LTP 61 Shut-off Nutrunner - Atlas Copco

LTP 61 Shut-off Nutrunner - Atlas Copco

LTP 61 Shut-off Nutrunner - Atlas Copco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

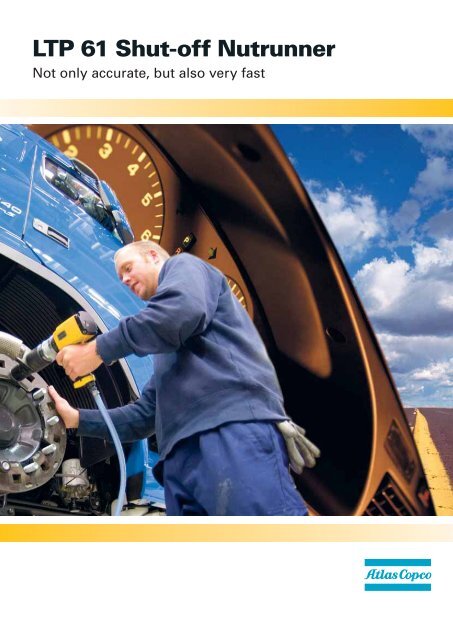

<strong>LTP</strong> <strong>61</strong> <strong>Shut</strong>-<strong>off</strong> <strong>Nutrunner</strong><br />

Not only accurate, but also very fast

2<br />

How important is accurate<br />

tightening for your customers?<br />

Some joints are more critical than others. If you need<br />

a higher level of accuracy in your work, take a look at<br />

<strong>Atlas</strong> <strong>Copco</strong>’s shut-<strong>off</strong> nutrunners.<br />

They have become standard pieces of equipment<br />

at truck manufacturers such as Scania and Volvo.<br />

And are becoming more and more common in<br />

service workshops. Why?<br />

The same torque time after time<br />

A shut-<strong>off</strong> nutrunner is a reliable tool. You decide<br />

what torque you want – anything from 60 - 4 000 Nm<br />

depending on the model – and that’s what you get.<br />

No more, no less. Even in soft joints.<br />

And as the name suggests, it shuts <strong>off</strong> at the<br />

torque you have selected. So you get the same accurate<br />

result time after time – regardless of the operator<br />

and their level of experience.<br />

A clear shut-<strong>off</strong> signal tells operators when the<br />

tightening cycle is fi nished. Not only does this<br />

ensure high accuracy, but it also boosts productivity<br />

because the operator can immediately move on to<br />

the next bolt without having to spend time checking<br />

to see if the bolt needs tightening a little more.<br />

First the bad news<br />

A shut-<strong>off</strong> nutrunner gives you reliable tightening<br />

because of the way it builds up torque in a smooth,<br />

controlled and continuous way.<br />

This produces excellent quality in the tightening<br />

phase. However, with a standard shut-<strong>off</strong> nutrunner,

this controlled action slows things down during the<br />

rundown phase.<br />

Now for the good news<br />

Ever changed a wheel? First you spin the wrench,<br />

then tighten slowly with both hands. Two-speed<br />

tightening. That’s what you get with the <strong>LTP</strong> <strong>61</strong><br />

– the market’s only nutrunner with two motors.<br />

One for rundown. One for tightening.<br />

If you want to know how this can boost<br />

productivity, turn the page.<br />

Adjustable torque range<br />

The Multi-Torque Selector allows you<br />

to preset four different torque levels<br />

per tool.<br />

3

4<br />

How important is productivity<br />

for your company?<br />

With the <strong>LTP</strong> <strong>61</strong>, you don’t have to compromise: you<br />

get highly accurate tightening and high productivity.<br />

The secret is two motors. One high speed motor for<br />

fast rundown. And one high torque motor for reliable<br />

tightening.<br />

Ten times faster rundown<br />

A conventional, mid-size, shut-<strong>off</strong> nutrunner<br />

works at around 20 rpm, during both rundown<br />

and tightening. A mid-range <strong>LTP</strong> <strong>61</strong> runs down at<br />

210 rpm – that’s 10 times faster.<br />

If you have a large number of nuts to tighten,<br />

the <strong>LTP</strong> <strong>61</strong> will save you a considerable amount of<br />

time, boosting the productivity of your company.<br />

Chances are, it will pay for itself within months.<br />

The fastest tool on the market<br />

just got faster<br />

Twin motors might sound simple. But you won’t<br />

fi nd another nutrunner like the <strong>LTP</strong> <strong>61</strong> on the<br />

market.<br />

Its predecessor, the <strong>LTP</strong> 51, has been winning<br />

over fans for over twenty years. In some industries,<br />

such as truck and bus manufacturing, it has<br />

become an accepted standard.

