Deposition of PZT thin films with - Advanced Materials Letters

Deposition of PZT thin films with - Advanced Materials Letters

Deposition of PZT thin films with - Advanced Materials Letters

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Research Article Adv. Mat. Lett. 2012, 3(2), 102-106 ADVANCED MATERIALS <strong>Letters</strong><br />

film N where as for {111}-orientation, there are three 71 0<br />

domain j and one 180 0 domain ( ) w.r.t. film normal N.<br />

Table 2. Electrical characteristics <strong>of</strong> <strong>PZT</strong> <strong>thin</strong> <strong>films</strong>.<br />

Orientation e r tan<br />

{110}<br />

{001}<br />

{111}<br />

Random<br />

1081<br />

961<br />

915<br />

798<br />

0.05<br />

0.07<br />

0.06<br />

0.05<br />

Dielectric<br />

tunability at<br />

E= 200kV/cm<br />

62%<br />

48%<br />

39%<br />

50%<br />

2P r<br />

(c/cm 2 )<br />

40<br />

40<br />

22<br />

33<br />

2E c<br />

(kV/cm)<br />

100<br />

150<br />

125<br />

160<br />

|e 31 * | (C/m 2 ) at<br />

100kV/cm<br />

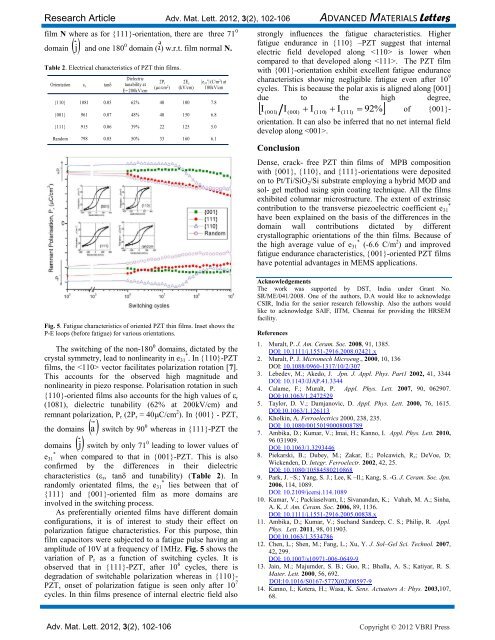

Fig. 5. Fatigue characteristics <strong>of</strong> oriented <strong>PZT</strong> <strong>thin</strong> <strong>films</strong>. Inset shows the<br />

P-E loops (before fatigue) for various orientations.<br />

The switching <strong>of</strong> the non-180 0 domains, dictated by the<br />

crystal symmetry, lead to nonlinearity in e31 * . In {110}-<strong>PZT</strong><br />

<strong>films</strong>, the vector facilitates polarization rotation [7].<br />

This accounts for the observed high magnitude and<br />

nonlinearity in piezo response. Polarisation rotation in such<br />

{110}-oriented <strong>films</strong> also accounts for the high values <strong>of</strong> er<br />

(1081), dielectric tunability (62% at 200kV/cm) and<br />

remnant polarization, Pr (2Pr = 40C/cm 2 ). In {001} - <strong>PZT</strong>,<br />

the domains a switch by 90 0 whereas in {111}-<strong>PZT</strong> the<br />

domains j switch by only 71 0 leading to lower values <strong>of</strong><br />

e31 * when compared to that in {001}-<strong>PZT</strong>. This is also<br />

confirmed by the differences in their dielectric<br />

characteristics er, tan and tunability) (Table 2). In<br />

randomly orientated <strong>films</strong>, the e31 * lies between that <strong>of</strong><br />

{111} and {001}-oriented film as more domains are<br />

involved in the switching process.<br />

As preferentially oriented <strong>films</strong> have different domain<br />

configurations, it is <strong>of</strong> interest to study their effect on<br />

polarization fatigue characteristics. For this purpose, <strong>thin</strong><br />

film capacitors were subjected to a fatigue pulse having an<br />

amplitude <strong>of</strong> 10V at a frequency <strong>of</strong> 1MHz. Fig. 5 shows the<br />

variation <strong>of</strong> Pr as a function <strong>of</strong> switching cycles. It is<br />

observed that in {111}-<strong>PZT</strong>, after 10 6 cycles, there is<br />

degradation <strong>of</strong> switchable polarization whereas in {110}-<br />

<strong>PZT</strong>, onset <strong>of</strong> polarization fatigue is seen only after 10 7<br />

cycles. In <strong>thin</strong> <strong>films</strong> presence <strong>of</strong> internal electric field also<br />

