LEFT HAND Toromont CAT Engine<br />

18 1 BUSBM6R POWER TERMINAL STRIP REMOVAL Toromont CAT Engine<br />

19 1 CA0866 LANGUAGE MARKINGS-ENGLISH Toromont CAT Engine<br />

20 1 CERTEXP CERTIFICATION EMISSION LOC Toromont CAT Engine<br />

21 1 CERTIF2 PACKAGE GEN SET Toromont CAT Engine<br />

22 1 CERTSTA CERTIFIED APPLICATION Toromont CAT Engine<br />

23 1 CT05005 CURRENT TRANSFORMERS Toromont CAT Engine<br />

24 1 CUSTCNR CUSTOMER CONNECTION LOCATION Toromont CAT Engine<br />

25 1 ECP5GT1 ESC COVERAGE Toromont CAT Engine<br />

26 1 EMCP33A EMCP 3.3 CONTROL PANEL Toromont CAT Engine<br />

27 1 EMCSD10 ADDL EMCP 3 ATTACHMENTS Toromont CAT Engine<br />

28 1 GC0194 GEN-1824-3300/4160V-PM-FW-2B Toromont CAT Engine<br />

29 1 GC2893 MOUNTING GP-CT (500:5) Toromont CAT Engine<br />

30 1 GC2912 BUS BAR MOUNTING-REMOVAL Toromont CAT Engine<br />

31 1 GC2913 BUSS BAR POWER CONNECTIONS (NE Toromont CAT Engine<br />

http://apps.toromontcat.com/iMACS/QuoteLog/default.asp?SID=%7B74b47727%2D895c...<br />