The new <strong>LTP</strong> <strong>61</strong> is as accurate as its predecessor,<br />

but it is faster. Twice as fast in rundown.<br />

And yet the new range is only marginally heavier<br />

than the existing one.<br />

When we say that <strong>Atlas</strong> <strong>Copco</strong> stands for<br />

“innovation, commitment and interaction”<br />

we really mean it.<br />

<strong>LTP</strong> <strong>61</strong><br />

<strong>LTP</strong> 51<br />

Single-motor<br />

Time<br />

Run-down speed is up to ten times higher compared<br />

with a single-motor nutrunner.<br />

5

6<br />

How important is<br />

ergonomics at your<br />

workplace?<br />

<strong>Shut</strong>-<strong>off</strong> nutrunners are quite in operations and vibration<br />

levels are low. Operators who progress from impact<br />

wrenches really appreciate the difference.<br />

Very quiet<br />

But how quiet is the <strong>LTP</strong> <strong>61</strong>? A shut-<strong>off</strong> nutrunner<br />

builds up torque continuously, without interruption.<br />

In other words, there is no noise generated by the<br />

actual process.<br />

Sound levels are also kept low because all<br />

exhaust air is piped through the handle into a hose,<br />

minimizing noise from the pneumatic system.<br />

Low vibration levels<br />

The <strong>LTP</strong> <strong>61</strong> has low vibration level because torque is<br />

transferred continuously. Compare this to an impact<br />

wrench in which torque is produced by a rotating<br />

metal hammer slamming into the output shaft.<br />

Minimize strain on wrists and arms<br />

Wrist and arm strain is kept to a minimum with shut<strong>off</strong><br />

nutrunners because the reaction force is handled<br />

by a torque-reaction bar. Our unique, innovative reaction<br />

bars are easy to use to keep productivity levels<br />

high.

Single-handed operation<br />

The <strong>LTP</strong> <strong>61</strong> is light, compact and well-balanced and<br />

so can be used with just one hand. The rubber pistol<br />

grip has been ergonomically optimized for maximum<br />

operator comfort.<br />

Increasing output at Volvo Trucks<br />

“With output being ramped up every year,<br />

productivity is getting more and more<br />

important,” says Dennis Johansson, Process<br />

Engineer at Volvo Trucks in southern Sweden.<br />

Volvo Trucks is already using more than<br />

200 <strong>LTP</strong> 51 shut-<strong>off</strong> nutrunners on axle and<br />

chassis assembly lines. “The <strong>Atlas</strong> <strong>Copco</strong><br />

machines are reliable and they give us the<br />

accurate torque that we need,” says Dennis.<br />

Perfect for long run-downs<br />

Producing over 26,000 units every year, the<br />

need to shave <strong>off</strong> a few seconds here, a<br />

few seconds there is a pressing matter.<br />

“The <strong>LTP</strong> <strong>61</strong> is that much faster, ”says<br />

Dennis, “so it’s perfect for long run-downs.<br />

We expect to see more <strong>LTP</strong> <strong>61</strong>s turning<br />

up on the production lines in the near<br />

future.”<br />

7

8<br />

How many tools do<br />

you really need in your<br />

workshop?<br />

A shut-<strong>off</strong> nutrunner is a sophisticated tool. But for<br />

many workshops it has not been economically viable<br />

to own an advanced wrench that performs just one<br />

dedicated task. However, with three simple accessories,<br />

you can use one <strong>LTP</strong> <strong>61</strong> for dozens of different jobs.<br />