7.8<br />

6.8<br />

5.0<br />

6.1<br />

strongly influences the fatigue characteristics. Higher<br />

fatigue endurance in {110} –<strong>PZT</strong> suggest that internal<br />

electric field developed along is lower when<br />

compared to that developed along . The <strong>PZT</strong> film<br />

<strong>with</strong> {001}-orientation exhibit excellent fatigue endurance<br />

characteristics showing negligible fatigue even after 10 9<br />

cycles. This is because the polar axis is aligned along [001]<br />

due to the high degree,<br />

I I I 92%<br />

<strong>of</strong> {001}-<br />

<br />

I ( 001)<br />

( 00l)<br />

( 110)<br />

( 111)<br />

orientation. It can also be inferred that no net internal field<br />

develop along .<br />

Conclusion<br />

Dense, crack- free <strong>PZT</strong> <strong>thin</strong> <strong>films</strong> <strong>of</strong> MPB composition<br />

<strong>with</strong> {001}, {110}, and {111}-orientations were deposited<br />

on to Pt/Ti/SiO2/Si substrate employing a hybrid MOD and<br />

sol- gel method using spin coating technique. All the <strong>films</strong><br />

exhibited columnar microstructure. The extent <strong>of</strong> extrinsic<br />

contribution to the transverse piezoelectric coefficient e31 *<br />

have been explained on the basis <strong>of</strong> the differences in the<br />

domain wall contributions dictated by different<br />

crystallographic orientations <strong>of</strong> the <strong>thin</strong> <strong>films</strong>. Because <strong>of</strong><br />

the high average value <strong>of</strong> e31 * (-6.6 C/m 2 ) and improved<br />

fatigue endurance characteristics, {001}-oriented <strong>PZT</strong> <strong>films</strong><br />

have potential advantages in MEMS applications.<br />

Acknowledgements<br />

The work was supported by DST, India under Grant No.<br />

SR/ME/041/2008. One <strong>of</strong> the authors, D.A would like to acknowledge<br />

CSIR, India for the senior research fellowship. Also the authors would<br />

like to acknowledge SAIF, IITM, Chennai for providing the HRSEM<br />

facility.<br />

References<br />

1. Muralt, P. J. Am. Ceram. Soc. 2008, 91, 1385.<br />

DOI: 10.1111/j.1551-2916.2008.02421.x<br />

2. Muralt, P. J. Micromech Microeng., 2000, 10, 136<br />

DOI: 10.1088/0960-1317/10/2/307<br />

3. Lebedev, M.; Akedo, J. Jpn. J. Appl. Phys. Part1 2002, 41, 3344<br />

DOI: 10.1143/JJAP.41.3344<br />

4. Calame, F.; Muralt, P. Appl. Phys. Lett. 2007, 90, 062907.<br />

DOI:10.1063/1.2472529<br />

5. Taylor, D. V.; Damjanovic, D. Appl. Phys. Lett. 2000, 76, 1615.<br />

DOI:10.1063/1.126113<br />

6. Kholkin, A. Ferroelectrics 2000, 238, 235.<br />

DOI: 10.1080/00150190008008789<br />

7. Ambika, D.; Kumar, V.; Imai, H.; Kanno, I. Appl. Phys. Lett. 2010,<br />

96 031909.<br />

DOI: 10.1063/1.3293446<br />

8. Piekarski, B.; Dubey, M.; Zakar, E.; Polcawich, R,; DeVoe, D;<br />

Wickenden, D. Integr. Ferroelectr. 2002, 42, 25.<br />

DOI: 10.1080/10584580210868<br />

9. Park, J. –S.; Yang, S. J.; Lee, K –Il.; Kang, S. -G. J. Ceram. Soc. Jpn.<br />

2006, 114, 1089.<br />

DOI: 10.2109/jcersj.114.1089<br />

10. Kumar, V.; Packiaselvam, I.; Sivanandan, K.; Vahab, M. A.; Sinha,<br />

A. K. J. Am. Ceram. Soc. 2006, 89, 1136.<br />

DOI: 10.1111/j.1551-2916.2005.00838.x<br />

11. Ambika, D.; Kumar, V.; Suchand Sandeep, C. S.; Philip, R. Appl.<br />

Phys. Lett. 2011, 98, 011903.<br />

DOI:10.1063/1.3534786<br />

12. Chen, L.; Shen, M.; Fang, L.; Xu, Y. J. Sol–Gel Sci. Technol. 2007,<br />

42, 299.<br />

DOI: 10.1007/s10971-006-0649-9<br />

13. Jain, M.; Majumder, S. B.; Guo, R.; Bhalla, A. S.; Katiyar, R. S.<br />

Mater. Lett. 2000, 56, 692.<br />

DOI:10.1016/S0167-577X(02)00597-9<br />

14. Kanno, I.; Kotera, H.; Wasa, K. Sens. Actuators A: Phys. 2003,107,<br />

68.<br />

Adv. Mat. Lett. 2012, 3(2), 102-106 Copyright © 2012 VBRI Press