1/29/2010

iMACS<br />

32 1 GC2959 NFPA 99-110/CSA 282 Toromont CAT Engine<br />

33 1 GC2963 OPTIONAL MODULE HARNESS Toromont CAT Engine<br />

34 1 GC3238 EMCP3.3 Toromont CAT Engine<br />

35 1 GC4610 REMOVAL SR5 GLOBAL DESIGN FORM Toromont CAT Engine<br />

36 1 GC5037 SPARE DISCRETE I/O PACKAGE Toromont CAT Engine<br />

37 1 GP1280 3516C HD 2500SC2 GLOBAL GEN SE Toromont CAT Engine<br />

38 1 GP1285 208V JACKET WATER COOLANT HEAT Toromont CAT Engine<br />

39 1 GZ0292 VIBRATION ISOLATOR REMOVAL Toromont CAT Engine<br />

40 1 GZ0696 BOTTOM CABLE ENTRY (WITH SHROU Toromont CAT Engine<br />

41 1 JWHWP52 JACKET WATER HEATERS Toromont CAT Engine<br />

42 1 KW02500 RATING Toromont CAT Engine<br />

43 1 LANENGO LANGUAGE OPTIONS Toromont CAT Engine<br />

44 1 LE0195 PRIMARY FUEL FILTER Toromont CAT Engine<br />

45 1 LL5718 3634 BHP 2500 GEN KW W/F 60 HZ Toromont CAT Engine<br />

46 1 MSCEC77 SUB MARKET CODE Toromont CAT Engine<br />

47 1 MSEPGGN MARKET SEGMENT Toromont CAT Engine<br />

48 1 MWCODEF MARKET WORK CODE Toromont CAT Engine<br />

49 1 NGRDCNN GROUNDING CONNECTIONS REAR Toromont CAT Engine<br />

50 1 NOENCPB CIRCUIT BREAKER REAR Toromont CAT Engine<br />

51 1 NOENCPR CIRCUIT BREAKER RIGHT HAND Toromont CAT Engine<br />

52 1 NONULL UL LISTING Toromont CAT Engine<br />

53 1 OGNPM9Y OPTIONAL GENERATORS Toromont CAT Engine<br />

54 1 RPA0337 GENERATOR REMOVALS Toromont CAT Engine<br />

55 1 RTDDIOH GENERATOR OPT MODULE HARNESS Toromont CAT Engine<br />

56 1 SHK0003 GENERATOR ATTACHMENTS Toromont CAT Engine<br />

57 1 SHROUDL CABLE ENTRY LEFT SIDE Toromont CAT Engine<br />

58 1 STANDBY DUTY TYPE Toromont CAT Engine<br />

59 1 SWP0001 SHRINK WRAP PROTECTION Toromont CAT Engine<br />

60 1 TRSGEN7 ADDITIONAL TESTS OR REPORTS Toromont CAT Engine<br />

61 1 UIPBBHS EMCP 3 PANEL LOCATION Toromont CAT Engine<br />

62 1 ZONE1 EXTENDED SERVICE COVERAGE Toromont CAT Engine<br />

63 2 0P9715 EXTRA LITERATURE - ENGLISH Toromont CAT Shipped<br />

Loose<br />

64 1 1320L Fuel<br />

Tank<br />

1320L Cylindrical Double Wall Fuel Tank 1320 L cylindrical<br />

double wall day tank,<br />

38" x 71" overall length (internal tank) Built and labelled to<br />

ULC S602.<br />

EACH TANK COMPLETE WITH: 7 ports on top<br />

2 - saddles<br />

1 - VM-3 vacuum gauge with cover, c/w switch<br />

1 - golden gallon tank gauge, shipped loose (reads in<br />

inches)<br />

1 - low level float switch<br />

1- four station level switch stainless steel construction<br />

V243125 clemmer<br />

technologies<br />

http://apps.toromontcat.com/iMACS/QuoteLog/default.asp?SID=%7B74b47727%2D895c...<br />