And that means a sophisticated tool has now become<br />

a very economical one too.<br />

Multi-Torque Selector<br />

Transform one nutrunner into four: the Multi-Torque<br />

Selector allows you to preset four different torque<br />

levels per tool. Order ready-mounted or as an accessory<br />

to existing <strong>LTP</strong> 51 and <strong>61</strong> nutrunners.<br />

Multi-Point Reaction Bar<br />

In many workshops, an application that requires a<br />

different torque also requires a different reaction<br />

point. The Multi-Point Reaction Bar features a sliding<br />

bracket that gives you a number of different reaction<br />

points.<br />

S-Bar – straight out of the box<br />

A blank reaction bar has to be bent, cut or welded<br />

– an extra “to do”. The geometry of the S-Bar has<br />

been optimized to provide a maximum number of<br />

reaction points. This means you’ll be able to use<br />

the S-Bar in about 70-80 percent of all applications<br />

straight out of the box.

From 60-4 000 Nm<br />

With a range consisting of 11 different tool sizes,<br />

there is an <strong>LTP</strong> <strong>61</strong> to suit all kinds of applications.<br />

The smallest model weighs just 2.6 kg and delivers<br />

60 Nm, while the largest version supplies 4 000 Nm.<br />

9

10<br />

<strong>LTP</strong> <strong>61</strong> – accurate, fast<br />

and ergonomic<br />

Increase tightening<br />

accuracy<br />

With automatic shut-<strong>off</strong> you get a high level<br />

of tightening precision, even in soft joints.<br />

This helps increase productivity since the<br />

operator gets a clear shut-<strong>off</strong> signal when<br />

tightening is completed.<br />

Boost productivity<br />

Unique twin-motor drive: one for high<br />

speed rundown, the other for high<br />

precision tightening.<br />

Optimized S-Bar<br />

A blank reaction bar has to be bent, cut<br />

or welded. The S-Bar has been optimized<br />

for use in 70-80 percent of all applications<br />

straight out of the box.<br />

Single-handed<br />

operation<br />

Because the <strong>LTP</strong> <strong>61</strong> is light, compact<br />

and well-balanced, it can be used<br />

with just one hand.<br />

One reaction bar,<br />

dozens of jobs<br />

Now easier to<br />

run in reverse<br />

The Multi-Point Reaction Bar features a sliding<br />

bracket that gives you a number of different<br />

reaction points for different applications.<br />

Unlike its predecessor, the <strong>LTP</strong> <strong>61</strong><br />

runs in reverse and stays in reverse<br />

until you change the setting. Thanks<br />

to a new mode selection, you can<br />

now hold the tool with just one<br />

hand, whatever direction you run<br />

the machine.

Twice as fast as the <strong>LTP</strong> 51<br />

Thanks to the new motors, the rundown<br />

speed has been doubled in comparison<br />

with its predecessor.<br />

Adjustable torque range<br />

Virtually silent and<br />

vibration-free<br />

<strong>Shut</strong>-<strong>off</strong> nutrunners generate no<br />

process noise. And by building up<br />

torque continuously, they are much<br />

quieter than impact wrenches.<br />

From 60-4 000 Nm<br />

Multi-torque for<br />

multi-tasking<br />

With a range consisting of 11 different<br />

tool sizes, there is an <strong>LTP</strong> <strong>61</strong> to suit<br />

your needs. The smallest model weighs<br />

just 2.6 kg and delivers 60 Nm, while<br />

the largest supplies 4 000 Nm. Stall<br />

versions, designated LMP <strong>61</strong>, are also<br />

available.<br />

With this easy-to-mount selector,<br />

you transform one nutrunner into four.<br />

The Multi-Torque Selector allows you<br />

to preset four different torque levels<br />

per tool.<br />

11

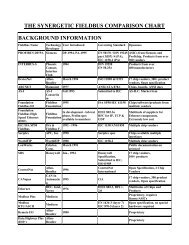

Technical data<br />

Air con- Air<br />

Bolt Square Torque range Min torque Free CS sumption at inlet<br />

size drive at 6.3 bar at 3 bar speed Weight Length distance free speed thread Spline<br />

Model mm in Nm ft lb Nm ft lb r/min kg lb mm mm l/s cfm in type Ordering No.<br />

