chapter 1 - Bentham Science

chapter 1 - Bentham Science

chapter 1 - Bentham Science

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Fiber Bragg Gratings: Advances in Fabrication Process and Tools Fiber Bragg Grating Sensors 11<br />

There are three basic types of grating associated with UV inscription and these are known as Type I, Type II and<br />

Regenerated. Type I gratings are associated with refractive index changes that occur below the damage threshold of<br />

glass whereas Type II gratings are associated with changes in refractive index above the damage threshold of glass.<br />

Each type is summarized below. There are several Type I sub-classes that are identified according to the writing<br />

conditions and properties of the gratings.<br />

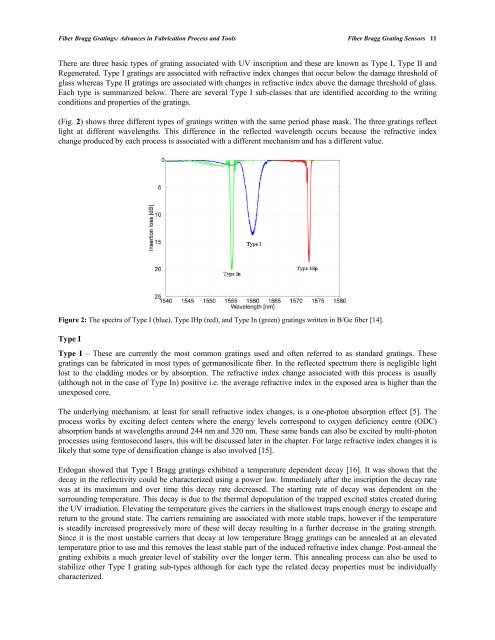

(Fig. 2) shows three different types of gratings written with the same period phase mask. The three gratings reflect<br />

light at different wavelengths. This difference in the reflected wavelength occurs because the refractive index<br />

change produced by each process is associated with a different mechanism and has a different value.<br />

Figure 2: The spectra of Type I (blue), Type IHp (red), and Type In (green) gratings written in B/Ge fiber [14].<br />

Type I<br />

Type I – These are currently the most common gratings used and often referred to as standard gratings. These<br />

gratings can be fabricated in most types of germanosilicate fiber. In the reflected spectrum there is negligible light<br />

lost to the cladding modes or by absorption. The refractive index change associated with this process is usually<br />

(although not in the case of Type In) positive i.e. the average refractive index in the exposed area is higher than the<br />

unexposed core.<br />

The underlying mechanism, at least for small refractive index changes, is a one-photon absorption effect [5]. The<br />

process works by exciting defect centers where the energy levels correspond to oxygen deficiency centre (ODC)<br />

absorption bands at wavelengths around 244 nm and 320 nm. These same bands can also be excited by multi-photon<br />

processes using femtosecond lasers, this will be discussed later in the <strong>chapter</strong>. For large refractive index changes it is<br />

likely that some type of densification change is also involved [15].<br />

Erdogan showed that Type I Bragg gratings exhibited a temperature dependent decay [16]. It was shown that the<br />

decay in the reflectivity could be characterized using a power law. Immediately after the inscription the decay rate<br />

was at its maximum and over time this decay rate decreased. The starting rate of decay was dependent on the<br />

surrounding temperature. This decay is due to the thermal depopulation of the trapped excited states created during<br />

the UV irradiation. Elevating the temperature gives the carriers in the shallowest traps enough energy to escape and<br />

return to the ground state. The carriers remaining are associated with more stable traps, however if the temperature<br />

is steadily increased progressively more of these will decay resulting in a further decrease in the grating strength.<br />

Since it is the most unstable carriers that decay at low temperature Bragg gratings can be annealed at an elevated<br />

temperature prior to use and this removes the least stable part of the induced refractive index change. Post-anneal the<br />

grating exhibits a much greater level of stability over the longer term. This annealing process can also be used to<br />

stabilize other Type I grating sub-types although for each type the related decay properties must be individually<br />

characterized.