Page 2 <strong>of</strong> 4<br />

Shipped<br />

Loose<br />

1/29/2010

iMACS<br />

65 1 30 Day Equalize<br />

Timer<br />

66 3 36 x 34 x 2 - 16<br />

ga.<br />

SPST 15VA<br />

c/w lead wires & 2" mounting plug<br />

1- 1” fusible link shut-<strong>of</strong>f valve Final Release to<br />

Manufacture is UPON FINAL CUSTOMER DRAWING<br />

APPROVALS.<br />

per quote# CJR-12325-09 REV 1<br />

December 4 2009<br />

John Richards, 1-800-265-8840 x218,<br />

jrichards@clemmersteelcraft.com<br />

30 Day Equalize Timer Make: Vulcan, Feature#1, 30 Day 6<br />

Hour Automatic Equalize Timer<br />

Engine Oil Drip Tray - 16 AWG galvanized construction<br />

- 2" Deep<br />

- seam welded<br />

- folded lip along top edges<br />

- satin coat<br />

67 1 79/1000FHV10 Fuel / Water Separator - turbine series with three(3)<br />

replaceable 10 micron filter elements<br />

- max. flow rate 540 USGPM<br />

- 3/4" MNPT connections<br />

- replaces 79/1000FGV (same fittings, new element)<br />

68 2 AC-HW-AN-18 18" ANSI Hardware Kit - c/w nuts, bolts & gasket QUOTE<br />

ID 19516<br />

69 2 AC-HW-CA-8 8” CAT Hardware Kit 8" Cat gasket c/w nuts, bolts QUOTE<br />

ID 19516<br />

70 1 Alarms<br />

Package#4<br />

71 1 EY-18-8-8-<br />

3516C-C<br />

72 2 H-SS101-<br />

041041-016-<br />

0024.00<br />

73 1 JDDS-18-SI6-C-<br />

B<br />

Alarms Package#4 Make: Vulcan, Four Alarms for Battery<br />

Charger SCA 24VDC, Low Voltage, High Voltage, No<br />

Charge & AC Fail alarms with red light LED and Form "C"<br />

Contact<br />

3516C Exhaust Flex Connector Wye Connector to suit -<br />

3516C Dual 8in Caterpillar Floating Flange Inlet x 18in<br />

ANSI Floating<br />

Flange Outlet , OAL - 36 in, Style 1, Carbon Steel, Black<br />

Paint QUOTE ID 19516<br />

1" Diesel Fuel Flex Hose x 24" long CUSTOM HOSE<br />

ASSEMBLY<br />

H-SS101-041041-016-0024.00<br />

1 INCH X 24 INCHES O.A.L. MODEL 101 SINGLE<br />

BRAIDED T321 SS HOSE C/W 1 INCH (-16) CS<br />

FEMALE JIC SWIVEL C/W 1 INCH (-16) CS<br />

MALE NPT ADAPTER ON EACH END<br />

* WORKING PRESSURE 150 PSI @ 150°F<br />

18 Hospital Grade Silencer - side inlet at 6 o'clock position,<br />

F = 21" with 18" plate flange with ANSI pattern<br />

- end outlet with 18" plate flange with ANSI pattern<br />

- carbon steel construction<br />

- high temperature black paint<br />

- drain connection QUOTE ID 19516, Laura Palmer<br />

Vulcan Electric Co. Shipped<br />

Loose<br />

Quality Metal<br />

Fabricating Ltd.<br />

Shipped<br />

Loose<br />

Racor Shipped<br />

Loose<br />

Silex Inc. Shipped<br />

Loose<br />

Silex Inc. Shipped<br />

Loose<br />

Vulcan Electric Co. Shipped<br />

Loose<br />

Silex Inc. Shipped<br />

Loose<br />

Senior Flexonics Shipped<br />

Loose<br />

Silex Inc. Shipped<br />

Loose<br />

74 2 LITENGE EXTRA ENGLISH LIT (CD) (1-6) Toromont CAT Shipped<br />

Loose<br />

75 14 LKE 56 Spring Vibration Isolator - cast iron housing<br />

- 4 spring design, colour purple<br />

- adjustable mounting bolt 3/4-10 unc x 5 in lg<br />

- external level adjustment<br />

- adjustable snubbers with synthetic rubber inserts<br />

- bonded synthetic rubber sound pad<br />

- 4800 lb load rating<br />

- spring constant 6600 lb<br />

- free height 5-7/8 in<br />

- min working height 4-5/8 in<br />

Korfund Dynamics Shipped<br />

Loose<br />

76 1 PFF0001 FUEL SYSTEM Toromont CAT Shipped<br />

Loose<br />

77 1 SCA 24V/20A SCA 24V/20A Battery Charger, Make: Vulcan, Model:<br />

24V/20A, Automatic dual rate, constant voltage, current<br />

Page 3 <strong>of</strong> 4<br />

Vulcan Electric Co. Shipped<br />

Loose<br />

http://apps.toromontcat.com/iMACS/QuoteLog/default.asp?SID=%7B74b47727%2D895c...<br />

1/29/2010

iMACS<br />

limited, 24VDC output, 20 Amps, 120 VAC, 60 Hz input<br />

with illuminated ON/OFF switch, AC & DC breakers, 2%<br />

AM & VM, LED's for "current limit", "float charge" &<br />

"equailze charge".<br />

78 1 VIBRM10 MOUNTING SYSTEM Toromont CAT Shipped<br />

Loose<br />

Customer Bill <strong>of</strong> Materials<br />

http://apps.toromontcat.com/iMACS/QuoteLog/default.asp?SID=%7B74b47727%2D895c...<br />

Page 4 <strong>of</strong> 4<br />

29-Jan-<br />

10<br />

1/29/2010

DIESEL GENERATOR SET<br />

FEATURES<br />

FUEL/EMISSIONS STRATEGY<br />

• EPA Tier 2<br />

Image shown may not<br />

reflect actual package.<br />

DESIGN CRITERIA<br />

• The generator set accepts 100% rated load in one<br />

step per NFPA 110 and meets ISO 8528-5 transient<br />

response.<br />

UL 2200<br />

• UL 2200 listed packages available. Certain<br />

restrictions may apply. Consult with your<br />

Caterpillar Dealer.<br />

FULL RANGE OF ATTACHMENTS<br />

• Wide range <strong>of</strong> bolt-on system expansion<br />

attachments, factory designed and tested<br />

• Flexible packaging options for easy and cost<br />

effective installation<br />

SINGLE-SOURCE SUPPLIER<br />

• Fully prototype tested with certified torsional<br />

vibration analysis available<br />

WORLDWIDE PRODUCT SUPPORT<br />

• Cat® dealers provide extensive post sale support<br />

including maintenance and repair agreements<br />

• Cat dealers have over 1,600 dealer branch stores<br />

operating in 200 countries<br />

• The Cat S•O•S SM program cost effectively detects<br />

internal engine component condition, even the<br />

presence <strong>of</strong> unwanted fluids and combustion<br />

by-products<br />

STANDBY<br />

2500 ekW 3125 kVA<br />

60 Hz 1800 rpm 4160 Volts<br />

Caterpillar is leading the power generation<br />

marketplace with Power Solutions engineered<br />

to deliver unmatched flexibility, expandability,<br />

reliability, and cost-effectiveness.<br />

CAT 3516C-HD TA DIESEL ENGINE<br />

• Reliable, rugged, durable design<br />

• Field-proven in thousands <strong>of</strong> applications<br />

worldwide<br />

• Four-stroke-cycle diesel engine combines<br />

consistent performance and excellent fuel<br />

economy with minimum weight<br />

CAT EMCP 3 SERIES CONTROL PANELS<br />

• Simple user friendly interface and navigation<br />

• Scalable system to meet a wide range <strong>of</strong><br />

customer needs<br />

• Integrated Control System and Communications<br />

Gateway<br />

®

STANDBY 2500 ekW 3125 kVA<br />

60 Hz 1800 rpm 4160 Volts<br />

FACTORY INSTALLED STANDARD & OPTIONAL EQUIPMENT<br />

System Standard Optional<br />

Air Inlet • Single element canister type air cleaner<br />

• Service indicator<br />

Cooling • Radiator with guard (43ºC)<br />

• Coolant drain line with valve<br />

• Fan and belt guards<br />

• Caterpillar Extended Life Coolant<br />

• Low coolant level & high temperature alarm or<br />

shutdown<br />

Exhaust • Dry exhaust manifold<br />