Non reversible<br />

<strong>LTP</strong><strong>61</strong> H100-13 M12 1/2 55-100 40-75 45 35 1800 3.0 6.6 223 29 20 42 3/8 3 8431 0800 07<br />

<strong>LTP</strong><strong>61</strong> H170-13 M14 1/2 95-170 70-125 70 50 1100 3.0 6.6 223 29 20 42 3/8 3 8431 0800 14<br />

<strong>LTP</strong><strong>61</strong> H230-19 M16 3/4 125-230 90-170 85 60 820 3.0 6.6 223 29 20 42 3/8 3 8431 0800 21<br />

<strong>LTP</strong><strong>61</strong> H350-20 M18 3/4 190-350 140-255 145 105 520 3.9 8.6 260 31 20 42 3/8 4 8431 0800 28<br />

<strong>LTP</strong><strong>61</strong> H500-20 M20 3/4 275-500 200-370 220 160 360 3.9 8.6 260 31 20 42 3/8 4 8431 0800 35<br />

<strong>LTP</strong><strong>61</strong> H700-25 M22 1 360-650 265-480 280 207 280 4.5 9.9 305 34 20 42 3/8 5 8431 0800 42<br />

<strong>LTP</strong><strong>61</strong> H900-25 M24 1 480-870 350-640 300 220 210 4.5 9.9 282 32 20 42 3/8 5 8431 0800 49<br />

<strong>LTP</strong><strong>61</strong> H1500-25 M30 1 850-1500 625-1100 700 516 115 6.8 14.5 323 42 20 42 3/8 9 8431 0800 56<br />

<strong>LTP</strong><strong>61</strong> H1900-38 M30 1 1/2 1050-1900 770-1400 800 576 90 14.1 31.0 380 68 20 42 3/8 8 8431 0800 63<br />

<strong>LTP</strong><strong>61</strong> H2800-38 M36 1 1/2 1550-2800 1140-2060 1200 864 65 14.1 31.0 380 68 20 42 3/8 8 8431 0800 70<br />

<strong>LTP</strong><strong>61</strong> H3800-38<br />

Reversible<br />

M42 1 1/2 2100-3800 1540-2790 1600 1152 50 14.1 31.0 380 68 20 42 3/8 8 8431 0800 77<br />

<strong>LTP</strong><strong>61</strong> HR100-13 M12 1/2 55-100 40-75 45 35 1800 3.0 6.6 235 30 20 42 3/8 3 8431 0801 08<br />

<strong>LTP</strong><strong>61</strong> HR170-13 M14 1/2 95-170 70-125 70 50 1100 3.0 6.6 238 30 20 42 3/8 3 8431 0801 15<br />

<strong>LTP</strong><strong>61</strong> HR230-19 M16 3/4 125-230 90-170 85 60 820 3.0 6.6 275 34 20 42 3/8 3 8431 0801 22<br />

<strong>LTP</strong><strong>61</strong> HR350-20 M18 3/4 190-350 140-255 145 105 520 3.9 8.6 275 34 20 42 3/8 4 8431 0801 29<br />

<strong>LTP</strong><strong>61</strong> HR500-20 M20 3/4 275-500 200-370 220 160 360 3.9 8.6 275 34 20 42 3/8 4 8431 0801 36<br />

<strong>LTP</strong><strong>61</strong> HR700-25 M22 1 360-650 265-480 280 207 280 4.5 9.9 305 34 20 42 3/8 5 8431 0801 43<br />

<strong>LTP</strong><strong>61</strong> HR900-25 M24 1 480-870 350-640 300 220 210 4.5 9.9 305 34 20 42 3/8 5 8431 0801 50<br />

<strong>LTP</strong><strong>61</strong> HR1500-25 M30 1 850-1500 625-1100 700 516 115 6.8 14.5 345 42 20 42 3/8 9 8431 0801 57<br />

<strong>LTP</strong><strong>61</strong> HR1900-38 M30 1 1/2 1050-1900 770-1400 800 576 90 14.1 31.0 380 68 20 42 3/8 8 8431 0801 64<br />

<strong>LTP</strong><strong>61</strong> HR2800-38 M36 1 1/2 1550-2800 1140-2060 1200 864 65 14.1 31.0 380 68 20 42 3/8 8 8431 0801 71<br />

<strong>LTP</strong><strong>61</strong> HR3800-38 M42 1 1/2 2100-3800 1540-2790 1600 1152 50 14.1 31.0 380 68 20 42 3/8 8 8431 0801 78<br />

Weight excluding reaction bar . Recommended hose size 13 mm for hose length up to 5 m.<br />

Air con- Air<br />

Bolt Square Torque range Min torque Free CS sumption at inlet<br />

size drive at 6.3 bar at 3 bar speed Weight Length distance free speed thread Spline<br />

Model mm in Nm ft lb Nm ft lb r/min kg lb mm mm l/s cfm in type Ordering No.<br />

Equipped with Multi Torque unit<br />

<strong>LTP</strong><strong>61</strong> HR100-13-MT M12 1/2 55-100 40-75 45 35 1800 3.3 7.3 288 30 20 42 3/8 3 8431 0806 02<br />

<strong>LTP</strong><strong>61</strong> HR170-13-MT M14 1/2 95-170 70-125 70 50 1100 3.3 7.3 288 30 20 42 3/8 3 8431 0806 09<br />

<strong>LTP</strong><strong>61</strong> HR230-19-MT M16 3/4 125-230 90-170 85 60 820 3.3 7.3 288 34 20 42 3/8 4 8431 0806 16<br />

<strong>LTP</strong><strong>61</strong> HR350-20-MT M18 3/4 190-350 140-255 145 105 520 4.2 9.2 325 34 20 42 3/8 4 8431 0806 23<br />

<strong>LTP</strong><strong>61</strong> HR500-20-MT M20 3/4 275-500 200-370 220 160 360 4.2 9.2 325 34 20 42 3/8 4 8431 0806 30<br />

<strong>LTP</strong><strong>61</strong> HR700-25-MT M22 1 360-650 265-480 280 207 280 4.8 10.6 355 34 20 42 3/8 5 8431 0806 33<br />

<strong>LTP</strong><strong>61</strong> HR900-25-MT M24 1 480-870 350-640 300 220 210 4.8 10.6 355 34 20 42 3/8 5 8431 0806 37<br />

<strong>LTP</strong><strong>61</strong> HR1500-25-MT M30 1 850-1500 625-1100 700 516 115 7.1 15.6 395 42 20 42 3/8 9 8431 0806 44<br />

<strong>LTP</strong><strong>61</strong> HR1900-38-MT M30 1 1/2 1050-1900 770-1400 800 576 90 14.4 31.7 430 68 20 42 3/8 8 8431 0806 51<br />

<strong>LTP</strong><strong>61</strong> HR2800-38-MT M36 1 1/2 1550-2800 1140-2060 1200 864 65 14.4 31.7 430 68 20 42 3/8 8 8431 0806 58<br />

<strong>LTP</strong><strong>61</strong> HR3800-38-MT M42 1 1/2 2100-3800 1540-2790 1600 1152 50 14.4 31.7 430 68 20 42 3/8 8 8431 0806 65<br />

Weight excluding reaction bar . Recommended hose size 13 mm for hose lenght up to 5 m.<br />

<strong>LTP</strong> <strong>61</strong> H/HR accessories<br />

Modell<br />

Hose nipple<br />

Swivelling type MultiFlex connector (3/8’’ BSP)<br />

Exhaust hose<br />

Protective cover for <strong>61</strong> standard (transparent)<br />

Protective cover for <strong>61</strong> Multi-torque (transparent)<br />

Multi torque selector for <strong>LTP</strong> <strong>61</strong><br />

Quick change retainer, 1/2” square models<br />

Quick change retainer, 3/4” square models<br />

Quick change retainer, 1” square models<br />

Bestell-Nr.<br />

9000 0242 00<br />

8202 1350 22<br />

4210 2201 00<br />

4210 4672 00<br />

4210 4672 01<br />

4210 4636 95<br />

4250 1190 00<br />

4210 3476 80<br />

4210 3524 80<br />

MultiFlex connector, swivelling type<br />

Protective cover<br />

Multi torque selector

Swivelling suspension yokes for <strong>LTP</strong> <strong>61</strong><br />

Modell<br />

Mounting dia Ø54mm<br />

H 100-13<br />

H 170-13<br />

H 230-19<br />

H 350-20<br />

H 500-20<br />

H 700-25<br />

H 900-25<br />

Mounting dia Ø60mm<br />

HR 100-13<br />

HR 170-13<br />

HR 230-19<br />

Mounting dia Ø63.5mm<br />

H 1900-38<br />

H 2800-38<br />

H 3800-38<br />

Mounting dia Ø67mm<br />

HR 350-20<br />

HR 500-20<br />

HR 700-25<br />

HR 900-25<br />

HR 1900-38<br />

HR 2800-38<br />

HR 3800-38<br />

Mounting dia Ø83.5mm<br />

H 1500-25<br />

HR 1500-25<br />

Reaction bars<br />

Modell<br />

Aluminium, max torque 175Nm, spline 3<br />

Square braket, spline 3<br />

Square braket, spline 4<br />

Square braket, spline 5<br />

Square braket, spline 9<br />

S-type, spline 3<br />

S-type, spline 4<br />

S-type, spline 5<br />

S-type, spline 9<br />

Sliding drive type (short), spline 3<br />

Sliding drive type (short), spline 3<br />

Sliding drive type (short), spline 4<br />

Sliding drive type (short), spline 5<br />

Sliding drive type (short), spline 9<br />

Sliding drive type (long), spline 4<br />

Sliding drive type (long), spline 5<br />

Extended sliding rectionbar, quick change att., spline 5<br />

Specially designed for truck rear wheel tightening<br />

Installation Proposal<br />

Ball Valve +<br />

MIDI F/RD 15 +<br />

ErgoQIC 10<br />

8202 0829 11<br />

Ball Valve +<br />

MIDI FR 15 +<br />

DOS 15B<br />

8202 0845 67<br />

Service kits<br />

Modell<br />

Trigger kit<br />

General service kit<br />

ErgoNIP 10 10 5 m CABLAIR 13 13 ErgoQIC ErgoQIC 10 10<br />

ErgoNip 10 M10<br />

8202 1180 79 79*<br />

ErgoNIP Nipple 1/2’’ 10 BSP 10 10 m CABLAIR 16 16 ErgoQIC ErgoQIC 10 10 ErgoNIP 10 M10<br />

8202 1182 00<br />

Bestell-Nr.<br />

4210 3088 80<br />

4210 3088 84<br />

4210 3088 83<br />

4210 3088 82<br />

4210 3088 81<br />

L=400mm<br />

50 x 100 x 12 mm<br />

65 x 125 x 16 mm<br />

65 x 125 x 16 mm<br />

85 x 150 x 20 mm<br />

–<br />

–<br />

–<br />

–<br />

1/2” square drive<br />

3/4” square drive<br />

3/4” square drive<br />

1” square drive<br />

1” square drive<br />

3/4” square drive<br />

1” square drive<br />

1” square drive<br />

Bestell-Nr.<br />

4081 2190 90<br />

4081 0397 90<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

C-C 70-120mm<br />

C-C 70-120mm<br />

C-C 76-126mm<br />

C-C 80-125mm<br />

C-C 80-130mm<br />

C-C 82-218mm<br />

C-C 82-218mm<br />

C-C 68-112mm<br />

Suspension yoke<br />

Bestell-Nr.<br />

4210 2219 01<br />

4210 2219 03<br />

4210 2183 01<br />

4210 2726 01<br />

4210 3899 00<br />

4210 4480 03<br />

4210 4480 04<br />

4210 4480 05<br />

4210 4480 09<br />

4210 4481 83<br />

4210 4481 63<br />

4210 4481 84<br />

4210 4481 85<br />

4210 4481 89<br />

4210 4<strong>61</strong>6 84<br />

4210 4<strong>61</strong>6 85<br />

4210 4498 80<br />

Bracket<br />

S type<br />

Sliding drive type, short<br />

Sliding drive type, long<br />

Sliding drive, no drive, long<br />

and short<br />

Extended sliding reaction bar<br />

13

www.atlascopco.com<br />

9833 1859 01 E.C.O Reklambyrå AB. Åtta.45 Tryckeri AB 2008:1